Leading HDPE Technologies for Construction Applications

HDPE in Construction: Background and Objectives

High-density polyethylene (HDPE) has emerged as a revolutionary material in the construction industry, offering a unique combination of durability, flexibility, and cost-effectiveness. The evolution of HDPE technologies for construction applications has been driven by the growing demand for sustainable, long-lasting, and versatile building materials. This technological progression has its roots in the mid-20th century when HDPE was first synthesized, but it has gained significant momentum in recent decades.

The primary objective of leading HDPE technologies in construction is to address the industry's pressing needs for materials that can withstand harsh environmental conditions, reduce maintenance costs, and contribute to energy efficiency. HDPE's inherent properties, such as its resistance to corrosion, chemicals, and UV radiation, make it an ideal candidate for various construction applications, ranging from piping systems to geomembranes and structural components.

In the realm of piping systems, HDPE has revolutionized water distribution, sewage management, and gas transportation. The material's flexibility and leak-resistant nature have led to the development of trenchless installation techniques, significantly reducing construction time and environmental disruption. The ongoing technological advancements aim to further enhance HDPE pipes' performance, including improved pressure ratings, increased diameter options, and enhanced joining methods.

Another critical area of HDPE application in construction is geosynthetics. HDPE geomembranes and geogrids play a crucial role in soil stabilization, erosion control, and environmental protection. The technological trajectory in this field focuses on developing HDPE products with superior tensile strength, enhanced UV resistance, and improved interface friction properties to ensure long-term stability in diverse geological conditions.

The use of HDPE in structural applications represents a frontier in construction technology. Researchers and industry leaders are exploring innovative ways to incorporate HDPE into load-bearing elements, taking advantage of its lightweight nature and resistance to environmental degradation. This includes the development of HDPE composite materials that combine the polymer's beneficial properties with those of traditional construction materials like concrete and steel.

As the construction industry increasingly embraces sustainable practices, HDPE technologies are evolving to meet these new demands. Current research and development efforts are focused on improving the recyclability of HDPE products, incorporating recycled content into new materials, and reducing the carbon footprint associated with HDPE production and installation. These initiatives align with global efforts to create more environmentally friendly and circular construction practices.

The technological evolution of HDPE in construction is closely tied to advancements in polymer science, manufacturing processes, and installation techniques. Future developments are expected to push the boundaries of HDPE's capabilities, potentially leading to self-healing materials, smart HDPE products with embedded sensors, and novel applications in 3D-printed construction components.

Market Analysis for HDPE in Construction

The global market for High-Density Polyethylene (HDPE) in construction applications has been experiencing significant growth, driven by the material's versatility, durability, and cost-effectiveness. HDPE's unique properties, including high strength-to-density ratio, chemical resistance, and low maintenance requirements, have positioned it as a preferred choice for various construction applications.

In recent years, the construction industry has witnessed a surge in HDPE adoption across multiple sectors. The pipes and fittings segment dominates the market, accounting for a substantial share of HDPE usage in construction. This is primarily due to the material's excellent resistance to corrosion, abrasion, and chemical degradation, making it ideal for water supply, sewage systems, and gas distribution networks.

The building and construction sector has also embraced HDPE for applications such as geomembranes, waterproofing membranes, and insulation materials. The growing emphasis on sustainable and energy-efficient construction practices has further boosted the demand for HDPE-based products in this segment.

Geographically, Asia-Pacific leads the HDPE construction market, with China and India being the major contributors to regional growth. The rapid urbanization, infrastructure development, and government initiatives in these countries have been key drivers for HDPE adoption. North America and Europe follow closely, with mature markets focusing on renovation and replacement activities.

The market landscape is characterized by intense competition among key players, including major petrochemical companies and specialized HDPE manufacturers. These companies are investing heavily in research and development to enhance product performance and expand their application range in the construction sector.

Looking ahead, the HDPE construction market is poised for continued growth. Factors such as increasing infrastructure investments, growing awareness of HDPE's benefits, and stringent regulations promoting the use of sustainable materials are expected to drive market expansion. Additionally, technological advancements in HDPE production and processing are likely to open up new opportunities and applications in the construction industry.

However, the market also faces challenges, including fluctuations in raw material prices and competition from alternative materials. Despite these obstacles, the overall outlook for HDPE in construction remains positive, with innovations in material science and manufacturing processes expected to further enhance its market position and broaden its application scope in the coming years.

Current HDPE Technologies and Challenges

High-density polyethylene (HDPE) has become a prominent material in the construction industry due to its exceptional properties and versatility. Current HDPE technologies for construction applications have advanced significantly, offering improved durability, chemical resistance, and cost-effectiveness. However, these technologies also face several challenges that need to be addressed for wider adoption and enhanced performance.

One of the primary HDPE technologies in construction is the production of large-diameter pipes for water and sewage systems. These pipes offer excellent corrosion resistance and longevity compared to traditional materials. The current manufacturing processes, such as extrusion and rotational molding, allow for the production of pipes with varying diameters and wall thicknesses to suit different applications. However, challenges persist in ensuring consistent quality across large pipe sections and optimizing the joining techniques for leak-free installations.

HDPE geomembranes represent another significant application in construction, particularly for landfill liners and water containment structures. The current technology allows for the production of large, seamless sheets with high puncture resistance and flexibility. While these geomembranes offer excellent impermeability, there are ongoing challenges in improving their long-term UV resistance and developing more efficient installation methods for large-scale projects.

In the realm of structural applications, HDPE lumber and profiles have gained traction as alternatives to traditional wood and metal materials. These products offer resistance to rot, insects, and weathering, making them ideal for outdoor structures. Current manufacturing technologies allow for the production of HDPE lumber with various densities and reinforcements. However, challenges remain in improving the material's load-bearing capacity and fire resistance to expand its use in more demanding structural applications.

HDPE foam technology has also found its place in construction, particularly for insulation and lightweight structural elements. Current manufacturing processes can produce HDPE foams with varying densities and cell structures. While these foams offer excellent thermal insulation properties, there are ongoing efforts to enhance their fire retardancy and develop more sustainable production methods.

A significant challenge across all HDPE construction applications is the need for improved recycling and sustainability. While HDPE is recyclable, the current technologies for separating and processing construction waste HDPE are not yet optimized. There is a pressing need for developing more efficient recycling processes and increasing the use of recycled HDPE in new construction products without compromising performance.

Another overarching challenge is the development of HDPE composites that can enhance the material's properties for specific construction applications. Current research focuses on incorporating nanomaterials, fibers, and other additives to improve strength, thermal properties, and fire resistance. However, challenges persist in achieving uniform dispersion of these additives and maintaining the ease of processing that makes HDPE attractive for construction applications.

Leading HDPE Solutions for Construction

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and automotive parts.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Examples include HDPE blended with other polymers, reinforced with natural fibers, or combined with nanoparticles to create materials with tailored properties for specific applications.

- HDPE processing techniques: Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Advanced processing techniques can improve the material's performance or enable the creation of complex shapes and structures.

- Recycling and sustainability of HDPE: HDPE is a recyclable material, and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in various applications. This includes developing new recycling technologies, improving the quality of recycled HDPE, and finding innovative uses for recycled material. Sustainability initiatives also focus on reducing the environmental impact of HDPE production and use.

- HDPE applications in specific industries: HDPE finds applications in various industries due to its versatile properties. It is used in packaging for food and beverages, chemical storage containers, and personal care products. In construction, HDPE is used for pipes, geomembranes, and insulation. The automotive industry utilizes HDPE for fuel tanks and interior components. Other applications include medical devices, toys, and outdoor furniture.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, or specific mechanical properties. The resulting materials find applications in areas where standard HDPE may not meet all requirements.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. Each method offers specific advantages and is suited for different product types. Innovations in processing techniques focus on improving efficiency, reducing cycle times, and enhancing the quality of the final products.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is recyclable and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in new products. Research focuses on enhancing the properties of recycled HDPE, developing more efficient recycling methods, and finding new applications for recycled materials to promote sustainability and reduce environmental impact.Expand Specific Solutions05 HDPE applications in specific industries

HDPE finds extensive use in various industries due to its versatile properties. It is commonly used in packaging, construction, automotive parts, and consumer goods. Ongoing research and development focus on expanding HDPE applications, such as in 3D printing, medical devices, and advanced composite materials for specialized industrial uses.Expand Specific Solutions

Key Players in HDPE Construction Materials

The market for leading HDPE technologies in construction applications is in a growth phase, driven by increasing demand for durable and cost-effective materials. The global HDPE construction market is expanding, with significant potential in infrastructure and building sectors. Technologically, HDPE solutions are mature but continue to evolve, with companies like ExxonMobil Chemical Patents, Dow Global Technologies, and China Petroleum & Chemical Corp leading innovation. These firms, along with others like PetroChina and Celanese Polymers Holding, are advancing HDPE formulations and manufacturing processes to enhance performance in construction applications. The competitive landscape is characterized by a mix of established petrochemical giants and specialized materials companies, each striving to develop superior HDPE solutions for the construction industry's evolving needs.

ExxonMobil Chemical Patents, Inc.

Dow Global Technologies LLC

Innovative HDPE Technologies in Construction

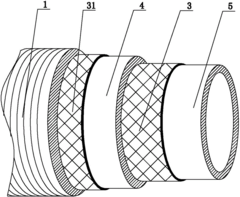

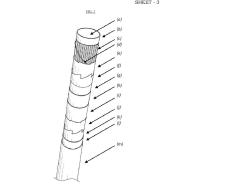

- The HDPE core pipe is used to wrap the first stainless steel mesh layer, the middle bonding layer and the outer wrapping second stainless steel mesh layer. The outer layer is HDPE weather-resistant layer. A combination of materials such as thermoplastic polyurethane elastomer and antioxidant is used to improve toughness and wear resistance. .

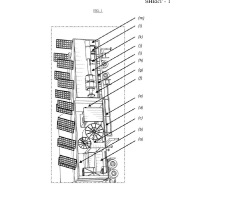

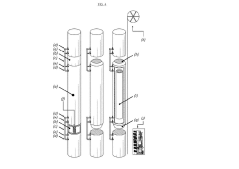

- The development of a tubular composite structure (TCS) comprising multiple layers of sealing, reinforcement, sensing, and protection materials, with optional interspatial annular cylinders, which can be manufactured on-site using a mobile factory to provide a flexible, durable, and efficient solution for pipeline renewal and storage.

Environmental Impact of HDPE in Construction

The environmental impact of HDPE in construction is a critical consideration as the industry increasingly adopts this versatile material. HDPE's durability and longevity contribute to reduced waste and resource consumption over time. Its resistance to corrosion and chemical degradation means fewer replacements are needed, minimizing the environmental footprint associated with manufacturing and transportation of replacement materials.

HDPE's lightweight nature also offers environmental benefits during transportation and installation, reducing fuel consumption and emissions. Additionally, its thermal insulation properties can enhance energy efficiency in buildings, potentially lowering long-term energy consumption and associated carbon emissions.

However, the production of HDPE does raise environmental concerns. The material is derived from non-renewable petroleum resources, and its manufacturing process involves significant energy consumption and greenhouse gas emissions. While HDPE is recyclable, the actual recycling rates in the construction industry remain relatively low due to challenges in collection and processing of construction waste.

The end-of-life management of HDPE in construction applications presents both challenges and opportunities. When properly collected and processed, HDPE can be recycled multiple times without significant loss of quality, potentially reducing the demand for virgin materials. However, improper disposal can lead to long-lasting environmental pollution, as HDPE does not biodegrade readily.

Recent advancements in HDPE technology are addressing some of these environmental concerns. Bio-based HDPE, derived from renewable resources such as sugarcane, is emerging as a more sustainable alternative. Additionally, improved recycling technologies and the development of closed-loop systems in construction are enhancing the material's circularity.

The construction industry is also exploring innovative applications of HDPE that leverage its environmental benefits. For instance, HDPE is being used in green infrastructure projects, such as permeable paving systems that help manage stormwater runoff and reduce urban heat island effects.

As sustainability becomes increasingly important in construction, the environmental impact of HDPE will likely drive further innovations. Future developments may focus on enhancing the material's recyclability, reducing its carbon footprint during production, and expanding its use in energy-efficient building designs. The ongoing research into biodegradable additives for HDPE could also address concerns about its persistence in the environment.

HDPE Standards and Regulations in Construction

The construction industry's use of High-Density Polyethylene (HDPE) is governed by a comprehensive framework of standards and regulations. These guidelines ensure the safety, reliability, and performance of HDPE materials in various construction applications. The American Society for Testing and Materials (ASTM) plays a crucial role in establishing these standards, with ASTM D3350 being a key specification for polyethylene plastics pipe and fittings materials.

ASTM D3350 categorizes HDPE materials based on their physical properties, including density, melt index, flexural modulus, tensile strength, and environmental stress crack resistance. This classification system enables engineers and contractors to select the most appropriate HDPE grade for specific construction projects. Additionally, ASTM F714 provides standards for polyethylene (PE) plastic pipe based on outside diameter controlled pipe, which is particularly relevant for HDPE pipes used in construction.

The International Organization for Standardization (ISO) also contributes to HDPE regulations in construction. ISO 4427 sets standards for polyethylene (PE) piping systems for water supply, specifying requirements for pipes, fittings, and the system as a whole. This standard is widely adopted globally, ensuring consistency in HDPE pipe quality across international markets.

In the United States, the National Sanitation Foundation (NSF) plays a vital role in regulating HDPE materials used in potable water systems. NSF/ANSI 61 certification is required for HDPE pipes and fittings that come into contact with drinking water, ensuring they do not leach harmful contaminants. This standard is crucial for maintaining public health and safety in water infrastructure projects.

The European Committee for Standardization (CEN) has developed EN 12201, which specifies requirements for HDPE piping systems for water supply and sewerage under pressure. This standard is widely used across Europe and influences global practices in HDPE pipe manufacturing and installation.

Building codes also incorporate HDPE-specific regulations. The International Building Code (IBC) and the International Plumbing Code (IPC) reference ASTM and other standards for HDPE materials, providing guidelines for their use in various construction applications. These codes ensure that HDPE products meet minimum safety and performance requirements in building projects.

Environmental regulations also impact HDPE use in construction. Many jurisdictions require HDPE products to be recyclable and have minimal environmental impact. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation affects the chemical composition of HDPE materials, ensuring they meet strict environmental and health standards.

As HDPE technologies continue to advance, standards and regulations evolve to address new applications and performance requirements. Industry associations, such as the Plastics Pipe Institute (PPI), work closely with regulatory bodies to develop and update standards that reflect the latest technological advancements and best practices in HDPE construction applications.