Environmental Impact of HDPE Waste Management Solutions

HDPE Waste Management Evolution and Objectives

High-density polyethylene (HDPE) waste management has evolved significantly over the past few decades, driven by increasing environmental concerns and the need for sustainable resource management. The journey began in the 1970s with the introduction of recycling programs, which initially focused on collecting and sorting plastic waste. However, these early efforts were limited in scope and efficiency.

As awareness of plastic pollution grew in the 1980s and 1990s, more sophisticated HDPE recycling technologies emerged. This period saw the development of improved sorting techniques, such as near-infrared spectroscopy, which enhanced the quality of recycled HDPE. Concurrently, manufacturers began incorporating recycled HDPE into their production processes, albeit on a limited scale.

The turn of the millennium marked a significant shift in HDPE waste management strategies. Governments worldwide implemented stricter regulations on plastic waste disposal, prompting industries to invest in more advanced recycling technologies. This era witnessed the rise of chemical recycling methods, which break down HDPE into its molecular components, allowing for higher-quality recycled materials.

In recent years, the focus has expanded beyond recycling to encompass the entire lifecycle of HDPE products. This holistic approach includes designing for recyclability, reducing material usage, and exploring biodegradable alternatives. The concept of a circular economy has gained traction, emphasizing the importance of keeping HDPE materials in use for as long as possible before recycling.

The current objectives of HDPE waste management are multifaceted and ambitious. Primarily, there is a push to significantly increase recycling rates globally, with many countries setting targets of 50% or higher for plastic recycling by 2030. This goal necessitates improvements in collection systems, sorting technologies, and public education on proper waste disposal.

Another key objective is to enhance the quality of recycled HDPE to make it competitive with virgin materials. This involves developing more sophisticated purification processes and exploring new applications for recycled HDPE in high-value products. Additionally, there is a growing emphasis on reducing the environmental impact of the recycling process itself, through energy-efficient technologies and the use of renewable energy sources.

Looking ahead, the field of HDPE waste management aims to achieve near-zero waste through a combination of recycling, reuse, and redesign strategies. This includes exploring innovative technologies such as chemical recycling at scale, developing smart sorting systems using artificial intelligence, and creating new materials that combine the durability of HDPE with enhanced recyclability or biodegradability.

Market Analysis for HDPE Recycling Solutions

The global market for HDPE recycling solutions has been experiencing significant growth in recent years, driven by increasing environmental concerns and regulatory pressures. The demand for recycled HDPE is on the rise across various industries, including packaging, construction, and automotive sectors. This trend is expected to continue as more companies commit to sustainability goals and circular economy principles.

Market size estimates for the HDPE recycling industry vary, but most projections indicate substantial growth potential. The market is influenced by factors such as raw material prices, technological advancements in recycling processes, and government policies promoting recycling and waste reduction. Developing economies, particularly in Asia and Africa, are emerging as key growth markets due to their increasing plastic consumption and growing awareness of environmental issues.

The HDPE recycling market is characterized by a mix of established players and new entrants. Large waste management companies and petrochemical firms are expanding their recycling capabilities, while innovative startups are introducing novel technologies and business models. This competitive landscape is driving innovation in recycling processes, product quality, and end-use applications for recycled HDPE.

One of the key trends shaping the market is the increasing demand for high-quality recycled HDPE that can compete with virgin materials in performance and consistency. This has led to investments in advanced sorting and processing technologies, such as near-infrared spectroscopy and artificial intelligence-powered sorting systems. These technologies enable the production of higher-grade recycled HDPE, expanding its potential applications and market value.

The packaging industry remains the largest consumer of recycled HDPE, particularly for non-food contact applications. However, there is growing interest in using recycled HDPE in more demanding applications, such as automotive parts and construction materials. This diversification of end-use markets is crucial for the long-term growth and stability of the HDPE recycling industry.

Challenges in the market include the volatility of oil prices, which affects the competitiveness of recycled HDPE against virgin materials, and the need for consistent supply of high-quality post-consumer HDPE waste. Improving collection and sorting infrastructure remains a priority for many regions to ensure a steady supply of recyclable materials.

The regulatory landscape is increasingly favorable for HDPE recycling, with many countries implementing extended producer responsibility schemes and setting targets for plastic recycling rates. These policies are expected to drive further investment in recycling infrastructure and technologies, creating new opportunities in the market.

Current HDPE Waste Management Challenges

The management of High-Density Polyethylene (HDPE) waste presents significant environmental challenges globally. As HDPE production and consumption continue to rise, the volume of waste generated has reached alarming levels, posing serious threats to ecosystems and human health. One of the primary challenges is the persistence of HDPE in the environment, with an estimated decomposition time of up to 450 years. This longevity leads to accumulation in landfills and natural habitats, contributing to soil and water pollution.

Inadequate waste collection and sorting systems exacerbate the problem, as a substantial portion of HDPE waste ends up in uncontrolled dumpsites or is improperly disposed of. This mismanagement results in HDPE waste entering waterways and oceans, forming part of the growing marine plastic pollution crisis. Microplastic particles derived from HDPE degradation have been detected in various marine organisms, potentially entering the food chain and impacting human health.

The recycling of HDPE waste, while theoretically viable, faces numerous obstacles. Contamination of HDPE products with other materials or substances often renders them unsuitable for conventional recycling processes. Additionally, the lack of standardized labeling and collection systems makes it difficult to efficiently sort and process HDPE waste. The economic viability of recycling HDPE is also a concern, as the costs associated with collection, sorting, and processing can sometimes exceed the value of the recycled material.

Energy recovery through incineration is another waste management option, but it raises concerns about air pollution and greenhouse gas emissions. The incomplete combustion of HDPE can release toxic substances, including dioxins and furans, posing risks to air quality and public health. Moreover, incineration does not align with circular economy principles, as it represents a loss of valuable resources that could potentially be recycled or reused.

The global nature of plastic production and consumption adds another layer of complexity to HDPE waste management. Many developed countries export their plastic waste to developing nations, which often lack the infrastructure and resources to manage it effectively. This practice not only shifts the environmental burden but also complicates international efforts to address the HDPE waste crisis.

Technological limitations in current waste management systems also hinder progress. Many existing recycling facilities are not equipped to handle the diverse range of HDPE products and their varying compositions. The development of advanced sorting technologies and chemical recycling methods is ongoing but has yet to reach widespread commercial implementation.

Addressing these challenges requires a multifaceted approach involving improved waste collection systems, enhanced recycling technologies, and the development of more sustainable alternatives to HDPE. It also necessitates greater collaboration between governments, industries, and consumers to reduce HDPE consumption, improve product design for recyclability, and establish more effective waste management infrastructures.

Existing HDPE Waste Management Approaches

01 Recycling and upcycling of HDPE waste

This approach focuses on converting HDPE waste into valuable products or materials. It involves processes such as mechanical recycling, chemical recycling, and upcycling to transform waste HDPE into new products or raw materials. This method reduces the environmental impact by decreasing the amount of HDPE waste sent to landfills and conserving resources.- Recycling and upcycling of HDPE waste: This approach focuses on converting HDPE waste into valuable products or materials. It involves processes such as mechanical recycling, chemical recycling, and upcycling to transform waste HDPE into new products or raw materials. This method reduces the environmental impact by decreasing the amount of HDPE waste in landfills and conserving resources.

- Biodegradable alternatives to HDPE: Development of biodegradable materials as alternatives to HDPE can significantly reduce the environmental impact of plastic waste. These materials are designed to break down naturally in the environment, reducing long-term pollution. Research in this area focuses on creating materials with similar properties to HDPE but with improved end-of-life characteristics.

- Advanced sorting and separation technologies: Implementing advanced technologies for sorting and separating HDPE waste from other materials can improve recycling efficiency. This includes the use of optical sorting, artificial intelligence, and other innovative techniques to accurately identify and separate HDPE from mixed waste streams, leading to higher quality recycled materials and reduced environmental impact.

- Chemical treatment and decomposition of HDPE: Chemical methods for treating and decomposing HDPE waste can provide alternative solutions to traditional recycling. These processes aim to break down HDPE into its chemical components, which can then be used as raw materials for new products. This approach can help address the challenges of contaminated or mixed plastic waste that is difficult to recycle mechanically.

- Life cycle assessment and environmental impact studies: Conducting comprehensive life cycle assessments and environmental impact studies on HDPE products and waste management solutions is crucial. These studies help in understanding the full environmental implications of different HDPE waste management approaches, from production to disposal or recycling. The insights gained can inform policy decisions and guide the development of more sustainable waste management strategies.

02 HDPE waste collection and sorting systems

Efficient collection and sorting systems are crucial for effective HDPE waste management. This includes the development of advanced sorting technologies, implementation of separate collection schemes, and establishment of collection centers. Proper sorting ensures higher quality recycled materials and reduces contamination, leading to improved environmental outcomes.Expand Specific Solutions03 Energy recovery from HDPE waste

When recycling is not feasible, energy recovery from HDPE waste can be an alternative solution. This involves using HDPE waste as a fuel source in waste-to-energy facilities or as an alternative fuel in industrial processes. While not as environmentally friendly as recycling, it can help reduce landfill waste and greenhouse gas emissions associated with waste decomposition.Expand Specific Solutions04 Biodegradable alternatives to HDPE

Research and development of biodegradable alternatives to HDPE can help reduce the environmental impact of plastic waste. This includes the creation of bio-based plastics or composites that have similar properties to HDPE but can degrade naturally in the environment. These alternatives can help address the long-term environmental issues associated with HDPE waste.Expand Specific Solutions05 Life cycle assessment and environmental impact studies

Conducting comprehensive life cycle assessments and environmental impact studies of HDPE products and waste management solutions is essential. These studies help identify the most effective and environmentally friendly approaches to HDPE waste management, considering factors such as energy consumption, greenhouse gas emissions, and resource depletion throughout the entire life cycle of HDPE products.Expand Specific Solutions

Key Players in HDPE Recycling Industry

The environmental impact of HDPE waste management solutions is a critical issue in the maturing plastics industry. The market for sustainable HDPE management is expanding rapidly, driven by increasing environmental concerns and regulatory pressures. Companies like Alpla Werke, Procter & Gamble, and SABIC Global Technologies are at the forefront of developing innovative solutions. The technology maturity varies, with some firms like LG Chem and Solvay focusing on advanced recycling methods, while others like Zhejiang University of Technology and Louisiana State University are exploring novel biodegradable alternatives. The competitive landscape is diverse, featuring collaborations between industry leaders and research institutions to address the complex challenges of HDPE waste reduction and circular economy principles.

Alpla Werke Alwin Lehner GmbH & Co. KG

Procter & Gamble Co.

Innovative HDPE Recycling Technologies

- A solvent-based recycling process that swells contaminated polyolefin materials to dissolve and remove low-molecular weight impurities, stabilizers, and contaminants, increasing the average molecular weight and reducing melt volume flow rate, allowing for the production of high-quality, food-safe polyolefin recyclates.

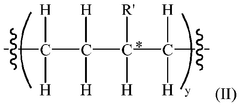

- A blend of repeatedly recyclable-polymer mimic (RR-PM) of HDPE with a second polymer, such as mechanically recycled or virgin HDPE, is used to create articles that can be repeatedly recycled and reused, maintaining similar structural and functional properties to virgin HDPE.

Environmental Regulations on Plastic Waste

Environmental regulations on plastic waste have become increasingly stringent in recent years, reflecting growing concerns about the environmental impact of HDPE and other plastic materials. These regulations aim to address the entire lifecycle of plastic products, from production to disposal, with a focus on reducing waste generation and promoting recycling.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal has been amended to include plastic waste. This amendment, effective from January 2021, requires countries to obtain prior informed consent before exporting contaminated, mixed, or unrecyclable plastic waste.

In the European Union, the Single-Use Plastics Directive, implemented in 2019, targets the reduction of single-use plastic items, including those made from HDPE. This directive mandates extended producer responsibility schemes, requiring manufacturers to cover the costs of waste collection, treatment, and clean-up.

The EU's Circular Economy Action Plan, adopted in 2020, further emphasizes the need for sustainable plastic use. It sets targets for recycled content in packaging and aims to make all plastic packaging recyclable or reusable by 2030. This plan directly impacts HDPE waste management solutions, pushing for more efficient recycling processes and the development of eco-friendly alternatives.

In the United States, regulations vary by state, but there is a growing trend towards more comprehensive plastic waste management. California, for instance, has implemented the Rigid Plastic Packaging Container Law, which requires manufacturers to meet specific recycling rates or use a certain percentage of recycled content in their packaging.

China's National Sword policy, implemented in 2018, has had a significant global impact on plastic waste management. By banning the import of most plastic waste, this policy has forced many countries to reassess their waste management strategies and invest in domestic recycling infrastructure.

Many countries are also implementing Extended Producer Responsibility (EPR) programs for plastic packaging. These programs make manufacturers responsible for the entire lifecycle of their products, including collection and recycling after use. This approach incentivizes companies to design products with better recyclability and use more recycled content in their packaging.

As regulations continue to evolve, there is a clear trend towards more comprehensive and stringent controls on plastic waste. This regulatory landscape is driving innovation in HDPE waste management solutions, pushing for more efficient recycling technologies, the development of biodegradable alternatives, and the implementation of circular economy principles in plastic production and consumption.

Life Cycle Assessment of HDPE Products

Life Cycle Assessment (LCA) of HDPE products is a crucial tool for evaluating the environmental impact of High-Density Polyethylene throughout its entire lifecycle. This comprehensive analysis encompasses raw material extraction, manufacturing processes, product use, and end-of-life disposal or recycling.

The production phase of HDPE products typically begins with the extraction of fossil fuels, primarily natural gas or petroleum. These raw materials undergo refining and processing to create ethylene, which is then polymerized to form HDPE. This initial stage often accounts for a significant portion of the product's overall environmental impact due to energy consumption and emissions associated with extraction and processing.

During the manufacturing phase, HDPE pellets are molded or extruded into various products. This process requires energy for heating and shaping the material, contributing to the carbon footprint. However, HDPE's relatively low melting point compared to other plastics can result in lower energy requirements during production.

The use phase of HDPE products generally has minimal direct environmental impact, as the material is inert and does not release harmful substances under normal conditions. The durability and long lifespan of HDPE products can contribute positively to their overall environmental profile by reducing the need for frequent replacements.

End-of-life management is a critical aspect of HDPE's lifecycle assessment. HDPE is highly recyclable, and when properly collected and processed, it can be remanufactured into new products with minimal quality loss. This closed-loop recycling potential significantly reduces the environmental burden compared to virgin material production.

However, the reality of HDPE waste management often falls short of ideal scenarios. Improper disposal, inadequate recycling infrastructure, and contamination issues can lead to HDPE products ending up in landfills or the environment. When landfilled, HDPE's resistance to degradation means it persists for hundreds of years, contributing to long-term waste accumulation.

LCA studies have shown that recycling HDPE can result in substantial environmental benefits, including reduced energy consumption, greenhouse gas emissions, and resource depletion compared to producing virgin HDPE. However, these benefits are contingent on effective collection, sorting, and recycling systems being in place.

The transportation involved in each stage of the HDPE lifecycle also contributes to its environmental impact. This includes the movement of raw materials, finished products, and waste for recycling or disposal. The impact of transportation can vary significantly based on distances and modes of transport used.

In conclusion, LCA of HDPE products reveals a complex environmental profile with opportunities for improvement, particularly in end-of-life management. Enhancing recycling rates, improving collection and sorting technologies, and developing more efficient production processes are key areas for reducing the overall environmental impact of HDPE throughout its lifecycle.