Graphene Oxide in Electronics: Building the Future Edge

Graphene Oxide Evolution

Graphene oxide has undergone a remarkable evolution since its initial discovery, marking significant milestones in the field of materials science and electronics. The journey began with the isolation of graphene in 2004, which sparked intense research into its derivatives, including graphene oxide. This oxidized form of graphene quickly gained attention due to its unique properties and potential applications in various fields, particularly in electronics.

In the early stages of its development, researchers focused on understanding the fundamental properties of graphene oxide and refining production methods. The Hummers method, developed in the 1950s for producing graphite oxide, was adapted and optimized for graphene oxide synthesis. This led to improved yield and quality, paving the way for more extensive research and application development.

As the understanding of graphene oxide deepened, scientists began exploring its potential in electronic applications. The material's tunable electronic properties, high surface area, and ability to be functionalized made it an attractive candidate for various electronic components. Early applications included its use in transparent conductive films, supercapacitors, and sensors.

The mid-2010s saw a surge in research focused on graphene oxide's integration into more complex electronic systems. Efforts to develop graphene oxide-based field-effect transistors, memory devices, and flexible electronics gained momentum. Researchers also began investigating its potential in optoelectronics, leveraging its unique optical properties for applications in photovoltaics and photodetectors.

Recent years have witnessed a shift towards more sophisticated applications of graphene oxide in electronics. The material has shown promise in neuromorphic computing, where its properties are being harnessed to create brain-like computing architectures. Additionally, its role in quantum electronics and spintronics has become an area of intense research, potentially opening new frontiers in computing and information processing.

The evolution of graphene oxide has also been marked by advancements in production techniques and quality control. Large-scale production methods have been developed, addressing one of the key challenges in commercialization. Simultaneously, efforts to precisely control the degree of oxidation and reduction have led to more tailored properties, expanding the range of potential applications in electronics.

As we look to the future, the evolution of graphene oxide in electronics continues to accelerate. Researchers are exploring its integration with other 2D materials to create novel heterostructures with enhanced properties. The potential of graphene oxide in flexible, wearable, and implantable electronics is also being intensively investigated, promising to revolutionize personal health monitoring and human-machine interfaces.

Market Potential Analysis

The market potential for graphene oxide in electronics is substantial and rapidly expanding. As a key component in next-generation electronic devices, graphene oxide is poised to revolutionize various sectors of the electronics industry. The global market for graphene-based products, including graphene oxide, is projected to grow significantly in the coming years, driven by increasing demand for high-performance electronic components.

In the consumer electronics sector, graphene oxide shows promise in enhancing the performance of smartphones, tablets, and wearable devices. Its exceptional electrical and thermal conductivity properties make it an ideal material for improving battery life, touch screen responsiveness, and overall device efficiency. As consumers continue to demand faster, more powerful, and longer-lasting electronic devices, the market for graphene oxide in this sector is expected to experience robust growth.

The semiconductor industry is another area where graphene oxide holds immense potential. As traditional silicon-based semiconductors approach their physical limits, graphene oxide offers a pathway to continue Moore's Law and develop more powerful and energy-efficient chips. This potential has attracted significant interest from major semiconductor manufacturers, who are investing in research and development to incorporate graphene oxide into their production processes.

In the field of flexible electronics, graphene oxide's unique properties make it a prime candidate for creating bendable displays, wearable sensors, and other innovative devices. The market for flexible electronics is projected to grow substantially in the coming years, with graphene oxide playing a crucial role in enabling this technological shift.

Energy storage is another sector where graphene oxide shows considerable market potential. Its use in supercapacitors and advanced batteries could lead to significant improvements in energy density and charging speeds, addressing key challenges in electric vehicles and renewable energy storage systems. As the global push for clean energy intensifies, the demand for graphene oxide in this sector is expected to surge.

The aerospace and defense industries are also exploring the use of graphene oxide in advanced electronic systems, including radar technology and lightweight, high-strength materials for aircraft and spacecraft. This niche but high-value market segment represents another avenue for growth in graphene oxide applications.

While the market potential for graphene oxide in electronics is undoubtedly vast, it's important to note that challenges remain in scaling up production and integrating the material into existing manufacturing processes. However, as research progresses and production techniques improve, these barriers are expected to diminish, paving the way for widespread adoption across the electronics industry.

Technical Hurdles

Despite the promising potential of graphene oxide in electronics, several significant technical hurdles remain to be overcome before its widespread adoption. One of the primary challenges is the scalable production of high-quality graphene oxide with consistent properties. Current synthesis methods often result in variations in thickness, size, and defect density, which can significantly impact the material's electronic properties and performance in devices.

Another major obstacle is the development of reliable and cost-effective methods for reducing graphene oxide to graphene. The reduction process is crucial for restoring the excellent electrical conductivity of graphene, but existing techniques often introduce defects or leave residual oxygen groups, compromising the material's performance. Achieving a balance between efficient reduction and maintaining structural integrity remains a significant challenge.

The integration of graphene oxide into existing semiconductor manufacturing processes poses another technical hurdle. Compatibility issues with traditional fabrication techniques, such as photolithography and etching, need to be addressed to enable seamless incorporation of graphene oxide-based components into electronic devices. This includes developing new deposition methods, patterning techniques, and surface treatments that are compatible with both graphene oxide and conventional semiconductor materials.

Controlling the bandgap of graphene oxide is another critical challenge. While the ability to tune the bandgap makes graphene oxide attractive for various electronic applications, precise control over this property remains difficult. Developing reliable methods to manipulate the bandgap while maintaining other desirable characteristics is essential for realizing the full potential of graphene oxide in electronics.

The stability and reliability of graphene oxide-based devices under various environmental conditions also present significant hurdles. Graphene oxide is sensitive to humidity and temperature changes, which can affect its electrical properties and long-term performance. Developing effective encapsulation techniques and improving the material's resistance to environmental factors are crucial for ensuring the reliability of graphene oxide-based electronic components.

Furthermore, the development of efficient and reproducible methods for creating high-quality contacts between graphene oxide and other materials in electronic devices remains challenging. Poor contact resistance can significantly degrade device performance, and finding ways to minimize this issue is essential for realizing the full potential of graphene oxide in electronics.

Lastly, the lack of standardization in graphene oxide production and characterization poses a challenge for widespread industrial adoption. Establishing industry-wide standards for material quality, characterization methods, and performance metrics is crucial for enabling consistent and reliable integration of graphene oxide into electronic devices across different manufacturers and applications.

Current GO Applications

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in electronics and energy storage: Graphene oxide is utilized in electronic devices and energy storage systems due to its unique properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.

- Functionalization and modification of graphene oxide: Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its performance in various fields.

- Graphene oxide-based composites and materials: The development of graphene oxide-based composites and materials is discussed, focusing on combining graphene oxide with other substances to create novel materials with enhanced properties for applications in various industries.

- Characterization and analysis techniques for graphene oxide: Various methods and techniques for characterizing and analyzing graphene oxide are presented. These include spectroscopic, microscopic, and other analytical approaches to determine the structure, composition, and properties of graphene oxide materials.

02 Applications of graphene oxide in electronics and energy storage

Graphene oxide is utilized in electronic devices and energy storage systems due to its unique properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its performance in various fields.Expand Specific Solutions04 Graphene oxide-based composites and materials

The development of graphene oxide-based composites and materials is discussed, focusing on combining graphene oxide with other substances to create novel materials with enhanced properties for applications in various industries.Expand Specific Solutions05 Characterization and analysis techniques for graphene oxide

Various methods and techniques for characterizing and analyzing graphene oxide are presented. These include spectroscopic, microscopic, and other analytical approaches to determine the structure, composition, and properties of graphene oxide materials.Expand Specific Solutions

Key Industry Players

The graphene oxide market in electronics is in a rapid growth phase, driven by increasing demand for advanced electronic components. The market size is expanding significantly, with projections indicating substantial growth in the coming years. Technologically, graphene oxide is advancing quickly, with companies like Samsung Electronics, Nokia Technologies, and IBM leading research and development efforts. Academic institutions such as The University of Manchester and Zhejiang University are also contributing significantly to technological advancements. The maturity of graphene oxide technology varies across applications, with some areas nearing commercialization while others remain in early research stages. Overall, the competitive landscape is dynamic, with both established tech giants and specialized startups vying for market share and technological breakthroughs.

The University of Manchester

Samsung Electronics Co., Ltd.

Breakthrough Patents

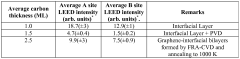

- The use of free-radical assisted chemical vapor deposition (FRA-CVD) and physical vapor deposition (PVD) processes to form ordered graphene films directly on dielectric substrates, such as MgO, with annealing at high temperatures to create a stable graphene surface suitable for logic device applications.

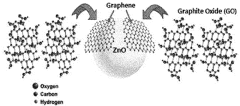

- A method involving the treatment of graphite with an acid to form graphite oxide, followed by mixing with a metal oxide nanoparticle and subsequent acid treatment to achieve a quasi metal oxide-graphene core-shell structure, allowing for the exfoliation and separation of graphene.

Environmental Impact

The integration of graphene oxide (GO) in electronics presents both promising opportunities and potential environmental challenges. As this innovative material gains traction in the industry, it is crucial to assess its environmental impact throughout its lifecycle, from production to disposal.

The production of graphene oxide involves chemical processes that may generate hazardous waste and consume significant energy. However, recent advancements in manufacturing techniques have shown potential for reducing the environmental footprint of GO production. Green synthesis methods, such as using plant extracts or eco-friendly reducing agents, are being explored to minimize the use of harsh chemicals and decrease energy consumption.

During the use phase, graphene oxide-based electronics offer several environmental benefits. The material's exceptional properties, including high conductivity and flexibility, enable the development of more energy-efficient devices. This can lead to reduced power consumption and extended battery life in various electronic applications, potentially lowering overall energy demand and associated carbon emissions.

The durability and stability of graphene oxide also contribute to longer-lasting electronic components, which could help mitigate the growing issue of electronic waste. By extending the lifespan of devices, GO-based electronics may reduce the frequency of replacements and, consequently, the volume of e-waste generated.

However, the end-of-life management of graphene oxide-containing electronics poses new challenges. The nanoscale nature of GO particles raises concerns about their potential release into the environment during disposal or recycling processes. Research is ongoing to understand the long-term environmental fate and potential toxicity of graphene oxide nanoparticles in various ecosystems.

Efforts are being made to develop effective recycling and recovery methods for graphene oxide from electronic waste. These include chemical and thermal treatments to separate GO from other materials, as well as exploring the potential for reusing recovered graphene oxide in new applications. Such circular economy approaches could significantly reduce the environmental impact of GO-based electronics.

As the adoption of graphene oxide in electronics continues to grow, it is essential to conduct comprehensive life cycle assessments to fully understand and mitigate its environmental impact. This includes evaluating resource consumption, emissions, and potential ecological effects at each stage of the material's life cycle. Ongoing research and development in this area will be crucial for ensuring that the benefits of graphene oxide in electronics are realized without compromising environmental sustainability.

Scalability Challenges

The scalability of graphene oxide (GO) production and integration into electronic devices presents significant challenges that must be addressed to realize its full potential in the electronics industry. One of the primary obstacles is the lack of standardized, large-scale production methods for high-quality GO. Current synthesis techniques, such as the modified Hummers method, often result in inconsistent quality and yield, making it difficult to achieve uniform properties across batches. This variability hinders the reliable integration of GO into electronic components and devices.

Another major challenge lies in the development of efficient and cost-effective processes for depositing GO onto various substrates at an industrial scale. While lab-scale deposition techniques like spin coating and drop-casting have shown promise, they are not suitable for high-volume manufacturing. The need for precise control over GO film thickness and uniformity across large areas further complicates the scaling process.

The reduction of GO to reduced graphene oxide (rGO) or graphene-like materials also poses scalability issues. Current reduction methods, including thermal, chemical, and electrochemical approaches, often struggle to maintain consistent quality and electrical properties when scaled up. This inconsistency can lead to variations in device performance and reliability, making it challenging to meet the stringent requirements of the electronics industry.

Integration of GO-based materials into existing semiconductor manufacturing processes presents another hurdle. The compatibility of GO with traditional CMOS fabrication techniques and the development of new processes that can seamlessly incorporate GO into complex electronic structures are critical areas that require further research and development.

Furthermore, the environmental stability and long-term reliability of GO-based electronic devices remain concerns for large-scale adoption. GO's sensitivity to moisture and other environmental factors can affect device performance and lifespan, necessitating the development of effective encapsulation and protection strategies that can be implemented at scale.

Addressing these scalability challenges will require collaborative efforts between materials scientists, process engineers, and device manufacturers. Innovations in synthesis methods, deposition techniques, and integration processes are essential to bridge the gap between laboratory demonstrations and commercial-scale production of GO-based electronic devices. As these challenges are overcome, the path to realizing graphene oxide's transformative potential in the electronics industry will become clearer, paving the way for next-generation devices with enhanced performance and functionality.