Harnessing HDPE for Enhanced Infrastructure Durability

HDPE in Infrastructure: Background and Objectives

High-density polyethylene (HDPE) has emerged as a revolutionary material in the field of infrastructure development, offering unprecedented durability and versatility. The journey of HDPE in infrastructure applications began in the mid-20th century, with its initial use in water and gas distribution systems. Since then, its application has expanded to various sectors, including transportation, waste management, and marine structures.

The evolution of HDPE technology has been driven by the growing demand for more resilient and sustainable infrastructure solutions. As urbanization accelerates and climate change poses new challenges, the need for materials that can withstand extreme conditions while maintaining long-term performance has become paramount. HDPE's unique properties, such as high strength-to-density ratio, chemical resistance, and flexibility, position it as an ideal candidate for addressing these evolving infrastructure needs.

The primary objective in harnessing HDPE for enhanced infrastructure durability is to maximize its potential in creating longer-lasting, more efficient, and environmentally friendly structures. This involves exploring innovative applications, improving manufacturing processes, and developing advanced HDPE composites that can outperform traditional materials in various infrastructure settings.

One of the key trends in HDPE technology is the development of high-performance grades with enhanced mechanical properties and UV resistance. These advancements aim to extend the service life of HDPE-based infrastructure components, reducing maintenance requirements and lifecycle costs. Additionally, there is a growing focus on incorporating recycled HDPE into infrastructure applications, aligning with global sustainability goals and circular economy principles.

The future trajectory of HDPE in infrastructure is expected to involve further refinements in material science, such as nanotechnology-enhanced HDPE composites and smart HDPE materials with self-healing capabilities. These innovations could revolutionize infrastructure design and maintenance practices, leading to more resilient and adaptive built environments.

As we delve deeper into the potential of HDPE for infrastructure durability, it is crucial to consider the multifaceted aspects of its implementation. This includes addressing technical challenges, such as long-term creep behavior and joint integrity, as well as overcoming regulatory barriers and industry inertia. The successful integration of HDPE into mainstream infrastructure practices will require collaborative efforts between material scientists, engineers, policymakers, and industry stakeholders.

Market Analysis for HDPE in Construction

The global market for High-Density Polyethylene (HDPE) in construction is experiencing significant growth, driven by the material's exceptional durability, versatility, and cost-effectiveness. As infrastructure development continues to surge worldwide, HDPE has emerged as a preferred material for various applications, including pipes, fittings, and structural components.

The construction industry's increasing focus on sustainable and long-lasting materials has propelled HDPE to the forefront of market demand. Its resistance to corrosion, chemical inertness, and ability to withstand extreme temperatures make it an ideal choice for both above-ground and underground infrastructure projects. The material's lightweight nature also contributes to reduced transportation and installation costs, further enhancing its appeal to construction firms and project managers.

In recent years, the HDPE market in construction has witnessed a compound annual growth rate (CAGR) of over 5%, with projections indicating continued expansion in the coming decade. This growth is particularly pronounced in developing regions, where rapid urbanization and infrastructure modernization efforts are driving demand for reliable and cost-effective building materials.

The Asia-Pacific region leads the global HDPE construction market, accounting for a substantial share of the overall demand. Countries like China and India are at the forefront of this trend, with massive infrastructure projects and urban development initiatives fueling the need for HDPE products. North America and Europe follow closely, with mature markets focusing on infrastructure rehabilitation and replacement projects that favor HDPE's longevity and performance characteristics.

Water management systems represent a significant portion of HDPE applications in construction, with the material being widely used in water supply lines, sewage systems, and stormwater management. The increasing emphasis on water conservation and efficient distribution has further boosted the adoption of HDPE pipes and fittings in municipal projects worldwide.

The construction industry's shift towards prefabrication and modular building techniques has also created new opportunities for HDPE. Its moldability and ease of fabrication make it an excellent choice for creating standardized components that can be quickly assembled on-site, reducing construction time and labor costs.

Despite the positive market outlook, challenges such as fluctuating raw material prices and competition from alternative materials like PVC and concrete persist. However, ongoing research and development efforts are focused on enhancing HDPE's properties and expanding its applications, which is expected to maintain its competitive edge in the construction sector.

As sustainability becomes increasingly crucial in construction practices, HDPE's recyclability and long service life align well with green building standards and circular economy principles. This aspect is likely to drive further adoption of HDPE in eco-friendly construction projects, opening up new market segments and opportunities for growth in the coming years.

Current HDPE Applications and Challenges

High-density polyethylene (HDPE) has become a cornerstone material in modern infrastructure due to its exceptional durability, chemical resistance, and versatility. Currently, HDPE finds extensive applications across various sectors, including water and wastewater systems, gas distribution networks, and geosynthetic liners for environmental protection.

In the water industry, HDPE pipes have gained significant traction for their corrosion resistance and flexibility. These pipes are widely used in potable water distribution systems, sewage networks, and stormwater management. The material's resistance to chemicals and abrasion makes it particularly suitable for transporting aggressive fluids and withstanding harsh underground conditions.

The gas distribution sector has also embraced HDPE for its excellent leak-tight properties and long-term performance. HDPE pipes are increasingly replacing traditional metal pipes in natural gas networks, offering improved safety and reduced maintenance requirements. The material's ability to withstand ground movement and resist corrosion contributes to the overall reliability of gas infrastructure.

In geotechnical applications, HDPE geomembranes serve as effective barriers in landfills, mining operations, and contaminated site remediation. These liners prevent the migration of pollutants and protect groundwater resources, playing a crucial role in environmental conservation efforts.

Despite its widespread adoption, HDPE faces several challenges in infrastructure applications. One significant issue is the material's susceptibility to stress cracking, particularly in high-pressure or high-temperature environments. This phenomenon can lead to premature failure of HDPE components, potentially compromising the integrity of critical infrastructure systems.

Another challenge lies in the joining of HDPE pipes and structures. While heat fusion techniques provide strong and reliable connections, they require specialized equipment and skilled operators. Improper fusion can result in weak joints, leading to leaks or structural failures. Additionally, the repair and maintenance of HDPE systems in existing infrastructure can be complex, often requiring specialized techniques and tools.

The material's thermal expansion properties also present challenges in certain applications. HDPE's relatively high coefficient of thermal expansion can lead to dimensional changes in response to temperature fluctuations, necessitating careful design considerations to accommodate these movements in infrastructure projects.

Furthermore, the long-term performance of HDPE under various environmental conditions remains an area of ongoing research. While the material has demonstrated excellent durability in many applications, predicting its behavior over extended periods, especially under complex loading conditions and exposure to various chemicals, continues to be a challenge for engineers and material scientists.

As infrastructure demands evolve, there is a growing need for HDPE materials with enhanced properties, such as improved resistance to slow crack growth, higher temperature resistance, and better dimensional stability. Addressing these challenges through innovative material formulations and advanced manufacturing techniques remains a key focus for researchers and industry professionals working to harness the full potential of HDPE in enhancing infrastructure durability.

Existing HDPE Infrastructure Solutions

01 Improving HDPE durability through additives

Various additives can be incorporated into HDPE to enhance its durability. These additives may include antioxidants, UV stabilizers, and other compounds that protect the polymer from degradation caused by environmental factors such as sunlight, heat, and oxidation. The addition of these substances can significantly extend the lifespan of HDPE products and improve their resistance to weathering and chemical exposure.- Enhancing HDPE durability through additives: Various additives can be incorporated into HDPE to improve its durability. These additives may include antioxidants, UV stabilizers, and other compounds that enhance the material's resistance to environmental factors, oxidation, and degradation. The addition of these substances can significantly extend the lifespan of HDPE products and improve their performance in various applications.

- HDPE composites for improved durability: Combining HDPE with other materials to create composites can enhance its durability. These composites may include reinforcing fibers, nanoparticles, or other polymers that work synergistically with HDPE to improve its mechanical properties, chemical resistance, and overall longevity. The resulting materials often exhibit superior durability compared to pure HDPE.

- Surface treatment techniques for HDPE: Various surface treatment methods can be applied to HDPE to enhance its durability. These techniques may include plasma treatment, chemical etching, or the application of protective coatings. Such treatments can improve the material's resistance to wear, weathering, and chemical attack, thereby extending its useful life in demanding environments.

- Optimizing HDPE processing for durability: The durability of HDPE products can be significantly influenced by the processing methods used during manufacturing. Techniques such as optimized extrusion parameters, controlled cooling rates, and specific molding processes can enhance the material's molecular structure and orientation, leading to improved mechanical properties and long-term durability.

- HDPE blends for enhanced durability: Blending HDPE with other polymers or elastomers can result in materials with improved durability characteristics. These blends may offer a combination of properties that pure HDPE lacks, such as increased impact resistance, better chemical resistance, or improved weatherability. The careful selection and proportion of blend components can tailor the material's durability to specific application requirements.

02 HDPE composites for enhanced durability

Combining HDPE with other materials to form composites can greatly improve its durability. These composites may include reinforcing fibers, nanoparticles, or other polymers that enhance the mechanical properties and chemical resistance of HDPE. Such composites often exhibit superior strength, impact resistance, and longevity compared to pure HDPE.Expand Specific Solutions03 Surface treatments for HDPE durability

Various surface treatment techniques can be applied to HDPE to improve its durability. These may include plasma treatment, chemical etching, or the application of protective coatings. Such treatments can enhance the material's resistance to wear, abrasion, and chemical attack, thereby extending its useful life in demanding applications.Expand Specific Solutions04 Optimizing HDPE molecular structure

The durability of HDPE can be enhanced by optimizing its molecular structure during polymerization. This may involve controlling factors such as molecular weight distribution, degree of branching, and crystallinity. By fine-tuning these parameters, manufacturers can produce HDPE with improved mechanical properties, chemical resistance, and long-term stability.Expand Specific Solutions05 HDPE blends for improved durability

Blending HDPE with other polymers or elastomers can result in materials with enhanced durability. These blends may combine the desirable properties of HDPE with those of other materials, leading to improved impact resistance, flexibility, or chemical resistance. The resulting blends can offer superior performance in applications where standard HDPE may fall short.Expand Specific Solutions

Key HDPE Manufacturers and Suppliers

The market for HDPE in infrastructure durability is in a growth phase, driven by increasing demand for long-lasting and corrosion-resistant materials. The global HDPE market size is projected to expand significantly, with key players like Dow Global Technologies LLC, Borealis AG, and SABIC Global Technologies BV leading innovation. Technological maturity varies, with companies such as China Petroleum & Chemical Corp. and PetroChina Co., Ltd. focusing on advanced applications. Research institutions like Chang'an University and Tianjin University are contributing to material improvements. The industry sees a mix of established petrochemical giants and specialized materials companies like Kingfa Sci. & Tech. Co., Ltd., indicating a competitive and evolving landscape in HDPE technology for infrastructure applications.

China Petroleum & Chemical Corp.

Dow Global Technologies LLC

Innovative HDPE Formulations and Processes

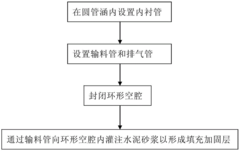

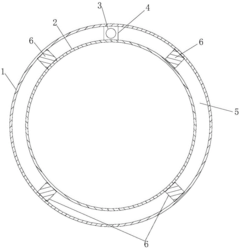

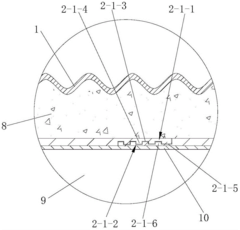

- HDPE winding reinforced pipes and cement mortar reinforcement methods are used to set up lining pipes in the round pipe culvert and pour cement mortar to form a filling reinforcement layer to increase the cross-sectional area and corrosion resistance of the load-bearing components and avoid excavation of roadbed and temporary traffic. sidewalk.

- A foamable polymer composition comprising a polyolefin polymer, specifically linear low density polyethylene, combined with a blowing agent like citric acid or expandable polymeric microspheres, which allows for controlled foaming to enhance flexibility and tensile properties, thereby improving the cable's installation and durability.

Environmental Impact of HDPE in Construction

The environmental impact of High-Density Polyethylene (HDPE) in construction is a multifaceted issue that requires careful consideration. HDPE, known for its durability and versatility, has become increasingly popular in infrastructure projects. However, its widespread use raises important questions about its long-term effects on the environment.

One of the primary environmental benefits of HDPE in construction is its longevity. HDPE structures and components can last for decades, reducing the need for frequent replacements and minimizing the overall resource consumption associated with infrastructure maintenance. This durability translates to fewer raw materials extracted, less energy expended in manufacturing, and reduced transportation emissions over time.

HDPE's resistance to corrosion and chemical degradation also contributes to its environmental profile. Unlike traditional materials such as metal or concrete, HDPE does not leach harmful substances into the surrounding soil or water, helping to maintain ecosystem health in the vicinity of construction projects. This property is particularly valuable in sensitive environmental areas or in applications where material integrity is crucial for preventing contamination.

However, the production of HDPE does have environmental drawbacks. The manufacturing process relies heavily on fossil fuels, both as raw materials and energy sources. This dependency contributes to greenhouse gas emissions and the depletion of non-renewable resources. The energy-intensive nature of HDPE production also raises concerns about its carbon footprint, especially when compared to some natural or recycled building materials.

End-of-life management of HDPE in construction presents another environmental challenge. While HDPE is theoretically recyclable, the reality of recycling large-scale construction components is often complex and economically challenging. The long lifespan of HDPE structures means that significant volumes of material may not enter the waste stream for many years, potentially delaying the development of efficient recycling systems.

The use of HDPE in construction can also impact local ecosystems. Large-scale HDPE installations, such as pipelines or erosion control structures, may alter natural habitats or disrupt wildlife patterns. However, when properly designed and implemented, HDPE solutions can also play a role in environmental protection, such as in the construction of stormwater management systems that help prevent pollution and flooding.

Advancements in HDPE technology are addressing some of these environmental concerns. Research into bio-based HDPE, derived from renewable resources, shows promise in reducing the material's reliance on fossil fuels. Additionally, improvements in recycling technologies and the incorporation of recycled content in new HDPE products are helping to close the loop on material use, potentially mitigating some of the end-of-life issues associated with HDPE in construction.

HDPE Standards and Regulations

The development and implementation of High-Density Polyethylene (HDPE) in infrastructure projects are governed by a comprehensive framework of standards and regulations. These guidelines ensure the consistent quality, performance, and safety of HDPE materials across various applications.

International standards organizations, such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO), have established key specifications for HDPE. ASTM D3350 defines the standard specification for polyethylene plastics pipe and fittings materials, while ISO 4427 outlines the requirements for HDPE piping systems for water supply.

In the United States, the National Transportation Product Evaluation Program (NTPEP) plays a crucial role in evaluating HDPE products for use in transportation infrastructure. Their rigorous testing protocols ensure that HDPE materials meet the stringent requirements for durability and performance in demanding environments.

The American Association of State Highway and Transportation Officials (AASHTO) has developed specific guidelines for the use of HDPE in highway construction. AASHTO M 294 sets the standard specification for corrugated polyethylene pipe, which is widely used in drainage applications.

Environmental regulations also impact the use of HDPE in infrastructure. The U.S. Environmental Protection Agency (EPA) has established guidelines for the use of recycled HDPE in construction projects, promoting sustainability in infrastructure development. These regulations encourage the use of post-consumer HDPE in non-critical applications, reducing environmental impact while maintaining structural integrity.

In the water and wastewater sector, the American Water Works Association (AWWA) has developed standards specifically for HDPE pipe and fittings. AWWA C906 provides guidelines for the manufacture and testing of HDPE pressure pipe and fittings for water transmission and distribution.

Building codes in many jurisdictions now include provisions for the use of HDPE in construction. The International Building Code (IBC) and the International Plumbing Code (IPC) both reference HDPE standards, providing a regulatory framework for its use in building infrastructure.

As the applications of HDPE in infrastructure continue to expand, regulatory bodies are adapting their standards to keep pace with technological advancements. This ongoing evolution of standards and regulations ensures that HDPE remains a reliable and durable material for enhancing infrastructure resilience in the face of growing environmental challenges and increasing demands on public infrastructure systems.