How to Develop Protective Coatings Using Graphene Oxide?

Graphene Oxide Coating Development Background

Graphene oxide (GO) has emerged as a promising material for developing advanced protective coatings due to its unique properties and versatile applications. The journey of GO in coating technology began with the discovery of graphene in 2004, which sparked intense research into its derivatives, including GO. As a two-dimensional carbon nanomaterial, GO possesses exceptional mechanical strength, thermal stability, and barrier properties, making it an ideal candidate for protective coatings.

The development of GO-based coatings has been driven by the increasing demand for high-performance protective materials across various industries. Traditional coating materials often fall short in providing comprehensive protection against multiple environmental factors simultaneously. GO coatings offer a potential solution to this challenge, as they can be engineered to provide resistance against corrosion, UV radiation, moisture, and even microbial growth.

The evolution of GO coating technology has been marked by significant advancements in synthesis methods, functionalization techniques, and application processes. Initially, the focus was on developing efficient methods to produce high-quality GO in large quantities. This was followed by research into various functionalization strategies to enhance the compatibility of GO with different substrate materials and to tailor its properties for specific applications.

One of the key milestones in GO coating development was the realization of its potential in corrosion protection. Researchers discovered that GO coatings could form an impermeable barrier, effectively preventing the penetration of corrosive agents. This led to extensive studies on optimizing GO coatings for metal substrates, particularly in marine and industrial environments where corrosion is a major concern.

Another significant advancement was the development of GO-based nanocomposite coatings. By incorporating GO into polymer matrices, researchers were able to create coatings with enhanced mechanical properties, improved thermal stability, and superior barrier performance. This opened up new possibilities for applications in aerospace, automotive, and construction industries.

The ongoing research in GO coating technology aims to address several challenges and explore new frontiers. Current efforts are focused on improving the scalability of GO production and coating processes, enhancing the long-term stability of GO coatings, and developing environmentally friendly and cost-effective formulations. Additionally, there is growing interest in exploring the potential of GO coatings in emerging fields such as flexible electronics, energy storage devices, and biomedical applications.

As the field continues to evolve, the development of GO-based protective coatings is expected to play a crucial role in advancing material science and addressing critical challenges in various industrial sectors. The journey from laboratory experiments to commercial applications is ongoing, with researchers and industries collaborating to unlock the full potential of this remarkable material in coating technology.

Market Analysis for Graphene Oxide Coatings

The market for graphene oxide coatings is experiencing significant growth and attracting attention across various industries. This innovative material offers exceptional properties that make it highly desirable for protective coating applications. The global graphene oxide market is projected to expand rapidly in the coming years, driven by increasing demand in sectors such as aerospace, automotive, electronics, and construction.

Graphene oxide coatings provide superior protection against corrosion, wear, and environmental degradation compared to traditional coating materials. This has led to a surge in research and development activities, with many companies and research institutions exploring new applications and improving existing formulations. The aerospace industry, in particular, has shown keen interest in graphene oxide coatings due to their potential to enhance the durability and performance of aircraft components.

The automotive sector is another key driver of market growth, as manufacturers seek to improve the longevity and efficiency of vehicle parts. Graphene oxide coatings can provide enhanced protection against rust, scratches, and chemical exposure, making them ideal for both exterior and interior automotive applications. Additionally, the electronics industry is exploring the use of these coatings to protect sensitive components from moisture and electromagnetic interference.

In the construction industry, graphene oxide coatings are gaining traction for their ability to improve the durability of building materials and protect against weathering. This application is expected to see substantial growth, especially in regions with harsh environmental conditions. The marine industry is also showing interest in these coatings for their potential to prevent biofouling and corrosion in saltwater environments.

Despite the promising outlook, challenges remain in the widespread adoption of graphene oxide coatings. The relatively high production costs and the need for specialized application techniques are currently limiting factors. However, ongoing research and technological advancements are expected to address these issues, potentially leading to more cost-effective production methods and easier application processes.

The market is characterized by intense competition among key players, with several companies investing heavily in research and development to gain a competitive edge. Collaborations between academic institutions and industry partners are becoming increasingly common, fostering innovation and accelerating the development of new graphene oxide coating technologies.

As environmental regulations become more stringent, the demand for eco-friendly coating solutions is rising. Graphene oxide coatings, being potentially more sustainable than some traditional alternatives, are well-positioned to capitalize on this trend. This environmental aspect is likely to be a significant driver of market growth in the coming years, particularly in regions with strict environmental policies.

Technical Challenges in Graphene Oxide Coatings

The development of protective coatings using graphene oxide (GO) faces several significant technical challenges that researchers and engineers must overcome. One of the primary obstacles is achieving uniform dispersion of GO in coating matrices. Due to its tendency to agglomerate, GO often forms clusters within the coating, leading to inconsistent protection and potential weak points in the protective layer.

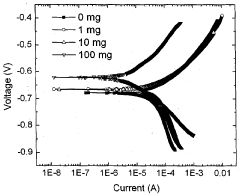

Another major challenge lies in the optimization of GO concentration within the coating. While higher concentrations of GO can enhance certain protective properties, they may also negatively impact other characteristics such as adhesion or flexibility. Finding the right balance to maximize overall performance without compromising essential coating attributes remains a complex task.

The integration of GO into existing coating formulations presents additional difficulties. Many conventional coating systems are not designed to accommodate nanomaterials, and the introduction of GO can disrupt the delicate balance of components. This often necessitates a complete reformulation of the coating, which is both time-consuming and costly.

Ensuring long-term stability of GO-enhanced coatings is another critical challenge. Environmental factors such as UV radiation, temperature fluctuations, and chemical exposure can potentially degrade GO over time, reducing its protective efficacy. Developing strategies to maintain the integrity of GO within the coating matrix under various conditions is crucial for practical applications.

The scalability of GO production and its incorporation into coatings on an industrial scale present further technical hurdles. Current methods for producing high-quality GO are often limited in scale and can be expensive, making large-scale implementation challenging. Additionally, ensuring consistent quality and performance of GO-enhanced coatings across large production batches remains a significant concern.

Addressing the potential environmental and health impacts of GO in coatings is also a technical challenge. While GO itself is generally considered less toxic than other nanomaterials, its long-term effects when used in coatings are not fully understood. Developing methods to assess and mitigate any potential risks associated with GO-enhanced coatings is essential for their widespread adoption.

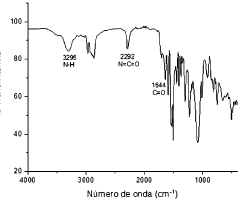

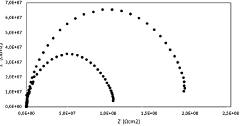

Finally, the challenge of characterizing and quantifying the performance improvements provided by GO in coatings requires advanced analytical techniques. Developing standardized testing methods and metrics to accurately measure the impact of GO on various coating properties is crucial for comparing different formulations and optimizing coating performance.

Current Graphene Oxide Coating Solutions

01 Graphene oxide-based protective coatings for various applications

Graphene oxide is utilized in protective coatings for diverse applications due to its exceptional properties. These coatings offer enhanced protection against corrosion, wear, and environmental factors. The incorporation of graphene oxide in coatings can significantly improve their durability, strength, and barrier properties, making them suitable for use in industries such as electronics, automotive, and aerospace.- Graphene oxide-based protective coatings for various applications: Graphene oxide is utilized in protective coatings for diverse applications due to its excellent barrier properties, mechanical strength, and chemical resistance. These coatings can be applied to various substrates to enhance their durability, corrosion resistance, and overall performance in challenging environments.

- Functionalization of graphene oxide for improved coating properties: Functionalization of graphene oxide is employed to enhance its compatibility with different matrices and improve specific properties of the protective coatings. This can include surface modifications, chemical treatments, or incorporation of additional components to tailor the coating's performance for specific applications.

- Graphene oxide-based nanocomposite coatings: Nanocomposite coatings incorporating graphene oxide are developed to combine the unique properties of graphene oxide with other materials. These nanocomposites can offer enhanced mechanical, thermal, and barrier properties, making them suitable for advanced protective coating applications.

- Graphene oxide coatings for electronic and energy applications: Graphene oxide-based protective coatings are utilized in electronic and energy-related applications. These coatings can provide protection against environmental factors, improve device performance, and enhance the longevity of components in various electronic and energy systems.

- Environmentally friendly and sustainable graphene oxide coating processes: Development of eco-friendly and sustainable processes for producing and applying graphene oxide protective coatings. This includes the use of green solvents, reduction of harmful chemicals, and optimization of coating techniques to minimize environmental impact while maintaining high-performance characteristics.

02 Functionalization and modification of graphene oxide for improved coating performance

Various methods are employed to functionalize and modify graphene oxide to enhance its performance in protective coatings. These modifications can include chemical treatments, surface functionalization, and the incorporation of additional materials. Such processes aim to improve the dispersion, adhesion, and compatibility of graphene oxide within the coating matrix, resulting in superior protective properties.Expand Specific Solutions03 Graphene oxide-based nanocomposite coatings

Nanocomposite coatings incorporating graphene oxide are developed to achieve synergistic effects and enhanced protective properties. These coatings combine graphene oxide with other nanomaterials, polymers, or functional additives to create advanced protective layers. The resulting nanocomposite coatings exhibit improved mechanical strength, thermal stability, and barrier properties compared to conventional coatings.Expand Specific Solutions04 Application methods for graphene oxide protective coatings

Various application techniques are developed to effectively apply graphene oxide-based protective coatings on different substrates. These methods include spray coating, dip coating, spin coating, and electrophoretic deposition. The choice of application method depends on factors such as substrate geometry, desired coating thickness, and specific performance requirements. Optimizing the application process is crucial for achieving uniform and defect-free protective coatings.Expand Specific Solutions05 Characterization and performance evaluation of graphene oxide protective coatings

Advanced characterization techniques and performance evaluation methods are employed to assess the quality and effectiveness of graphene oxide protective coatings. These include surface analysis, mechanical testing, corrosion resistance measurements, and accelerated aging tests. Such evaluations are essential for optimizing coating formulations, understanding degradation mechanisms, and ensuring the long-term reliability of graphene oxide-based protective coatings in various applications.Expand Specific Solutions

Key Players in Graphene Oxide Industry

The development of protective coatings using graphene oxide is in a rapidly evolving phase, with significant market potential due to graphene's exceptional properties. The global market for graphene-based coatings is expanding, driven by increasing demand in various industries. Technologically, the field is progressing from early-stage research to more advanced applications, with key players like The University of Manchester, Nitto Denko Corp., and Harbin Institute of Technology leading innovation. Companies such as Grafoid, Inc. and Tata Steel Ltd. are also making strides in commercialization efforts. The technology's maturity varies across different applications, with some areas nearing commercial readiness while others remain in the research phase. Overall, the competitive landscape is characterized by a mix of academic institutions and industrial players collaborating to overcome challenges in scalability and cost-effectiveness.

The University of Manchester

Nitto Denko Corp.

Core Innovations in Graphene Oxide Coatings

- A polyurethane coating is developed using graphene oxide as a polyol substitute, reacting with diisocyanate to form cross-linked sheets with urethane-type covalent bonds, providing adhesion, hydrophobicity, and corrosion resistance without the need for a primer, utilizing a method that omits polyols.

- A process for producing functionalized graphene by oxidizing graphite, exfoliating graphite oxide, and partially reducing it with hydrazine hydrate to create a stable dispersion that acts as an adsorption-type corrosion inhibitor, enhancing corrosion resistance by adsorbing onto metal surfaces and slowing down hydrogen reduction reactions.

Environmental Impact of Graphene Oxide Coatings

The environmental impact of graphene oxide coatings is a critical consideration in their development and application. These coatings, while offering exceptional protective properties, also raise concerns about their potential effects on ecosystems and human health.

One of the primary environmental benefits of graphene oxide coatings is their potential to reduce the use of toxic materials in traditional protective coatings. Many conventional coatings contain volatile organic compounds (VOCs) and heavy metals, which can have detrimental effects on air and water quality. Graphene oxide-based coatings, being largely carbon-based, offer a more environmentally friendly alternative.

However, the production of graphene oxide itself can have environmental implications. The synthesis process often involves the use of strong oxidizing agents and acids, which can generate hazardous waste if not properly managed. Researchers are actively working on developing greener synthesis methods to mitigate these issues, such as electrochemical exfoliation techniques that reduce the need for harsh chemicals.

The durability of graphene oxide coatings also contributes to their environmental profile. These coatings can significantly extend the lifespan of materials, reducing the need for frequent replacements and thereby decreasing overall resource consumption and waste generation. This longevity is particularly valuable in applications such as corrosion protection for infrastructure and marine vessels.

Concerns have been raised about the potential release of graphene oxide nanoparticles into the environment during the coating's lifecycle. While research is ongoing, some studies suggest that these nanoparticles could accumulate in aquatic environments and potentially affect organisms. The long-term ecological impacts of such accumulation are not yet fully understood and require further investigation.

In terms of end-of-life considerations, the recyclability and biodegradability of graphene oxide coatings are areas of active research. Some studies indicate that graphene oxide can be biodegraded by certain enzymes, suggesting potential for environmentally friendly disposal. However, the rate and extent of this biodegradation in real-world conditions need further exploration.

The potential for graphene oxide coatings to contribute to energy efficiency is another important environmental aspect. These coatings can improve thermal insulation and reduce heat transfer, potentially leading to energy savings in buildings and transportation. This indirect environmental benefit could contribute to reduced greenhouse gas emissions in various sectors.

As research progresses, it is crucial to conduct comprehensive life cycle assessments of graphene oxide coatings to fully understand their environmental footprint. This includes evaluating the impacts from raw material extraction, production processes, application methods, use phase, and end-of-life disposal or recycling. Such assessments will guide the development of more sustainable coating technologies and inform regulatory frameworks for their safe use and disposal.

Scalability and Manufacturing Processes

The scalability and manufacturing processes for developing protective coatings using graphene oxide (GO) are critical factors in determining the commercial viability and widespread adoption of this technology. Current manufacturing methods for GO-based coatings face several challenges that need to be addressed to achieve large-scale production.

One of the primary obstacles is the production of high-quality graphene oxide in sufficient quantities. Traditional methods, such as the Hummers method, are time-consuming and produce limited amounts of GO. Recent advancements in exfoliation techniques and chemical vapor deposition (CVD) have shown promise in increasing production capacity, but further optimization is required to meet industrial demands.

The dispersion of GO in coating formulations presents another challenge. Achieving uniform dispersion is crucial for coating performance but becomes increasingly difficult as production scales up. Researchers are exploring various dispersion techniques, including ultrasonic treatment and the use of surfactants, to improve the stability and homogeneity of GO dispersions in large batches.

Coating application methods also need to be adapted for large-scale manufacturing. While lab-scale techniques like spin coating and dip coating produce high-quality coatings, they are not suitable for industrial-scale production. Spray coating and roll-to-roll processing are being investigated as potential solutions, offering the ability to coat large surface areas continuously.

The curing and drying processes of GO-based coatings require careful control to ensure optimal performance. As production scales up, maintaining consistent curing conditions across large batches becomes more challenging. Advanced curing technologies, such as UV curing and infrared heating, are being explored to reduce processing times and improve coating uniformity.

Quality control and characterization of GO-based coatings at industrial scales present additional challenges. Developing rapid, non-destructive testing methods for large-scale production is essential to ensure consistent coating properties and performance. Techniques like Raman spectroscopy and electrical impedance spectroscopy show promise for in-line quality control.

To address these challenges, collaborative efforts between academia and industry are crucial. Research initiatives focusing on scalable production methods, improved dispersion techniques, and advanced coating application processes are underway. Additionally, the development of standardized protocols for GO production and coating formulation will be essential for ensuring consistency across different manufacturers and applications.