Graphene Oxide: Transforming Membrane Technologies

Graphene Oxide Membranes: Evolution and Objectives

Graphene oxide membranes represent a revolutionary advancement in membrane technology, offering unprecedented potential for various separation and filtration applications. The evolution of these membranes can be traced back to the discovery of graphene in 2004, which sparked intense research into its derivatives, including graphene oxide.

The primary objective of graphene oxide membrane development is to harness the unique properties of this two-dimensional material to create highly efficient, selective, and durable membranes. These membranes aim to address critical challenges in water purification, gas separation, and molecular sieving, offering solutions that surpass the capabilities of conventional membrane technologies.

Over the past decade, significant progress has been made in understanding the fundamental properties of graphene oxide and its behavior in membrane structures. Researchers have focused on optimizing the synthesis methods, controlling the interlayer spacing, and functionalizing the graphene oxide sheets to enhance their performance in specific applications.

One of the key goals in this field is to develop graphene oxide membranes with precise control over pore size and distribution, enabling molecular-level separation. This has led to breakthroughs in water desalination, where graphene oxide membranes have demonstrated exceptional salt rejection rates while maintaining high water permeability.

Another important objective is to improve the stability and longevity of graphene oxide membranes under various operational conditions. This includes enhancing their resistance to fouling, chemical degradation, and mechanical stress, which are critical factors for practical industrial applications.

The evolution of graphene oxide membranes has also been driven by the need for scalable and cost-effective production methods. Researchers are exploring various techniques to fabricate large-area membranes with consistent properties, a crucial step towards commercialization.

As the field progresses, there is an increasing focus on developing multifunctional graphene oxide membranes that can simultaneously perform multiple separation tasks or incorporate additional functionalities such as antimicrobial properties or self-cleaning capabilities.

The future objectives for graphene oxide membrane technology include further improving selectivity and permeability, expanding the range of applications to include emerging fields such as energy storage and biomedical devices, and addressing environmental concerns by developing sustainable production methods and exploring the potential for membrane recycling.

Market Demand Analysis for GO Membrane Applications

The market demand for Graphene Oxide (GO) membrane applications has been experiencing significant growth in recent years, driven by the unique properties and versatile applications of this advanced material. GO membranes have shown remarkable potential in various sectors, including water purification, gas separation, and energy storage, leading to a surge in research and development activities.

In the water treatment industry, GO membranes have garnered substantial attention due to their exceptional filtration capabilities. The global water purification market, valued at $29.3 billion in 2020, is projected to reach $47.5 billion by 2026, with GO membranes poised to capture a significant share. The increasing demand for clean water, coupled with stringent environmental regulations, has created a favorable environment for the adoption of GO membrane technologies.

The gas separation sector presents another lucrative market for GO membranes. With the growing emphasis on reducing carbon emissions and improving energy efficiency, industries are seeking advanced separation technologies. The global gas separation membrane market is expected to grow at a CAGR of 6.8% from 2021 to 2028, with GO membranes emerging as a promising solution for applications such as CO2 capture and hydrogen purification.

In the energy storage domain, GO membranes have shown potential in enhancing the performance of batteries and supercapacitors. The global energy storage market is projected to reach $546 billion by 2035, with a significant portion attributed to advanced materials like GO. The automotive and electronics industries, in particular, are driving the demand for high-performance energy storage solutions.

The pharmaceutical and biomedical sectors are also exploring GO membrane applications for drug delivery systems and biosensors. The global drug delivery market, valued at $1,430 billion in 2020, is expected to grow at a CAGR of 7.8% from 2021 to 2028, presenting opportunities for GO membrane technologies.

Despite the promising market outlook, challenges such as scalability, cost-effectiveness, and long-term stability of GO membranes need to be addressed to facilitate widespread commercial adoption. Ongoing research and development efforts are focused on overcoming these hurdles, with collaborations between academic institutions and industry players driving innovation in this field.

As the technology matures and production processes become more efficient, the market demand for GO membrane applications is expected to accelerate. The growing emphasis on sustainability and environmental protection across industries will likely fuel the adoption of GO membrane technologies in the coming years, positioning them as a transformative force in membrane-based separation and filtration processes.

Current Challenges in GO Membrane Technology

Despite the promising potential of Graphene Oxide (GO) in membrane technologies, several significant challenges persist in its practical implementation. One of the primary obstacles is the scalability of GO membrane production. While laboratory-scale synthesis has shown remarkable results, translating these processes to industrial-scale manufacturing remains problematic. The current methods for producing large-area, defect-free GO membranes with consistent quality and performance are limited, hindering widespread commercial adoption.

Another critical challenge lies in the long-term stability of GO membranes. When exposed to water or humid environments, GO membranes tend to swell, leading to changes in their interlayer spacing and, consequently, their separation performance. This instability affects the membrane's selectivity and permeability over time, reducing its effectiveness in real-world applications. Researchers are actively seeking ways to enhance the structural stability of GO membranes without compromising their unique properties.

The precise control of GO membrane thickness and pore size distribution presents another significant hurdle. The separation performance of GO membranes is highly dependent on these parameters, yet achieving consistent and uniform control across large membrane areas remains challenging. This variability can lead to inconsistent separation results and reduced overall efficiency in industrial settings.

Furthermore, the fouling propensity of GO membranes poses a substantial challenge to their long-term operation. While GO exhibits some inherent anti-fouling properties, prolonged exposure to complex feed streams can still result in membrane fouling, necessitating frequent cleaning or replacement. Developing effective anti-fouling strategies that do not compromise the membrane's separation capabilities is crucial for the technology's practical implementation.

The environmental impact and potential toxicity of GO materials also raise concerns. As nanomaterials, the long-term effects of GO on ecosystems and human health are not fully understood. Ensuring the safe production, use, and disposal of GO membranes is essential for their sustainable application in water treatment and other industries.

Lastly, the cost-effectiveness of GO membrane technology compared to existing solutions remains a significant challenge. While GO membranes offer superior performance in many aspects, the current production costs and scalability issues make them less economically viable for large-scale applications. Bridging this gap between performance and cost-effectiveness is crucial for the widespread adoption of GO membrane technology in various industries.

State-of-the-Art GO Membrane Fabrication Techniques

01 Preparation methods of graphene oxide membranes

Various techniques are employed to prepare graphene oxide membranes, including chemical vapor deposition, solution-based methods, and exfoliation processes. These methods aim to create thin, uniform layers of graphene oxide with controlled porosity and surface properties, suitable for membrane applications.- Fabrication methods for graphene oxide membranes: Various techniques are employed to fabricate graphene oxide membranes, including layer-by-layer assembly, vacuum filtration, and spin coating. These methods allow for precise control over membrane thickness and structure, resulting in improved performance for applications such as water purification and gas separation.

- Functionalization of graphene oxide membranes: Graphene oxide membranes can be functionalized with various chemical groups or nanoparticles to enhance their properties. This modification can improve selectivity, permeability, and stability of the membranes for specific applications such as desalination, heavy metal removal, or gas separation.

- Applications in water treatment and purification: Graphene oxide membranes show promising results in water treatment and purification processes. They exhibit high selectivity and permeability for water molecules while effectively rejecting contaminants such as salts, organic pollutants, and heavy metals. These membranes are being developed for applications in desalination, wastewater treatment, and drinking water purification.

- Gas separation and barrier properties: Graphene oxide membranes demonstrate excellent gas separation capabilities and barrier properties. They can selectively allow certain gases to pass through while blocking others, making them suitable for applications in gas purification, carbon capture, and packaging materials with enhanced barrier properties.

- Composite membranes incorporating graphene oxide: Researchers are developing composite membranes that incorporate graphene oxide with other materials such as polymers or inorganic compounds. These composite membranes aim to combine the unique properties of graphene oxide with the advantages of other materials, resulting in enhanced performance and durability for various separation and filtration applications.

02 Functionalization of graphene oxide membranes

Graphene oxide membranes can be functionalized with various chemical groups or nanoparticles to enhance their performance in specific applications. This modification can improve selectivity, permeability, or anti-fouling properties of the membrane, making it more effective for water purification, gas separation, or other filtration processes.Expand Specific Solutions03 Applications in water treatment and desalination

Graphene oxide membranes show promising results in water treatment and desalination processes. Their unique structure allows for efficient removal of contaminants and salt ions while maintaining high water flux. These membranes can potentially revolutionize water purification technologies, offering more energy-efficient and cost-effective solutions.Expand Specific Solutions04 Gas separation and barrier properties

Graphene oxide membranes exhibit excellent gas separation capabilities and barrier properties. Their molecular sieving effect allows for selective permeation of certain gases while blocking others. This makes them suitable for applications in gas purification, carbon capture, and packaging materials with enhanced gas barrier properties.Expand Specific Solutions05 Composite membranes incorporating graphene oxide

Graphene oxide is often incorporated into composite membrane structures to enhance overall performance. These composites combine the unique properties of graphene oxide with other materials such as polymers or inorganic compounds, resulting in membranes with improved mechanical strength, chemical stability, and separation efficiency for various applications.Expand Specific Solutions

Key Players in GO Membrane Research and Production

The graphene oxide membrane technology sector is in a dynamic growth phase, with significant market potential and ongoing research across academia and industry. The global market for graphene-based membranes is expanding rapidly, driven by increasing demand for water purification and desalination solutions. While the technology is still evolving, it has reached a moderate level of maturity, with key players like Massachusetts Institute of Technology, The University of Manchester, and Nitto Denko Corp. leading research and development efforts. Universities such as Tsinghua University and Rice University are also making substantial contributions, pushing the boundaries of graphene oxide membrane applications. The competitive landscape is characterized by a mix of academic institutions and commercial entities, with collaborations between the two sectors accelerating technological advancements and market adoption.

Massachusetts Institute of Technology

William Marsh Rice University

Breakthrough Patents in GO Membrane Technology

- The development of reduced graphene oxide (rGO) nanofiltration membranes fabricated using an integrated roll-to-roll (R2R) process with aqueous-phase slot-die coating and vacuum filtration, eliminating the need for organic solvents and volatile organic compounds (VOCs, and enabling the production of high-quality membranes with excellent stability and water flux.

- Development of crosslinked graphene oxide membranes with chemical linkages that maintain a stable interlayer spacing and charge neutrality, formed through functional group interconversion reactions and activation processes, enabling resistance to environmental degradation and fouling.

Environmental Impact of GO Membrane Production

The production of graphene oxide (GO) membranes has significant environmental implications that warrant careful consideration. The manufacturing process of GO membranes involves several stages, each with potential environmental impacts.

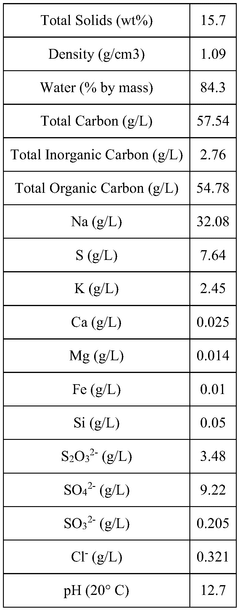

The initial production of graphene oxide requires the oxidation of graphite, typically using strong oxidizing agents such as potassium permanganate and sulfuric acid. This process generates hazardous waste and potentially harmful byproducts, including heavy metals and acidic solutions. Proper waste management and treatment are crucial to mitigate the environmental risks associated with these chemicals.

Water consumption is another critical factor in GO membrane production. The synthesis and purification of GO require substantial amounts of water, potentially straining local water resources in areas of production. Additionally, the wastewater generated during these processes may contain trace amounts of graphene oxide particles, which could have unforeseen impacts on aquatic ecosystems if not properly treated before discharge.

Energy consumption is a significant concern in GO membrane manufacturing. The production process, including oxidation, exfoliation, and membrane formation, requires considerable energy inputs. The source of this energy plays a crucial role in determining the overall environmental footprint of GO membrane production. Reliance on fossil fuels for energy generation could contribute to increased greenhouse gas emissions and air pollution.

The use of solvents in GO membrane production also raises environmental concerns. Organic solvents used in the process can be volatile and potentially harmful to both human health and the environment. Proper handling, storage, and disposal of these solvents are essential to prevent air and soil contamination.

On a positive note, the potential for GO membranes to improve water treatment and desalination processes could lead to significant environmental benefits. These membranes have shown promise in reducing energy consumption and improving efficiency in water purification, which could offset some of the environmental impacts associated with their production.

As the technology advances, there is a growing focus on developing more environmentally friendly production methods for GO membranes. Research into green synthesis techniques, such as using less harmful oxidizing agents or exploring bio-based alternatives, aims to reduce the environmental impact of production processes. Additionally, efforts to improve recycling and recovery of materials used in GO membrane production could help minimize waste and resource consumption.

Scalability and Commercialization Prospects

The scalability and commercialization prospects for graphene oxide (GO) in membrane technologies are promising, yet face several challenges. The unique properties of GO, including its high surface area, mechanical strength, and tunable functionality, make it an attractive material for advanced membrane applications. However, transitioning from laboratory-scale production to industrial-scale manufacturing remains a significant hurdle.

One of the primary challenges in scaling up GO membrane production is the development of cost-effective and efficient synthesis methods. Current production techniques, such as the modified Hummers method, are often time-consuming and involve hazardous chemicals. Researchers are exploring alternative approaches, such as electrochemical exfoliation and green synthesis methods, to address these issues and make large-scale production more feasible.

Another critical aspect of scalability is the ability to produce consistent, high-quality GO sheets with controlled thickness and lateral dimensions. Achieving uniformity in GO properties is essential for ensuring reliable membrane performance across large-scale production batches. Advances in nanomaterial characterization techniques and quality control processes are crucial for overcoming this challenge.

The integration of GO membranes into existing manufacturing processes and infrastructure presents another hurdle. Developing compatible fabrication techniques that can be seamlessly incorporated into current membrane production lines is vital for widespread adoption. This may require modifications to existing equipment or the development of new manufacturing processes specifically tailored for GO-based membranes.

From a commercialization perspective, the potential applications of GO membranes span various industries, including water treatment, gas separation, and energy storage. The growing demand for efficient and sustainable separation technologies in these sectors provides a significant market opportunity for GO-based membranes. However, competing with established membrane technologies and materials requires demonstrating clear advantages in performance, durability, and cost-effectiveness.

Addressing regulatory and safety concerns is also crucial for successful commercialization. As a relatively new material, GO must undergo rigorous testing and certification processes to ensure its safety for use in applications such as water purification and food packaging. Collaborations between academic institutions, industry partners, and regulatory bodies are essential for establishing standardized protocols and guidelines for GO membrane production and implementation.

Despite these challenges, several companies and research institutions are making significant strides in scaling up GO membrane technologies. Investments in pilot-scale production facilities and strategic partnerships between material suppliers and membrane manufacturers are paving the way for commercial-scale applications. As production processes become more refined and cost-effective, the market penetration of GO-based membranes is expected to increase, potentially revolutionizing various separation and filtration processes across multiple industries.