How to Boost Electromagnetic Interference Shielding with GO?

GO EMI Shielding Background and Objectives

Electromagnetic interference (EMI) shielding has become increasingly crucial in modern electronic devices and systems. As technology advances and electronic components become more compact and powerful, the need for effective EMI shielding solutions has grown exponentially. Graphene oxide (GO) has emerged as a promising material for enhancing EMI shielding due to its unique properties and versatile nature.

The field of EMI shielding has evolved significantly over the past few decades, driven by the rapid growth of wireless communications, high-speed electronics, and the Internet of Things (IoT). Traditional metallic shields, while effective, often face limitations in terms of weight, flexibility, and integration with modern electronic designs. This has led researchers and engineers to explore alternative materials and techniques for EMI shielding, with a focus on lightweight, flexible, and highly effective solutions.

Graphene oxide, a derivative of graphene, has garnered significant attention in the scientific community due to its exceptional electrical, mechanical, and thermal properties. The two-dimensional structure of GO, combined with its high surface area and tunable electronic properties, makes it an ideal candidate for EMI shielding applications. The ability to functionalize and modify GO further enhances its potential for tailored EMI shielding solutions across various industries and applications.

The primary objective of research into GO-based EMI shielding is to develop innovative materials and composites that can effectively attenuate electromagnetic waves across a wide frequency range. This includes exploring various synthesis methods, optimizing GO's structure and composition, and investigating its integration with other materials to create hybrid shielding solutions. Additionally, researchers aim to enhance the mechanical properties and environmental stability of GO-based shields to ensure their long-term performance in real-world applications.

Another critical goal is to address the scalability and cost-effectiveness of GO production and its incorporation into EMI shielding materials. As the demand for advanced EMI shielding solutions continues to grow, developing economically viable and industrially scalable processes for GO-based shields becomes paramount. This involves optimizing synthesis techniques, exploring new manufacturing methods, and identifying potential synergies with existing materials and production processes.

Furthermore, the research community is focused on understanding the fundamental mechanisms of EMI shielding in GO-based materials. This includes investigating the roles of various factors such as GO sheet size, oxygen content, defects, and interlayer spacing on shielding effectiveness. By gaining deeper insights into these mechanisms, researchers aim to design more efficient and targeted GO-based EMI shielding solutions for specific applications and frequency ranges.

Market Analysis for GO-based EMI Shielding

The market for GO-based EMI shielding is experiencing significant growth, driven by the increasing demand for electronic devices and the need for effective electromagnetic interference protection. The global EMI shielding market is projected to reach substantial value in the coming years, with GO-based solutions playing a crucial role in this expansion.

The automotive sector represents a key market for GO-based EMI shielding, as modern vehicles incorporate more electronic components and systems. The rise of electric and autonomous vehicles further amplifies this demand, as these advanced vehicles require robust EMI protection to ensure proper functioning of their sensitive electronic systems.

In the consumer electronics industry, GO-based EMI shielding finds applications in smartphones, tablets, laptops, and wearable devices. As these devices become more compact and powerful, the need for effective EMI shielding solutions grows. GO-based materials offer advantages in terms of lightweight properties and flexibility, making them ideal for integration into sleek, modern designs.

The aerospace and defense sectors also present significant opportunities for GO-based EMI shielding. These industries require high-performance materials that can withstand extreme conditions while providing superior electromagnetic protection. GO-based solutions offer potential advantages in terms of weight reduction and enhanced shielding effectiveness.

The healthcare industry is another emerging market for GO-based EMI shielding. Medical devices and equipment are becoming increasingly sophisticated, requiring advanced protection against electromagnetic interference to ensure accurate diagnostics and treatment. GO-based materials show promise in providing effective shielding while meeting the stringent requirements of medical applications.

The telecommunications sector, particularly with the ongoing rollout of 5G networks, presents a growing market for GO-based EMI shielding. As network infrastructure expands and becomes more complex, the need for reliable EMI protection increases. GO-based solutions offer potential benefits in terms of performance and integration into next-generation communication systems.

Geographically, Asia-Pacific is expected to be a key market for GO-based EMI shielding, driven by the region's strong electronics manufacturing base and rapid technological advancements. North America and Europe also represent significant markets, particularly in high-tech industries and research and development activities.

The market for GO-based EMI shielding faces some challenges, including the need for cost-effective production methods and ensuring consistent quality at scale. However, ongoing research and development efforts are addressing these issues, potentially leading to broader adoption across various industries.

Current Challenges in GO EMI Shielding

Despite the promising potential of graphene oxide (GO) in electromagnetic interference (EMI) shielding, several challenges persist in fully harnessing its capabilities. One of the primary obstacles is the difficulty in achieving uniform dispersion of GO sheets within the matrix material. The tendency of GO to agglomerate due to strong van der Waals forces between layers can lead to inconsistent shielding performance across the material.

Another significant challenge lies in maintaining the structural integrity of GO during the manufacturing process. High-temperature processing or chemical treatments used in composite fabrication can potentially reduce or alter the functional groups on GO, affecting its electrical conductivity and overall shielding effectiveness. This sensitivity to processing conditions necessitates careful optimization of manufacturing parameters.

The scalability of GO production for large-scale EMI shielding applications presents a considerable hurdle. While laboratory-scale synthesis of high-quality GO is well-established, translating this to industrial-scale production while maintaining consistent quality and properties remains challenging. This scaling issue directly impacts the cost-effectiveness and widespread adoption of GO-based EMI shielding solutions.

Furthermore, the long-term stability of GO in EMI shielding applications is a concern. Environmental factors such as humidity, temperature fluctuations, and exposure to various electromagnetic frequencies can potentially degrade GO's performance over time. Ensuring the durability and reliability of GO-based shielding materials under diverse operating conditions is crucial for their practical implementation.

The integration of GO with other materials to form effective composites poses another challenge. While GO itself exhibits excellent EMI shielding properties, its incorporation into polymers or other matrices without compromising the host material's properties requires careful engineering. Achieving the right balance between GO content, dispersion, and interfacial interactions with the matrix material is critical for optimal shielding performance.

Lastly, the environmental impact and potential health risks associated with GO production and use in EMI shielding applications need thorough investigation. As nanomaterials, GO particles may pose unique environmental and health challenges that must be addressed to ensure safe and sustainable implementation in consumer and industrial products.

Overcoming these challenges requires interdisciplinary research efforts, combining expertise in materials science, electrical engineering, and manufacturing processes. Addressing these issues will be crucial in realizing the full potential of GO for advanced EMI shielding applications across various industries.

Existing GO EMI Shielding Solutions

01 Graphene oxide-based composite materials for EMI shielding

Composite materials incorporating graphene oxide (GO) are developed for electromagnetic interference (EMI) shielding applications. These composites often combine GO with polymers or other materials to enhance shielding effectiveness. The unique properties of GO, such as high electrical conductivity and large surface area, contribute to improved EMI shielding performance.- Graphene oxide-based composite materials for EMI shielding: Composite materials incorporating graphene oxide (GO) are developed for electromagnetic interference (EMI) shielding applications. These composites often combine GO with polymers or other materials to enhance shielding effectiveness. The unique properties of GO, such as high electrical conductivity and large surface area, contribute to improved EMI shielding performance.

- Fabrication methods for GO-based EMI shielding materials: Various fabrication techniques are employed to produce GO-based EMI shielding materials. These methods may include solution processing, layer-by-layer assembly, or in-situ reduction of GO. The fabrication process significantly influences the final structure and properties of the shielding material, affecting its EMI shielding performance.

- Functionalization of GO for enhanced EMI shielding: GO is functionalized or modified to improve its EMI shielding capabilities. This may involve chemical treatments, doping with other elements, or creating hybrid structures. Functionalization can enhance the electrical conductivity, magnetic properties, or absorption characteristics of GO, leading to better EMI shielding performance.

- Multi-layered GO structures for EMI shielding: Multi-layered structures incorporating GO are designed for effective EMI shielding. These structures may combine different materials or use varying concentrations of GO in each layer. The multi-layered approach allows for tailored shielding properties across different frequency ranges and can provide additional benefits such as flexibility or heat dissipation.

- GO-based EMI shielding for specific applications: GO-based EMI shielding materials are developed for specific applications such as electronic devices, aerospace, or medical equipment. These tailored solutions consider factors like weight, thickness, flexibility, and environmental resistance. The shielding materials are optimized to meet the unique requirements of each application while providing effective EMI protection.

02 Fabrication methods for GO-based EMI shielding materials

Various fabrication techniques are employed to produce GO-based EMI shielding materials. These methods may include solution processing, layer-by-layer assembly, or in-situ reduction of GO. The fabrication process significantly influences the final structure and properties of the shielding material, affecting its EMI shielding performance.Expand Specific Solutions03 Functionalization of GO for enhanced EMI shielding

GO is functionalized or modified to improve its EMI shielding capabilities. This may involve chemical treatments, doping with other elements, or creating hybrid structures. Functionalization can enhance the electrical conductivity, magnetic properties, or absorption characteristics of GO, leading to superior EMI shielding performance.Expand Specific Solutions04 Multi-layered GO structures for EMI shielding

Multi-layered structures incorporating GO are designed for effective EMI shielding. These structures may combine GO with other materials in alternating layers or use different forms of GO to create a gradient structure. The multi-layered approach allows for tuning of the shielding properties and can provide broadband EMI protection.Expand Specific Solutions05 GO-based flexible and lightweight EMI shielding materials

Flexible and lightweight EMI shielding materials are developed using GO as a key component. These materials are designed for applications where traditional metal-based shielding is impractical, such as wearable electronics or aerospace. The flexibility and low density of GO-based materials make them suitable for conformal shielding applications while maintaining effective EMI protection.Expand Specific Solutions

Key Players in GO EMI Shielding Industry

The electromagnetic interference (EMI) shielding market using graphene oxide (GO) is in a growth phase, driven by increasing demand for electronic devices and the need for advanced shielding solutions. The market size is expanding rapidly, with a projected CAGR of over 20% in the coming years. Technologically, GO-based EMI shielding is advancing quickly, with companies like 3M Innovative Properties Co., Koninklijke Philips NV, and Mitsubishi Electric Corp. leading research and development efforts. These industry giants, along with academic institutions such as Massachusetts Institute of Technology and Northwestern University, are pushing the boundaries of GO's EMI shielding capabilities. The technology is approaching maturity, with commercial applications emerging across various sectors, including electronics, aerospace, and telecommunications.

3M Innovative Properties Co.

Harbin Institute of Technology

Core GO EMI Shielding Innovations

- A nano additive coating method involving the sequential immersion of fibers or fabrics in water-based suspensions of graphene oxide and carbon nanotubes, followed by a reduction process using hydrazine hydrate, to form a hybrid structure that enhances electrical conductivity without damaging the surface chemistry.

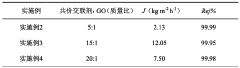

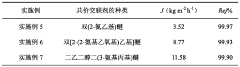

- Through covalent cross-linking with diamine small molecules containing ether oxygen groups, a graphene oxide framework composite membrane is formed, and is prepared on an inorganic porous support. Vacuum filtration and oven drying are used to form a stable GOF structure, which can be regulated and controlled. The size of the nanometer water channels in the membrane layer improves the selectivity and rejection rate of salt ions.

Environmental Impact of GO EMI Shielding

The environmental impact of graphene oxide (GO) electromagnetic interference (EMI) shielding is a crucial aspect to consider as this technology gains prominence in various applications. GO-based EMI shielding materials offer significant advantages in terms of performance and versatility, but their environmental implications must be carefully evaluated.

One of the primary environmental concerns associated with GO EMI shielding is the potential release of nanoparticles during production, use, and disposal. These nanoparticles may pose risks to ecosystems and human health if not properly managed. Studies have shown that GO nanoparticles can accumulate in aquatic environments and potentially affect marine organisms. However, the long-term effects of GO nanoparticle exposure on ecosystems are still not fully understood and require further research.

On the positive side, GO EMI shielding materials have the potential to reduce electronic waste by enhancing the longevity and reliability of electronic devices. By effectively protecting sensitive components from electromagnetic interference, GO-based shielding can extend the lifespan of electronic products, potentially reducing the overall environmental impact of the electronics industry.

The production of GO for EMI shielding applications also raises environmental considerations. The synthesis of GO typically involves chemical oxidation processes that may generate hazardous waste. However, recent advancements in green synthesis methods have shown promise in reducing the environmental footprint of GO production. These eco-friendly approaches utilize less toxic reagents and more sustainable processes, aligning with the principles of green chemistry.

Energy consumption is another factor to consider when assessing the environmental impact of GO EMI shielding. While the production of GO can be energy-intensive, the lightweight nature of GO-based shielding materials may contribute to energy savings in transportation and application. Additionally, the high efficiency of GO EMI shielding could potentially lead to reduced power consumption in electronic devices, indirectly contributing to energy conservation.

The recyclability and end-of-life management of GO EMI shielding materials are critical aspects of their environmental impact. Current research is exploring methods to recover and recycle GO from composite materials, which could significantly reduce waste and promote a circular economy approach. However, the development of efficient recycling processes for GO-based products remains a challenge that requires further innovation.

As the adoption of GO EMI shielding technology increases, it is essential to conduct comprehensive life cycle assessments to fully understand its environmental implications. These assessments should consider the entire lifecycle of GO-based shielding materials, from raw material extraction to disposal or recycling. By identifying potential environmental hotspots, researchers and industry professionals can work towards optimizing the sustainability of GO EMI shielding solutions.

GO EMI Shielding Standards and Regulations

The development and implementation of graphene oxide (GO) for electromagnetic interference (EMI) shielding applications are subject to various standards and regulations. These guidelines ensure the safety, reliability, and effectiveness of GO-based EMI shielding materials across different industries and applications.

One of the primary standards governing EMI shielding is the IEC 61000 series, which provides guidelines for electromagnetic compatibility (EMC) testing and measurement. Specifically, IEC 61000-4-21 outlines the methods for measuring shielding effectiveness in reverberation chambers, which is particularly relevant for evaluating GO-based EMI shielding materials.

The IEEE Standard 299-2006 is another crucial standard that defines methods for measuring the effectiveness of electromagnetic shielding enclosures. This standard is applicable to GO-based shielding materials used in enclosures and can help assess their performance in real-world applications.

In the aerospace industry, the RTCA DO-160G standard is widely used for environmental testing of avionics hardware. Section 20 of this standard specifically addresses EMI shielding requirements, which GO-based materials must meet for use in aircraft systems.

For military applications, MIL-STD-461G sets the requirements for the control of electromagnetic interference characteristics of subsystems and equipment. GO-based EMI shielding materials intended for military use must comply with these stringent standards to ensure operational effectiveness in challenging environments.

The automotive industry relies on standards such as ISO 11452 and CISPR 25 for EMC testing of vehicles and components. As GO-based EMI shielding materials find applications in automotive electronics, adherence to these standards becomes crucial for market acceptance and regulatory compliance.

In the realm of consumer electronics, the FCC Part 15 regulations in the United States and the CE marking requirements in the European Union set the standards for EMI emissions and immunity. GO-based shielding materials used in consumer devices must help manufacturers meet these regulatory requirements to ensure market access.

As nanotechnology advances, specific regulations addressing nanomaterials, including GO, are emerging. The EU's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires the registration of nanomaterials, including those used in EMI shielding applications. Similarly, the US EPA has introduced reporting rules for nanoscale materials under the Toxic Substances Control Act (TSCA).

Compliance with these standards and regulations is essential for the widespread adoption of GO-based EMI shielding solutions. Manufacturers and researchers must consider these requirements throughout the development process, from material design to final product testing, to ensure that GO-enhanced EMI shielding materials meet the necessary performance and safety criteria across various industries and applications.