How to Harness Graphene Oxide for Anti-Bacterial Coating Solutions?

Graphene Oxide Antibacterial Coatings: Background and Objectives

Graphene oxide (GO) has emerged as a promising material in the field of antibacterial coatings, attracting significant attention from researchers and industry professionals alike. This revolutionary nanomaterial, derived from graphene, possesses unique properties that make it particularly suitable for developing advanced antibacterial solutions. The journey of graphene oxide in this domain began with the discovery of graphene in 2004, which opened up new possibilities in materials science and nanotechnology.

The evolution of graphene oxide as an antibacterial agent has been driven by the growing need for more effective and sustainable antimicrobial solutions. Traditional antibiotics and chemical-based antibacterial coatings have faced challenges such as bacterial resistance and environmental concerns. In this context, graphene oxide presents a novel approach to combating bacterial growth and contamination.

The primary objective of harnessing graphene oxide for antibacterial coating solutions is to develop highly effective, durable, and environmentally friendly coatings that can be applied across various sectors. These sectors include healthcare, food packaging, water treatment, and consumer goods. The goal is to create coatings that not only inhibit bacterial growth but also overcome the limitations of existing antibacterial technologies.

One of the key technological trends in this field is the development of composite materials that incorporate graphene oxide. By combining GO with other materials such as polymers, metals, or ceramics, researchers aim to enhance the overall performance and applicability of antibacterial coatings. This trend is driven by the synergistic effects observed when graphene oxide is integrated with complementary materials.

Another significant trend is the exploration of different mechanisms through which graphene oxide exerts its antibacterial effects. Initial studies focused on the physical interactions between GO and bacterial cells, but recent research has expanded to investigate chemical and electrochemical mechanisms as well. Understanding these mechanisms is crucial for optimizing the antibacterial properties of GO-based coatings.

The development of scalable and cost-effective production methods for graphene oxide is also a critical aspect of the technological landscape. As research progresses, there is a growing emphasis on developing environmentally friendly and economically viable processes for large-scale GO production, which is essential for the widespread adoption of GO-based antibacterial coatings.

In conclusion, the background and objectives of harnessing graphene oxide for antibacterial coating solutions reflect a dynamic and rapidly evolving field. The intersection of nanotechnology, materials science, and microbiology in this domain promises to yield innovative solutions to pressing challenges in public health and hygiene. As research continues to advance, the potential applications and impact of graphene oxide-based antibacterial coatings are expected to expand significantly, paving the way for a new generation of antimicrobial technologies.

Market Analysis for Antibacterial Coating Solutions

The global market for antibacterial coating solutions has been experiencing significant growth, driven by increasing awareness of hygiene and the need for infection control across various industries. The market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to be in the high single digits over the next five years.

Healthcare and medical devices remain the largest application segments for antibacterial coatings, accounting for a substantial portion of the market share. The ongoing COVID-19 pandemic has further accelerated demand in these sectors, as hospitals and healthcare facilities seek to enhance their infection prevention measures. Additionally, the food and beverage industry has emerged as a rapidly growing segment, driven by stringent food safety regulations and consumer preferences for hygienic packaging.

Geographically, North America and Europe currently dominate the antibacterial coating solutions market, owing to advanced healthcare infrastructure and stringent regulatory standards. However, the Asia-Pacific region is expected to witness the fastest growth, fueled by rapid industrialization, increasing healthcare expenditure, and growing awareness of hygiene in countries like China and India.

The market is characterized by intense competition among key players, with a mix of established multinational corporations and innovative start-ups. Major companies are investing heavily in research and development to introduce novel antibacterial coating technologies, with a focus on improving efficacy, durability, and environmental sustainability.

Graphene oxide-based antibacterial coatings represent a promising segment within the broader market. The unique properties of graphene oxide, including its high surface area, excellent mechanical strength, and inherent antibacterial activity, make it an attractive material for developing advanced coating solutions. The potential applications of graphene oxide coatings span across multiple industries, including healthcare, consumer electronics, textiles, and water treatment.

Despite the promising outlook, challenges remain in the widespread adoption of graphene oxide-based antibacterial coatings. These include high production costs, scalability issues, and the need for further research to fully understand the long-term environmental and health impacts of graphene-based materials. Overcoming these hurdles will be crucial for realizing the full market potential of graphene oxide in antibacterial coating applications.

As the demand for more effective and sustainable antibacterial solutions continues to grow, the market for graphene oxide-based coatings is poised for significant expansion. Success in this segment will likely depend on continued technological advancements, cost reduction strategies, and the ability to meet evolving regulatory requirements across different industries and regions.

Current Challenges in Graphene Oxide-Based Antibacterial Coatings

Despite the promising potential of graphene oxide (GO) in antibacterial coatings, several significant challenges hinder its widespread adoption and practical application. One of the primary obstacles is the difficulty in achieving uniform dispersion of GO in coating matrices. The tendency of GO sheets to aggregate due to strong van der Waals interactions compromises the overall antibacterial efficacy and mechanical properties of the coating.

Another critical challenge lies in maintaining the long-term stability of GO-based coatings. Exposure to environmental factors such as UV radiation, moisture, and temperature fluctuations can lead to degradation of the GO structure, potentially reducing its antibacterial performance over time. This instability raises concerns about the durability and reliability of GO-based coatings in real-world applications.

The controlled release of antibacterial agents from GO-based coatings presents another hurdle. While the high surface area of GO allows for efficient loading of antibacterial compounds, achieving a sustained and controlled release profile remains challenging. Rapid initial release followed by a sharp decline in antibacterial activity is a common issue that needs to be addressed for prolonged protection.

Biocompatibility and potential toxicity of GO-based coatings are also areas of concern, particularly in medical and food-related applications. While GO exhibits antibacterial properties, its potential cytotoxicity to human cells and long-term effects on the environment require thorough investigation and mitigation strategies.

The scalability of GO production and coating processes poses a significant challenge for industrial-scale applications. Current methods for synthesizing high-quality GO are often time-consuming and costly, limiting its commercial viability. Additionally, developing efficient and cost-effective techniques for large-scale coating application and integration with existing manufacturing processes remains a hurdle.

Ensuring consistent antibacterial performance across different bacterial strains, including antibiotic-resistant bacteria, is another challenge. The mechanism of GO's antibacterial action is not fully understood, and its effectiveness may vary depending on the type of bacteria and environmental conditions.

Regulatory compliance and standardization of GO-based antibacterial coatings present additional challenges. The lack of established guidelines and testing protocols specific to GO-based materials hinders their approval and adoption in various industries, particularly in highly regulated sectors such as healthcare and food packaging.

Addressing these challenges requires interdisciplinary research efforts, combining expertise from materials science, microbiology, and engineering. Innovative approaches to GO functionalization, novel coating formulations, and advanced characterization techniques are needed to overcome these obstacles and fully harness the potential of GO for antibacterial coating solutions.

Existing Graphene Oxide-Based Antibacterial Coating Technologies

01 Graphene oxide-based antibacterial composites

Graphene oxide can be combined with other materials to create antibacterial composites. These composites enhance the antibacterial properties of graphene oxide and can be used in various applications such as water treatment, medical devices, and packaging materials.- Graphene oxide-based antibacterial composites: Graphene oxide can be combined with other materials to create antibacterial composites. These composites enhance the antibacterial properties of graphene oxide and can be used in various applications such as water treatment, medical devices, and packaging materials. The synergistic effect of graphene oxide and other components results in improved antibacterial efficacy.

- Graphene oxide modification for enhanced antibacterial activity: Various methods can be employed to modify graphene oxide to enhance its antibacterial properties. These modifications may include functionalization with specific chemical groups, doping with metal ions, or creating hybrid structures. Modified graphene oxide exhibits improved antibacterial performance compared to unmodified graphene oxide.

- Graphene oxide-based antibacterial coatings and films: Graphene oxide can be incorporated into coatings and films to impart antibacterial properties to surfaces. These coatings and films can be applied to various substrates, including textiles, plastics, and metals, to create antibacterial surfaces for use in healthcare, food packaging, and other industries where bacterial contamination is a concern.

- Mechanisms of graphene oxide's antibacterial action: Research has been conducted to understand the mechanisms by which graphene oxide exhibits antibacterial properties. These mechanisms may include physical damage to bacterial cell membranes, oxidative stress induction, and disruption of bacterial metabolic processes. Understanding these mechanisms helps in optimizing the antibacterial performance of graphene oxide-based materials.

- Graphene oxide in water treatment and purification: Graphene oxide has shown promise in water treatment and purification applications due to its antibacterial properties. It can be used in filtration systems, membranes, and other water treatment technologies to remove bacteria and other contaminants from water. The high surface area and unique properties of graphene oxide make it an effective material for water purification.

02 Mechanism of graphene oxide's antibacterial action

The antibacterial properties of graphene oxide are attributed to its ability to physically damage bacterial cell membranes, generate reactive oxygen species, and interfere with bacterial metabolic processes. Understanding these mechanisms helps in optimizing graphene oxide-based antibacterial solutions.Expand Specific Solutions03 Functionalization of graphene oxide for enhanced antibacterial activity

Graphene oxide can be functionalized with various chemical groups or nanoparticles to improve its antibacterial properties. This modification can increase the efficacy against a broader spectrum of bacteria and potentially reduce the risk of bacterial resistance.Expand Specific Solutions04 Graphene oxide in antibacterial coatings and films

Graphene oxide can be incorporated into coatings and films to impart antibacterial properties to surfaces. These coatings can be applied to medical devices, textiles, and other materials to prevent bacterial growth and reduce the risk of infections.Expand Specific Solutions05 Environmental and biocompatibility considerations

While graphene oxide exhibits potent antibacterial properties, its environmental impact and biocompatibility must be carefully evaluated. Research focuses on developing eco-friendly production methods and assessing the long-term effects of graphene oxide-based antibacterial materials on human health and the environment.Expand Specific Solutions

Key Players in Graphene Oxide and Antibacterial Coating Industry

The development of graphene oxide for anti-bacterial coating solutions is in its early stages, with significant research activity but limited commercial applications. The market size is growing, driven by increasing demand for advanced antimicrobial materials in healthcare, food packaging, and consumer goods. Technologically, the field is rapidly evolving, with universities like Northwestern University, Hanyang University, and University of California leading academic research. Companies such as Nitto Denko Corp., LG Electronics, and Eni SpA are actively developing commercial applications. The technology's maturity varies, with some basic coatings available but more advanced solutions still in development. Collaboration between academia and industry is crucial for advancing this technology towards widespread adoption and commercialization.

Northwestern University

Nitto Denko Corp.

Innovative Approaches in Graphene Oxide Antibacterial Mechanisms

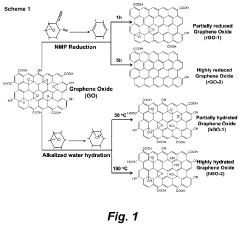

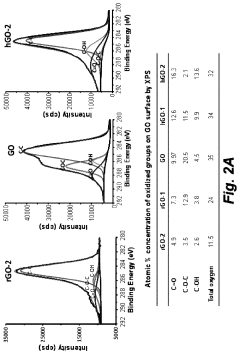

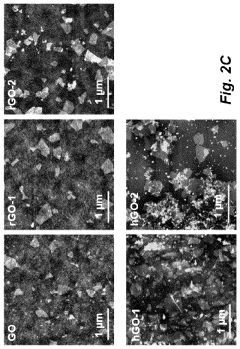

- A library of graphene oxide samples with varying oxidation states and carbon radical densities is created through reduction and hydration methods, allowing for a quantitative assessment of hydroxyl, carboxyl, epoxy, and carbon radical contents, which are then tested for their impact on epithelial cells and macrophages, revealing that hydrated GO with high carbon radical density induces cell death through lipid peroxidation.

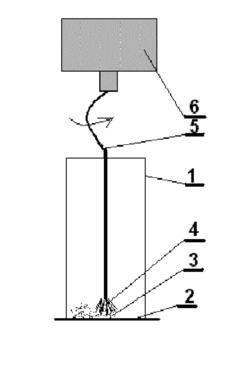

- A method involving the mechanical distribution and rubbing of graphite powder onto a polypropylene film, followed by oxidation to form a graphene oxide layer, using a simple device with a rotating brush and a solution of NaNO3, KMnO4, and H2SO4, which simplifies the process and eliminates the need for specialized equipment or materials.

Environmental Impact and Safety Considerations

The environmental impact and safety considerations of harnessing graphene oxide for anti-bacterial coating solutions are crucial aspects that require thorough examination. Graphene oxide, while promising in its antibacterial properties, presents potential risks to both human health and the environment throughout its lifecycle.

In terms of environmental impact, the production of graphene oxide involves chemical processes that may generate hazardous waste. The use of strong oxidizing agents and acids in the synthesis process can lead to the release of toxic byproducts if not properly managed. Additionally, the disposal of graphene oxide-coated products at the end of their life cycle raises concerns about potential contamination of soil and water systems.

The nanoscale nature of graphene oxide particles poses unique environmental challenges. These particles can potentially accumulate in ecosystems, with unknown long-term effects on flora and fauna. Studies have shown that graphene oxide can interact with aquatic organisms, potentially disrupting their biological functions. The persistence of these nanoparticles in the environment is another area of concern, as their degradation pathways are not yet fully understood.

From a safety perspective, the handling and application of graphene oxide in coating solutions require stringent precautions. Inhalation of graphene oxide particles during manufacturing or application processes can pose respiratory risks to workers. The potential for skin irritation or sensitization upon direct contact necessitates appropriate personal protective equipment and handling protocols.

The long-term effects of exposure to graphene oxide-based coatings on human health are still under investigation. While the antibacterial properties are beneficial, there are concerns about the potential for these nanoparticles to penetrate cellular membranes and accumulate in organs. Rigorous toxicological studies are essential to establish safe exposure limits and understand any potential chronic health effects.

Regulatory frameworks for nanomaterials, including graphene oxide, are still evolving. Compliance with existing regulations and proactive engagement with regulatory bodies are crucial for the responsible development and application of graphene oxide-based antibacterial coatings. This includes adhering to guidelines for nanomaterial handling, disposal, and product labeling.

To address these environmental and safety concerns, ongoing research is focused on developing more sustainable production methods for graphene oxide and exploring its biodegradability. Efforts are also being made to optimize coating formulations to minimize the release of nanoparticles into the environment while maintaining antibacterial efficacy. The development of standardized testing protocols for assessing the environmental fate and toxicity of graphene oxide-based coatings is crucial for informed decision-making and risk management.

Scalability and Cost-Effectiveness Analysis

The scalability and cost-effectiveness of graphene oxide (GO) for anti-bacterial coating solutions are critical factors in determining its commercial viability and widespread adoption. Current production methods for GO, such as the modified Hummers method, can be scaled up to industrial levels, but challenges remain in maintaining consistent quality and properties across large batches. The oxidation process, which is key to GO's anti-bacterial properties, requires careful control and optimization to ensure uniformity in the final product.

Large-scale production of GO has seen significant improvements in recent years, with some manufacturers capable of producing tons of GO annually. However, the cost of production remains a concern. The raw material, graphite, is relatively inexpensive, but the chemical processes involved in oxidation and exfoliation can be costly. Additionally, the purification steps required to remove impurities and achieve the desired GO quality add to the overall production expenses.

The application of GO as an anti-bacterial coating presents its own set of scalability challenges. Developing efficient and uniform coating techniques that can be applied to various substrates and geometries is crucial for widespread implementation. Spray coating and dip coating have shown promise for large-scale applications, but further optimization is needed to ensure consistent coverage and adhesion across different materials and surface types.

Cost-effectiveness analysis reveals that while GO production costs have decreased over time, they are still higher than many traditional anti-bacterial materials. However, the superior performance and multifunctional properties of GO coatings may justify the higher initial costs in certain high-value applications, such as medical devices or food packaging. The long-term durability and effectiveness of GO coatings could potentially offset the initial investment by reducing the frequency of reapplication or replacement.

Environmental considerations also play a role in the scalability and cost-effectiveness of GO anti-bacterial coatings. The production process of GO can generate hazardous waste, which requires proper treatment and disposal. Developing more environmentally friendly synthesis methods and exploring recycling options for GO materials could improve both the sustainability and cost-effectiveness of these solutions in the long term.

To enhance scalability and reduce costs, research efforts are focusing on optimizing GO production processes, exploring alternative oxidation methods, and developing more efficient coating techniques. Collaborative efforts between academia and industry are crucial in bridging the gap between laboratory-scale discoveries and industrial-scale applications. As production volumes increase and technologies mature, economies of scale are expected to drive down costs, potentially making GO anti-bacterial coatings more competitive in the global market.