Graphene Oxide: New Frontiers in Point-of-Use Sensing

Graphene Oxide Sensing Evolution and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of sensing technologies, particularly in point-of-use applications. The evolution of GO-based sensing can be traced back to the early 2000s when graphene was first isolated. Since then, researchers have been exploring the unique properties of GO that make it an ideal candidate for sensing applications.

The journey of GO in sensing began with its exceptional electronic properties, high surface area, and ease of functionalization. Early studies focused on utilizing GO's electrical conductivity changes in the presence of various analytes. As research progressed, scientists discovered that GO's optical properties could also be leveraged for sensing applications, leading to the development of fluorescence-based and colorimetric sensors.

A significant milestone in GO sensing was the realization of its potential in electrochemical sensing. The large surface area and abundant functional groups of GO allowed for enhanced electron transfer and improved sensitivity in electrochemical detection methods. This breakthrough opened up new avenues for detecting a wide range of analytes, from heavy metals to biomolecules.

The evolution of GO sensing has been driven by the need for rapid, sensitive, and portable detection methods. As point-of-use applications gained importance in fields such as healthcare, environmental monitoring, and food safety, GO-based sensors emerged as promising candidates due to their versatility and adaptability.

Recent years have witnessed a surge in research focused on developing multifunctional GO-based sensors. These advanced sensors combine multiple detection mechanisms or target multiple analytes simultaneously, addressing the growing demand for comprehensive and efficient sensing solutions.

The objectives of current and future GO sensing research are multifaceted. One primary goal is to enhance the sensitivity and selectivity of GO-based sensors, pushing the limits of detection to unprecedented levels. This involves optimizing GO synthesis methods, exploring novel functionalization strategies, and developing innovative sensing architectures.

Another crucial objective is to improve the stability and reproducibility of GO-based sensors, addressing challenges related to long-term performance and batch-to-batch variations. Researchers are also focusing on developing scalable and cost-effective production methods to facilitate the widespread adoption of GO-based sensing technologies.

Furthermore, there is a growing emphasis on creating user-friendly, portable GO sensing devices that can be easily integrated into existing systems or used as standalone point-of-use tools. This objective aligns with the broader trend of decentralized testing and on-site analysis across various industries.

As we look to the future, the evolution of GO sensing is expected to continue, with emerging objectives including the development of wearable GO sensors for continuous health monitoring, the integration of GO sensors with artificial intelligence for smart sensing systems, and the exploration of GO's potential in next-generation biosensing platforms.

Market Demand for Point-of-Use Sensors

The market demand for point-of-use sensors, particularly those utilizing graphene oxide technology, has been experiencing significant growth in recent years. This surge is driven by the increasing need for rapid, on-site detection and monitoring across various industries, including healthcare, environmental monitoring, food safety, and industrial processes.

In the healthcare sector, point-of-use sensors are revolutionizing diagnostics by enabling quick and accurate testing at the patient's bedside or in remote locations. The global point-of-care diagnostics market, which heavily relies on these sensors, is projected to reach substantial growth in the coming years. This growth is fueled by the rising prevalence of infectious diseases, the aging population, and the increasing demand for home-based testing solutions.

Environmental monitoring represents another key area driving the demand for point-of-use sensors. With growing concerns about air and water quality, there is a pressing need for real-time, on-site monitoring solutions. Graphene oxide-based sensors offer superior sensitivity and selectivity in detecting various pollutants and contaminants, making them ideal for environmental applications.

The food safety industry is also contributing to the market demand for point-of-use sensors. As consumers become more conscious about food quality and safety, there is an increasing need for rapid testing methods to detect contaminants, pathogens, and adulterants in food products. Graphene oxide sensors show promise in providing quick and accurate results, potentially revolutionizing food safety practices.

Industrial processes, particularly in manufacturing and quality control, are another significant driver of market demand. Point-of-use sensors enable real-time monitoring of production parameters, ensuring product quality and process efficiency. The ability to detect minute changes in chemical composition or physical properties makes graphene oxide sensors particularly valuable in this sector.

The market for wearable devices and Internet of Things (IoT) applications is also fueling the demand for miniaturized, highly sensitive sensors. Graphene oxide's unique properties make it an excellent candidate for developing next-generation wearable sensors for health monitoring, fitness tracking, and environmental sensing.

As the technology matures and manufacturing processes improve, the cost of graphene oxide-based sensors is expected to decrease, further driving market adoption. This cost reduction, coupled with the sensors' superior performance characteristics, is likely to expand their applications across various industries and create new market opportunities.

Graphene Oxide Sensing: Current State and Challenges

Graphene oxide (GO) has emerged as a promising material for point-of-use sensing applications, offering unique properties that enable highly sensitive and selective detection of various analytes. However, the current state of GO-based sensing technologies faces several challenges that need to be addressed to fully realize its potential in real-world applications.

One of the primary challenges in GO sensing is the lack of standardization in material synthesis and characterization. The properties of GO can vary significantly depending on the production method, oxidation degree, and post-processing treatments. This variability affects the reproducibility and reliability of GO-based sensors, making it difficult to compare results across different studies and implement large-scale production.

Another significant challenge is the stability of GO-based sensors in complex environments. While GO exhibits excellent sensitivity to many analytes, its performance can be affected by interfering substances, pH changes, and temperature fluctuations. Developing robust sensing platforms that maintain their accuracy and reliability under diverse environmental conditions remains a critical area of research.

The selectivity of GO sensors also presents a challenge, particularly in multi-analyte detection scenarios. Although GO can be functionalized to target specific molecules, achieving high selectivity without compromising sensitivity is often difficult. Cross-reactivity with similar compounds can lead to false positives or negatives, limiting the practical applicability of GO sensors in complex matrices such as biological fluids or environmental samples.

Signal transduction and readout mechanisms pose another hurdle in GO sensing technology. While various detection methods have been explored, including electrochemical, optical, and field-effect transistor-based approaches, each has its limitations in terms of sensitivity, response time, or ease of use. Developing integrated sensing platforms that combine multiple detection modalities while maintaining simplicity and cost-effectiveness is an ongoing challenge.

The scalability and manufacturability of GO-based sensors also present significant obstacles. Transitioning from laboratory-scale production to industrial-scale manufacturing while maintaining consistent quality and performance is crucial for widespread adoption. This includes developing efficient and cost-effective methods for large-scale GO production, sensor fabrication, and quality control processes.

Lastly, the long-term stability and shelf life of GO sensors remain concerns. GO's reactivity and tendency to aggregate over time can affect sensor performance and reliability. Developing strategies to enhance the long-term stability of GO-based sensing materials and devices is essential for their practical implementation in point-of-use applications.

Current Graphene Oxide Sensing Solutions

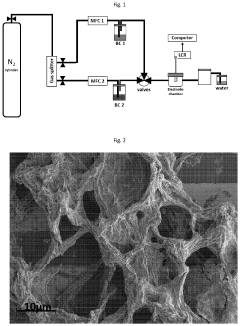

01 Graphene oxide-based sensors for gas detection

Graphene oxide is utilized in the development of highly sensitive gas sensors. These sensors can detect various gases with high selectivity and sensitivity due to the unique properties of graphene oxide, such as its large surface area and excellent electrical conductivity. The sensors can be used for environmental monitoring, industrial safety, and other applications requiring precise gas detection.- Graphene oxide-based sensors for gas detection: Graphene oxide is utilized in the development of highly sensitive gas sensors. These sensors can detect various gases with high selectivity and sensitivity due to the unique properties of graphene oxide, such as its large surface area and excellent electrical conductivity. The sensors can be used for environmental monitoring, industrial safety, and other applications requiring precise gas detection.

- Graphene oxide-based biosensors: Graphene oxide is employed in the creation of biosensors for detecting biological molecules and pathogens. These biosensors offer high sensitivity and specificity in detecting various biomolecules, including proteins, DNA, and enzymes. The unique properties of graphene oxide, such as its biocompatibility and ability to be functionalized, make it an ideal material for biosensing applications in medical diagnostics and environmental monitoring.

- Graphene oxide-based electrochemical sensors: Electrochemical sensors utilizing graphene oxide offer enhanced sensitivity and selectivity for various analytes. These sensors exploit the excellent electron transfer properties of graphene oxide to improve detection limits and response times. Applications include environmental monitoring, food safety testing, and pharmaceutical analysis.

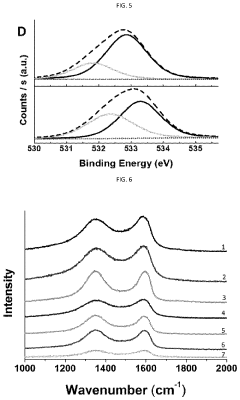

- Functionalization of graphene oxide for sensing applications: Various methods are employed to functionalize graphene oxide, enhancing its sensing capabilities. These functionalization techniques include chemical modification, doping, and incorporation of nanoparticles. The modified graphene oxide exhibits improved selectivity and sensitivity towards specific target analytes, expanding its potential applications in sensing technologies.

- Graphene oxide-based optical sensors: Optical sensors based on graphene oxide utilize its unique optical properties for sensing applications. These sensors can detect changes in fluorescence, absorbance, or surface plasmon resonance upon interaction with target analytes. Applications include chemical sensing, biological imaging, and environmental monitoring, offering high sensitivity and rapid response times.

02 Graphene oxide-based biosensors

Graphene oxide is employed in the creation of biosensors for detecting biological molecules and pathogens. These biosensors offer high sensitivity and specificity in detecting various biomolecules, including proteins, DNA, and enzymes. The unique properties of graphene oxide, such as its biocompatibility and ease of functionalization, make it an ideal material for biosensing applications in medical diagnostics and environmental monitoring.Expand Specific Solutions03 Graphene oxide-based electrochemical sensors

Electrochemical sensors utilizing graphene oxide offer enhanced sensitivity and selectivity for various analytes. These sensors exploit the excellent electron transfer properties of graphene oxide to improve detection limits and response times. Applications include environmental monitoring, food safety testing, and pharmaceutical analysis.Expand Specific Solutions04 Functionalization of graphene oxide for improved sensing

Various methods are employed to functionalize graphene oxide, enhancing its sensing capabilities. These modifications can include doping with heteroatoms, attaching specific functional groups, or creating nanocomposites with other materials. Functionalization improves selectivity, sensitivity, and stability of graphene oxide-based sensors for a wide range of applications.Expand Specific Solutions05 Graphene oxide-based optical sensors

Optical sensing techniques utilizing graphene oxide are developed for various applications. These sensors exploit the unique optical properties of graphene oxide, such as its fluorescence quenching ability and surface plasmon resonance. Applications include chemical and biological sensing, as well as environmental monitoring, offering high sensitivity and rapid detection capabilities.Expand Specific Solutions

Key Players in Graphene Oxide Sensor Industry

The field of graphene oxide-based point-of-use sensing is in a rapid growth phase, with significant market potential driven by increasing demand for portable and efficient sensing technologies. The global market for graphene-based sensors is expanding, with projections indicating substantial growth in the coming years. Technologically, the field is advancing quickly, with various institutions and companies making notable progress. Key players like The Regents of the University of California, Naval Research Laboratory, and Northwestern University are at the forefront of research and development. Companies such as Flextrapower, Inc. and Lyten, Inc. are commercializing graphene oxide-based sensing technologies. The involvement of diverse organizations, from academic institutions to private companies, indicates a maturing technology landscape with increasing commercial viability and potential for widespread application in point-of-use sensing.

Dioxide Materials, Inc.

National Aeronautics & Space Administration

Core Innovations in Graphene Oxide Sensors

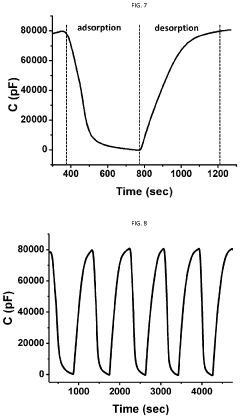

- The development of capacitive sensors incorporating divalent transition metal cations such as Co2+ and Ni2+ into porous graphene oxide, which exhibit high sensitivity and rapid response times, allowing for the detection of organophosphate vapors at concentrations as low as 5 parts per million with minimal cross-reactivity to volatile organic compounds.

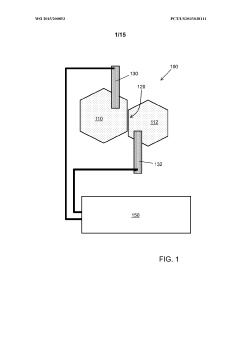

- A graphene-based sensing device with a grain boundary configuration, where two graphene grains are in substantial contact, forming a grain boundary, and electrodes are positioned close to the boundary to measure electrical properties, enhancing sensitivity by isolating the grain boundary and minimizing the interrogated graphene area.

Environmental Impact of Graphene Oxide Sensors

The environmental impact of graphene oxide sensors is a critical consideration as these innovative devices gain prominence in point-of-use sensing applications. Graphene oxide, a derivative of graphene, possesses unique properties that make it highly suitable for sensor development. However, its widespread adoption raises concerns about potential environmental consequences throughout the sensor lifecycle.

During the production phase, the synthesis of graphene oxide typically involves chemical oxidation processes that may generate hazardous byproducts. These processes often require strong oxidizing agents and acids, which, if not properly managed, could lead to environmental contamination. Additionally, the energy-intensive nature of graphene oxide production contributes to its carbon footprint, necessitating a careful evaluation of the overall environmental cost versus the benefits of its application in sensors.

The use phase of graphene oxide sensors presents both positive and negative environmental implications. On the positive side, these sensors often enable more efficient and accurate monitoring of environmental parameters, potentially leading to improved resource management and reduced pollution. Their high sensitivity and specificity can contribute to early detection of contaminants, allowing for timely interventions that mitigate environmental damage.

However, the deployment of graphene oxide sensors in various environmental matrices raises questions about their potential release and fate in ecosystems. The nanoscale dimensions of graphene oxide particles make them susceptible to environmental transport and interaction with biota. Studies have shown that graphene oxide can exhibit toxicity to certain aquatic organisms, highlighting the need for comprehensive risk assessments before widespread environmental application.

End-of-life considerations for graphene oxide sensors are equally important. The complex nature of these devices, often incorporating graphene oxide with other materials, poses challenges for recycling and proper disposal. Improper handling at this stage could lead to the release of nanomaterials into the environment, with potential long-term ecological consequences that are not yet fully understood.

To address these environmental concerns, ongoing research is focused on developing more sustainable production methods for graphene oxide, such as green synthesis approaches using renewable resources. Additionally, efforts are being made to design sensors with improved durability and recyclability, minimizing their environmental impact throughout their lifecycle. As the field advances, it is crucial to maintain a balance between harnessing the technological benefits of graphene oxide sensors and ensuring their environmental compatibility.

Scalability and Mass Production Challenges

The scalability and mass production of graphene oxide (GO) for point-of-use sensing applications present significant challenges that must be addressed to realize its full potential in the field. One of the primary obstacles is the development of cost-effective and efficient methods for large-scale synthesis of high-quality GO. Current production techniques, such as the modified Hummers method, often yield inconsistent results and are difficult to scale up without compromising the material's properties.

To overcome these challenges, researchers are exploring alternative synthesis routes, including electrochemical exfoliation and microwave-assisted methods. These approaches show promise for increased production rates and improved control over GO's physicochemical properties. However, further optimization is required to ensure consistent quality across large batches and to reduce production costs to levels suitable for commercial viability.

Another critical aspect of scalability is the integration of GO into sensing devices. The development of automated, high-throughput manufacturing processes for GO-based sensors is essential for mass production. This includes challenges in GO deposition, patterning, and functionalization on various substrates. Advances in printing technologies, such as inkjet and screen printing, are being investigated to enable rapid and precise deposition of GO on flexible and rigid substrates.

The stability and shelf life of GO-based sensors also pose significant challenges for mass production and distribution. GO's tendency to aggregate and its sensitivity to environmental factors can affect the long-term performance and reliability of sensors. Researchers are exploring various stabilization techniques, including the use of polymer matrices and encapsulation methods, to enhance the durability of GO-based sensing devices.

Standardization of GO production and characterization methods is crucial for ensuring consistency across different manufacturers and applications. The lack of universally accepted standards for GO quality and performance metrics hinders the widespread adoption of GO-based sensors in commercial applications. Efforts are underway to establish industry-wide standards and quality control measures to address this issue.

Environmental and safety concerns associated with the large-scale production of GO must also be addressed. The use of strong oxidizing agents and acids in traditional GO synthesis methods raises concerns about waste management and worker safety. Developing greener synthesis routes and implementing robust safety protocols are essential for sustainable mass production of GO-based sensing devices.