Graphene Oxide: A Core Component in Wearables Revolution

Graphene Oxide Wearables: Evolution and Objectives

Graphene oxide has emerged as a revolutionary material in the field of wearable technology, marking a significant milestone in the evolution of smart devices. The journey of graphene oxide in wearables began with its discovery and isolation in the early 2000s, sparking intense research into its unique properties and potential applications.

Initially, the focus was on understanding the fundamental characteristics of graphene oxide, such as its exceptional electrical conductivity, mechanical strength, and flexibility. These properties made it an ideal candidate for integration into wearable devices, promising enhanced performance and functionality.

As research progressed, the development of graphene oxide-based wearables followed a clear trajectory. Early experiments centered on incorporating graphene oxide into existing wearable structures, such as textiles and flexible substrates. This phase was crucial in demonstrating the material's compatibility with wearable form factors and manufacturing processes.

The next stage saw the creation of prototype devices that leveraged graphene oxide's unique properties. Researchers developed sensors capable of detecting various physiological parameters with unprecedented sensitivity and accuracy. These advancements paved the way for more sophisticated health monitoring devices and opened up new possibilities in personalized healthcare.

Concurrently, efforts were made to overcome challenges associated with large-scale production and integration of graphene oxide into wearable devices. Innovations in manufacturing techniques, such as roll-to-roll processing and 3D printing with graphene oxide-infused materials, marked significant progress in this direction.

Recent years have witnessed a shift towards more advanced applications, with graphene oxide being used to create multifunctional wearables. These devices not only monitor health parameters but also offer features like energy harvesting, wireless communication, and even drug delivery capabilities.

Looking ahead, the objectives for graphene oxide in wearables are ambitious and multifaceted. One primary goal is to further enhance the sensitivity and accuracy of sensors, pushing the boundaries of what can be monitored non-invasively through wearable devices. This includes developing sensors capable of detecting molecular-level changes in the body, potentially revolutionizing early disease detection and personalized medicine.

Another key objective is to improve the energy efficiency and power management of wearable devices. Researchers aim to harness graphene oxide's excellent conductivity to create more efficient batteries and supercapacitors, potentially leading to self-powered wearables that can operate indefinitely without external charging.

Durability and biocompatibility remain critical areas of focus. Future research will likely concentrate on developing graphene oxide-based materials that are not only robust enough to withstand daily wear and tear but also safe for long-term contact with the skin.

Market Demand Analysis for Graphene Oxide Wearables

The market demand for graphene oxide in wearable technology is experiencing a significant upward trajectory, driven by the material's exceptional properties and the growing consumer appetite for advanced wearable devices. Graphene oxide's unique combination of flexibility, conductivity, and strength makes it an ideal candidate for next-generation wearables, spanning applications from health monitoring to smart textiles.

In the healthcare sector, the demand for graphene oxide-based wearables is particularly robust. The global market for wearable medical devices is projected to expand rapidly, with graphene oxide playing a crucial role in enhancing the performance of these devices. Its ability to create ultra-thin, highly sensitive sensors is revolutionizing the development of continuous health monitoring systems, including glucose monitors, heart rate sensors, and sweat analyzers.

The fitness and wellness industry is another key driver of market demand for graphene oxide wearables. Consumers are increasingly seeking more accurate and comprehensive data about their physical activities and physiological states. Graphene oxide-enhanced wearables offer improved accuracy in tracking metrics such as heart rate variability, blood oxygen levels, and stress indicators, meeting the growing demand for personalized health insights.

Smart textiles represent a burgeoning market segment where graphene oxide is poised to make significant inroads. The integration of graphene oxide into fabrics enables the creation of clothing that can monitor vital signs, regulate temperature, and even harvest energy from body movements. This aligns with the increasing consumer interest in multifunctional, tech-integrated apparel for both everyday wear and specialized applications like sports and military use.

The industrial and enterprise sectors are also contributing to the market demand for graphene oxide wearables. There is a growing need for advanced personal protective equipment (PPE) and worker safety monitoring systems in industries such as construction, manufacturing, and mining. Graphene oxide's properties allow for the development of lightweight, durable, and sensor-equipped protective gear that can significantly enhance workplace safety and productivity.

Environmental concerns and sustainability trends are further fueling the demand for graphene oxide in wearables. As consumers become more environmentally conscious, there is a preference for materials that offer durability and recyclability. Graphene oxide's potential to create long-lasting, energy-efficient devices aligns with these consumer values, potentially driving market growth in eco-friendly wearable technology.

Despite the promising market outlook, challenges such as production scalability and cost-effectiveness need to be addressed to fully realize the market potential of graphene oxide in wearables. However, ongoing research and development efforts are focused on overcoming these hurdles, indicating a positive trajectory for market growth in the coming years.

Current Challenges in Graphene Oxide Wearable Technology

Despite the promising potential of graphene oxide in wearable technology, several significant challenges currently hinder its widespread adoption and commercialization. One of the primary obstacles is the scalability of production. While laboratory-scale synthesis of high-quality graphene oxide is well-established, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a formidable task.

The stability of graphene oxide in various environmental conditions poses another critical challenge. Wearable devices are exposed to a range of temperatures, humidity levels, and mechanical stresses during everyday use. Ensuring that graphene oxide maintains its exceptional properties under these diverse conditions is crucial for long-term device reliability and performance.

Biocompatibility and toxicity concerns also present significant hurdles. As wearable devices come into direct contact with the skin, ensuring the safety of graphene oxide-based materials is paramount. While initial studies have shown promising results, more comprehensive long-term studies are needed to fully understand and mitigate any potential health risks associated with prolonged exposure to graphene oxide.

Integration of graphene oxide with other materials and components in wearable devices presents technical challenges. Achieving seamless interfaces between graphene oxide and traditional electronic components, while preserving the unique properties of both, requires innovative engineering solutions and advanced manufacturing techniques.

The cost of production remains a significant barrier to widespread adoption. Current methods for producing high-quality graphene oxide are often expensive and energy-intensive, making it challenging to compete with established materials in terms of cost-effectiveness. Developing more economical production methods is essential for the commercial viability of graphene oxide-based wearables.

Standardization and quality control pose additional challenges. The lack of universally accepted standards for graphene oxide production and characterization makes it difficult to ensure consistency across different manufacturers and applications. Establishing robust quality control measures and industry-wide standards is crucial for the reliable performance of graphene oxide-based wearable devices.

Addressing these challenges requires a multidisciplinary approach, combining expertise from materials science, chemistry, electronics, and bioengineering. Collaborative efforts between academia and industry are essential to overcome these hurdles and unlock the full potential of graphene oxide in the wearables revolution.

Existing Graphene Oxide Wearable Solutions

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in electronics and energy storage: Graphene oxide is utilized in electronic devices and energy storage systems due to its unique electrical and thermal properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.

- Functionalization and modification of graphene oxide: Various methods for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. These include chemical treatments, doping, and surface modifications to enhance its performance in different fields.

- Graphene oxide-based composites and materials: The development of graphene oxide-based composites and materials is described, combining graphene oxide with other substances to create novel materials with enhanced properties. These composites find applications in various fields, including aerospace, automotive, and construction.

- Environmental and biomedical applications of graphene oxide: Graphene oxide is explored for its potential in environmental remediation and biomedical applications. Its use in water purification, pollutant removal, drug delivery systems, and biosensors is investigated, leveraging its unique properties for these specialized fields.

02 Applications of graphene oxide in energy storage devices

Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and surface modifications to improve its performance in different fields.Expand Specific Solutions04 Graphene oxide-based composites and nanocomposites

The development of graphene oxide-based composites and nanocomposites is described, combining graphene oxide with other materials to create hybrid structures with enhanced properties. These composites find applications in various fields, including electronics, sensors, and structural materials.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic techniques, microscopy, and other analytical tools to understand the material's composition, morphology, and behavior.Expand Specific Solutions

Key Players in Graphene Oxide Wearable Industry

The graphene oxide market in wearables is experiencing rapid growth, transitioning from early-stage development to commercial applications. The market size is expanding significantly, driven by increasing demand for advanced wearable technologies. Technologically, graphene oxide is progressing towards maturity, with key players like NanoXplore, Inc., BGT Materials Ltd., and Hubei Highland Graphene Technology Co., Ltd. leading innovation. Research institutions such as Qingdao University, Rice University, and Tsinghua University are contributing to fundamental advancements. Major tech companies like IBM and Nokia are exploring graphene oxide applications, indicating its potential for mainstream adoption in wearables. The competitive landscape is diverse, with collaborations between academia and industry accelerating development and commercialization efforts.

NanoXplore, Inc.

BOE Technology Group Co., Ltd.

Core Innovations in Graphene Oxide Wearable Tech

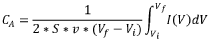

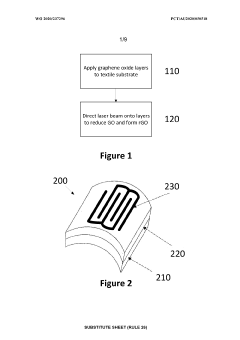

- A method involving the application of graphene oxide layers on a textile substrate followed by laser reduction to form porous layers of reduced graphene oxide (rGO), which are patterned and integrated with electrolytes to create flexible, washable, and stretchable supercapacitors.

- The process of in situ hydrolytic polymerization is used to prepare graphene oxide reinforced heterocyclic polyamide nanocomposites, where graphene oxide is pre-polymerized with polyamide at specific temperatures and then polymerized with heterocyclic compounds, followed by washing and drying to achieve uniform dispersion.

Environmental Impact of Graphene Oxide Wearables

The environmental impact of graphene oxide wearables is a critical consideration as this technology gains prominence in the wearable device market. Graphene oxide, while offering remarkable properties for wearable applications, presents both potential benefits and challenges from an environmental perspective.

One of the primary environmental advantages of graphene oxide in wearables is its potential to reduce electronic waste. The durability and longevity of graphene oxide-based components could significantly extend the lifespan of wearable devices, thereby decreasing the frequency of device replacement and disposal. This reduction in e-waste could have a positive impact on landfill usage and resource conservation.

However, the production of graphene oxide raises environmental concerns. The synthesis process often involves the use of harsh chemicals and energy-intensive procedures. These manufacturing methods can lead to the generation of hazardous waste and contribute to greenhouse gas emissions. As the demand for graphene oxide wearables increases, it becomes crucial to develop and implement more sustainable production techniques.

The biodegradability of graphene oxide in wearables is another area of environmental consideration. While some studies suggest that graphene oxide can degrade under certain environmental conditions, the long-term fate of these materials in ecosystems remains uncertain. There is a need for comprehensive research to understand the potential accumulation of graphene oxide in the environment and its effects on various organisms.

Water pollution is a potential risk associated with graphene oxide wearables. The nanoscale particles could potentially leach from devices during use or disposal, entering water systems. The impact of these nanoparticles on aquatic ecosystems and human health through water consumption is an area that requires thorough investigation and monitoring.

On the positive side, the energy efficiency of graphene oxide-based wearables could contribute to reduced power consumption. This efficiency could lead to smaller batteries and less frequent charging, potentially decreasing the overall energy demand and associated carbon footprint of wearable technology.

The recyclability of graphene oxide wearables is an important factor in their environmental impact. While the material itself may be recyclable, the integration of graphene oxide with other components in wearable devices could complicate the recycling process. Developing effective recycling methods for these complex devices will be crucial for minimizing their environmental footprint.

As the wearables industry continues to evolve, it is essential to prioritize eco-friendly design principles in the development of graphene oxide-based devices. This includes considering the entire lifecycle of the product, from raw material extraction to end-of-life disposal or recycling. Implementing circular economy principles could significantly mitigate the environmental impact of these innovative wearables.

Scalability Challenges in Graphene Oxide Production

The scalability of graphene oxide (GO) production presents a significant challenge in the widespread adoption of this material for wearable technology applications. As the demand for GO in wearable devices continues to grow, manufacturers face several hurdles in scaling up production to meet market needs.

One of the primary obstacles is the current reliance on batch processing methods, which limit production capacity and efficiency. These methods, while suitable for laboratory-scale synthesis, struggle to maintain consistent quality and yield when scaled to industrial levels. The transition from small-scale to large-scale production often results in variations in GO sheet size, thickness, and oxidation degree, which can significantly impact the material's performance in wearable applications.

Another critical challenge lies in the sourcing and processing of high-quality graphite precursors. The quality and consistency of the starting material directly influence the properties of the resulting GO. As production scales up, ensuring a steady supply of suitable graphite becomes increasingly difficult and costly. Moreover, the purification processes required to remove impurities from large quantities of graphite can be time-consuming and resource-intensive.

The oxidation process itself poses scalability issues. Traditional methods like the Hummers method involve the use of strong oxidizing agents and acids, which can be hazardous when handled in large quantities. Scaling up these processes requires significant investments in safety measures and specialized equipment, adding to the overall production costs. Additionally, the exfoliation and separation of GO sheets from the oxidized graphite often rely on sonication or centrifugation techniques, which are challenging to scale efficiently.

Water consumption and waste management also become more pronounced concerns as production scales up. The synthesis and purification of GO typically require large volumes of water, and the resulting acidic waste needs proper treatment before disposal. Developing more environmentally friendly and resource-efficient production methods is crucial for sustainable large-scale manufacturing.

Lastly, the drying and storage of GO present scalability challenges. GO is typically produced in aqueous dispersions, and the drying process can lead to aggregation and restacking of GO sheets, potentially altering their properties. Developing scalable drying techniques that preserve the material's unique characteristics is essential for maintaining product quality in large-scale production.

Addressing these scalability challenges is crucial for the widespread integration of GO in wearable technologies. Innovations in continuous flow production methods, greener synthesis approaches, and advanced purification techniques are actively being researched to overcome these hurdles and pave the way for industrial-scale GO production.