Graphene Oxide Innovations: A New Era in Filtration Methods

Graphene Oxide Evolution

Graphene oxide has undergone a remarkable evolution since its initial discovery, transforming from a novel material to a key player in advanced filtration technologies. The journey began with the isolation of graphene in 2004, which quickly led to the development of graphene oxide as a more versatile and processable form of graphene. Early research focused on understanding the unique properties of graphene oxide, including its high surface area, exceptional mechanical strength, and tunable chemical functionalities.

As scientists delved deeper into graphene oxide's potential, its application in filtration methods emerged as a promising field. The material's nanoscale thickness and ability to form stable membranes with controllable pore sizes made it an ideal candidate for next-generation filtration systems. The evolution of graphene oxide in filtration can be traced through several key milestones.

Initially, researchers explored graphene oxide's capacity for water purification, demonstrating its effectiveness in removing various contaminants, including heavy metals and organic pollutants. This breakthrough opened the door to more sophisticated applications, such as desalination and gas separation. The development of graphene oxide membranes with precise pore sizes and surface chemistries allowed for selective molecular sieving, pushing the boundaries of filtration efficiency.

Concurrent with these advancements, manufacturing techniques for graphene oxide evolved rapidly. Early production methods were limited in scale and consistency, but innovations in chemical exfoliation and reduction processes enabled the production of high-quality graphene oxide at larger scales. This progress was crucial in transitioning graphene oxide from a laboratory curiosity to a commercially viable material for filtration applications.

The evolution of graphene oxide also saw significant improvements in its stability and performance under various environmental conditions. Researchers developed methods to enhance its resistance to fouling and degradation, addressing key challenges in long-term filtration applications. Additionally, the integration of graphene oxide with other materials, such as polymers and nanoparticles, led to the creation of composite membranes with enhanced properties and functionalities.

Recent years have witnessed a shift towards more sustainable and environmentally friendly production methods for graphene oxide, aligning with global efforts to reduce the environmental impact of advanced materials. This trend has further accelerated the adoption of graphene oxide in filtration technologies across various industries, from water treatment to air purification and beyond.

As graphene oxide continues to evolve, its role in filtration methods is expanding beyond traditional applications. Emerging areas include biomedical filtration, where graphene oxide membranes show promise in drug delivery and tissue engineering, and smart filtration systems that can adapt to changing environmental conditions. These developments signal a new era in filtration technology, with graphene oxide at the forefront of innovation.

Filtration Market Analysis

The global filtration market has been experiencing significant growth, driven by increasing environmental concerns, stringent regulations, and the need for clean water and air across various industries. As of 2021, the market was valued at approximately $89 billion, with projections indicating a compound annual growth rate (CAGR) of 6.8% from 2022 to 2030. This growth is attributed to the rising demand for filtration systems in sectors such as water treatment, healthcare, automotive, and industrial manufacturing.

The water treatment segment dominates the filtration market, accounting for over 40% of the total market share. This is primarily due to the growing global population, urbanization, and the increasing need for clean drinking water in developing countries. The industrial sector follows closely, with a focus on air and liquid filtration systems to meet environmental regulations and improve production efficiency.

Geographically, North America and Europe lead the filtration market, owing to stringent environmental regulations and advanced industrial infrastructure. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing awareness about water and air quality in countries like China and India.

The market is characterized by the presence of both large multinational corporations and smaller specialized companies. Key players include Danaher Corporation, Parker Hannifin Corporation, and Donaldson Company, Inc., among others. These companies are investing heavily in research and development to introduce innovative filtration technologies and maintain their competitive edge.

The emergence of nanotechnology-based filtration methods, such as graphene oxide membranes, is poised to revolutionize the industry. These advanced materials offer superior filtration efficiency, reduced energy consumption, and improved durability compared to traditional filtration methods. The market for nanofiltration is expected to grow at a CAGR of 15.2% from 2021 to 2028, indicating a strong potential for graphene oxide-based filtration technologies.

Consumer trends are also shaping the filtration market, with an increasing demand for home water and air purification systems. This trend has been further accelerated by the COVID-19 pandemic, which has heightened awareness about air quality and the importance of clean environments.

GO Filtration Challenges

Despite the promising potential of graphene oxide (GO) in filtration applications, several significant challenges hinder its widespread adoption and practical implementation. One of the primary obstacles is the scalability of GO production. While laboratory-scale synthesis methods have been well-established, translating these processes to industrial-scale production while maintaining consistent quality and properties remains a formidable task. The high cost associated with large-scale GO production further compounds this issue, making it economically challenging for widespread commercial use in filtration systems.

Another critical challenge lies in the stability and durability of GO-based filtration membranes. When exposed to water or other solvents for extended periods, GO membranes tend to swell and become unstable, compromising their filtration efficiency and structural integrity. This instability limits the long-term performance and reliability of GO-based filtration systems, particularly in applications requiring continuous operation or exposure to harsh environmental conditions.

The selectivity and permeability trade-off presents another significant hurdle in GO filtration technology. While GO membranes exhibit excellent selectivity for certain molecules, achieving high permeability simultaneously remains challenging. Balancing these two crucial parameters to optimize filtration performance across various applications and contaminant types is an ongoing area of research and development.

Furthermore, the potential environmental and health impacts of GO nanoparticles pose concerns that need to be thoroughly addressed. As GO-based filtration systems become more prevalent, the potential release of GO particles into the environment and their long-term effects on ecosystems and human health require comprehensive study and risk assessment. Developing methods to effectively contain and recover GO particles from filtration systems is crucial for ensuring the safety and sustainability of this technology.

Lastly, the integration of GO-based filtration technologies into existing infrastructure and processes presents both technical and practical challenges. Adapting current filtration systems to incorporate GO membranes often requires significant modifications and investments. Additionally, the lack of standardized testing and performance metrics specific to GO-based filtration systems makes it difficult to compare and evaluate different solutions, hindering widespread adoption and regulatory approval.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, chemical engineering, and environmental studies. Overcoming these hurdles is essential for realizing the full potential of GO in revolutionizing filtration methods across various industries and applications.

Current GO Filtration Tech

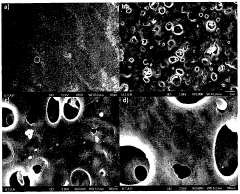

01 Graphene oxide membrane fabrication

Methods for fabricating graphene oxide membranes with controlled pore size and structure for enhanced filtration performance. These techniques involve various assembly processes and modifications to optimize the membrane's properties for specific filtration applications.- Graphene oxide membrane fabrication: Methods for fabricating graphene oxide membranes with controlled thickness and pore size for filtration applications. These techniques involve layer-by-layer assembly, vacuum filtration, or spin coating to create highly selective and permeable membranes.

- Water purification using graphene oxide: Utilization of graphene oxide-based materials for water purification, including the removal of contaminants such as heavy metals, organic pollutants, and microorganisms. The high surface area and functional groups of graphene oxide enable efficient adsorption and filtration processes.

- Functionalization of graphene oxide for enhanced filtration: Modification of graphene oxide through chemical functionalization or composite formation to improve its filtration properties. This includes incorporating nanoparticles, polymers, or other materials to enhance selectivity, flux, and fouling resistance.

- Gas separation using graphene oxide membranes: Application of graphene oxide membranes for gas separation, including CO2 capture, hydrogen purification, and other industrial gas separations. The unique molecular sieving properties of graphene oxide enable highly efficient and selective gas separation processes.

- Graphene oxide-based sensors for contaminant detection: Development of graphene oxide-based sensors for detecting and monitoring contaminants in water or air. These sensors utilize the electrical and optical properties of graphene oxide to achieve high sensitivity and selectivity in environmental monitoring applications.

02 Water purification using graphene oxide

Application of graphene oxide-based materials in water purification systems. These materials demonstrate high efficiency in removing contaminants, including heavy metals, organic pollutants, and microorganisms, due to their large surface area and unique chemical properties.Expand Specific Solutions03 Functionalization of graphene oxide for selective filtration

Techniques for functionalizing graphene oxide to enhance its selectivity in filtration processes. This includes chemical modifications and incorporation of specific functional groups to target particular contaminants or molecules.Expand Specific Solutions04 Graphene oxide-based composite materials for filtration

Development of composite materials incorporating graphene oxide for improved filtration performance. These composites combine the advantages of graphene oxide with other materials to create synergistic effects in filtration applications.Expand Specific Solutions05 Scalable production of graphene oxide for filtration applications

Methods for large-scale production of graphene oxide suitable for filtration applications. These processes focus on maintaining quality and consistency while increasing production volume to meet industrial demands.Expand Specific Solutions

Key GO Industry Players

The graphene oxide filtration market is in a rapid growth phase, driven by increasing demand for advanced water purification and environmental remediation solutions. The market size is expanding, with projections indicating significant growth potential in the coming years. Technologically, graphene oxide filtration is advancing rapidly, with key players like The University of Manchester, Zhejiang University, and the US Air Force leading research and development efforts. Companies such as The Sixth Element Materials Technology and Shandong Lite Nano Technology are commercializing these innovations. The technology's maturity varies across applications, with some areas nearing commercial readiness while others remain in early developmental stages, indicating a dynamic and competitive landscape with ample room for further innovation and market expansion.

The University of Manchester

The Sixth Element (Changzhou) Materials Technology Co., Ltd.

GO Filtration Breakthroughs

- The development of graphene oxide/polymer composite membranes, where graphene oxide is embedded within the polymer matrix rather than on the surface, is achieved through the oxidation and exfoliation of graphite nanofibers, resulting in a more hydrophilic membrane that enhances water flux and COD rejection rates.

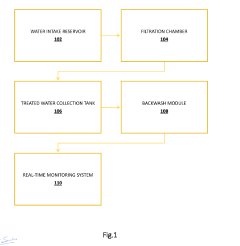

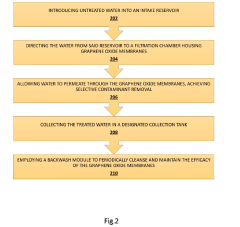

- The integration of graphene oxide membranes into water treatment systems, characterized by high selectivity and permeability, which effectively separate and capture a broad spectrum of contaminants from macroscopic particulates to microscopic molecules, combined with a sophisticated system featuring a filtration chamber lined with these membranes, a backwash module for membrane maintenance, real-time monitoring, and automated control for optimal operation.

Environmental Impact of GO

The environmental impact of graphene oxide (GO) in filtration methods is a critical aspect to consider as this innovative material gains prominence in water treatment and purification processes. GO's unique properties, including its high surface area and excellent adsorption capabilities, make it a promising candidate for removing various contaminants from water. However, the widespread use of GO in filtration systems also raises concerns about its potential effects on ecosystems and human health.

One of the primary environmental benefits of GO-based filtration is its ability to effectively remove a wide range of pollutants, including heavy metals, organic compounds, and microorganisms. This high efficiency in contaminant removal can lead to improved water quality and reduced environmental pollution. Additionally, GO-based filters often require less energy and fewer chemicals compared to conventional filtration methods, potentially reducing the overall environmental footprint of water treatment processes.

However, the potential release of GO nanoparticles into the environment during the filtration process or through the disposal of used filters is a significant concern. Studies have shown that GO can interact with various organisms in aquatic ecosystems, potentially causing adverse effects on their growth, reproduction, and overall health. The long-term persistence of GO in the environment and its potential to accumulate in food chains are areas that require further investigation.

The production of GO itself also has environmental implications. The synthesis of GO typically involves the use of strong oxidizing agents and acids, which can generate hazardous waste and contribute to air and water pollution if not properly managed. Efforts are being made to develop more environmentally friendly production methods, such as electrochemical exfoliation, to mitigate these impacts.

On the positive side, the use of GO in filtration systems may lead to a reduction in the use of conventional water treatment chemicals, such as chlorine and coagulants. This could result in decreased chemical pollution and associated environmental risks. Furthermore, the high efficiency of GO-based filters could potentially reduce the energy consumption and carbon footprint of water treatment facilities.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of GO-based filtration technologies to fully understand their environmental impacts from production to disposal. This will help in developing sustainable practices for the implementation of GO in water treatment and ensure that the benefits of this innovative material outweigh any potential environmental risks.

GO Filtration Applications

Graphene oxide (GO) has emerged as a revolutionary material in filtration applications, offering unprecedented performance and versatility. Its unique properties, including high surface area, excellent mechanical strength, and tunable surface chemistry, make it an ideal candidate for various filtration processes.

In water treatment, GO-based membranes have shown exceptional capabilities in removing contaminants such as heavy metals, organic pollutants, and pathogens. These membranes exhibit superior flux rates and selectivity compared to conventional filtration materials. For instance, GO-enhanced ultrafiltration membranes have demonstrated remarkable efficiency in removing pharmaceutical residues and personal care products from wastewater.

Air purification is another domain where GO filtration excels. GO-based air filters can effectively capture particulate matter, volatile organic compounds, and other airborne pollutants. The high adsorption capacity of GO, coupled with its ability to be functionalized with specific chemical groups, allows for targeted removal of various air contaminants. This has significant implications for improving indoor air quality and industrial emission control.

In the food and beverage industry, GO filtration technologies are being explored for applications such as desalination, juice clarification, and protein separation. The selective permeability of GO membranes enables efficient separation of molecules based on size and charge, leading to improved product quality and process efficiency.

The biomedical field has also witnessed the potential of GO in filtration applications. GO-based materials are being investigated for blood purification, hemodialysis, and drug delivery systems. The ability to tailor GO's surface properties allows for selective filtration of biomolecules and toxins, opening new avenues in medical treatments.

Industrial processes benefit from GO filtration as well. In gas separation, GO membranes show promise for applications such as CO2 capture and hydrogen purification. The molecular sieving properties of GO enable highly selective gas separation, potentially revolutionizing energy-intensive industrial processes.

As research in GO filtration continues to advance, new applications are constantly emerging. From oil-water separation in environmental remediation to selective ion transport in energy storage devices, the versatility of GO in filtration applications seems boundless. The scalability and cost-effectiveness of GO production further enhance its potential for widespread adoption across various industries.