Future of Graphene Oxide in Flexible Electronics

Graphene Oxide Evolution

Graphene oxide has undergone a remarkable evolution since its initial discovery, marking significant milestones in the field of flexible electronics. The journey began with the isolation of graphene in 2004, which sparked intense research into its derivatives, including graphene oxide. As scientists explored the potential of this material, they quickly recognized its unique properties that make it particularly suitable for flexible electronic applications.

In the early stages of development, researchers focused on understanding the fundamental characteristics of graphene oxide, such as its electrical conductivity, mechanical flexibility, and optical transparency. These properties laid the foundation for its potential use in flexible electronics. The first breakthrough came with the development of solution-processable graphene oxide, which allowed for easier integration into various electronic devices.

As the field progressed, scientists made significant advancements in controlling the reduction process of graphene oxide, enabling fine-tuning of its electrical and mechanical properties. This led to the creation of reduced graphene oxide (rGO), which exhibited improved conductivity while maintaining flexibility. The ability to precisely control the degree of reduction opened up new possibilities for tailoring graphene oxide for specific applications in flexible electronics.

The next major milestone was the development of graphene oxide-based composites. By combining graphene oxide with other materials such as polymers or nanoparticles, researchers created hybrid materials with enhanced properties. These composites demonstrated improved mechanical strength, electrical conductivity, and even self-healing capabilities, further expanding the potential applications in flexible electronics.

Recent years have seen a shift towards large-scale production and integration of graphene oxide in flexible electronic devices. Researchers have made significant progress in developing scalable manufacturing processes, including roll-to-roll production techniques. This has paved the way for the commercialization of graphene oxide-based flexible electronics, with prototypes of flexible displays, sensors, and energy storage devices emerging in the market.

The latest advancements in graphene oxide evolution focus on its functionalization and integration with other emerging technologies. Scientists are exploring ways to incorporate graphene oxide into 3D printing processes, enabling the fabrication of complex, flexible electronic structures. Additionally, research is underway to combine graphene oxide with other 2D materials, creating heterostructures with novel properties and functionalities.

As we look to the future, the evolution of graphene oxide in flexible electronics continues to accelerate. Ongoing research aims to further improve its electrical properties, enhance its stability, and develop new manufacturing techniques. With these advancements, graphene oxide is poised to play a crucial role in the next generation of flexible, wearable, and stretchable electronic devices, revolutionizing industries ranging from consumer electronics to healthcare and beyond.

Flexible Electronics Market

The flexible electronics market has been experiencing significant growth and transformation in recent years, driven by advancements in materials science and manufacturing technologies. This sector encompasses a wide range of products, including flexible displays, wearable devices, bendable sensors, and stretchable circuits. The market's expansion is fueled by increasing demand for lightweight, portable, and durable electronic devices across various industries such as consumer electronics, healthcare, automotive, and aerospace.

One of the key factors propelling the flexible electronics market is the growing consumer preference for compact and versatile devices. Smartphones with foldable screens, smartwatches with curved displays, and electronic textiles are prime examples of products that have gained traction in recent years. These innovations have not only enhanced user experience but also opened up new possibilities for product design and functionality.

The healthcare sector has emerged as a major adopter of flexible electronics, with applications ranging from wearable health monitors to smart bandages and implantable sensors. These devices offer continuous health tracking, real-time data analysis, and improved patient care, contributing significantly to the market's growth. Similarly, the automotive industry is incorporating flexible electronics in vehicle interiors, heads-up displays, and touch-sensitive control panels, enhancing both aesthetics and functionality.

Advancements in materials science, particularly in the development of conductive polymers and nanomaterials, have been crucial in overcoming the limitations of traditional rigid electronics. Graphene oxide, with its exceptional electrical and mechanical properties, has shown great promise in this field. Its ability to be integrated into flexible substrates while maintaining high conductivity and strength makes it an ideal candidate for next-generation flexible electronic devices.

The market is also witnessing a shift towards sustainable and eco-friendly manufacturing processes. This trend aligns well with the properties of graphene oxide, which can be produced using environmentally friendly methods and potentially reduce the overall environmental impact of electronic device production.

Despite the positive outlook, challenges such as high production costs, scalability issues, and the need for standardization in manufacturing processes persist. However, ongoing research and development efforts, coupled with increasing investments in the sector, are expected to address these challenges and further drive market growth.

As the flexible electronics market continues to evolve, the integration of graphene oxide and other advanced materials is likely to play a pivotal role in shaping its future. The potential for creating more durable, efficient, and versatile electronic devices opens up new avenues for innovation across multiple industries, promising a dynamic and expanding market landscape in the coming years.

GO Challenges in Electronics

Despite the promising potential of graphene oxide (GO) in flexible electronics, several significant challenges hinder its widespread adoption and integration. One of the primary obstacles is the inconsistent quality and properties of GO produced through various synthesis methods. The oxidation process can introduce defects and impurities, leading to variations in electrical, mechanical, and thermal properties. This lack of uniformity makes it difficult to achieve consistent performance in electronic devices, hampering large-scale manufacturing and commercialization efforts.

Another major challenge is the inherent insulating nature of GO. While pristine graphene is highly conductive, the presence of oxygen-containing functional groups in GO disrupts its sp2 carbon network, resulting in reduced electrical conductivity. This limitation necessitates additional processing steps, such as reduction or functionalization, to restore conductivity for electronic applications. However, these processes can be complex, time-consuming, and may not fully recover the desired electrical properties.

The stability of GO in electronic devices poses another significant hurdle. GO is sensitive to environmental factors such as humidity, temperature, and light exposure, which can alter its properties over time. This instability can lead to performance degradation and reduced device lifespan, making it challenging to develop reliable and durable flexible electronic products. Additionally, the interaction between GO and other materials in multilayer structures can result in interfacial issues, affecting device performance and longevity.

Scalability and cost-effectiveness remain critical challenges in GO-based flexible electronics. While laboratory-scale production of GO has shown promising results, scaling up to industrial levels while maintaining quality and consistency is complex. The current production methods are often time-consuming, energy-intensive, and involve hazardous chemicals, making large-scale manufacturing economically and environmentally challenging. Furthermore, the high cost of high-quality GO compared to traditional electronic materials limits its competitiveness in the market.

Lastly, the integration of GO into existing electronic manufacturing processes presents significant technical challenges. Conventional fabrication techniques may not be directly applicable to GO-based materials, requiring the development of new processing methods and equipment. This includes challenges in patterning, deposition, and integration with other electronic components. The need for specialized manufacturing processes and equipment adds complexity and cost to the production of GO-based flexible electronics, slowing down its adoption in the industry.

Current GO Applications

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in electronics and energy storage: Graphene oxide is utilized in electronic devices and energy storage systems due to its unique properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.

- Functionalization and modification of graphene oxide: Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its performance in various fields.

- Graphene oxide-based composites and materials: The development of graphene oxide-based composites and materials is described, combining graphene oxide with other substances to create novel materials with enhanced properties for applications in areas such as structural materials, coatings, and filters.

- Characterization and analysis techniques for graphene oxide: Various methods and techniques for characterizing and analyzing graphene oxide are presented. These include spectroscopic, microscopic, and other analytical approaches to determine the structure, composition, and properties of graphene oxide materials.

02 Applications of graphene oxide in energy storage devices

Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and composite formation with other materials.Expand Specific Solutions04 Graphene oxide in environmental applications

Graphene oxide is used in environmental applications such as water purification, pollutant removal, and environmental sensing. Its high adsorption capacity and large surface area make it an effective material for these purposes.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic techniques, microscopy, and other analytical tools to understand the material's composition and behavior.Expand Specific Solutions

Key GO Industry Players

The future of graphene oxide in flexible electronics is at a pivotal stage, with the industry transitioning from research to early commercialization. The market size is projected to grow significantly, driven by increasing demand for lightweight, durable, and high-performance electronic devices. Technologically, graphene oxide is advancing rapidly, with companies like Nanyang Technological University, Northwestern University, and Global Graphene Group leading in research and development. The technology's maturity varies across applications, with some areas like sensors and conductive coatings showing more immediate potential. Key players such as Versarien Plc and Archer Materials Ltd. are pushing boundaries in scalable production and integration, while academic institutions like MIT and industry leaders like Semiconductor Energy Laboratory Co., Ltd. continue to explore novel applications, indicating a competitive and dynamic landscape.

Global Graphene Group, Inc.

Versarien Plc

GO Innovations Analysis

- A method involving graphene ink compositions with nitrocellulose and organic solvents for scalable, low-temperature, and environmentally benign deposition, using shear mixing and annealing to achieve high-concentration, conductive, and adhesive graphene patterns suitable for flexible electronics, with photonic annealing for enhanced properties.

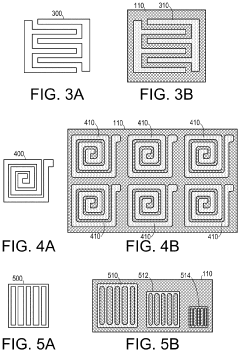

- A method involving the application of a reducing agent to specific regions of graphene oxide composite paper, using a photoresist and mask to localize reduction, allowing for controlled exposure and removal to achieve reduced graphene oxide regions with sub-micron critical dimensions, enabling the creation of conductive structures suitable for microelectronic components.

Environmental Impact of GO

The environmental impact of graphene oxide (GO) in flexible electronics is a critical consideration as this technology advances. GO production processes, while efficient, can generate harmful byproducts and consume significant energy. The synthesis often involves strong oxidizing agents and acids, potentially leading to hazardous waste if not properly managed. However, recent advancements in green synthesis methods are mitigating these concerns, utilizing more environmentally friendly reagents and processes.

In terms of product lifecycle, GO-based flexible electronics offer potential environmental benefits. Their lightweight nature and flexibility can lead to reduced material usage and energy consumption in manufacturing and transportation. Additionally, the durability and longevity of GO-enhanced devices may contribute to a reduction in electronic waste, a growing environmental concern.

The end-of-life management of GO-containing electronics presents both challenges and opportunities. While the recyclability of GO is still under investigation, its potential for biodegradation in certain forms is promising. Research indicates that some GO materials can be broken down by natural processes, potentially reducing long-term environmental accumulation. However, the behavior of GO nanoparticles in various ecosystems remains a subject of ongoing study.

The potential release of GO into the environment during the use or disposal of flexible electronics is an area of concern. Studies have shown that GO can interact with living organisms and ecosystems in complex ways. While some research suggests minimal toxicity, others indicate potential impacts on aquatic life and soil microorganisms. The long-term effects of GO accumulation in the environment are not yet fully understood, necessitating continued research and monitoring.

As the adoption of GO in flexible electronics grows, regulatory frameworks are evolving to address its environmental implications. Many countries are developing or updating guidelines for the safe handling, use, and disposal of nanomaterials, including GO. These regulations aim to balance technological advancement with environmental protection, ensuring responsible development and application of GO-based technologies.

GO Manufacturing Scalability

The scalability of graphene oxide (GO) manufacturing is a critical factor in determining the future of flexible electronics. Current production methods, such as the modified Hummers method, face challenges in scaling up to meet industrial demands. The primary obstacles include maintaining consistent quality, reducing production costs, and minimizing environmental impact.

Recent advancements in GO manufacturing have focused on improving yield and quality while reducing production time. Continuous flow reactors have shown promise in increasing production rates and ensuring more uniform oxidation. These systems allow for better control of reaction parameters, resulting in GO with more consistent properties. However, the implementation of such systems at an industrial scale requires significant investment and optimization.

Another approach to enhance scalability is the development of green synthesis methods. These techniques aim to reduce the use of harsh chemicals and minimize waste generation. For instance, electrochemical exfoliation of graphite has emerged as a promising alternative, offering faster production times and lower environmental impact. However, the challenge lies in maintaining the desired oxidation level and sheet size distribution when scaling up this process.

Automation and process control are becoming increasingly important in GO manufacturing. Advanced sensors and machine learning algorithms are being employed to monitor and adjust production parameters in real-time. This not only improves consistency but also allows for more efficient use of resources. The integration of these technologies into large-scale production lines is an ongoing area of research and development.

The supply chain for raw materials, particularly high-quality graphite, is another crucial aspect of GO manufacturing scalability. As demand for GO increases, securing a stable and cost-effective source of graphite becomes essential. This has led to exploration of alternative carbon sources and recycling methods to reduce dependence on mined graphite.

In conclusion, while significant progress has been made in GO manufacturing scalability, several challenges remain. Addressing these issues will be crucial for the widespread adoption of GO in flexible electronics. Future research should focus on optimizing continuous production methods, developing more sustainable synthesis techniques, and improving process control to ensure consistent quality at industrial scales.