Future of High Density Polyethylene in Automotive Sector

HDPE Automotive Evolution

High Density Polyethylene (HDPE) has undergone a significant evolution in the automotive sector over the past few decades. Initially introduced as a lightweight alternative to metal components, HDPE has steadily gained prominence due to its excellent strength-to-weight ratio, chemical resistance, and recyclability.

In the 1970s, HDPE made its debut in automotive applications, primarily in non-critical components such as fluid reservoirs and interior trim parts. The 1980s saw an expansion of HDPE usage, with the material finding its way into fuel tanks, a milestone that showcased its chemical resistance and durability.

The 1990s marked a turning point for HDPE in the automotive industry. As environmental concerns grew, manufacturers began to recognize HDPE's potential for reducing vehicle weight and improving fuel efficiency. This decade witnessed the introduction of HDPE in larger exterior components, including bumper systems and body panels.

The early 2000s brought about advancements in HDPE formulations and processing techniques. Enhanced grades of HDPE with improved impact resistance and thermal stability were developed, allowing for broader applications in under-the-hood components and structural parts.

From 2010 onwards, the focus shifted towards sustainability and circular economy principles. The automotive industry began to prioritize the use of recycled HDPE, driven by both environmental regulations and consumer demand for eco-friendly vehicles. This period saw the development of advanced recycling technologies that enabled the production of high-quality recycled HDPE suitable for automotive applications.

Recent years have witnessed the integration of HDPE into electric vehicle (EV) designs. The material's lightweight properties and electrical insulation capabilities make it an ideal choice for battery housings and charging infrastructure components. Additionally, advancements in composite technologies have led to the development of HDPE-based composites that offer enhanced mechanical properties while maintaining the material's inherent benefits.

Looking ahead, the future of HDPE in the automotive sector appears promising. Ongoing research focuses on improving the material's heat resistance and structural integrity, potentially expanding its use in more demanding applications. The development of bio-based HDPE variants aligns with the industry's push towards sustainability, offering a renewable alternative to traditional petroleum-based HDPE.

As vehicle electrification and autonomous driving technologies continue to evolve, HDPE is expected to play a crucial role in lightweight design strategies and the integration of sensors and electronic components. The material's versatility and adaptability position it as a key player in the automotive industry's ongoing transformation towards more efficient, sustainable, and technologically advanced vehicles.

Market Demand Analysis

The automotive industry's demand for High Density Polyethylene (HDPE) is experiencing significant growth, driven by the sector's focus on lightweight materials to improve fuel efficiency and reduce emissions. HDPE's unique properties, including high strength-to-density ratio, excellent chemical resistance, and recyclability, make it an attractive option for various automotive applications.

In recent years, the global automotive HDPE market has shown a steady increase, with projections indicating continued growth. This trend is primarily attributed to the rising production of vehicles worldwide and the increasing adoption of plastic components in automotive design. The push for electric vehicles (EVs) has further accelerated this demand, as manufacturers seek to offset the weight of heavy battery packs with lighter body components.

The market demand for HDPE in the automotive sector spans various applications. Interior components such as door panels, dashboards, and center consoles are increasingly being manufactured using HDPE due to its durability and aesthetic appeal. Exterior applications include fuel tanks, bumpers, and body panels, where HDPE's impact resistance and weather durability prove advantageous.

A notable trend in the market is the growing demand for recycled HDPE in automotive manufacturing. This shift is driven by sustainability initiatives and regulatory pressures to increase the use of recycled materials in vehicle production. Automakers are actively seeking suppliers who can provide high-quality recycled HDPE that meets stringent performance requirements.

The Asia-Pacific region, particularly China and India, is expected to witness the highest growth in HDPE demand for automotive applications. This is due to the rapid expansion of their automotive industries and increasing vehicle ownership rates. North America and Europe also show strong demand, primarily driven by the shift towards electric vehicles and stringent fuel efficiency standards.

Despite the positive outlook, the market faces challenges. Fluctuations in raw material prices can impact the cost-effectiveness of HDPE in automotive applications. Additionally, competition from other lightweight materials such as carbon fiber and advanced composites poses a potential threat to HDPE's market share in certain high-performance applications.

Looking ahead, the future of HDPE in the automotive sector appears promising. Technological advancements in HDPE formulations, such as the development of nano-composites and improved recycling techniques, are expected to further enhance its properties and expand its applications in vehicle manufacturing. As the automotive industry continues its transition towards more sustainable and efficient vehicles, HDPE is well-positioned to play a crucial role in meeting these evolving market demands.

Technical Challenges

The automotive industry's adoption of High Density Polyethylene (HDPE) faces several technical challenges that need to be addressed for its widespread implementation. One of the primary obstacles is the material's limited heat resistance compared to traditional metals and engineering plastics. This characteristic restricts its use in high-temperature environments within vehicles, such as engine compartments or exhaust system components.

Another significant challenge lies in achieving the necessary mechanical strength and stiffness required for structural automotive parts. While HDPE offers excellent impact resistance and flexibility, it falls short in providing the rigidity and load-bearing capabilities essential for certain critical components. This limitation necessitates innovative design approaches or composite solutions to enhance its mechanical properties without compromising its lightweight advantages.

The processing and manufacturing of HDPE parts for automotive applications also present technical hurdles. The material's high shrinkage rate during cooling can lead to dimensional instability and warpage, affecting the precision and quality of molded components. This issue is particularly critical in the automotive sector, where tight tolerances and consistent part quality are paramount.

Surface finish and paintability pose additional challenges for HDPE in automotive applications. The material's low surface energy makes it difficult to achieve strong adhesion with paints and coatings, potentially affecting the aesthetic appeal and long-term durability of exterior parts. Developing effective surface treatment techniques or compatible coating systems is crucial to overcome this limitation.

Recycling and end-of-life considerations present another set of technical challenges. While HDPE is recyclable, the presence of additives, fillers, and other materials in automotive-grade HDPE can complicate the recycling process. Developing efficient separation and recycling technologies specific to automotive HDPE waste is essential for improving its environmental footprint and meeting increasingly stringent sustainability regulations.

The integration of HDPE components with other materials in vehicle assembly also requires careful consideration. Joining techniques such as welding, adhesive bonding, or mechanical fastening may need to be adapted or newly developed to ensure robust and durable connections between HDPE parts and other automotive materials.

Lastly, the long-term performance and aging characteristics of HDPE in automotive applications remain areas of concern. Exposure to UV radiation, temperature fluctuations, and various automotive fluids can potentially degrade the material over time. Developing effective stabilization systems and conducting comprehensive long-term testing are crucial to ensure the material's reliability throughout the vehicle's lifespan.

Current HDPE Solutions

01 Manufacturing processes for HDPE

Various manufacturing processes are employed to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to achieve specific molecular structures and properties, such as high density and improved mechanical strength.- Manufacturing processes for HDPE: Various manufacturing processes are used to produce high-density polyethylene (HDPE), including polymerization techniques and extrusion methods. These processes aim to create HDPE with specific properties such as high strength, durability, and chemical resistance.

- HDPE blends and composites: HDPE is often blended with other materials or used in composites to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, and processability, making them suitable for a wide range of applications.

- HDPE applications in packaging and containers: HDPE is widely used in packaging and container applications due to its excellent barrier properties, chemical resistance, and durability. It is commonly used in the production of bottles, containers, and packaging materials for various industries.

- Recycling and sustainability of HDPE: Recycling processes and sustainable practices for HDPE are being developed to address environmental concerns. These include methods for collecting, sorting, and reprocessing HDPE materials, as well as the development of bio-based alternatives.

- HDPE modifications and additives: Various modifications and additives are used to enhance the properties of HDPE. These can include crosslinking agents, stabilizers, and other additives that improve characteristics such as UV resistance, long-term durability, and processing behavior.

02 HDPE blends and composites

HDPE is often blended with other materials or used in composites to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, or specific mechanical properties, making the resulting material suitable for a wide range of applications.Expand Specific Solutions03 HDPE in packaging and containers

High-density polyethylene is widely used in packaging and container applications due to its excellent chemical resistance, durability, and barrier properties. Innovations in this area focus on improving the material's performance for specific packaging needs, such as food storage or industrial containers.Expand Specific Solutions04 Recycling and sustainability of HDPE

As environmental concerns grow, there is increasing focus on recycling and improving the sustainability of HDPE. This includes developing more efficient recycling processes, creating products from recycled HDPE, and exploring bio-based alternatives to traditional petroleum-derived HDPE.Expand Specific Solutions05 HDPE modifications for specific applications

HDPE is often modified to meet the requirements of specific applications. This can involve adding fillers, modifying the molecular structure, or incorporating additives to enhance properties such as UV resistance, flame retardancy, or electrical conductivity.Expand Specific Solutions

Key Industry Players

The future of High Density Polyethylene (HDPE) in the automotive sector is entering a mature growth phase, with a steadily expanding market size driven by increasing demand for lightweight, durable materials. The global HDPE market in automotive applications is projected to grow significantly, reflecting the industry's shift towards fuel efficiency and sustainability. Technologically, HDPE is well-established, with major players like Dow Global Technologies LLC, SABIC Global Technologies BV, and ExxonMobil Chemical Patents, Inc. continuously innovating to enhance its properties. These companies, along with others such as Borealis AG and LG Chem Ltd., are focusing on developing advanced HDPE formulations tailored for specific automotive applications, indicating a high level of technological maturity and ongoing refinement in this field.

Borealis AG

Dow Global Technologies LLC

Breakthrough Technologies

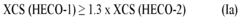

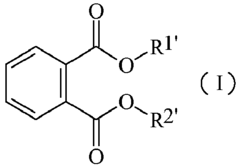

- A polypropylene-based composition comprising heterophasic propylene copolymers, high-density polyethylene, an inorganic anti-blocking agent, and optionally a reinforcing mineral filler and plastomer, which balances gloss reduction and scratch resistance.

- A composition comprising 30-75 wt.% of a first heterophasic propylene copolymer, 5-25 wt.% of a second heterophasic propylene copolymer, 2-15 wt.% of an ethylene-based plastomer, 2-15 wt.% of high density polyethylene, and 5-20 wt.% of an inorganic filler, which enhances melt flow rate and reduces coefficient of linear thermal expansion.

Environmental Impact

The environmental impact of High Density Polyethylene (HDPE) in the automotive sector is a critical consideration for its future applications. As the industry moves towards more sustainable practices, HDPE's environmental footprint throughout its lifecycle becomes increasingly important.

HDPE's production process, while energy-intensive, has seen significant improvements in efficiency over recent years. Compared to traditional materials like steel or aluminum, HDPE requires less energy to manufacture, potentially reducing the carbon footprint of vehicle production. However, the petrochemical origin of HDPE remains a concern, as it is derived from non-renewable fossil fuels.

In terms of vehicle use, HDPE's lightweight properties contribute to improved fuel efficiency and reduced emissions. As automotive manufacturers strive to meet stringent environmental regulations, the incorporation of HDPE components can play a crucial role in achieving these goals. The material's durability also extends the lifespan of parts, reducing the need for frequent replacements and associated environmental impacts.

End-of-life considerations for HDPE in automotive applications present both challenges and opportunities. HDPE is highly recyclable, with the potential for closed-loop recycling systems within the automotive industry. However, the current infrastructure for collecting and processing automotive plastics is not yet fully developed in many regions, leading to suboptimal recycling rates.

Advancements in recycling technologies, such as chemical recycling and improved sorting methods, are expected to enhance the recyclability of HDPE automotive components. This could significantly reduce the environmental impact of HDPE by decreasing the demand for virgin materials and minimizing waste sent to landfills.

The automotive industry's shift towards electric vehicles (EVs) presents new environmental considerations for HDPE usage. While EVs reduce operational emissions, the importance of lightweight materials like HDPE becomes even more pronounced to offset battery weight and extend vehicle range. This could lead to increased use of HDPE in EV designs, potentially amplifying both its positive and negative environmental impacts.

Looking ahead, biodegradable and bio-based alternatives to traditional HDPE are being researched and developed. These materials aim to address the end-of-life concerns associated with petroleum-based plastics while maintaining the desirable properties of HDPE. However, their scalability and cost-effectiveness for automotive applications remain to be proven.

As environmental regulations become more stringent globally, the future of HDPE in the automotive sector will likely depend on continuous improvements in its environmental performance. This includes enhancing production efficiency, increasing recycled content, improving end-of-life management, and potentially transitioning to more sustainable feedstocks. The industry's ability to address these environmental challenges will be crucial in determining HDPE's long-term viability in automotive applications.

Regulatory Compliance

Regulatory compliance plays a crucial role in shaping the future of High Density Polyethylene (HDPE) in the automotive sector. As environmental concerns and safety standards continue to evolve, manufacturers must adapt their materials and processes to meet increasingly stringent regulations.

One of the primary regulatory drivers affecting HDPE usage in automobiles is the push for improved fuel efficiency and reduced emissions. Many countries have implemented strict fuel economy standards, such as the Corporate Average Fuel Economy (CAFE) regulations in the United States. These standards incentivize automakers to reduce vehicle weight, making lightweight materials like HDPE more attractive for various components.

Environmental regulations also impact HDPE's future in the automotive industry. The European Union's End-of-Life Vehicles (ELV) Directive, for instance, mandates that 95% of a vehicle's weight must be reusable or recyclable. This requirement has led to increased focus on the recyclability of HDPE components, driving innovations in material formulations and recycling processes.

Safety regulations continue to influence HDPE applications in vehicles. The material must meet rigorous crash test standards and fire safety requirements. Regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) regularly update their safety protocols, necessitating ongoing research and development in HDPE formulations to ensure compliance.

Chemical regulations, such as the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) in the European Union, also affect HDPE usage. These regulations require manufacturers to assess and manage the risks associated with chemicals used in their products, including additives and stabilizers in HDPE formulations.

As the automotive industry shifts towards electric vehicles, new regulations are emerging that will impact HDPE applications. For example, regulations concerning battery safety and thermal management may create new opportunities for HDPE in battery enclosures and cooling systems.

To navigate this complex regulatory landscape, automotive manufacturers and HDPE suppliers must maintain close collaboration. This partnership ensures that HDPE components not only meet current regulations but also anticipate future regulatory changes. Continuous innovation in HDPE formulations, processing techniques, and design methodologies will be essential to maintain compliance while maximizing the material's benefits in automotive applications.