Graphene Oxide: Leading the Charge in Sustainable Energy

Graphene Oxide Evolution

Graphene oxide has undergone a remarkable evolution since its initial discovery, marking significant milestones in the field of sustainable energy. The journey began with the isolation of graphene in 2004, which led to the subsequent development of graphene oxide as a more versatile and processable form of this revolutionary material.

In the early stages, researchers focused on understanding the fundamental properties of graphene oxide, including its unique structure, high surface area, and exceptional electrical conductivity. These investigations laid the groundwork for its potential applications in energy storage and conversion systems.

As the research progressed, scientists developed various synthesis methods to produce graphene oxide with controlled properties. The Hummers method, introduced in the 1950s, became a widely adopted approach, undergoing numerous modifications to enhance yield and quality. These advancements in synthesis techniques paved the way for large-scale production, making graphene oxide more accessible for practical applications.

The mid-2010s saw a surge in research exploring graphene oxide's potential in energy-related applications. Scientists discovered its promising role in supercapacitors, lithium-ion batteries, and fuel cells. The material's high surface area and excellent electron mobility made it an ideal candidate for improving energy storage capacity and charge/discharge rates.

Concurrently, researchers began investigating graphene oxide's potential in solar energy harvesting. Its unique optical properties and ability to be functionalized with various materials opened up new avenues for enhancing the efficiency of photovoltaic devices.

In recent years, the focus has shifted towards developing hybrid materials and nanocomposites incorporating graphene oxide. These advanced materials combine the exceptional properties of graphene oxide with other functional components, leading to synergistic effects and enhanced performance in energy applications.

The latest developments in graphene oxide research have centered on addressing environmental concerns and sustainability. Scientists are exploring eco-friendly synthesis methods and investigating the material's potential in water purification and environmental remediation, further expanding its role in sustainable technologies.

As we look to the future, graphene oxide continues to evolve, with ongoing research aimed at optimizing its properties, scaling up production, and integrating it into commercial energy systems. The material's journey from a laboratory curiosity to a key player in sustainable energy solutions exemplifies the rapid progress and immense potential of advanced materials in addressing global energy challenges.

Energy Market Dynamics

The global energy market is undergoing a significant transformation, driven by the increasing demand for sustainable and efficient energy solutions. Graphene oxide, a revolutionary material derived from graphene, is poised to play a crucial role in this evolving landscape. The energy sector, traditionally dominated by fossil fuels, is now shifting towards renewable sources and advanced energy storage technologies.

In recent years, the renewable energy market has experienced exponential growth, with solar and wind power leading the charge. This growth has created a pressing need for more efficient energy storage solutions to address the intermittent nature of these renewable sources. Graphene oxide, with its exceptional electrical and thermal properties, is emerging as a promising material for enhancing energy storage devices, particularly in the development of high-performance batteries and supercapacitors.

The electric vehicle (EV) market, a key driver of energy storage innovation, has seen remarkable expansion. As countries worldwide set ambitious targets for phasing out internal combustion engines, the demand for advanced battery technologies continues to surge. Graphene oxide-based materials are being explored to improve the energy density, charging speed, and overall performance of EV batteries, potentially revolutionizing the automotive industry.

In the power grid sector, the integration of renewable energy sources has necessitated the development of more robust and flexible energy storage systems. Grid-scale energy storage solutions incorporating graphene oxide are being researched to enhance grid stability, manage peak loads, and facilitate the seamless integration of intermittent renewable energy sources.

The hydrogen economy, another emerging trend in the energy market, is gaining traction as a potential solution for long-term energy storage and clean transportation. Graphene oxide's unique properties make it an attractive candidate for improving hydrogen production, storage, and fuel cell technologies, potentially accelerating the adoption of hydrogen as a clean energy carrier.

As the global focus on sustainability intensifies, the market for energy-efficient buildings and smart energy management systems is expanding rapidly. Graphene oxide-based materials are being explored for applications in thermal management, energy-efficient coatings, and smart windows, contributing to the overall reduction of energy consumption in the built environment.

The energy market dynamics surrounding graphene oxide are further influenced by increasing government support and investments in clean energy technologies. Many countries are implementing policies and incentives to promote research and development in advanced materials for energy applications, creating a favorable environment for the commercialization of graphene oxide-based solutions.

GO Tech Challenges

Despite the promising potential of graphene oxide (GO) in sustainable energy applications, several significant technical challenges persist in its development and implementation. One of the primary obstacles is the scalable and cost-effective production of high-quality GO. Current synthesis methods, such as the modified Hummers' method, often result in inconsistent quality and limited yield, hindering large-scale industrial applications.

Another critical challenge lies in controlling the oxygen content and functional groups on GO surfaces. The precise manipulation of these factors is crucial for tailoring GO's properties to specific energy applications, such as supercapacitors or fuel cells. Achieving a balance between conductivity and reactivity remains a complex task, as excessive oxidation can compromise electrical conductivity while insufficient oxidation may limit functionality.

The stability of GO in various environments poses another significant hurdle. In energy storage devices, GO's tendency to restack due to van der Waals forces can lead to reduced surface area and diminished performance over time. Additionally, GO's susceptibility to reduction in certain conditions can alter its properties unpredictably, affecting long-term reliability in energy applications.

Interfacing GO with other materials in composite structures presents further challenges. Achieving uniform dispersion and strong interfacial bonding between GO and matrix materials is essential for enhancing mechanical and electrical properties. However, the hydrophilic nature of GO often leads to agglomeration in hydrophobic matrices, compromising the overall performance of composites.

The environmental impact and potential toxicity of GO production and usage also raise concerns. While GO is often touted as an environmentally friendly material, the chemicals used in its synthesis and potential nanoparticle release during use or disposal require careful consideration and mitigation strategies.

Lastly, the translation of laboratory-scale successes to commercial-scale production and application remains a significant challenge. Bridging the gap between promising research results and viable industrial processes demands substantial engineering efforts, particularly in maintaining consistent quality and properties at larger scales.

Addressing these technical challenges is crucial for realizing the full potential of GO in sustainable energy applications. Overcoming these hurdles will require interdisciplinary collaboration, innovative synthesis and processing techniques, and continued research into the fundamental properties and behaviors of GO in various energy-related contexts.

Current GO Solutions

01 Synthesis and production methods of graphene oxide

Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.- Synthesis and production methods of graphene oxide: Various methods for synthesizing and producing graphene oxide are described, including chemical exfoliation, oxidation of graphite, and reduction processes. These techniques aim to create high-quality graphene oxide with controlled properties for different applications.

- Applications of graphene oxide in energy storage: Graphene oxide is utilized in energy storage devices such as batteries and supercapacitors. Its unique properties, including high surface area and conductivity, make it an excellent material for improving the performance and efficiency of these devices.

- Functionalization and modification of graphene oxide: Various methods for functionalizing and modifying graphene oxide are explored to enhance its properties and tailor it for specific applications. These modifications can include chemical treatments, doping, and composite formation with other materials.

- Graphene oxide in environmental applications: Graphene oxide is used in environmental applications such as water purification, pollutant removal, and environmental sensing. Its high adsorption capacity and selectivity make it an effective material for addressing environmental challenges.

- Characterization and analysis techniques for graphene oxide: Various characterization and analysis techniques are employed to study the properties and structure of graphene oxide. These methods include spectroscopic, microscopic, and electrochemical techniques, which help in understanding and optimizing the material for different applications.

02 Applications of graphene oxide in electronics and energy storage

Graphene oxide is utilized in electronic devices and energy storage systems due to its unique electrical and thermal properties. It is incorporated into batteries, supercapacitors, and other electronic components to enhance performance and efficiency.Expand Specific Solutions03 Functionalization and modification of graphene oxide

Techniques for functionalizing and modifying graphene oxide are explored to tailor its properties for specific applications. This includes chemical treatments, doping, and surface modifications to enhance its reactivity, dispersibility, and compatibility with other materials.Expand Specific Solutions04 Graphene oxide-based composites and nanocomposites

The development of graphene oxide-based composites and nanocomposites is described, combining graphene oxide with polymers, metals, or other nanomaterials. These composites exhibit enhanced mechanical, thermal, and electrical properties for various applications.Expand Specific Solutions05 Environmental and biomedical applications of graphene oxide

Graphene oxide is explored for environmental remediation and biomedical applications. Its use in water purification, pollutant removal, drug delivery systems, and biosensors is investigated due to its large surface area and unique chemical properties.Expand Specific Solutions

Key GO Industry Players

The graphene oxide market for sustainable energy is in a growth phase, with increasing research and commercial applications. The market size is expanding rapidly, driven by the material's exceptional properties and potential in energy storage and conversion. Technologically, graphene oxide is advancing from lab-scale to industrial production, with varying levels of maturity across applications. Key players like The University of Manchester, Northwestern University, and Rice University are leading academic research, while companies such as C2CNT LLC and SABIC Global Technologies BV are pushing commercial development. The field is highly competitive, with institutions worldwide contributing to technological advancements, indicating a global race for innovation in graphene oxide-based sustainable energy solutions.

The University of Manchester

Centre National de la Recherche Scientifique

GO Innovations Analysis

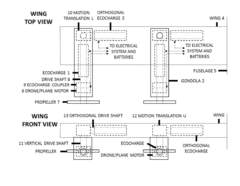

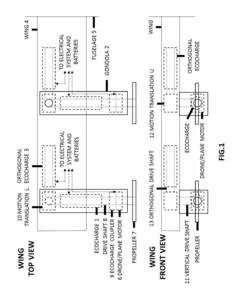

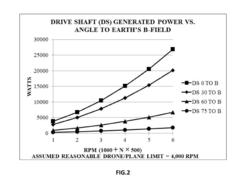

- The use of graphene sheets, with their high conductivity and low resistivity, to convert the earth's magnetic field into electrical energy, mounted orthogonally on planes and drones to maximize energy conversion, allowing continuous power generation day and night.

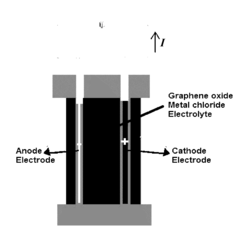

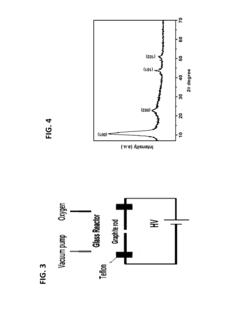

- A graphene oxide-based electrochemical cell with an aqueous electrolyte solution containing water, graphene oxide nanosheets, and a transition metal salt like CuCl2, paired with an aluminum anode and graphite cathode, which enhances energy density and stability, reducing the need for additional energy sources.

Environmental Impact

Graphene oxide (GO) has emerged as a promising material in sustainable energy applications, but its environmental impact must be carefully considered. The production and utilization of GO can have both positive and negative effects on the environment, necessitating a comprehensive assessment of its lifecycle.

One of the primary environmental benefits of GO is its potential to enhance energy efficiency and reduce carbon emissions in various applications. When used in energy storage devices, such as supercapacitors and batteries, GO can significantly improve their performance and longevity. This leads to more efficient energy utilization and potentially reduces the need for frequent replacements, thereby minimizing waste generation and resource consumption.

However, the production of GO raises some environmental concerns. The synthesis process often involves the use of strong oxidizing agents and acids, which can generate hazardous waste if not properly managed. Additionally, the energy-intensive nature of GO production may contribute to increased carbon emissions if not powered by renewable energy sources.

The environmental impact of GO extends to its potential release into ecosystems. While research is ongoing, preliminary studies suggest that GO nanoparticles may have adverse effects on aquatic organisms and soil microbiota. The long-term persistence and potential bioaccumulation of GO in the environment are areas that require further investigation to ensure its sustainable use.

On the positive side, GO's applications in water treatment and environmental remediation show promise for mitigating pollution. Its high adsorption capacity makes it effective in removing contaminants from water and air, potentially contributing to cleaner ecosystems. Furthermore, GO-based materials can be used to develop more efficient catalysts for industrial processes, reducing energy consumption and harmful emissions.

The recyclability and end-of-life management of GO-containing products are crucial aspects of its environmental impact. While GO itself can be recycled to some extent, the composite materials it is often incorporated into may pose challenges for recycling. Developing effective recycling strategies for GO-based products is essential to minimize waste and promote a circular economy approach.

As research progresses, efforts are being made to develop greener synthesis methods for GO, aiming to reduce its environmental footprint. These include using less harmful reagents, implementing closed-loop production systems, and exploring bio-based precursors for GO synthesis. Such advancements are crucial for ensuring that the environmental benefits of GO applications outweigh the potential risks associated with its production and use.

GO Scalability Issues

The scalability of graphene oxide (GO) production remains a significant challenge in its widespread adoption for sustainable energy applications. While laboratory-scale synthesis methods have demonstrated promising results, transitioning to industrial-scale production presents several hurdles that need to be addressed.

One of the primary issues is the lack of standardized, large-scale production methods. Current synthesis techniques, such as the modified Hummers method, are often batch processes that are difficult to scale up without compromising product quality and consistency. The oxidation process, which is crucial for GO production, requires precise control of reaction conditions, including temperature, time, and reagent concentrations. Maintaining these parameters uniformly across larger reaction volumes is technically challenging and often leads to inconsistencies in the final product.

Another scalability concern is the environmental impact of GO production. The traditional synthesis methods involve the use of strong oxidizing agents and acids, which generate hazardous waste and pose potential environmental risks. Scaling up these processes would significantly increase the volume of waste produced, necessitating more robust waste management and treatment systems. This not only adds to the production costs but also raises concerns about the overall sustainability of GO manufacturing.

The energy-intensive nature of GO production also presents scalability challenges. The processes involved in GO synthesis, including oxidation, exfoliation, and purification, require substantial energy inputs. As production scales up, the energy demand increases proportionally, potentially offsetting some of the energy-saving benefits that GO-based technologies aim to provide in sustainable energy applications.

Quality control and characterization of GO at larger scales pose additional challenges. The properties of GO, such as oxygen content, sheet size distribution, and defect density, can significantly impact its performance in energy applications. Ensuring consistent quality across large batches requires advanced analytical techniques and quality control measures, which may be difficult to implement effectively at industrial scales.

Furthermore, the cost of scaling up GO production remains a significant barrier. While the raw material, graphite, is relatively inexpensive, the complex processing steps and specialized equipment required for GO synthesis contribute to high production costs. Achieving economies of scale to make GO economically viable for widespread use in sustainable energy technologies is a critical challenge that needs to be addressed.