Graphene Oxide: Redefining Photovoltaic Efficiency

Graphene Oxide PV Evolution and Objectives

Graphene oxide has emerged as a revolutionary material in the field of photovoltaics, promising to redefine the efficiency standards of solar energy conversion. The evolution of graphene oxide in photovoltaic applications traces back to the early 2010s when researchers first recognized its potential as a transparent conductive electrode. Since then, the trajectory of graphene oxide in solar technology has been marked by rapid advancements and breakthroughs.

The primary objective in utilizing graphene oxide for photovoltaics is to overcome the limitations of traditional silicon-based solar cells. These limitations include high production costs, rigidity, and efficiency plateaus. Graphene oxide offers a pathway to ultra-thin, flexible, and potentially more efficient solar cells. The material's unique properties, such as high optical transmittance and excellent electrical conductivity, make it an ideal candidate for next-generation photovoltaic devices.

One of the key evolutionary milestones in graphene oxide photovoltaics was the development of solution-processable graphene oxide, which enabled easier and more cost-effective manufacturing processes. This breakthrough opened doors for large-scale production and integration into existing solar cell architectures. Subsequently, researchers focused on enhancing the electron transport properties of graphene oxide, leading to improved charge collection and overall cell efficiency.

The current technological landscape is witnessing a shift towards hybrid systems that combine graphene oxide with other advanced materials. These include perovskites, quantum dots, and organic semiconductors. The goal is to create synergistic effects that can push the boundaries of photovoltaic efficiency beyond what is achievable with single-material systems.

Looking ahead, the objectives for graphene oxide in photovoltaics are multifaceted. Researchers aim to achieve conversion efficiencies exceeding 30%, a significant leap from current standards. There is also a strong focus on developing graphene oxide-based solar cells that are not only highly efficient but also durable, environmentally friendly, and suitable for diverse applications, including building-integrated photovoltaics and wearable electronics.

Another critical objective is to optimize the scalability of graphene oxide production and its integration into solar cell manufacturing processes. This involves refining synthesis methods, improving quality control, and developing standardized procedures for incorporating graphene oxide into various solar cell architectures. The ultimate aim is to make graphene oxide-based photovoltaics commercially viable and competitive with traditional solar technologies.

Solar Market Demand Analysis

The global solar energy market has experienced significant growth in recent years, driven by increasing environmental concerns, government incentives, and technological advancements. The demand for photovoltaic (PV) systems continues to rise as countries worldwide aim to reduce their carbon footprint and transition towards renewable energy sources.

In 2022, the global solar PV market reached a total installed capacity of over 1 terawatt (TW), with annual installations exceeding 200 gigawatts (GW). This growth trend is expected to continue, with projections suggesting that the market could reach 3 TW of cumulative installed capacity by 2030. The increasing demand is fueled by both utility-scale and distributed solar installations, with residential and commercial sectors showing strong adoption rates.

The market demand for solar energy is not uniform across regions. China remains the largest market, accounting for a substantial portion of global installations. Other key markets include the United States, Europe, India, and Japan. Emerging markets in Southeast Asia, Latin America, and Africa are also showing promising growth potential as solar technology becomes more affordable and accessible.

Cost reduction has been a significant driver of solar market demand. The levelized cost of electricity (LCOE) for solar PV has decreased dramatically over the past decade, making it competitive with conventional energy sources in many regions. This trend is expected to continue as technology improves and economies of scale are realized.

The integration of energy storage solutions with solar PV systems is creating new market opportunities. The ability to store and dispatch solar energy on demand addresses the intermittency issue and enhances the value proposition of solar installations. This has led to increased demand for solar-plus-storage systems in both residential and commercial applications.

Corporate procurement of renewable energy, including solar power, has become a significant market driver. Many large corporations have set ambitious sustainability goals, leading to increased demand for utility-scale solar projects and power purchase agreements (PPAs). This trend is expected to continue as more businesses commit to reducing their carbon emissions.

Government policies and incentives continue to play a crucial role in shaping solar market demand. Feed-in tariffs, tax credits, and renewable portfolio standards have been instrumental in driving adoption in many countries. However, as the industry matures, there is a gradual shift towards market-based mechanisms and subsidy-free solar projects.

The demand for higher efficiency solar cells is a key market trend, driving research and development in advanced materials and technologies. This is where innovations like graphene oxide in photovoltaics could potentially have a significant impact, as improved efficiency can lead to better performance and lower costs, further stimulating market demand.

Graphene Oxide PV Challenges

The integration of graphene oxide (GO) into photovoltaic (PV) systems presents both promising opportunities and significant challenges. While GO offers exceptional electrical and optical properties that could potentially revolutionize solar cell efficiency, several hurdles must be overcome to fully harness its potential in PV applications.

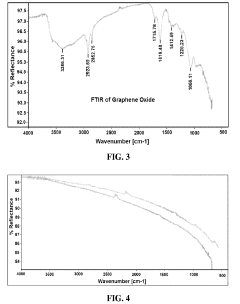

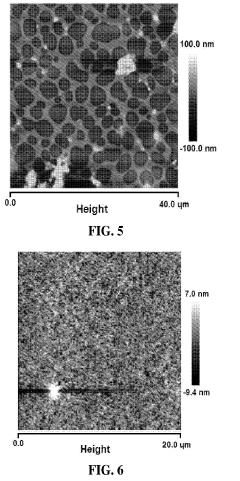

One of the primary challenges is the precise control of GO's oxidation level and structural defects. The degree of oxidation significantly impacts GO's electronic properties, affecting its conductivity and energy band structure. Achieving a consistent and optimal oxidation state across large-scale production remains a formidable task, as even slight variations can lead to substantial differences in PV performance.

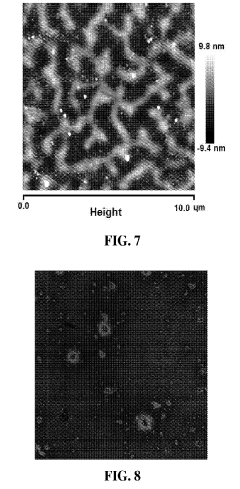

Another critical issue is the integration of GO into existing PV architectures. While GO shows promise as an electron transport layer or as a component in active layers, incorporating it seamlessly into current manufacturing processes without compromising the integrity of other materials or overall device structure is complex. This integration challenge is further compounded by GO's tendency to agglomerate, which can lead to non-uniform distribution and reduced effectiveness.

The stability of GO in PV devices under long-term operation and various environmental conditions is also a significant concern. GO's susceptibility to reduction under certain conditions can alter its properties over time, potentially leading to degradation in solar cell performance. Developing strategies to stabilize GO and maintain its desired characteristics throughout the operational lifetime of PV devices is crucial for commercial viability.

Furthermore, the scalability of GO production for large-area PV applications presents a substantial challenge. Current methods for producing high-quality GO are often limited in scale and can be costly. Developing economically viable processes for mass production of GO with consistent quality and properties is essential for its widespread adoption in the PV industry.

The environmental impact and toxicity of GO production and disposal also need careful consideration. While graphene-based materials are often touted for their potential to enhance sustainability, the processes involved in GO synthesis and the long-term environmental effects of GO-containing PV devices require thorough assessment and mitigation strategies.

Lastly, the optimization of GO's optical and electronic properties specifically for PV applications remains an ongoing challenge. While GO's high transparency and conductivity are beneficial, fine-tuning these properties to maximize light absorption, charge separation, and electron transport within the specific context of solar cells requires extensive research and development efforts.

Current Graphene Oxide PV Solutions

01 Graphene oxide-based photovoltaic materials

Graphene oxide is used as a key component in photovoltaic materials to enhance efficiency. Its unique properties, such as high conductivity and large surface area, contribute to improved charge transport and light absorption in solar cells.- Graphene oxide-based photovoltaic materials: Graphene oxide is used as a key component in photovoltaic materials to enhance efficiency. Its unique properties, such as high conductivity and large surface area, contribute to improved charge transport and light absorption in solar cells.

- Doping and functionalization of graphene oxide: Various doping and functionalization techniques are applied to graphene oxide to further improve its photovoltaic properties. These modifications can enhance light absorption, charge separation, and overall solar cell performance.

- Graphene oxide-based composite materials: Composite materials incorporating graphene oxide are developed to create synergistic effects and improve photovoltaic efficiency. These composites often combine graphene oxide with other nanomaterials or polymers to enhance overall performance.

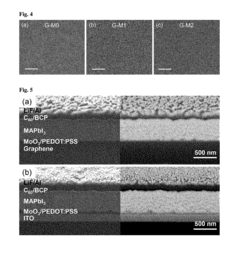

- Fabrication methods for graphene oxide photovoltaic devices: Novel fabrication techniques are developed to optimize the integration of graphene oxide into photovoltaic devices. These methods focus on improving the quality, uniformity, and scalability of graphene oxide-based solar cells.

- Characterization and performance evaluation: Advanced characterization techniques and performance evaluation methods are employed to assess and optimize the efficiency of graphene oxide-based photovoltaic devices. These approaches help in understanding the underlying mechanisms and identifying areas for improvement.

02 Doping and functionalization of graphene oxide

Various methods of doping and functionalizing graphene oxide are employed to tailor its electronic properties and improve photovoltaic performance. This includes incorporating heteroatoms or attaching functional groups to enhance charge separation and reduce recombination.Expand Specific Solutions03 Graphene oxide-based composite materials

Composite materials incorporating graphene oxide are developed to enhance photovoltaic efficiency. These composites often combine graphene oxide with other nanomaterials or polymers to create synergistic effects and improve overall device performance.Expand Specific Solutions04 Graphene oxide in perovskite solar cells

Graphene oxide is utilized in perovskite solar cells to enhance stability and efficiency. It can serve as an electron transport layer, hole transport layer, or as an additive in the perovskite layer itself, contributing to improved charge extraction and reduced recombination.Expand Specific Solutions05 Graphene oxide synthesis and processing for photovoltaic applications

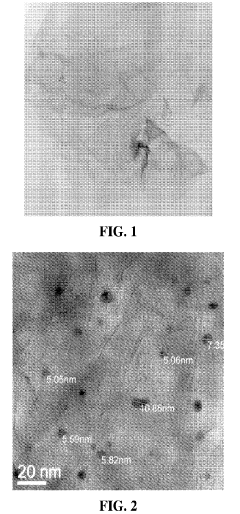

Specialized methods for synthesizing and processing graphene oxide are developed to optimize its properties for photovoltaic applications. This includes controlling the degree of oxidation, reducing defects, and improving the quality of graphene oxide sheets to enhance overall solar cell efficiency.Expand Specific Solutions

Key Players in Graphene PV Industry

The field of graphene oxide in photovoltaics is experiencing rapid growth, transitioning from early-stage research to potential commercial applications. The market size is expanding, driven by the increasing demand for high-efficiency solar cells. Technologically, graphene oxide is showing promise in enhancing photovoltaic efficiency, with varying levels of maturity across different applications. Key players like Massachusetts Institute of Technology, California Institute of Technology, and the Chinese Academy of Sciences are at the forefront, conducting advanced research. Companies such as Panasonic and Sumitomo Chemical are also actively involved, indicating a growing industrial interest. The technology is still evolving, with academic institutions and industry collaborating to overcome challenges and realize its full potential in solar energy applications.

Chinese Academy of Sciences Institute of Physics

King Abdullah University of Science & Technology

Graphene Oxide PV Innovations

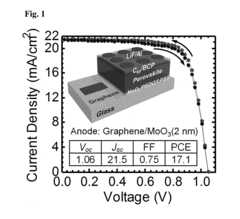

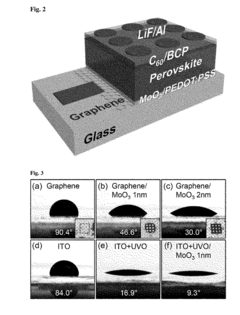

- A perovskite-based solar cell design utilizing a flexible graphene electrode as a substitute for traditional transparent conducting oxide electrodes, with a structure that includes a graphene layer as a transparent conductive electrode, a hole transport layer, a perovskite layer, and a cathode, optionally with a metal oxide layer, and using a lead halide adduct for perovskite preparation, achieving efficient and flexible operation on polymer substrates.

- Incorporating graphene oxide or reduced graphene oxide into the active layer of solar cells and fuel cells, along with metal or metal oxide modifications, to enhance the organization of polymer structures and improve charge transport, using a homogenous dispersion with poly(3-hexylthiophene-2,5-diyl) (P3HT) and 1-(3-methoxycarbonyl)propyl-1-phenyl[6,6]C61 (PCBM) with additional polymers like sulfonated polystyrene (PSS) or para-methoxy-N-methylamphetamine (PMMA), and functionalizing graphene with metals like gold, platinum, or palladium.

Environmental Impact Assessment

The integration of graphene oxide in photovoltaic technology brings both promising advancements and potential environmental concerns. As this innovative material redefines solar cell efficiency, it is crucial to assess its environmental impact throughout its lifecycle.

During the production phase, the synthesis of graphene oxide involves chemical processes that may generate hazardous byproducts. The use of strong oxidizing agents and acids in the modified Hummers method, a common production technique, raises concerns about chemical waste management and potential environmental contamination. However, ongoing research aims to develop greener synthesis methods, which could significantly reduce these environmental risks.

The application of graphene oxide in solar cells offers substantial environmental benefits. By enhancing photovoltaic efficiency, it contributes to increased clean energy production and reduced reliance on fossil fuels. This improvement in energy conversion efficiency translates to a smaller carbon footprint per unit of electricity generated, aligning with global efforts to mitigate climate change.

Durability is another critical factor in environmental impact assessment. Graphene oxide-enhanced solar cells potentially exhibit longer lifespans and improved resistance to environmental degradation. This increased durability could lead to reduced waste generation and less frequent replacement of solar panels, thereby minimizing the environmental burden associated with manufacturing and disposal.

However, the end-of-life management of graphene oxide-containing solar panels presents new challenges. The nanomaterial nature of graphene oxide raises questions about its potential release into the environment during disposal or recycling processes. Research is needed to develop safe and effective recycling methods that can recover valuable materials while preventing nanoparticle pollution.

The potential bioaccumulation and ecotoxicity of graphene oxide nanoparticles in aquatic and terrestrial ecosystems remain areas of concern. While initial studies suggest low acute toxicity, the long-term effects of chronic exposure to these nanoparticles on various organisms and ecosystems require further investigation.

In terms of resource consumption, the production of graphene oxide is less energy-intensive compared to traditional silicon-based solar cell materials. This could lead to a reduced environmental footprint in the manufacturing stage. Additionally, the material's high conductivity and flexibility open possibilities for more efficient and versatile solar panel designs, potentially reducing overall material usage in solar energy systems.

As the technology advances, ongoing life cycle assessments and environmental monitoring will be crucial to fully understand and mitigate any potential negative impacts while maximizing the environmental benefits of graphene oxide in photovoltaic applications. Balancing technological progress with environmental stewardship will be key to ensuring the sustainable development of this promising solar energy innovation.

Graphene PV Manufacturing Scalability

The scalability of graphene-based photovoltaic (PV) manufacturing remains a critical challenge in the widespread adoption of this promising technology. While graphene oxide has shown remarkable potential in enhancing the efficiency of solar cells, transitioning from laboratory-scale production to industrial-scale manufacturing presents several hurdles.

One of the primary obstacles is the development of cost-effective and reliable methods for large-scale synthesis of high-quality graphene oxide. Current production techniques, such as the modified Hummers method, are limited in their scalability and often result in inconsistent product quality. Researchers are exploring alternative approaches, including electrochemical exfoliation and chemical vapor deposition, to overcome these limitations.

Another significant challenge lies in the integration of graphene oxide into existing PV manufacturing processes. The delicate nature of graphene oxide sheets and their tendency to agglomerate pose difficulties in achieving uniform dispersion and deposition on solar cell substrates. Innovative coating techniques and surface modification strategies are being investigated to address these issues and ensure consistent performance across large-area devices.

The optimization of graphene oxide's optoelectronic properties for PV applications at scale is also a key focus area. Controlling the degree of oxidation, defect density, and sheet size distribution becomes increasingly complex as production volumes increase. Advanced characterization techniques and in-line quality control measures are being developed to maintain the desired material properties throughout the manufacturing process.

Environmental and safety considerations present additional challenges in scaling up graphene oxide production for PV applications. The use of strong oxidizing agents and acids in traditional synthesis methods raises concerns about waste management and worker safety. Sustainable production routes and green chemistry approaches are being explored to mitigate these issues and ensure compliance with environmental regulations.

Despite these challenges, significant progress has been made in recent years towards improving the scalability of graphene-based PV manufacturing. Collaborative efforts between academic institutions and industry partners have led to the development of pilot-scale production facilities and demonstration projects. These initiatives are crucial in bridging the gap between laboratory research and commercial viability.

As the field continues to evolve, addressing the scalability challenges of graphene PV manufacturing will be essential in realizing the full potential of this technology. Ongoing research and development efforts are focused on optimizing production processes, enhancing material quality, and reducing costs to pave the way for large-scale implementation of graphene-enhanced solar cells in the global energy landscape.