How to Use Graphene Oxide for Weight Reduction in Vehicles?

Graphene Oxide in Automotive Lightweighting

Graphene oxide has emerged as a promising material for weight reduction in vehicles due to its exceptional mechanical, thermal, and electrical properties. The automotive industry has been exploring its potential to address the growing demand for lightweight vehicles that offer improved fuel efficiency and reduced emissions. The journey of graphene oxide in automotive lightweighting began with its discovery and isolation, followed by extensive research into its unique characteristics and potential applications.

The evolution of graphene oxide technology in the automotive sector has been marked by several key milestones. Initially, researchers focused on understanding the material's structure and properties, which led to the development of various synthesis methods and functionalization techniques. As the understanding of graphene oxide deepened, efforts shifted towards its integration into composite materials, particularly for structural components in vehicles.

One significant breakthrough came with the successful incorporation of graphene oxide into polymer matrices, resulting in lightweight composites with enhanced mechanical strength and thermal stability. This development opened up new possibilities for replacing traditional metal components with graphene oxide-reinforced materials in various parts of vehicles, from body panels to interior components.

Another important milestone was the advancement in large-scale production techniques for graphene oxide, which made it more feasible for industrial applications. This progress addressed one of the major challenges in adopting graphene oxide for automotive lightweighting – the ability to produce high-quality material in sufficient quantities to meet industry demands.

The automotive industry has also witnessed the development of novel coating technologies utilizing graphene oxide. These coatings not only contribute to weight reduction but also provide additional benefits such as improved corrosion resistance and enhanced thermal management, further expanding the material's potential in vehicle manufacturing.

Recent years have seen an increased focus on the environmental aspects of graphene oxide production and application. Researchers have been working on developing more sustainable synthesis methods and exploring the recyclability of graphene oxide-based composites, aligning with the automotive industry's push towards more environmentally friendly practices.

As the technology continues to mature, the automotive sector is exploring more advanced applications of graphene oxide. This includes its potential use in energy storage systems for electric vehicles, where its high surface area and excellent electrical conductivity could lead to significant improvements in battery performance and weight reduction.

Market Demand for Lightweight Vehicles

The automotive industry is experiencing a significant shift towards lightweight vehicles, driven by stringent fuel efficiency regulations and growing environmental concerns. This market demand for weight reduction in vehicles has created a fertile ground for innovative materials like graphene oxide. The global lightweight materials market in automotive applications is projected to reach $110 billion by 2025, with a compound annual growth rate of 7.2% from 2020 to 2025.

Consumers are increasingly prioritizing fuel efficiency and environmental sustainability in their vehicle purchasing decisions. A survey conducted by J.D. Power revealed that 70% of consumers consider fuel economy as a crucial factor when buying a new car. This consumer preference aligns with government regulations aimed at reducing carbon emissions, such as the Corporate Average Fuel Economy (CAFE) standards in the United States and similar policies in Europe and Asia.

Lightweight vehicles offer numerous benefits that cater to market demands. They provide improved fuel efficiency, with studies showing that a 10% reduction in vehicle weight can lead to a 6-8% increase in fuel economy. This translates to significant cost savings for consumers over the lifetime of the vehicle. Additionally, lightweight vehicles exhibit enhanced performance characteristics, including better acceleration, handling, and braking, which appeal to performance-oriented consumers.

The electric vehicle (EV) market is a key driver for lightweight materials adoption. As battery technology continues to evolve, reducing vehicle weight becomes crucial for extending driving range and improving overall efficiency. The global EV market is expected to grow at a CAFE of 29% from 2021 to 2026, further intensifying the demand for lightweight solutions.

Commercial vehicle manufacturers are also recognizing the benefits of weight reduction. In the logistics and transportation sector, lighter vehicles can increase payload capacity, leading to improved operational efficiency and reduced costs. This has sparked interest in lightweight materials across various vehicle segments, from passenger cars to heavy-duty trucks.

The aerospace industry's successful implementation of lightweight materials has set a precedent for the automotive sector. As manufacturing processes improve and costs decrease, technologies like graphene oxide are becoming increasingly viable for mass-market vehicle production. This cross-industry influence is accelerating the adoption of advanced lightweight materials in automotive applications.

However, challenges remain in meeting market demands for lightweight vehicles. Balancing cost-effectiveness with performance and safety requirements is crucial. Manufacturers must also address concerns related to recyclability and end-of-life disposal of advanced materials. As the industry continues to innovate, collaborations between material scientists, automotive engineers, and environmental experts will be essential in developing sustainable lightweight solutions that meet evolving market demands.

Current State of Graphene Oxide in Vehicle Manufacturing

Graphene oxide has emerged as a promising material in vehicle manufacturing, particularly for weight reduction purposes. The current state of graphene oxide in this industry is characterized by ongoing research and development, with several automotive companies and research institutions exploring its potential applications.

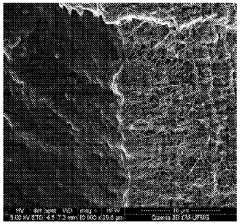

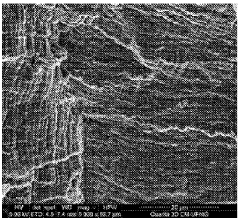

In recent years, there has been a significant increase in the use of graphene oxide in composite materials for vehicle components. These composites typically combine graphene oxide with polymers or metals to create lightweight yet strong materials. The automotive industry has shown particular interest in using graphene oxide-enhanced composites for body panels, interior components, and structural elements.

One of the primary advantages of graphene oxide in vehicle manufacturing is its ability to significantly reduce weight while maintaining or even improving strength and durability. This is crucial for automakers striving to meet increasingly stringent fuel efficiency and emissions standards. Some studies have shown that incorporating small amounts of graphene oxide into composite materials can lead to weight reductions of up to 20% compared to traditional materials.

Several major automotive manufacturers have initiated research programs and partnerships to explore the integration of graphene oxide into their production processes. For instance, Ford Motor Company has been collaborating with universities and research institutions to develop graphene-enhanced foam and plastic components. These components have shown potential for use in various applications, including engine covers, pump housings, and other under-hood parts.

Despite the promising developments, the widespread adoption of graphene oxide in vehicle manufacturing faces several challenges. One of the main obstacles is the high production cost of graphene oxide, which currently limits its use to high-end or specialized vehicles. Researchers and manufacturers are actively working on developing more cost-effective production methods to make graphene oxide more economically viable for mass-market vehicles.

Another challenge is the scalability of production processes. While laboratory-scale experiments have shown promising results, translating these into large-scale manufacturing processes remains a significant hurdle. Ensuring consistent quality and properties of graphene oxide-enhanced materials across large production volumes is crucial for its successful implementation in the automotive industry.

In terms of specific applications, graphene oxide is being explored for use in lightweight body panels, reinforced plastics for interior components, and even in battery technologies for electric vehicles. Some companies are also investigating its potential in coatings and paints to improve corrosion resistance and reduce overall vehicle weight.

Existing Graphene Oxide Integration Methods

01 Graphene oxide weight reduction methods

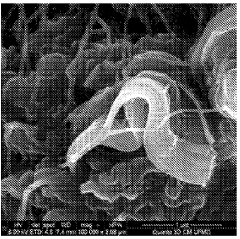

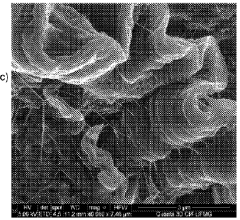

Various techniques are employed to reduce the weight of graphene oxide, including thermal reduction, chemical reduction, and electrochemical reduction. These methods aim to remove oxygen-containing functional groups from graphene oxide, resulting in a lighter and more conductive material.- Graphene oxide weight reduction methods: Various techniques are employed to reduce the weight of graphene oxide, including thermal, chemical, and electrochemical reduction processes. These methods aim to remove oxygen-containing functional groups from graphene oxide, resulting in a lighter and more conductive material with properties closer to pristine graphene.

- Graphene oxide weight control in composite materials: The weight percentage of graphene oxide in composite materials is carefully controlled to optimize mechanical, electrical, and thermal properties. Researchers investigate the effects of different graphene oxide loadings on the overall performance of composites, aiming to achieve desired characteristics while minimizing weight.

- Graphene oxide weight measurement techniques: Accurate measurement of graphene oxide weight is crucial for quality control and research purposes. Various analytical techniques are employed, including thermogravimetric analysis, X-ray photoelectron spectroscopy, and atomic force microscopy, to determine the weight and thickness of graphene oxide sheets and flakes.

- Lightweight graphene oxide-based energy storage devices: Researchers develop lightweight energy storage devices, such as supercapacitors and batteries, using graphene oxide as a key component. The low weight of graphene oxide, combined with its high surface area and conductivity, enables the creation of high-performance, portable energy storage solutions.

- Graphene oxide weight optimization for water treatment: The weight of graphene oxide is optimized for water treatment applications, such as desalination and pollutant removal. Researchers investigate the relationship between graphene oxide weight and its adsorption capacity, aiming to develop efficient and cost-effective water purification systems.

02 Graphene oxide weight measurement techniques

Accurate measurement of graphene oxide weight is crucial for quality control and research purposes. Techniques such as thermogravimetric analysis, atomic force microscopy, and X-ray photoelectron spectroscopy are used to determine the weight and composition of graphene oxide samples.Expand Specific Solutions03 Graphene oxide weight optimization for energy storage applications

The weight of graphene oxide plays a significant role in energy storage applications such as batteries and supercapacitors. Optimizing the weight of graphene oxide in these devices can lead to improved energy density, power density, and overall performance.Expand Specific Solutions04 Lightweight graphene oxide composites

Incorporating graphene oxide into composite materials can result in lightweight yet strong structures. These composites find applications in aerospace, automotive, and construction industries, where weight reduction is crucial for improved efficiency and performance.Expand Specific Solutions05 Graphene oxide weight control for electronic applications

Controlling the weight of graphene oxide is essential for electronic applications such as flexible displays, sensors, and transparent conductive films. The weight of graphene oxide affects its electrical and optical properties, which are crucial for these applications.Expand Specific Solutions

Key Players in Graphene Oxide and Automotive Sectors

The use of graphene oxide for weight reduction in vehicles is an emerging technology in the automotive industry, currently in its early development stage. The market for this application is growing, driven by increasing demand for fuel-efficient and environmentally friendly vehicles. The technology's maturity is still evolving, with various companies and research institutions at different stages of development. Key players like Tata Steel Ltd., TEIJIN AUTOMOTIVE TECHNOLOGIES, and Aisin Technical Center of America are actively researching and developing graphene oxide-based solutions for vehicle weight reduction. Academic institutions such as Northwestern University and the University of Porto are contributing to fundamental research, while companies like LG Electronics and Samsung Electronics are exploring potential applications in their automotive components. The collaboration between industry and academia is accelerating the technology's advancement, with promising results in enhancing material properties and reducing vehicle weight.

Tata Steel Ltd.

PetroChina Co., Ltd.

Core Innovations in Graphene Oxide Composites

- A process involving thermal reduction of graphene oxide via microwave irradiation to produce exfoliated graphene nanoplatelets, combined with solid/solid mixing and controlled heating/cooling rates, to achieve high dispersion and crystallinity in the polymeric matrix, resulting in nanostructured composites with enhanced properties.

- Incorporating reduced-oxygen graphene oxide (r-GO) into foamed asphalt, where r-GO is functionalized to react with calcium and silicon components, enhancing the strength of the final product by catalyzing C-S-H crystal formation, and using a mechanochemical process to produce edge-oxidized graphene/graphite oxide flakes for improved dispersion and chemical reactivity.

Environmental Impact of Graphene Oxide Use

The use of graphene oxide for weight reduction in vehicles presents both potential benefits and environmental concerns. As a lightweight and strong material, graphene oxide can significantly reduce vehicle weight, leading to improved fuel efficiency and reduced emissions during the use phase. However, the environmental impact of its production and end-of-life disposal must be carefully considered.

The production of graphene oxide involves chemical processes that may generate hazardous waste and consume significant energy. The use of strong oxidizing agents and acids in the synthesis process can lead to the release of harmful byproducts if not properly managed. Additionally, the energy-intensive nature of graphene oxide production may result in increased greenhouse gas emissions, potentially offsetting some of the environmental benefits gained during vehicle use.

Water consumption and contamination are also important factors to consider. The production and purification of graphene oxide often require large volumes of water, which can strain local water resources. Proper treatment and disposal of wastewater from these processes are crucial to prevent the release of toxic substances into the environment.

The long-term environmental effects of graphene oxide nanoparticles in the ecosystem are not yet fully understood. There are concerns about their potential accumulation in soil and water systems, as well as their impact on aquatic and terrestrial organisms. Further research is needed to assess the bioaccumulation and toxicity of graphene oxide in various environmental compartments.

End-of-life management of vehicles containing graphene oxide components presents another environmental challenge. The recyclability and biodegradability of graphene oxide-enhanced materials need to be thoroughly evaluated to ensure that they do not contribute to increased waste or environmental pollution when vehicles are decommissioned.

On the positive side, the use of graphene oxide in vehicles can contribute to overall environmental sustainability through improved fuel efficiency and reduced emissions during the vehicle's operational life. The lightweight nature of graphene oxide-enhanced components can lead to significant reductions in fuel consumption, particularly in long-distance transportation and freight vehicles.

To maximize the environmental benefits of graphene oxide use in vehicles, a comprehensive life cycle assessment approach is essential. This should include evaluating the environmental impacts from raw material extraction, production processes, vehicle use, and end-of-life disposal. Developing cleaner production methods, improving recycling technologies, and establishing proper disposal protocols for graphene oxide-containing materials are crucial steps in mitigating potential negative environmental impacts.

Cost-Benefit Analysis of Graphene Oxide Implementation

The implementation of graphene oxide for weight reduction in vehicles presents a complex cost-benefit scenario that requires careful analysis. Initial costs associated with graphene oxide integration are substantial, primarily due to the high production expenses and the need for specialized manufacturing processes. These upfront investments include retooling production lines, training personnel, and potentially redesigning vehicle components to optimize graphene oxide usage.

However, the long-term benefits of graphene oxide implementation could potentially outweigh these initial costs. The significant weight reduction achieved through graphene oxide incorporation leads to improved fuel efficiency, which translates to lower operational costs over the vehicle's lifetime. This fuel savings can be substantial, especially for commercial fleets or high-mileage vehicles, potentially offsetting the initial investment within a few years of operation.

Furthermore, the enhanced strength-to-weight ratio of graphene oxide-reinforced materials may lead to extended vehicle lifespans and reduced maintenance costs. The improved durability could result in fewer replacements of structural components, thereby decreasing long-term expenses for both manufacturers and consumers.

Environmental benefits also factor into the cost-benefit analysis. Reduced vehicle weight contributes to lower emissions, aligning with increasingly stringent environmental regulations. This compliance could help manufacturers avoid potential fines and capitalize on government incentives for eco-friendly technologies, further improving the economic viability of graphene oxide implementation.

Market positioning is another crucial consideration. Vehicles featuring graphene oxide technology may command premium prices, appealing to environmentally conscious consumers and early adopters of advanced materials. This price premium could help offset the higher production costs and potentially increase profit margins.

However, challenges remain in scaling up graphene oxide production to meet automotive industry demands. Current production methods are energy-intensive and costly, which could limit widespread adoption. Investments in research and development to improve production efficiency are necessary to make graphene oxide more economically viable for mass-market vehicles.

In conclusion, while the initial costs of implementing graphene oxide for weight reduction in vehicles are significant, the potential long-term benefits in fuel efficiency, durability, and environmental compliance present a compelling case for its adoption. The ultimate cost-effectiveness will depend on technological advancements in production methods, market acceptance, and regulatory landscapes.