Graphene Oxide for Mechanical Strength Enhancements: Insights

Graphene Oxide Background and Objectives

Graphene oxide, a derivative of graphene, has emerged as a revolutionary material in the field of mechanical strength enhancement. Since its discovery in 2004, graphene has captivated researchers worldwide due to its exceptional properties, including extraordinary mechanical strength, electrical conductivity, and thermal conductivity. Graphene oxide, obtained through the oxidation of graphite, retains many of these remarkable characteristics while offering enhanced processability and functionalization potential.

The development of graphene oxide technology has progressed rapidly over the past decade, driven by the increasing demand for stronger, lighter materials in various industries. From aerospace to automotive, and from construction to electronics, the potential applications of graphene oxide for mechanical reinforcement are vast and diverse. This technological evolution has been marked by significant breakthroughs in synthesis methods, characterization techniques, and integration strategies.

As we delve into the realm of graphene oxide for mechanical strength enhancements, our primary objective is to comprehensively explore its current capabilities, limitations, and future potential. We aim to analyze the fundamental mechanisms by which graphene oxide interacts with host materials to enhance their mechanical properties, including tensile strength, Young's modulus, and fracture toughness.

Furthermore, this investigation seeks to identify the key challenges that currently hinder the widespread adoption of graphene oxide in commercial applications. These challenges may include scalability issues, cost-effectiveness, and the need for standardization in production and characterization methods. By addressing these obstacles, we can pave the way for more efficient and economically viable implementation of graphene oxide-based mechanical reinforcements.

Another crucial aspect of our study is to examine the environmental impact and sustainability of graphene oxide production and application. As the world moves towards more eco-friendly technologies, it is essential to evaluate the life cycle of graphene oxide-enhanced materials and their potential for recyclability or biodegradability.

Lastly, we aim to forecast the future trajectory of graphene oxide technology in the context of mechanical strength enhancement. This includes identifying emerging trends, potential breakthroughs, and synergies with other advanced materials and technologies. By doing so, we can provide valuable insights to guide research efforts, industrial applications, and strategic investments in this promising field.

Market Demand Analysis for GO-Enhanced Materials

The market demand for graphene oxide (GO) enhanced materials has been steadily growing, driven by the increasing need for stronger, lighter, and more durable materials across various industries. The automotive sector has shown significant interest in GO-enhanced composites for lightweight vehicle components, aiming to improve fuel efficiency and reduce emissions. Aerospace manufacturers are exploring GO-reinforced materials for aircraft structures, seeking to enhance strength-to-weight ratios and extend the lifespan of critical components.

In the construction industry, GO-enhanced concrete and building materials are gaining traction due to their superior mechanical properties and potential for increased durability. This could lead to longer-lasting infrastructure and reduced maintenance costs. The electronics industry is also a key driver of demand, with GO being investigated for flexible displays, conductive inks, and high-performance batteries.

The sports equipment market has begun incorporating GO into products like tennis rackets, bicycle frames, and protective gear, capitalizing on its strength-enhancing properties. Additionally, the medical field is exploring GO-enhanced materials for implants and tissue engineering scaffolds, leveraging their biocompatibility and mechanical strength.

Market research indicates that the global graphene market, including GO applications, is projected to grow significantly in the coming years. The Asia-Pacific region, particularly China and South Korea, is expected to lead in terms of production and consumption of GO-enhanced materials. North America and Europe are also substantial markets, with strong research and development activities driving innovation in GO applications.

However, challenges remain in scaling up production and reducing costs to make GO-enhanced materials more commercially viable for mass-market applications. The regulatory landscape surrounding nanomaterials, including GO, is still evolving, which could impact market growth and adoption rates in certain sectors.

Despite these challenges, the unique properties of GO, particularly its ability to significantly enhance mechanical strength when incorporated into various matrices, continue to attract investment and research efforts. As manufacturing processes improve and new applications are developed, the market demand for GO-enhanced materials is expected to expand further, potentially disrupting traditional material markets and opening up new possibilities for product design and performance across multiple industries.

Current State and Challenges in GO Synthesis

The synthesis of graphene oxide (GO) has made significant strides in recent years, yet several challenges persist in achieving consistent, high-quality production at scale. Current methods predominantly rely on modified Hummers' method, which involves the oxidation of graphite using strong oxidizing agents. While effective, this approach faces issues with reproducibility and environmental concerns due to the use of harsh chemicals.

One of the primary challenges in GO synthesis is controlling the degree of oxidation. Over-oxidation can lead to structural defects and reduced mechanical properties, while under-oxidation results in incomplete exfoliation and poor dispersibility. Researchers are actively working on developing precise control mechanisms to achieve optimal oxidation levels for specific applications, particularly those requiring enhanced mechanical strength.

Another significant hurdle is the scalability of GO production. Laboratory-scale synthesis methods often do not translate well to industrial-scale production, leading to inconsistencies in GO quality and properties. This variability can significantly impact the mechanical strength enhancements sought in various applications, from composites to coatings.

The removal of toxic byproducts and residual chemicals from the GO synthesis process remains a critical challenge. These impurities can negatively affect the mechanical properties of GO and pose environmental risks. Developing more efficient purification techniques that do not compromise GO's structural integrity is an ongoing area of research.

Recent advancements in GO synthesis include the exploration of greener alternatives to traditional oxidizing agents. Electrochemical exfoliation and microwave-assisted synthesis methods show promise in reducing environmental impact while maintaining or even improving GO quality. However, these methods are still in their early stages and require further optimization for large-scale production.

The characterization of GO presents another challenge, as the material's properties can vary significantly based on synthesis conditions. Standardized protocols for assessing GO quality, particularly in terms of mechanical strength potential, are needed to ensure consistency across different production batches and research efforts.

Lastly, the cost-effectiveness of GO synthesis remains a concern for widespread industrial adoption. Current methods often involve expensive precursors and complex processes, limiting GO's commercial viability for mechanical strength enhancement applications. Developing more economical synthesis routes without compromising quality is crucial for expanding GO's use in various industries.

Existing GO Mechanical Enhancement Solutions

01 Enhancing mechanical strength of graphene oxide

Various methods are employed to enhance the mechanical strength of graphene oxide, including chemical modifications, structural reinforcements, and composite formations. These techniques aim to improve the material's tensile strength, elasticity, and overall durability for diverse applications.- Enhancing mechanical strength of graphene oxide: Various methods are employed to enhance the mechanical strength of graphene oxide, including chemical modifications, structural reinforcements, and composite formations. These techniques aim to improve the material's tensile strength, elasticity, and overall durability for diverse applications.

- Graphene oxide-based composites for improved mechanical properties: Graphene oxide is incorporated into composite materials to enhance their mechanical properties. This includes combining graphene oxide with polymers, metals, or other nanomaterials to create hybrid structures with superior strength, flexibility, and resistance to deformation.

- Functionalization of graphene oxide for mechanical enhancement: Chemical functionalization of graphene oxide is utilized to improve its mechanical properties. This process involves attaching specific functional groups or molecules to the graphene oxide surface, resulting in enhanced interactions with other materials and improved overall mechanical performance.

- Structural modifications for increased mechanical strength: Various structural modifications are applied to graphene oxide to increase its mechanical strength. These include creating specific patterns, introducing defects, or altering the layered structure to enhance the material's resistance to stress and strain.

- Characterization and measurement of graphene oxide mechanical properties: Advanced techniques and methodologies are developed for accurately characterizing and measuring the mechanical properties of graphene oxide. These include novel testing procedures, imaging technologies, and analytical methods to assess strength, elasticity, and other mechanical attributes at the nanoscale.

02 Graphene oxide-based composites for improved mechanical properties

Graphene oxide is incorporated into composite materials to enhance their mechanical properties. These composites combine the strength of graphene oxide with other materials, resulting in improved tensile strength, flexibility, and resistance to deformation.Expand Specific Solutions03 Functionalization of graphene oxide for mechanical enhancement

Chemical functionalization of graphene oxide is utilized to tailor its mechanical properties. This process involves modifying the surface chemistry of graphene oxide to improve its interaction with other materials and enhance its overall mechanical performance.Expand Specific Solutions04 Structural modifications for improved mechanical strength

Various structural modifications are applied to graphene oxide to enhance its mechanical strength. These modifications include creating specific patterns, layering techniques, and introducing defects or reinforcements to optimize the material's mechanical properties.Expand Specific Solutions05 Characterization and measurement of graphene oxide mechanical properties

Advanced techniques and methodologies are developed to accurately characterize and measure the mechanical properties of graphene oxide. These methods provide crucial insights into the material's strength, elasticity, and behavior under various conditions, enabling further improvements and optimizations.Expand Specific Solutions

Key Players in Graphene Oxide Industry

The graphene oxide market for mechanical strength enhancements is in a growth phase, with increasing research and commercial applications. The global market size is expanding rapidly, driven by demand in various industries. Technologically, graphene oxide is advancing from early-stage research to more mature applications, with varying levels of readiness across sectors. Key players like Massachusetts Institute of Technology, Northwestern University, and Centre National de la Recherche Scientifique are leading academic research, while companies such as XG Sciences, Inc. and Nanotek Instruments, Inc. are pushing commercial development. The involvement of major corporations like Boeing Co. and LG Electronics, Inc. indicates growing industrial interest, suggesting a transition towards broader market adoption and technological maturity.

Northwestern University

Massachusetts Institute of Technology

Core Innovations in GO Strength Improvement

- Functionalization of graphene oxide through chemical modification with additives like Tetra Ethyl Ortho Silicate, Hydroxysuccinimide, and Naphthalene, followed by sonication, to enhance its dispersibility and form covalent bonds with cement hydration products, maintaining high slump factors and improving mechanical properties.

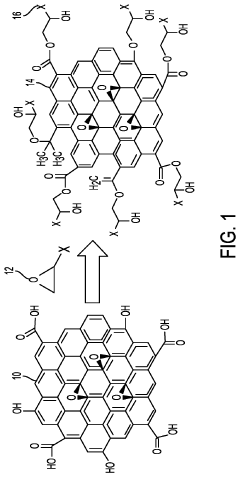

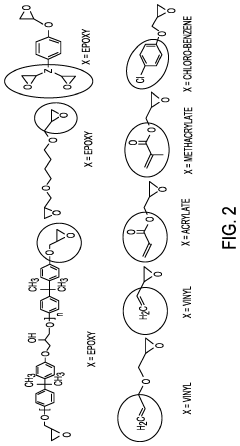

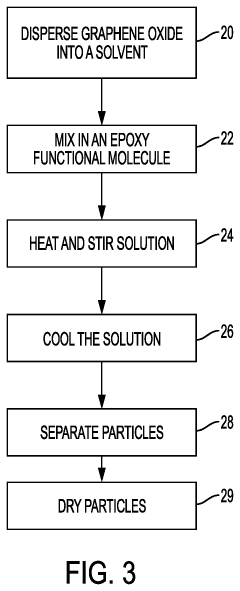

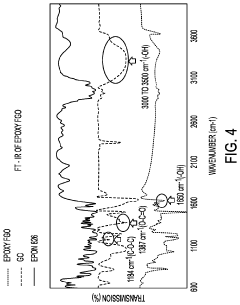

- Functionalized graphene oxide particles are produced by mixing graphene oxide with a reactive monomer containing epoxy functional groups, followed by heating and stirring, to create particles with identical functional groups to the polymer precursor, allowing for high concentration dispersion and chemical linking, resulting in enhanced mechanical properties.

Environmental Impact of GO Production

The production of graphene oxide (GO) for mechanical strength enhancements has significant environmental implications that warrant careful consideration. The synthesis process of GO typically involves the oxidation of graphite using strong oxidizing agents, such as potassium permanganate and sulfuric acid, in what is known as the Hummers method or its variations. This process generates substantial amounts of toxic waste and greenhouse gases, raising concerns about its environmental sustainability.

One of the primary environmental issues associated with GO production is the generation of hazardous chemical waste. The oxidation process produces a mixture of strong acids and heavy metals that require proper treatment and disposal. If not managed correctly, these waste products can contaminate soil and water sources, potentially harming ecosystems and human health. Additionally, the production process often involves the use of large quantities of water, which can strain local water resources in areas where GO is manufactured at scale.

The energy-intensive nature of GO production also contributes to its environmental footprint. The process requires high temperatures and prolonged reaction times, leading to significant energy consumption and associated greenhouse gas emissions. This aspect is particularly concerning given the growing demand for GO in various applications, including mechanical strength enhancement of materials.

Furthermore, the production of GO often involves the use of non-renewable resources as starting materials. While graphite, the primary precursor for GO, is relatively abundant, its extraction through mining activities can lead to habitat destruction and landscape alterations. The increasing demand for GO may accelerate these mining activities, potentially exacerbating their environmental impact.

However, it is important to note that efforts are being made to develop more environmentally friendly production methods for GO. Research is ongoing to explore greener synthesis routes that reduce the use of harsh chemicals and minimize waste generation. Some promising approaches include electrochemical exfoliation, which can significantly reduce chemical waste, and the use of bio-based reducing agents to replace traditional chemical oxidants.

The environmental impact of GO production must also be weighed against the potential benefits of its applications in enhancing mechanical strength. GO-enhanced materials can lead to lighter and stronger products, potentially reducing material consumption and energy use in various industries. This could result in indirect environmental benefits, such as improved fuel efficiency in transportation or extended product lifespans, which may partially offset the environmental costs of production.

In conclusion, while GO holds great promise for mechanical strength enhancements, its production process currently poses significant environmental challenges. Balancing the benefits of GO applications with the need for sustainable production methods will be crucial for the future development of this technology. Continued research into greener synthesis methods and life cycle assessments of GO-enhanced products will be essential in minimizing the environmental impact of GO production and maximizing its potential benefits.

Scalability and Cost-Effectiveness of GO Manufacturing

The scalability and cost-effectiveness of graphene oxide (GO) manufacturing are critical factors in determining its viability for widespread industrial applications, particularly in mechanical strength enhancement. Current production methods for GO, such as the modified Hummers method, face significant challenges when scaling up to industrial levels. These challenges include high energy consumption, the use of hazardous chemicals, and the generation of toxic by-products, all of which contribute to increased production costs and environmental concerns.

To address these issues, researchers are exploring alternative production methods that offer improved scalability and cost-effectiveness. One promising approach is the electrochemical exfoliation of graphite, which allows for continuous production of GO with reduced chemical usage and waste generation. This method has shown potential for large-scale production, but further optimization is needed to improve yield and quality consistency.

Another area of focus is the development of green synthesis methods that utilize environmentally friendly reagents and processes. These approaches aim to reduce the environmental impact of GO production while maintaining or improving product quality. For instance, the use of plant-based reducing agents and mild oxidants has shown promise in laboratory-scale experiments, but scaling up these processes remains a challenge.

The cost-effectiveness of GO manufacturing is closely tied to the availability and price of raw materials. Graphite, the primary precursor for GO, is relatively abundant and inexpensive. However, the chemicals used in the oxidation process, such as potassium permanganate and sulfuric acid, can significantly impact production costs. Efforts to reduce the reliance on these expensive and hazardous chemicals are ongoing, with researchers exploring alternative oxidants and process optimizations.

Automation and process intensification are key strategies for improving the scalability and cost-effectiveness of GO production. Continuous flow reactors and in-line monitoring systems can enhance production efficiency and product consistency while reducing labor costs. Additionally, the development of modular and scalable production units could enable more flexible manufacturing capabilities, allowing producers to adjust output based on market demand.

The recovery and recycling of reagents and solvents used in GO production are crucial for improving cost-effectiveness and reducing environmental impact. Implementing closed-loop systems and developing efficient separation techniques for recovering and reusing chemicals can significantly lower production costs and waste generation. However, these systems require careful design and optimization to ensure they do not compromise product quality or introduce additional complexities to the manufacturing process.