Graphene Oxide: Pivotal Advances in Conductivity Applications

Graphene Oxide Evolution and Objectives

Graphene oxide has emerged as a revolutionary material in the field of conductivity applications, marking a significant milestone in the evolution of carbon-based nanomaterials. Since its discovery in the early 2000s, graphene oxide has captivated researchers and industry professionals alike due to its unique properties and potential for widespread application.

The journey of graphene oxide began with the groundbreaking work on graphene by Andre Geim and Konstantin Novoselov in 2004, which later earned them the Nobel Prize in Physics. This discovery paved the way for intensive research into graphene-based materials, including graphene oxide. As a derivative of graphene, graphene oxide offered a more versatile and processable alternative, opening up new avenues for practical applications.

Over the past decade, the focus on graphene oxide has shifted from fundamental research to applied science, with a particular emphasis on enhancing its conductivity properties. This transition has been driven by the growing demand for advanced materials in electronics, energy storage, and sensing technologies. The ability to fine-tune the electrical properties of graphene oxide through various reduction and functionalization methods has been a key factor in its technological progression.

The primary objective in the field of graphene oxide conductivity applications is to develop scalable and cost-effective methods for producing high-quality, highly conductive graphene oxide-based materials. This goal encompasses several key areas of research and development, including optimizing synthesis techniques, improving reduction processes, and enhancing the stability and performance of graphene oxide in various environmental conditions.

Another critical objective is to bridge the gap between laboratory-scale production and industrial-scale manufacturing. This involves addressing challenges related to large-scale synthesis, quality control, and integration into existing manufacturing processes. Researchers and engineers are working tirelessly to develop standardized production methods that can consistently yield graphene oxide with desired conductivity properties.

Furthermore, the field is moving towards exploring novel applications that leverage the unique conductivity characteristics of graphene oxide. This includes its potential use in flexible electronics, transparent conductive films, supercapacitors, and advanced sensors. The ultimate aim is to create a new generation of high-performance, energy-efficient devices that can revolutionize various industries.

As we look to the future, the evolution of graphene oxide in conductivity applications is expected to continue at a rapid pace. With ongoing advancements in nanotechnology and materials science, researchers are poised to unlock even more potential applications and push the boundaries of what is possible with this remarkable material.

Market Demand Analysis for Conductive Materials

The market demand for conductive materials has been experiencing significant growth, driven by the rapid expansion of electronics, energy storage, and advanced manufacturing sectors. Graphene oxide, with its exceptional conductivity properties, is poised to revolutionize this market landscape. The global conductive materials market, valued at approximately $30 billion in 2020, is projected to reach $45 billion by 2026, with a compound annual growth rate (CAGR) of around 6.5%.

The electronics industry remains the largest consumer of conductive materials, accounting for over 40% of the market share. The miniaturization trend in consumer electronics and the increasing adoption of flexible displays and wearable devices are fueling the demand for advanced conductive materials like graphene oxide. These materials offer superior conductivity in thinner and more flexible forms, enabling the development of next-generation electronic devices.

In the energy storage sector, the growing electric vehicle (EV) market and renewable energy systems are creating substantial opportunities for conductive materials. Graphene oxide's potential to enhance battery performance, including improved energy density and faster charging capabilities, is attracting significant attention from battery manufacturers. The EV battery market alone is expected to grow at a CAGR of 25% from 2021 to 2026, indicating a robust demand for advanced conductive materials.

The aerospace and defense industries are also emerging as key consumers of high-performance conductive materials. Graphene oxide's lightweight properties, combined with its excellent conductivity, make it an ideal candidate for developing advanced composite materials for aircraft and military applications. This sector is projected to grow at a CAGR of 4.5% from 2021 to 2026, further driving the demand for innovative conductive solutions.

In the healthcare sector, the increasing use of wearable medical devices and biosensors is creating new opportunities for conductive materials. Graphene oxide's biocompatibility and conductivity make it suitable for developing advanced medical sensors and implantable devices. The global medical sensors market is expected to reach $15 billion by 2025, growing at a CAGR of 8.5%.

Regionally, Asia-Pacific dominates the conductive materials market, accounting for over 45% of the global share. The region's strong presence in electronics manufacturing and rapid industrialization in countries like China and India are the primary drivers. North America and Europe follow, with significant investments in research and development of advanced materials like graphene oxide.

Current Challenges in Graphene Oxide Conductivity

Despite the remarkable potential of graphene oxide (GO) in conductivity applications, several significant challenges persist in fully harnessing its capabilities. One of the primary obstacles is the inherent variability in GO's electrical properties, which stems from the complex interplay between its oxygen-containing functional groups and the graphene lattice. This variability makes it difficult to achieve consistent and predictable conductivity across different batches of GO, hindering its widespread adoption in industrial applications.

Another critical challenge lies in the trade-off between conductivity and other desirable properties of GO. While reducing GO to restore sp2 carbon networks can enhance conductivity, it often comes at the expense of other valuable characteristics, such as hydrophilicity and dispersibility. Striking the right balance between conductivity and these properties remains a significant hurdle for researchers and engineers alike.

The scalability of GO production with consistent quality and conductivity is another major concern. Current synthesis methods often result in GO with varying degrees of oxidation and defect densities, leading to inconsistent electrical properties. This lack of uniformity poses challenges for large-scale manufacturing processes that require precise control over material properties.

Furthermore, the environmental stability of GO-based conductive materials presents a substantial challenge. GO's sensitivity to humidity and temperature fluctuations can lead to changes in its conductivity over time, potentially compromising the long-term performance and reliability of devices incorporating GO.

The integration of GO into existing manufacturing processes and technologies also poses significant challenges. Many industries have established protocols and equipment optimized for traditional conductive materials, and adapting these for GO-based materials often requires substantial modifications and investments.

Lastly, the health and environmental impacts of GO nanoparticles remain a concern. While GO shows promise in various applications, including biomedical fields, the potential long-term effects of GO exposure on human health and the environment are not fully understood. This uncertainty creates regulatory hurdles and necessitates extensive safety studies before widespread adoption can occur.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, chemical engineering, and nanotechnology. Overcoming these obstacles will be crucial for unlocking the full potential of GO in conductivity applications and paving the way for its integration into next-generation electronic devices and energy storage systems.

Current Graphene Oxide Conductivity Solutions

01 Reduction methods to enhance conductivity

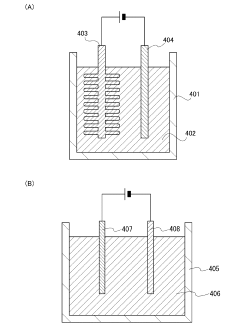

Various reduction methods are employed to enhance the conductivity of graphene oxide. These techniques aim to remove oxygen-containing functional groups, restoring the sp2 carbon network and improving electron mobility. Common reduction methods include chemical, thermal, and electrochemical approaches, each with its own advantages in terms of efficiency and scalability.- Reduction methods to enhance conductivity: Various reduction methods are employed to enhance the conductivity of graphene oxide. These techniques aim to remove oxygen-containing functional groups, restoring the sp2 carbon network and improving electron mobility. Common reduction methods include chemical, thermal, and electrochemical approaches, each with its own advantages in terms of efficiency and scalability.

- Doping and functionalization for conductivity control: Doping and functionalization techniques are used to modify the electronic properties of graphene oxide. By introducing specific atoms or functional groups, the conductivity can be fine-tuned for various applications. This approach allows for the creation of graphene oxide-based materials with tailored electrical characteristics.

- Structural modifications to improve conductivity: Structural modifications of graphene oxide, such as creating defects, controlling layer thickness, or introducing specific patterns, can significantly impact its conductivity. These modifications alter the electronic band structure and charge carrier transport properties, leading to enhanced conductivity in graphene oxide-based materials.

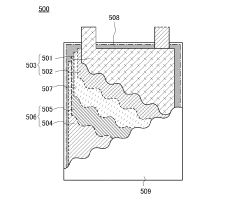

- Composite materials for enhanced conductivity: Graphene oxide is often combined with other materials to create composites with improved conductivity. These composites can leverage the unique properties of graphene oxide while addressing its limitations. Common composite materials include polymers, metals, and other carbon-based materials, resulting in enhanced electrical performance for various applications.

- Temperature and environmental effects on conductivity: The conductivity of graphene oxide is influenced by temperature and environmental factors. Understanding these effects is crucial for developing graphene oxide-based devices and materials with stable electrical properties under various conditions. Research in this area focuses on optimizing conductivity across different temperature ranges and environmental settings.

02 Doping and functionalization for conductivity control

Doping graphene oxide with various elements or functional groups allows for precise control over its conductivity. This approach enables the tailoring of electronic properties for specific applications. Nitrogen doping, in particular, has shown promising results in enhancing conductivity while maintaining other desirable properties of graphene oxide.Expand Specific Solutions03 Structural modifications to improve conductivity

Structural modifications of graphene oxide, such as creating defects, pores, or specific edge configurations, can significantly impact its conductivity. These modifications alter the electronic band structure and can create conductive pathways. Techniques like laser treatment or controlled oxidation are used to achieve desired structural changes.Expand Specific Solutions04 Composite materials for enhanced conductivity

Incorporating graphene oxide into composite materials can lead to enhanced conductivity. By combining graphene oxide with conductive polymers, metal nanoparticles, or other carbon nanomaterials, synergistic effects can be achieved. These composites often exhibit improved electrical properties compared to their individual components.Expand Specific Solutions05 Temperature and environmental effects on conductivity

The conductivity of graphene oxide is significantly influenced by temperature and environmental conditions. Understanding these effects is crucial for developing temperature-sensitive sensors or devices. Research focuses on characterizing conductivity changes under various conditions and developing methods to stabilize or exploit these variations for specific applications.Expand Specific Solutions

Key Players in Graphene Oxide Research

The field of graphene oxide conductivity applications is in a dynamic growth phase, with significant market potential and ongoing technological advancements. The market size is expanding rapidly, driven by increasing demand in electronics, energy storage, and biomedical sectors. Technological maturity varies across applications, with companies like Global Graphene Group, Corning, and Northwestern University leading in research and development. The Centre National de la Recherche Scientifique and The University of Manchester are contributing groundbreaking academic research, while companies such as Nanotek Instruments and Paragraf Ltd. are focusing on commercialization. The competitive landscape is diverse, with both established players and innovative startups vying for market share and technological breakthroughs in this promising field.

Global Graphene Group, Inc.

Corning, Inc.

Breakthrough Patents in Graphene Oxide Conductivity

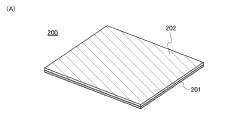

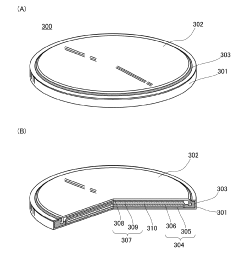

- The use of graphene oxide with a specific carbon-to-oxygen ratio (2.5 to 4) as a conductive additive in the positive electrode active material layer, which is uniformly dispersed and reduced to form a network with high electrical conductivity, enhancing the dispersibility and conductivity of the electrode.

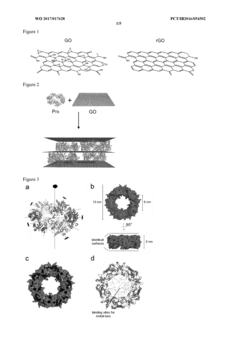

- The use of proteins that assemble into ring-like or nano-tube-like structures with hydrophobic amino acids to self-assemble with graphene oxide, reducing it to a partially reduced form while forming three-dimensional structures, such as hydrogels or aerogels, without the need for drastic conditions or toxic substances, and allowing for the incorporation of metal nanoparticles.

Environmental Impact of Graphene Oxide Production

The production of graphene oxide, while promising for various applications, raises significant environmental concerns that warrant careful consideration. The synthesis process typically involves the oxidation of graphite using strong oxidizing agents, such as potassium permanganate and sulfuric acid, which can lead to the generation of hazardous waste and potentially harmful byproducts.

One of the primary environmental impacts is the release of toxic chemicals during the production process. The use of strong acids and oxidizing agents can result in the emission of volatile organic compounds (VOCs) and other air pollutants. These emissions, if not properly controlled, may contribute to air quality degradation and pose risks to human health and ecosystems in the surrounding areas.

Water pollution is another critical concern associated with graphene oxide production. The synthesis process often requires large volumes of water for washing and purification steps. The resulting wastewater can contain residual chemicals, heavy metals, and nanomaterials, which, if not adequately treated, may contaminate water bodies and harm aquatic life.

The disposal of solid waste generated during graphene oxide production also presents environmental challenges. Residual materials, including unreacted graphite and chemical byproducts, require proper handling and disposal to prevent soil contamination and potential leaching into groundwater.

Energy consumption is a significant factor in the environmental footprint of graphene oxide production. The process often involves high-temperature reactions and energy-intensive purification steps, contributing to increased carbon emissions if the energy source is not renewable.

Furthermore, the potential release of graphene oxide nanoparticles into the environment during production, handling, or disposal raises concerns about their long-term ecological impacts. The unique properties of these nanomaterials, such as their high surface area and reactivity, may lead to unforeseen interactions with biological systems and ecosystems.

To address these environmental concerns, researchers and industry stakeholders are exploring more sustainable production methods. Green synthesis approaches, utilizing environmentally friendly reducing agents and milder reaction conditions, are being developed to minimize the use of harsh chemicals and reduce waste generation.

Efforts are also being made to improve the efficiency of graphene oxide production processes, aiming to reduce energy consumption and optimize resource utilization. Closed-loop systems and advanced wastewater treatment technologies are being implemented to minimize water pollution and promote water recycling.

As the demand for graphene oxide continues to grow, it is crucial to prioritize the development of environmentally responsible production methods and implement stringent safety measures to mitigate potential ecological risks. Ongoing research and regulatory frameworks will play a vital role in ensuring the sustainable production and application of this promising material.

Scalability of Graphene Oxide Manufacturing

The scalability of graphene oxide (GO) manufacturing is a critical factor in its widespread adoption for conductivity applications. Current production methods, such as the modified Hummers method, have been successful in laboratory settings but face significant challenges when scaled up to industrial levels.

One of the primary obstacles in large-scale GO production is maintaining consistent quality across batches. As production volumes increase, ensuring uniform oxidation and exfoliation becomes increasingly difficult. This variability can lead to inconsistent electrical and mechanical properties in the final product, potentially limiting its effectiveness in conductivity applications.

Another challenge is the environmental impact of GO manufacturing. The traditional Hummers method involves the use of strong oxidizing agents and acids, which can be hazardous and produce toxic byproducts. Scaling up production amplifies these environmental concerns, necessitating the development of more sustainable and eco-friendly production processes.

Cost-effectiveness is also a crucial consideration in GO scalability. While laboratory-scale production may be feasible, the economics of large-scale manufacturing need to be carefully evaluated. The high cost of raw materials, especially high-quality graphite, and the energy-intensive nature of GO production can significantly impact the economic viability of mass production.

Recent advancements in GO manufacturing have shown promise in addressing these scalability issues. Continuous flow reactors, for instance, have demonstrated potential for increasing production volumes while maintaining product quality. These systems allow for better control over reaction conditions and can potentially reduce waste and energy consumption.

Innovative approaches to GO synthesis, such as electrochemical exfoliation and microwave-assisted methods, are also being explored for their scalability potential. These techniques offer the possibility of faster production times and reduced chemical usage, which could contribute to more efficient large-scale manufacturing processes.

The development of automated production lines and in-line quality control systems is another area of focus for improving GO scalability. These technologies can help maintain consistent product quality and reduce human error in the manufacturing process, which becomes increasingly important as production scales up.

As research continues, the focus on scalable GO manufacturing is likely to intensify. The successful development of efficient, cost-effective, and environmentally friendly large-scale production methods will be crucial in unlocking the full potential of GO in conductivity applications across various industries.