How to Develop Superior Hydrogels with Graphene Oxide?

Graphene Oxide Hydrogels: Background and Objectives

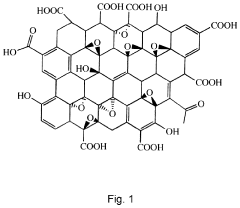

Graphene oxide (GO) hydrogels have emerged as a promising class of advanced materials, combining the unique properties of graphene with the versatility of hydrogels. These composite materials have garnered significant attention in recent years due to their potential applications in various fields, including biomedicine, environmental remediation, and energy storage.

The development of superior hydrogels with graphene oxide is driven by the need for materials with enhanced mechanical, electrical, and thermal properties. Graphene oxide, a two-dimensional carbon nanomaterial, offers exceptional strength, large surface area, and excellent conductivity. When incorporated into hydrogel networks, it can dramatically improve the overall performance and functionality of the resulting composite.

The evolution of GO hydrogels can be traced back to the discovery of graphene in 2004, which sparked a revolution in materials science. As researchers explored the potential of graphene-based materials, the idea of combining graphene oxide with hydrogels emerged as a promising avenue for creating multifunctional materials with tunable properties.

The primary objective in developing superior GO hydrogels is to achieve a synergistic integration of graphene oxide's unique characteristics with the three-dimensional network structure of hydrogels. This involves optimizing the dispersion of GO sheets within the hydrogel matrix, controlling the crosslinking density, and tailoring the interactions between GO and the polymer chains.

Key technical goals include enhancing mechanical strength and toughness, improving electrical conductivity, increasing thermal stability, and expanding the range of stimuli-responsiveness. Additionally, researchers aim to develop GO hydrogels with improved biocompatibility, controlled drug release capabilities, and enhanced adsorption properties for environmental applications.

The development of superior GO hydrogels faces several challenges, including the need for scalable and cost-effective production methods, ensuring uniform dispersion of GO sheets, and maintaining the desired properties over extended periods. Overcoming these hurdles requires interdisciplinary collaboration and innovative approaches to materials design and synthesis.

As the field progresses, researchers are exploring novel synthesis techniques, such as 3D printing and self-assembly, to create GO hydrogels with precise architectures and tailored properties. The ultimate goal is to develop a new generation of smart, multifunctional materials that can address complex challenges in healthcare, environmental protection, and energy technologies.

Market Analysis for Advanced Hydrogel Applications

The advanced hydrogel market is experiencing significant growth, driven by increasing demand across various industries. The global hydrogel market size was valued at USD 15.3 billion in 2020 and is projected to reach USD 31.4 billion by 2027, growing at a CAGR of 6.7% during the forecast period. This growth is primarily attributed to the expanding applications of hydrogels in healthcare, agriculture, and personal care sectors.

In the healthcare industry, hydrogels are gaining traction due to their biocompatibility and ability to mimic natural tissues. The wound care segment, in particular, is witnessing substantial growth, with hydrogel-based dressings becoming increasingly popular for their moisture-retaining properties and ability to promote faster healing. The market for hydrogel-based drug delivery systems is also expanding, driven by the need for controlled and targeted drug release.

The agriculture sector presents a promising market for advanced hydrogels, especially in water-scarce regions. Hydrogels' water-retention capabilities make them valuable for improving soil moisture content and reducing irrigation requirements. The market for hydrogel-based agricultural products is expected to grow significantly as farmers seek sustainable solutions to enhance crop yields and water efficiency.

Personal care and cosmetics represent another key market for advanced hydrogels. The demand for hydrogel-based skincare products, such as face masks and moisturizers, is rising due to their superior hydrating properties and ability to deliver active ingredients effectively. This segment is expected to witness robust growth, driven by increasing consumer awareness and preference for advanced skincare solutions.

The incorporation of graphene oxide in hydrogels is opening up new market opportunities across various sectors. Graphene oxide-enhanced hydrogels exhibit superior mechanical strength, electrical conductivity, and thermal properties, making them attractive for applications in tissue engineering, sensors, and energy storage devices. The market for these advanced hydrogels is still in its early stages but shows significant potential for growth as research and development efforts intensify.

Geographically, North America and Europe currently dominate the advanced hydrogel market, owing to their well-established healthcare and research infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth, driven by increasing healthcare expenditure, growing agricultural needs, and rising adoption of advanced materials in emerging economies like China and India.

Current Challenges in Graphene Oxide Hydrogel Development

The development of superior hydrogels with graphene oxide faces several significant challenges that researchers and engineers must overcome. One of the primary obstacles is achieving uniform dispersion of graphene oxide within the hydrogel matrix. Due to its strong tendency to aggregate, graphene oxide often forms clusters, leading to inhomogeneous distribution and compromised mechanical properties of the resulting hydrogel.

Another critical challenge lies in maintaining the structural integrity of graphene oxide during the hydrogel formation process. The harsh conditions often required for hydrogel synthesis, such as extreme pH levels or high temperatures, can potentially damage or alter the graphene oxide sheets, reducing their effectiveness in enhancing the hydrogel's properties.

Controlling the crosslinking density between graphene oxide and the polymer network presents another hurdle. Achieving the optimal balance is crucial for developing hydrogels with desired mechanical strength, flexibility, and swelling behavior. Insufficient crosslinking may result in weak structures, while excessive crosslinking can lead to brittle hydrogels with limited functionality.

The scalability of graphene oxide hydrogel production poses a significant challenge for industrial applications. Current laboratory-scale synthesis methods often struggle to maintain consistent quality and properties when scaled up to larger volumes, hindering the commercialization of these advanced materials.

Biocompatibility and potential toxicity concerns also present challenges, particularly for biomedical applications. While graphene oxide itself has shown promise in various biomedical fields, ensuring the long-term safety and biocompatibility of graphene oxide hydrogels remains a critical area of research and development.

Furthermore, achieving multifunctionality in graphene oxide hydrogels without compromising their core properties is a complex task. Integrating additional functionalities, such as electrical conductivity, self-healing capabilities, or stimuli-responsiveness, often requires careful engineering and may introduce new challenges in maintaining the hydrogel's overall performance.

Lastly, the high cost and complexity associated with producing high-quality graphene oxide remain significant barriers to widespread adoption. Developing more cost-effective and scalable production methods for graphene oxide is crucial for making these advanced hydrogels economically viable for various applications.

Existing Graphene Oxide Hydrogel Synthesis Methods

01 Enhanced mechanical properties of hydrogels with graphene oxide

Incorporation of graphene oxide into hydrogels significantly improves their mechanical strength, elasticity, and toughness. The unique structure of graphene oxide allows for better load distribution and reinforcement within the hydrogel matrix, resulting in superior mechanical properties compared to conventional hydrogels.- Enhanced mechanical properties of hydrogels with graphene oxide: Incorporation of graphene oxide into hydrogels significantly improves their mechanical strength, elasticity, and toughness. The unique structure of graphene oxide allows for better load distribution and reinforcement within the hydrogel matrix, resulting in superior mechanical properties compared to conventional hydrogels.

- Improved electrical conductivity and sensing capabilities: Graphene oxide-based hydrogels exhibit enhanced electrical conductivity, making them suitable for various sensing applications. These hydrogels can be used in the development of highly sensitive and responsive sensors for detecting environmental changes, biomolecules, or physiological parameters.

- Enhanced biocompatibility and drug delivery capabilities: Hydrogels with graphene oxide demonstrate improved biocompatibility and can be used as efficient drug delivery systems. The large surface area and functional groups of graphene oxide allow for better drug loading and controlled release, making these hydrogels promising candidates for biomedical applications.

- Improved thermal and chemical stability: The addition of graphene oxide to hydrogels enhances their thermal and chemical stability. These hydrogels exhibit better resistance to temperature changes and harsh chemical environments, making them suitable for applications in extreme conditions or industrial processes.

- Enhanced water absorption and retention capabilities: Graphene oxide-based hydrogels demonstrate superior water absorption and retention properties compared to conventional hydrogels. The unique structure of graphene oxide allows for better water interaction and storage within the hydrogel network, making these materials suitable for applications in agriculture, water purification, and personal care products.

02 Improved electrical conductivity and sensing capabilities

Graphene oxide-based hydrogels exhibit enhanced electrical conductivity, making them suitable for various sensing applications. These hydrogels can be used to develop highly sensitive and responsive sensors for detecting environmental changes, biomolecules, or physical stimuli.Expand Specific Solutions03 Enhanced biocompatibility and drug delivery capabilities

Hydrogels with graphene oxide demonstrate improved biocompatibility and can be used as efficient drug delivery systems. The large surface area and functional groups of graphene oxide allow for better drug loading and controlled release, making these hydrogels promising candidates for biomedical applications.Expand Specific Solutions04 Improved thermal and chemical stability

The addition of graphene oxide to hydrogels enhances their thermal and chemical stability. These hydrogels exhibit better resistance to temperature changes and harsh chemical environments, making them suitable for applications in extreme conditions or industrial settings.Expand Specific Solutions05 Enhanced water absorption and retention capabilities

Graphene oxide-based hydrogels demonstrate superior water absorption and retention properties compared to conventional hydrogels. The unique structure of graphene oxide allows for better water uptake and storage, making these hydrogels ideal for applications in agriculture, water purification, and personal care products.Expand Specific Solutions

Key Players in Graphene Oxide Hydrogel Research

The development of superior hydrogels with graphene oxide is in a rapidly evolving phase, characterized by intense research and growing market potential. The global hydrogel market is expanding, driven by applications in healthcare, agriculture, and consumer products. Technologically, the field is advancing but not yet fully mature, with ongoing innovations in synthesis methods and property enhancements. Key players like Northwestern University, The University of Manchester, and Zhejiang University are at the forefront, contributing significant research. Companies such as Global Graphene Group, Inc. and Nanotek Instruments, Inc. are also actively involved, indicating a growing industrial interest. The competition is fierce, with academic institutions and commercial entities vying for breakthroughs in improving hydrogel performance through graphene oxide incorporation.

Global Graphene Group, Inc.

The University of Manchester

Innovative Approaches in GO Hydrogel Fabrication

- Incorporating graphene oxide (GO) into poly(2-hydroxyethyl methacrylate) (pHEMA) hydrogels with specific oxidation degrees and concentrations to create a material with enhanced stiffness and tensile resistance while maintaining biocompatibility and swelling capacity.

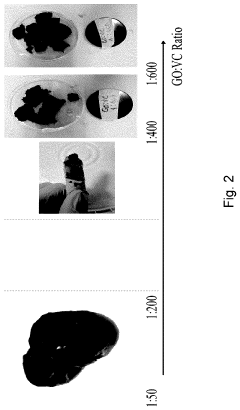

- The development of graphene oxide hydrogels using vitamin C as a gelling and cross-linking agent, combined with cellulose nano-particles, which self-assemble at low temperatures and low pressures to form stable, porous structures with enhanced mechanical properties and adsorption efficiency, allowing for efficient removal of contaminants without the need for toxic materials or high energy.

Environmental Impact of Graphene Oxide Hydrogels

The environmental impact of graphene oxide hydrogels is a critical consideration in their development and application. These advanced materials, while offering numerous benefits in various fields, also pose potential risks to ecosystems and human health that must be carefully evaluated.

One of the primary environmental concerns associated with graphene oxide hydrogels is their potential for nanoparticle release. As these hydrogels degrade or wear over time, they may release graphene oxide nanoparticles into the environment. These nanoparticles can persist in water and soil, potentially accumulating in living organisms through various exposure routes. The long-term effects of such accumulation on ecosystems and food chains are not yet fully understood, necessitating further research and monitoring.

Water contamination is another significant environmental issue related to graphene oxide hydrogels. The high surface area and strong adsorption properties of graphene oxide can lead to the accumulation of pollutants, heavy metals, and organic compounds. While this characteristic can be beneficial for water purification applications, it also raises concerns about the potential release of these concentrated contaminants back into the environment if the hydrogels are not properly disposed of or managed.

The production process of graphene oxide hydrogels also warrants environmental scrutiny. The synthesis of graphene oxide often involves the use of strong oxidizing agents and acids, which can generate hazardous waste streams if not properly managed. Sustainable production methods and efficient waste treatment processes are essential to mitigate these environmental risks.

Biodegradability is a crucial factor in assessing the environmental impact of graphene oxide hydrogels. While some hydrogels can be designed to be biodegradable, the persistence of graphene oxide in the environment remains a concern. The slow degradation rate of graphene oxide may lead to long-term environmental accumulation, potentially affecting soil and aquatic ecosystems.

On the positive side, graphene oxide hydrogels have shown promise in environmental remediation applications. Their high adsorption capacity and selectivity make them effective in removing pollutants from water and soil. This potential for environmental cleanup could offset some of the negative impacts associated with their production and use.

The lifecycle assessment of graphene oxide hydrogels is essential for a comprehensive understanding of their environmental impact. This includes evaluating the energy consumption and carbon footprint of their production, use, and disposal. Developing more sustainable synthesis methods and exploring recycling options for used hydrogels are important areas for future research and development.

Scalability and Commercialization Prospects

The scalability and commercialization prospects for superior hydrogels with graphene oxide are promising, driven by their unique properties and diverse applications. These advanced materials offer enhanced mechanical strength, electrical conductivity, and biocompatibility, making them attractive for various industries.

In terms of scalability, the production of graphene oxide-based hydrogels has seen significant improvements in recent years. Researchers have developed more efficient synthesis methods, such as one-pot reactions and continuous flow processes, which can potentially be scaled up for industrial production. However, challenges remain in maintaining consistent quality and properties when transitioning from laboratory-scale to large-scale manufacturing.

The commercialization potential of these hydrogels spans multiple sectors. In the biomedical field, they show promise for drug delivery systems, tissue engineering scaffolds, and wound dressings. The electronics industry is exploring their use in flexible sensors and energy storage devices. Environmental applications include water purification and contaminant removal.

Market demand for advanced hydrogels is expected to grow steadily, driven by aging populations, increasing healthcare expenditures, and the need for sustainable technologies. The global hydrogel market is projected to reach several billion dollars by 2025, with graphene oxide-based hydrogels poised to capture a significant share.

To fully realize the commercial potential, several key factors need to be addressed. Cost-effective production of high-quality graphene oxide remains a challenge, as does the optimization of hydrogel formulations for specific applications. Regulatory approval processes, particularly for biomedical applications, can be lengthy and complex, potentially slowing market entry.

Intellectual property landscape is another crucial consideration. As research in this field intensifies, companies must navigate a complex web of patents and ensure freedom to operate. Collaborations between academic institutions and industry partners are becoming increasingly important to bridge the gap between research and commercialization.

In conclusion, while technical and regulatory hurdles exist, the unique properties and versatility of graphene oxide-based hydrogels present significant opportunities for scalable production and commercial success across multiple industries. Continued research and development efforts, coupled with strategic partnerships and investments, will be key to unlocking their full potential in the coming years.