Graphene Oxide: Catalyzing Progress in Organic Electronics

Graphene Oxide Evolution

Graphene oxide has undergone a remarkable evolution since its initial discovery, marking significant milestones in the field of organic electronics. The journey began with the isolation of graphene in 2004, which sparked intense research into its derivatives, including graphene oxide. This oxidized form of graphene quickly gained attention due to its unique properties and potential applications.

In the early stages of development, researchers focused on understanding the fundamental structure and properties of graphene oxide. The presence of oxygen-containing functional groups on the graphene surface was found to dramatically alter its electronic, optical, and mechanical characteristics. This discovery opened up new avenues for tailoring the material's properties through controlled oxidation and reduction processes.

As research progressed, the synthesis methods for graphene oxide underwent significant refinement. The Hummers method, initially developed in 1958, was modified and optimized to produce high-quality graphene oxide with improved yield and reduced environmental impact. These advancements in synthesis techniques paved the way for large-scale production, making graphene oxide more accessible for practical applications.

The integration of graphene oxide into organic electronics marked a pivotal point in its evolution. Researchers began exploring its potential as a transparent conductive electrode, an active layer in organic photovoltaics, and a charge transport layer in organic light-emitting diodes (OLEDs). The material's high conductivity, transparency, and flexibility made it an attractive alternative to traditional materials like indium tin oxide (ITO).

Further developments saw the emergence of functionalized graphene oxide, where the material's surface was modified with various organic and inorganic compounds. This approach allowed for fine-tuning of its electronic properties and improved compatibility with organic semiconductors. The ability to tailor graphene oxide's characteristics opened up new possibilities for enhancing device performance and stability in organic electronics.

Recent years have witnessed a shift towards hybrid materials, combining graphene oxide with other nanomaterials such as quantum dots, metal nanoparticles, and conductive polymers. These hybrid structures leverage the synergistic effects of their components, leading to enhanced performance in various organic electronic devices, including solar cells, sensors, and transistors.

The evolution of graphene oxide in organic electronics continues to accelerate, driven by interdisciplinary collaborations and advanced characterization techniques. Researchers are now focusing on addressing challenges such as scalability, reproducibility, and long-term stability to facilitate the commercial adoption of graphene oxide-based organic electronic devices.

Organic Electronics Market

The organic electronics market has been experiencing significant growth and transformation in recent years, driven by advancements in materials science and increasing demand for flexible, lightweight, and energy-efficient electronic devices. This market encompasses a wide range of products, including organic light-emitting diodes (OLEDs), organic photovoltaics (OPVs), organic field-effect transistors (OFETs), and organic sensors.

The global organic electronics market is projected to expand rapidly, with a compound annual growth rate (CAGR) exceeding 20% over the next five years. This growth is fueled by the rising adoption of OLED displays in smartphones, televisions, and other consumer electronics. The automotive industry is also emerging as a key driver, incorporating OLED technology in dashboard displays and lighting systems.

Organic photovoltaics represent another promising segment within the market. While traditional silicon-based solar cells dominate the current photovoltaic landscape, OPVs offer unique advantages such as flexibility, semi-transparency, and the potential for low-cost, large-scale production. These attributes make OPVs particularly attractive for building-integrated photovoltaics and portable electronic applications.

The organic sensor market is gaining traction in healthcare and environmental monitoring sectors. Organic-based sensors offer benefits like biocompatibility, flexibility, and the ability to detect a wide range of analytes. This has led to increased research and development in areas such as wearable health monitors and smart packaging for food safety.

Geographically, Asia-Pacific leads the organic electronics market, with countries like South Korea, Japan, and China at the forefront of OLED display manufacturing. North America and Europe are also significant players, particularly in research and development of new organic electronic materials and applications.

However, the market faces challenges, including the need for improved device stability and lifetime, as well as scaling up production processes to reduce costs. The integration of graphene oxide in organic electronics presents a potential solution to some of these challenges, offering enhanced conductivity, stability, and performance.

As the organic electronics market continues to evolve, collaborations between academic institutions, research organizations, and industry players are becoming increasingly important. These partnerships are crucial for driving innovation, addressing technical challenges, and bringing new products to market. The ongoing research in materials science, particularly in the realm of graphene-based materials, is expected to further catalyze growth and open up new applications in the organic electronics sector.

GO Challenges in OE

Despite the promising potential of graphene oxide (GO) in organic electronics (OE), several significant challenges hinder its widespread adoption and optimal performance. One of the primary obstacles is the inconsistent quality and reproducibility of GO materials. The synthesis process of GO often results in variations in oxidation levels, sheet sizes, and defect densities, leading to inconsistent electronic properties and device performance.

Another major challenge lies in the complex interface between GO and organic semiconductors. The surface chemistry of GO, with its various oxygen-containing functional groups, can significantly affect charge transport and energy level alignment at the interface. This complexity makes it difficult to predict and control the electronic behavior of GO-based organic devices, often resulting in suboptimal performance or unexpected device characteristics.

The stability of GO in organic electronic devices presents another hurdle. GO is known to be sensitive to environmental factors such as humidity and temperature, which can lead to changes in its electronic properties over time. This instability can result in degradation of device performance and reduced operational lifetimes, limiting the long-term reliability of GO-based organic electronics.

Furthermore, the integration of GO into existing organic electronic fabrication processes poses significant challenges. Traditional methods for depositing and patterning organic materials may not be directly compatible with GO, requiring the development of new processing techniques. This integration challenge extends to issues of scalability and cost-effectiveness in manufacturing GO-based organic electronic devices at an industrial scale.

The electrical conductivity of GO also presents a paradox in its application to organic electronics. While GO's tunable bandgap is advantageous for certain applications, its inherently lower conductivity compared to pristine graphene can limit its effectiveness in applications requiring high charge mobility. Balancing the trade-off between conductivity and other desirable properties of GO remains a significant challenge in optimizing its performance in organic electronic devices.

Lastly, the environmental impact and potential toxicity of GO production and disposal need to be addressed. As the field of organic electronics strives for sustainability, the large-scale use of GO must be evaluated in terms of its life cycle assessment and potential health risks, ensuring that the benefits of GO in organic electronics do not come at an unacceptable environmental cost.

GO-OE Integration Methods

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in electronics and energy storage: Graphene oxide is utilized in electronic devices and energy storage systems due to its unique electrical and thermal properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.

- Functionalization and modification of graphene oxide: Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its reactivity, dispersibility, and compatibility with other materials.

- Graphene oxide-based composites and nanocomposites: The development of graphene oxide-based composites and nanocomposites is described, combining graphene oxide with polymers, metals, or other nanomaterials. These composites exhibit enhanced mechanical, thermal, and electrical properties for various applications.

- Characterization and analysis techniques for graphene oxide: Various methods and techniques for characterizing and analyzing graphene oxide are presented. These include spectroscopic, microscopic, and other analytical tools to determine the structure, composition, and properties of graphene oxide materials.

02 Applications of graphene oxide in electronics and energy storage

Graphene oxide is utilized in electronic devices and energy storage systems due to its unique electrical and thermal properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its reactivity, dispersibility, and compatibility with other materials.Expand Specific Solutions04 Graphene oxide-based composites and nanocomposites

The development of graphene oxide-based composites and nanocomposites is described, combining graphene oxide with polymers, metals, or other nanomaterials. These composites exhibit enhanced mechanical, thermal, and electrical properties for various applications in materials science and engineering.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various methods and techniques for characterizing and analyzing graphene oxide are presented. These include spectroscopic, microscopic, and other analytical approaches to determine the structure, composition, and properties of graphene oxide materials.Expand Specific Solutions

Key GO-OE Innovators

The field of graphene oxide in organic electronics is in a dynamic growth phase, with a rapidly expanding market and evolving technological landscape. The global market for graphene-based products is projected to reach significant scale, driven by increasing applications in electronics and energy storage. Technologically, graphene oxide is advancing from basic research to practical applications, with varying levels of maturity across different use cases. Companies like Merck Patent GmbH, BASF Corp., and LG Chem Ltd. are at the forefront, developing advanced materials and processes. Emerging players such as Graphene Square Co. Ltd. and Flexterra, Inc. are focusing on specialized applications, while established electronics firms like Universal Display Corp. and Semiconductor Energy Laboratory Co., Ltd. are integrating graphene oxide into next-generation devices, indicating a competitive and diverse ecosystem.

Universal Display Corp.

BASF Corp.

GO-OE Breakthroughs

- A composite comprising graphene oxide and phenothiazine (PTZ) is used to mediate electron transfer between glucose oxidase or glucose dehydrogenase and an electrode, enhancing the electrical signal and enabling a novel hybrid biosensor and extended release dosage form.

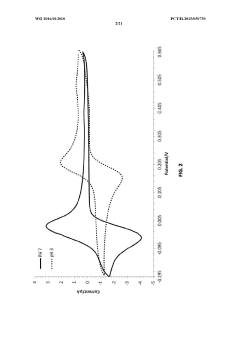

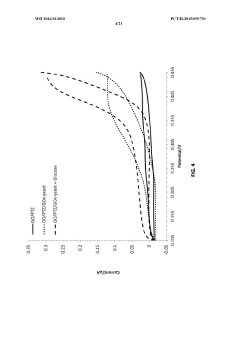

- Incorporation of large, continuous graphene sheets into organic electronics structures using a CVD method enhanced by a cylinder-like roller-substrate with patterned surface, allowing for periodic influence on organic molecules and reducing disorder, with the option to use multiple graphene layers and annealing for improved ordering and device performance.

GO-OE Sustainability

The sustainability of graphene oxide (GO) in organic electronics (OE) is a critical aspect that merits thorough examination. GO's potential to revolutionize OE devices stems from its unique properties, including high conductivity, flexibility, and transparency. However, the long-term viability of GO-based OE technologies hinges on several key factors.

Firstly, the production of GO must be evaluated from an environmental perspective. Traditional methods of GO synthesis often involve harsh chemicals and energy-intensive processes. Recent advancements in green synthesis techniques, such as electrochemical exfoliation and biomass-derived precursors, show promise in reducing the environmental footprint of GO production. These eco-friendly approaches not only minimize harmful waste but also potentially lower production costs, enhancing the overall sustainability of GO-OE technologies.

The recyclability and end-of-life management of GO-OE devices are crucial considerations. As electronic waste continues to be a global concern, the ability to recover and reuse GO from discarded devices could significantly enhance the sustainability profile of these technologies. Research into efficient recycling methods for GO-OE devices is ongoing, with some promising results in selective recovery of graphene materials from complex electronic waste streams.

Energy efficiency is another pivotal aspect of GO-OE sustainability. The incorporation of GO into organic electronic devices has shown potential for improving energy efficiency in various applications, including solar cells, light-emitting diodes, and transistors. By enhancing charge transport and reducing power consumption, GO-based devices could contribute to overall energy savings in electronic systems, aligning with global efforts to reduce carbon footprints.

The durability and longevity of GO-OE devices also play a significant role in their sustainability. GO's stability under various environmental conditions and its resistance to degradation are areas of active research. Improving the lifespan of GO-OE devices would reduce the frequency of replacement, thereby decreasing electronic waste generation and resource consumption.

Lastly, the scalability of GO production for large-scale OE applications is a critical factor in assessing long-term sustainability. Current research focuses on developing cost-effective and environmentally friendly methods for mass production of high-quality GO. Advancements in this area are essential for the widespread adoption of GO-OE technologies and their potential to create a more sustainable electronics industry.

GO-OE Scalability

The scalability of graphene oxide (GO) in organic electronics (OE) presents both significant opportunities and challenges. As the demand for organic electronic devices continues to grow, the ability to produce GO-based materials and components at scale becomes increasingly crucial. Currently, the production of high-quality GO is primarily limited to laboratory-scale processes, which poses a major hurdle for widespread industrial adoption.

One of the key challenges in scaling up GO production for OE applications is maintaining consistent quality and properties across large batches. The oxidation process of graphite to produce GO is highly sensitive to reaction conditions, and even minor variations can lead to significant differences in the final product's characteristics. This inconsistency can greatly affect the performance of organic electronic devices, making it difficult to achieve reliable and reproducible results at an industrial scale.

Another important aspect of GO-OE scalability is the development of efficient and cost-effective methods for integrating GO into organic electronic devices. While laboratory-scale fabrication techniques have shown promising results, translating these methods to large-scale manufacturing processes remains a significant challenge. Issues such as uniform dispersion of GO in organic matrices, precise control of layer thickness, and prevention of aggregation during processing need to be addressed to enable mass production of GO-enhanced organic electronic devices.

The environmental impact and sustainability of large-scale GO production for OE applications also warrant careful consideration. Current methods for GO synthesis often involve the use of harsh chemicals and generate significant amounts of waste. As production scales up, developing greener synthesis routes and implementing effective waste management strategies will be crucial to ensure the long-term viability and environmental friendliness of GO-based organic electronics.

Despite these challenges, recent advancements in GO production techniques show promise for improved scalability. Continuous flow reactors and microfluidic systems have demonstrated potential for producing GO with more consistent properties at higher throughput. Additionally, emerging approaches such as electrochemical exfoliation and plasma-assisted synthesis offer alternative routes for large-scale GO production with potentially lower environmental impact.

In conclusion, while the scalability of GO in organic electronics faces several hurdles, ongoing research and technological advancements are paving the way for industrial-scale production and integration. Overcoming these challenges will be critical in realizing the full potential of GO to revolutionize the field of organic electronics and enable the widespread adoption of next-generation electronic devices.