Graphene Oxide for Wearable Sensors: Current Trends

Graphene Oxide Wearable Sensor Evolution

The evolution of graphene oxide wearable sensors has been marked by significant advancements in materials science and nanotechnology. Initially, graphene oxide was primarily used in laboratory settings due to its unique properties, including high surface area, excellent electrical conductivity, and mechanical strength. As research progressed, scientists began exploring its potential in wearable sensor applications.

The first generation of graphene oxide wearable sensors focused on basic physiological monitoring, such as heart rate and skin temperature. These early devices were relatively bulky and had limited functionality. However, they demonstrated the potential of graphene oxide in creating flexible and sensitive sensors that could conform to the human body.

As fabrication techniques improved, the second generation of sensors emerged, featuring enhanced sensitivity and multi-parameter sensing capabilities. These sensors could detect multiple biomarkers simultaneously, including glucose levels, sweat composition, and even certain stress indicators. The integration of graphene oxide with other nanomaterials, such as metal nanoparticles and carbon nanotubes, further expanded the sensing capabilities and improved overall performance.

The third generation of graphene oxide wearable sensors saw a significant leap in miniaturization and integration. Researchers developed techniques to create ultrathin, highly flexible sensors that could be seamlessly incorporated into clothing or applied directly to the skin like temporary tattoos. These sensors offered real-time, continuous monitoring of various physiological parameters with minimal discomfort to the wearer.

Recent developments have focused on creating self-powered graphene oxide wearable sensors. By incorporating energy harvesting technologies, such as piezoelectric or triboelectric nanogenerators, these sensors can generate their own power from body movements or environmental sources, eliminating the need for external batteries and enhancing their practicality for long-term use.

The latest trends in graphene oxide wearable sensors involve the integration of artificial intelligence and machine learning algorithms. These advanced sensors can not only collect data but also process and analyze it in real-time, providing personalized health insights and early warning signs of potential health issues. Additionally, researchers are exploring the use of graphene oxide in biodegradable sensors, addressing environmental concerns associated with electronic waste.

Looking ahead, the future of graphene oxide wearable sensors is likely to involve further miniaturization, increased biocompatibility, and expanded sensing capabilities. Efforts are underway to develop sensors that can detect a wider range of biomarkers, including specific disease indicators and environmental pollutants. The integration of graphene oxide sensors with other emerging technologies, such as 5G networks and the Internet of Things, is expected to revolutionize personal health monitoring and telemedicine.

Market Demand Analysis

The market demand for graphene oxide-based wearable sensors has been experiencing significant growth in recent years, driven by the increasing focus on health monitoring, fitness tracking, and personalized healthcare. The global wearable sensor market is projected to expand rapidly, with graphene oxide emerging as a key material due to its exceptional properties.

In the healthcare sector, there is a growing demand for non-invasive, continuous monitoring devices. Graphene oxide-based wearable sensors offer the potential for real-time tracking of vital signs, such as heart rate, blood pressure, and glucose levels. This aligns with the trend towards preventive healthcare and remote patient monitoring, which has been accelerated by the recent global health crisis.

The sports and fitness industry represents another major market for graphene oxide wearable sensors. Athletes and fitness enthusiasts are increasingly seeking advanced performance tracking devices. Graphene oxide sensors can provide more accurate and comprehensive data on physical activities, including motion analysis, sweat composition, and muscle fatigue. This information is valuable for optimizing training regimens and preventing injuries.

Environmental monitoring is an emerging application area for graphene oxide wearable sensors. With growing concerns about air quality and exposure to harmful substances, there is a rising demand for personal environmental sensors. Graphene oxide-based devices can detect various pollutants and chemicals with high sensitivity, offering individuals real-time information about their surroundings.

The consumer electronics market is also driving demand for graphene oxide wearable sensors. Smartwatches, fitness bands, and other wearable devices are incorporating more advanced sensing capabilities. Graphene oxide sensors can enable thinner, more flexible, and more power-efficient devices, addressing consumer preferences for sleek, comfortable, and long-lasting wearables.

In the industrial sector, there is increasing interest in wearable sensors for worker safety and productivity. Graphene oxide sensors can be integrated into personal protective equipment to monitor exposure to hazardous materials or detect fatigue and stress levels. This aligns with the growing emphasis on workplace safety and the adoption of Industry 4.0 technologies.

The market for graphene oxide wearable sensors is expected to benefit from the overall growth in Internet of Things (IoT) and connected devices. As more devices become interconnected, the demand for sensors that can provide accurate, real-time data in a compact and energy-efficient form factor is likely to increase.

While the market potential is significant, challenges such as manufacturing scalability, cost reduction, and regulatory approvals need to be addressed to fully realize the market demand. However, ongoing research and development efforts are expected to overcome these hurdles, paving the way for widespread adoption of graphene oxide-based wearable sensors across various industries.

Technical Challenges

Despite the promising potential of graphene oxide (GO) in wearable sensors, several technical challenges persist in its widespread adoption and commercialization. One of the primary obstacles is the scalability and cost-effectiveness of GO production. While laboratory-scale synthesis methods have been well-established, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a significant hurdle.

Another critical challenge lies in the stability and durability of GO-based sensors in real-world applications. Wearable devices are subjected to various environmental factors, including moisture, temperature fluctuations, and mechanical stress. Ensuring the long-term stability of GO sensors under these conditions is crucial for their practical implementation. Additionally, the potential toxicity and biocompatibility of GO materials when in prolonged contact with human skin need to be thoroughly investigated and addressed.

The integration of GO into flexible and stretchable substrates poses another technical challenge. While GO exhibits excellent electrical and mechanical properties, achieving seamless integration with other materials without compromising sensor performance or durability is complex. This integration challenge extends to the development of reliable electrical connections and interfaces between GO-based sensing elements and conventional electronic components.

Furthermore, the selectivity and specificity of GO-based sensors in complex, real-world environments present ongoing challenges. Wearable sensors often operate in the presence of various interfering substances and environmental factors. Enhancing the ability of GO sensors to accurately detect and quantify target analytes while minimizing false positives or negatives is crucial for their reliability in practical applications.

The development of standardized characterization and testing protocols for GO-based wearable sensors is another area requiring attention. The lack of universally accepted standards makes it difficult to compare and validate sensor performance across different research groups and manufacturers. Establishing robust and reproducible testing methodologies is essential for advancing the field and facilitating the transition from research to commercial products.

Lastly, the challenge of power management and energy efficiency in GO-based wearable sensors cannot be overlooked. Many wearable applications require long-term, continuous operation with minimal user intervention. Developing low-power sensing mechanisms and efficient energy harvesting or storage solutions compatible with GO-based sensors is crucial for their practical implementation in everyday wearable devices.

Current GO Sensor Solutions

01 Graphene oxide-based flexible sensors

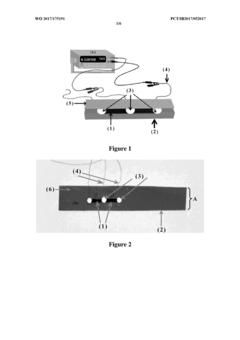

Graphene oxide is used to create flexible and wearable sensors due to its excellent electrical and mechanical properties. These sensors can be integrated into various wearable devices for monitoring physiological parameters, environmental conditions, or motion detection. The flexibility allows for comfortable and unobtrusive wear on the body.- Graphene oxide-based wearable sensor fabrication: Techniques for fabricating wearable sensors using graphene oxide as a key material. These methods involve processes for creating flexible, stretchable, and highly sensitive sensors that can be integrated into various wearable devices. The fabrication techniques may include methods for depositing graphene oxide onto flexible substrates, creating patterns, and incorporating other materials to enhance sensor performance.

- Functionalization of graphene oxide for enhanced sensing: Methods for functionalizing graphene oxide to improve its sensing capabilities in wearable devices. This may involve chemical modifications, doping, or the addition of specific functional groups to enhance sensitivity, selectivity, or other properties relevant to sensing applications. The functionalization can be tailored for detecting specific analytes or improving the overall performance of the sensor.

- Integration of graphene oxide sensors with wearable electronics: Techniques for integrating graphene oxide-based sensors with other electronic components to create complete wearable sensing systems. This includes methods for connecting sensors to data processing units, power sources, and communication modules. The integration focuses on maintaining flexibility and comfort while ensuring reliable data collection and transmission in wearable applications.

- Graphene oxide sensor applications in health monitoring: Specific applications of graphene oxide-based wearable sensors in health monitoring. This includes sensors designed for measuring various physiological parameters such as heart rate, blood pressure, glucose levels, or sweat composition. The focus is on developing sensors that can provide accurate, real-time health data in a non-invasive and comfortable manner.

- Environmental and chemical sensing with graphene oxide wearables: Development of graphene oxide-based wearable sensors for environmental and chemical detection. These sensors are designed to monitor air quality, detect pollutants, or identify specific chemical compounds in the environment. The emphasis is on creating sensitive and selective sensors that can provide real-time data on environmental conditions or potential hazards.

02 Graphene oxide synthesis and modification

Various methods are employed to synthesize and modify graphene oxide for use in wearable sensors. These techniques aim to enhance the material's properties, such as conductivity, sensitivity, or selectivity. Modifications may include doping, functionalization, or creating composite materials with other substances to tailor the sensor's performance.Expand Specific Solutions03 Graphene oxide-based electrochemical sensors

Graphene oxide is utilized in the development of electrochemical sensors for wearable applications. These sensors can detect various analytes in bodily fluids or environmental samples. The high surface area and unique electronic properties of graphene oxide contribute to improved sensitivity and faster response times in electrochemical sensing.Expand Specific Solutions04 Graphene oxide in strain and pressure sensors

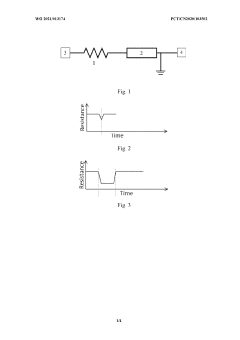

Graphene oxide is incorporated into strain and pressure sensors for wearable applications. These sensors can detect mechanical deformations or applied pressure, making them suitable for monitoring body movements, gestures, or touch interactions. The piezoresistive properties of graphene oxide enable high sensitivity to mechanical stimuli.Expand Specific Solutions05 Integration of graphene oxide sensors in wearable devices

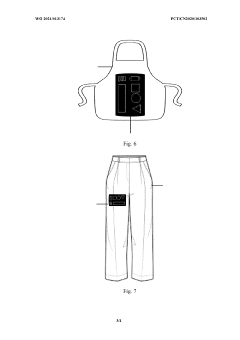

Graphene oxide sensors are integrated into various wearable devices and systems. This integration involves designing appropriate interfaces, power management, and data processing capabilities. The sensors can be incorporated into textiles, patches, or other wearable form factors to enable continuous monitoring of relevant parameters in real-world conditions.Expand Specific Solutions

Key Industry Players

The field of graphene oxide for wearable sensors is in a rapid growth phase, with increasing market size and technological advancements. The global wearable sensors market is expanding, driven by demand for health monitoring and IoT applications. Technologically, graphene oxide sensors are progressing from research to commercialization, with varying levels of maturity across applications. Key players like Indian Institute of Science, Nanjing University of Posts & Telecommunications, and Penn State Research Foundation are advancing fundamental research, while companies such as Nokia Technologies Oy and Flextrapower, Inc. are focusing on practical applications and product development. The involvement of diverse institutions worldwide indicates a competitive and collaborative landscape, with potential for significant breakthroughs in sensor sensitivity, flexibility, and integration.

Flextrapower, Inc.

Dioxide Materials, Inc.

Core GO Sensor Innovations

- A nanocomposite film composed of reduced graphene oxide (RGO) nanosheets and silver nanoparticles in a 2:1 wt/wt ratio is synthesized and fabricated on a flexible Kapton substrate, utilizing a method that includes oxidation, exfoliation, and reduction of graphite oxide, followed by dispersion with silver nanoparticles, to create a piezoresistive temperature sensor with a negative temperature coefficient.

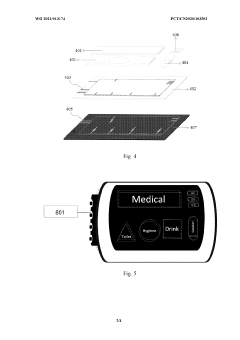

- Development of a truly wearable smart fabric with integrated pressure sensor functionality, addressing the limitations of previous designs in terms of wearability and practical application.

- Integration of graphene-based materials into the fabric structure to leverage graphene's advantageous properties such as flexibility, strength, and high conductivity.

- Design of a pressure sensor that can be seamlessly incorporated into fabric without compromising comfort or flexibility, overcoming the limitations of previous rigid or partially flexible designs.

Biocompatibility and Safety

Biocompatibility and safety are critical considerations in the development and application of graphene oxide (GO) for wearable sensors. As these devices are designed to be in close contact with the human body, ensuring their safety and compatibility with biological systems is paramount.

GO has shown promising results in terms of biocompatibility, with several studies indicating its potential for use in biomedical applications. The material's unique properties, such as its large surface area and excellent electrical conductivity, make it an attractive option for wearable sensor development. However, the biocompatibility of GO can vary depending on factors such as size, shape, surface functionalization, and concentration.

Recent research has focused on optimizing GO's biocompatibility through various surface modifications and functionalization techniques. These approaches aim to reduce potential cytotoxicity and improve the material's interaction with biological systems. For instance, the incorporation of biocompatible polymers or biomolecules onto GO surfaces has been shown to enhance its compatibility with living tissues.

Safety concerns surrounding GO primarily revolve around its potential long-term effects on human health and the environment. While acute toxicity studies have generally shown low toxicity levels, the long-term impact of GO exposure remains an area of ongoing investigation. Researchers are particularly interested in understanding the potential for GO accumulation in organs and tissues, as well as its ability to cross biological barriers.

To address these safety concerns, current trends in GO-based wearable sensors include the development of encapsulation techniques to prevent direct contact between GO and the skin. These methods aim to maintain the sensor's functionality while minimizing potential risks associated with GO exposure. Additionally, researchers are exploring biodegradable forms of GO that can break down safely in the body over time.

Standardization of safety protocols and testing methods for GO-based wearable sensors is another important trend. As the field advances, there is a growing need for consistent and reliable methods to assess the biocompatibility and safety of these devices. This includes the development of in vitro and in vivo models that can accurately predict the behavior of GO in biological systems.

The regulatory landscape surrounding GO-based wearable sensors is also evolving. As these devices move closer to commercial applications, regulatory bodies are working to establish guidelines and standards for their safety assessment. This includes considerations for manufacturing processes, quality control, and post-market surveillance to ensure the ongoing safety of GO-based wearable sensors.

Manufacturing Scalability

The manufacturing scalability of graphene oxide (GO) for wearable sensors is a critical factor in determining the widespread adoption and commercialization of this technology. Current trends indicate significant progress in scaling up GO production, but challenges remain in maintaining consistent quality and properties at larger scales.

One of the primary methods for large-scale GO production is the modified Hummers' method, which has been optimized for industrial-scale synthesis. This process involves the oxidation of graphite using strong oxidizing agents, followed by exfoliation to produce GO sheets. Recent advancements have focused on improving the efficiency and environmental impact of this method, including the use of safer reagents and the development of continuous flow reactors.

Another promising approach for scalable GO production is the electrochemical exfoliation of graphite. This method offers advantages in terms of process control and reduced chemical waste. However, it still faces challenges in terms of energy consumption and electrode degradation when scaled up to industrial levels.

The production of GO films and coatings, essential for many wearable sensor applications, has seen improvements in roll-to-roll manufacturing techniques. These processes allow for the continuous production of large-area GO films with controlled thickness and properties. However, maintaining uniformity and preventing defects over large areas remains a challenge.

Inkjet printing and screen printing of GO-based inks have emerged as scalable methods for producing patterned GO structures on various substrates. These techniques are particularly relevant for wearable sensor fabrication, as they allow for precise deposition of GO on flexible and conformable materials. Advances in ink formulation have improved the printability and stability of GO suspensions, enabling more consistent results in large-scale production.

The integration of GO into textile-based wearable sensors has also seen progress in terms of scalability. Dip-coating and spray-coating methods have been adapted for treating fabrics with GO, allowing for the production of conductive and responsive textiles at larger scales. However, ensuring uniform coverage and durable adhesion of GO to textile fibers remains an area of ongoing research.

As the demand for GO-based wearable sensors grows, there is an increasing focus on developing automated and high-throughput manufacturing processes. This includes the use of robotic systems for sensor assembly and quality control, as well as the implementation of in-line characterization techniques to monitor GO properties during production.

Despite these advancements, several challenges persist in the large-scale manufacturing of GO for wearable sensors. These include the need for better process control to ensure consistent GO quality, the development of more environmentally friendly production methods, and the optimization of integration techniques for different sensor designs and substrates.