Exploring Graphene Oxide's Role in Environmental Remediation

Graphene Oxide Remediation Background and Objectives

Graphene oxide (GO) has emerged as a promising material in the field of environmental remediation, attracting significant attention from researchers and industry professionals alike. This remarkable nanomaterial, derived from graphene, possesses unique properties that make it particularly suitable for addressing various environmental challenges. The development of GO-based remediation technologies has its roots in the broader field of nanotechnology, which has been rapidly advancing since the late 20th century.

The evolution of GO in environmental applications can be traced back to the early 2000s when researchers began exploring its potential for water purification and contaminant removal. As understanding of GO's properties deepened, its applications expanded to include air purification, soil remediation, and even radioactive waste management. The growing global concern over environmental pollution and the need for sustainable remediation solutions have been key drivers in the advancement of GO-based technologies.

The primary objective of exploring GO's role in environmental remediation is to develop efficient, cost-effective, and environmentally friendly solutions for addressing various forms of pollution. Researchers aim to leverage GO's exceptional adsorption capacity, large surface area, and unique chemical properties to create innovative remediation techniques. These techniques are expected to outperform conventional methods in terms of efficiency, selectivity, and sustainability.

One of the key goals in this field is to optimize GO's performance for specific environmental applications. This involves tailoring its surface chemistry, enhancing its stability in different environmental conditions, and improving its recyclability. Additionally, researchers are working on developing scalable production methods for GO to facilitate its widespread adoption in real-world remediation projects.

Another important objective is to assess the long-term environmental impacts of GO-based remediation technologies. This includes studying the fate of GO in the environment, its potential toxicity to ecosystems, and methods for its safe disposal or recycling after use. Ensuring the sustainability and safety of GO applications is crucial for their acceptance and implementation on a larger scale.

Furthermore, the integration of GO with other advanced materials and technologies is an area of active research. Scientists are exploring hybrid materials, such as GO-based composites, to enhance remediation performance and expand the range of treatable pollutants. The development of multifunctional GO-based materials that can simultaneously address multiple environmental issues is also a key objective in this field.

Environmental Remediation Market Analysis

The environmental remediation market has experienced significant growth in recent years, driven by increasing awareness of environmental issues and stricter regulations worldwide. The global market for environmental remediation was valued at approximately $85 billion in 2020 and is projected to reach $152 billion by 2025, growing at a CAGR of 7.5% during the forecast period.

The market is segmented into various categories based on the type of contaminant, including heavy metals, organic compounds, and inorganic compounds. Among these, heavy metal contamination remediation holds the largest market share due to its widespread presence in industrial and urban areas. The organic compounds segment is expected to witness the highest growth rate, driven by increasing concerns over persistent organic pollutants (POPs) and their impact on human health and ecosystems.

Geographically, North America dominates the environmental remediation market, accounting for about 40% of the global market share. This is primarily due to stringent environmental regulations and the presence of a large number of contaminated sites. The Asia-Pacific region is expected to exhibit the highest growth rate in the coming years, fueled by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

Key drivers of the environmental remediation market include growing public awareness of environmental issues, stringent government regulations, and increasing corporate social responsibility initiatives. The implementation of various international agreements and protocols, such as the Paris Agreement and the Stockholm Convention on Persistent Organic Pollutants, has further boosted the demand for remediation services.

The market is characterized by the presence of both large multinational corporations and small to medium-sized enterprises. Major players in the industry include AECOM, Jacobs Engineering Group, Clean Harbors, and Veolia Environment. These companies are increasingly focusing on developing innovative technologies and sustainable remediation solutions to gain a competitive edge in the market.

Emerging trends in the environmental remediation market include the adoption of in-situ remediation techniques, which are more cost-effective and less disruptive than traditional ex-situ methods. Additionally, there is a growing emphasis on the use of green and sustainable remediation technologies, such as phytoremediation and bioremediation, which leverage natural processes to clean up contaminated sites.

The potential application of graphene oxide in environmental remediation presents a significant opportunity for market growth. Its unique properties, including high surface area and excellent adsorption capabilities, make it a promising material for removing various pollutants from water and soil. As research in this area progresses, graphene oxide-based remediation technologies could potentially disrupt the market and offer more efficient and cost-effective solutions for environmental cleanup.

Graphene Oxide Properties and Current Challenges

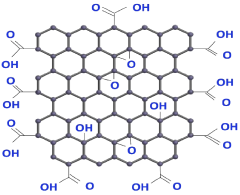

Graphene oxide (GO) possesses unique properties that make it a promising material for environmental remediation applications. Its large surface area, high adsorption capacity, and excellent dispersibility in aqueous solutions contribute to its effectiveness in removing various pollutants from water and soil. GO's structure consists of a single layer of carbon atoms arranged in a hexagonal lattice, with oxygen-containing functional groups attached to its surface.

One of the key properties of GO is its high specific surface area, which can reach up to 2630 m²/g. This extensive surface area provides numerous active sites for adsorption and interaction with contaminants. Additionally, the presence of oxygen-containing functional groups, such as hydroxyl, epoxy, and carboxyl groups, enhances GO's ability to form hydrogen bonds and electrostatic interactions with pollutants.

GO exhibits excellent adsorption capabilities for a wide range of environmental contaminants, including heavy metals, organic pollutants, and dyes. Its high adsorption capacity is attributed to the combination of π-π interactions, electrostatic attractions, and surface complexation mechanisms. Furthermore, GO's hydrophilic nature allows for easy dispersion in aqueous solutions, facilitating its application in water treatment processes.

Despite its promising properties, GO faces several challenges in environmental remediation applications. One significant challenge is the potential release of GO into the environment during treatment processes, which raises concerns about its ecological impact and long-term effects on ecosystems. The stability and aggregation behavior of GO in complex environmental matrices also need to be carefully considered to ensure its effectiveness and prevent secondary pollution.

Another challenge is the scalability and cost-effectiveness of GO-based remediation technologies. While GO shows excellent performance in laboratory-scale experiments, translating these results to large-scale applications remains a hurdle. The production of high-quality GO in large quantities at a reasonable cost is crucial for its widespread adoption in environmental remediation.

The regeneration and reusability of GO-based adsorbents pose additional challenges. Developing efficient and cost-effective methods for regenerating spent GO materials without compromising their adsorption performance is essential for sustainable remediation processes. Moreover, the potential toxicity of GO and its derivatives to various organisms needs to be thoroughly investigated to ensure the safety of GO-based remediation technologies.

Addressing these challenges requires interdisciplinary research efforts combining materials science, environmental engineering, and toxicology. Ongoing studies focus on developing novel GO-based composites with enhanced stability, selectivity, and regeneration capabilities. Additionally, research into the environmental fate and behavior of GO is crucial for assessing its long-term impacts and developing appropriate risk management strategies.

Current Graphene Oxide Remediation Techniques

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

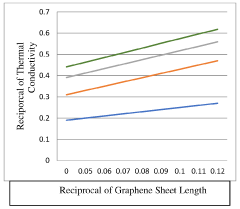

- Applications of graphene oxide in electronics and energy storage: Graphene oxide is utilized in electronic devices and energy storage systems due to its unique electrical and thermal properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.

- Functionalization and modification of graphene oxide: Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its reactivity, dispersibility, and compatibility with other materials.

- Graphene oxide-based composites and nanocomposites: The development of graphene oxide-based composites and nanocomposites is described, combining graphene oxide with polymers, metals, or other nanomaterials. These composites exhibit enhanced mechanical, thermal, and electrical properties for various applications.

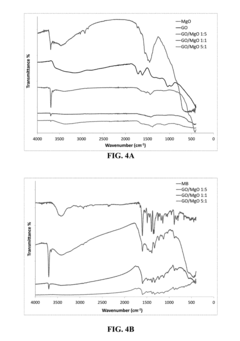

- Characterization and analysis techniques for graphene oxide: Various methods and techniques for characterizing and analyzing graphene oxide are presented. These include spectroscopic, microscopic, and other analytical tools to determine the structure, composition, and properties of graphene oxide materials.

02 Applications of graphene oxide in energy storage devices

Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and composite formation with other materials.Expand Specific Solutions04 Graphene oxide in environmental applications

Graphene oxide is used in environmental applications such as water purification, pollutant removal, and environmental sensing. Its high adsorption capacity and large surface area make it an effective material for these purposes.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic techniques, microscopy, and other analytical tools to understand and optimize the material's characteristics.Expand Specific Solutions

Key Players in Graphene Oxide Remediation

The field of graphene oxide in environmental remediation is in a growth phase, with increasing market size and technological advancements. The global market for graphene-based products in environmental applications is expanding, driven by the material's unique properties. Technological maturity varies across applications, with water treatment and air purification showing promising progress. Key players like William Marsh Rice University, Northwestern University, and The University of Manchester are leading research efforts, while institutions such as the Chinese Academy of Sciences and Huazhong University of Science & Technology are advancing practical applications. Companies like Nitto Denko Corp. and GRAFTA Nanotech, Inc. are commercializing graphene oxide-based solutions, indicating a transition from lab-scale to industrial-scale implementation in environmental remediation.

William Marsh Rice University

Northwestern University

Breakthrough Graphene Oxide Research

- Development of graphene oxide/magnesium oxide nanocomposites with varying weight ratios (10:1 to 1:10) that settle in aqueous solutions, allowing for efficient removal of organic molecules through sonication and subsequent separation without the need for a magnetic field.

- A modified Hummers' process is used to create graphene oxide membranes with enhanced separation performance, which can be combined with nanomaterials to form nanohybrids for improved pollutant adsorption, and the Fenton Reaction and Floc flotation methods are employed to reduce graphene oxide toxicity and facilitate environmentally friendly disposal.

Environmental Regulations and Compliance

The integration of graphene oxide in environmental remediation processes necessitates a thorough understanding of the regulatory landscape. Environmental regulations play a crucial role in shaping the adoption and implementation of this innovative technology. At the global level, organizations such as the United Nations Environment Programme (UNEP) and the World Health Organization (WHO) provide guidelines that influence national policies on environmental protection and human health.

In the United States, the Environmental Protection Agency (EPA) is the primary regulatory body overseeing the use of nanomaterials, including graphene oxide, in environmental applications. The EPA's Toxic Substances Control Act (TSCA) requires manufacturers to report new chemical substances, which includes nanomaterials like graphene oxide. This ensures that potential environmental and health impacts are assessed before widespread use.

The European Union has implemented the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, which applies to the production and use of chemical substances, including nanomaterials. Under REACH, companies must identify and manage the risks associated with substances they manufacture and market in the EU, including potential environmental hazards.

Compliance with these regulations involves rigorous testing and documentation. For graphene oxide applications in water treatment, for instance, companies must demonstrate that the material meets drinking water standards set by regulatory bodies such as the EPA in the US or the European Food Safety Authority (EFSA) in the EU. This includes proving that the material does not leach harmful substances into treated water and that it effectively removes targeted contaminants.

Environmental impact assessments are another critical component of regulatory compliance. These assessments evaluate the potential effects of graphene oxide on ecosystems, including its fate and behavior in the environment. Researchers and companies must provide data on biodegradability, bioaccumulation potential, and ecotoxicity to ensure that the use of graphene oxide in remediation does not inadvertently cause harm to the environment it aims to protect.

As the field of nanomaterial-based environmental remediation evolves, regulations are likely to adapt. Regulatory bodies are increasingly focusing on the unique properties of nanomaterials, which may lead to more specific guidelines for materials like graphene oxide. Companies and researchers working with graphene oxide must stay informed about these evolving regulations to ensure ongoing compliance and to contribute to the development of safe and effective environmental remediation technologies.

Scalability and Cost-Effectiveness Analysis

The scalability and cost-effectiveness of graphene oxide (GO) in environmental remediation are critical factors determining its widespread adoption and practical implementation. Current production methods for GO, such as the modified Hummers method, have shown potential for large-scale synthesis. However, challenges remain in optimizing these processes for industrial-scale production while maintaining consistent quality and reducing costs.

Scalability of GO production is primarily limited by the need for specialized equipment and controlled conditions during synthesis. Efforts to overcome these limitations have focused on developing continuous flow reactors and automated production lines. These advancements have significantly increased production capacity, with some facilities now capable of producing hundreds of kilograms of GO per day. However, further improvements in process efficiency and yield are necessary to meet the growing demand for environmental applications.

Cost-effectiveness analysis reveals that while GO production costs have decreased in recent years, they remain higher than those of traditional remediation materials. The primary cost drivers include raw materials, energy consumption, and specialized equipment. Economies of scale have contributed to cost reductions, but additional innovations in synthesis methods and process optimization are required to make GO competitive with conventional alternatives.

Environmental remediation applications of GO, such as water purification and soil decontamination, have demonstrated promising results in laboratory and pilot-scale studies. However, the transition to full-scale implementation faces economic challenges. The initial investment costs for GO-based remediation systems are often higher than those of established technologies. This necessitates a comprehensive life-cycle cost analysis to justify the long-term benefits of GO applications.

To improve cost-effectiveness, researchers are exploring strategies such as the use of cheaper precursor materials, recycling of reagents, and the development of more efficient synthesis methods. Additionally, efforts are being made to enhance the performance of GO-based remediation systems, thereby reducing the required dosage and frequency of application. These advancements could potentially offset the higher initial costs and improve the overall economic viability of GO in environmental remediation.

The scalability and cost-effectiveness of GO in environmental remediation are intrinsically linked to its performance advantages over conventional materials. As research continues to uncover new applications and optimize existing ones, the demand for GO is expected to increase. This growing market could drive further improvements in production efficiency and cost reduction, creating a positive feedback loop that enhances the economic feasibility of GO-based remediation technologies.