How to Enhance Market Resilience with Cellophane Solutions?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Technology Evolution and Objectives

Cellophane, a transparent sheet made from regenerated cellulose, has undergone significant technological evolution since its invention in 1908. Initially developed as a waterproof coating for tablecloths, cellophane's potential quickly expanded into various industries, revolutionizing packaging and preservation methods.

The evolution of cellophane technology has been driven by the need for improved functionality, sustainability, and cost-effectiveness. Early developments focused on enhancing its barrier properties against moisture and gases, crucial for food packaging applications. The introduction of moisture-proof cellophane in the 1920s marked a significant milestone, extending the shelf life of packaged products.

As environmental concerns grew, the cellophane industry shifted its focus towards developing more sustainable production methods and biodegradable variants. This led to the exploration of alternative raw materials and the optimization of manufacturing processes to reduce environmental impact. Recent advancements have centered on improving cellophane's mechanical properties, such as tensile strength and flexibility, to broaden its application range.

The primary objective of cellophane technology evolution is to enhance market resilience by addressing key challenges in various sectors. In the food industry, the goal is to develop cellophane solutions that provide superior barrier properties while maintaining product freshness and extending shelf life. For the pharmaceutical sector, the focus is on creating cellophane packaging that ensures drug stability and prevents contamination.

Another crucial objective is to improve the cost-effectiveness of cellophane production without compromising quality. This involves optimizing manufacturing processes, exploring new raw material sources, and developing innovative production techniques. The aim is to make cellophane a more competitive option compared to synthetic alternatives, thereby increasing its market share and resilience.

Sustainability remains a central objective in cellophane technology evolution. Efforts are directed towards developing fully biodegradable cellophane variants that maintain the material's desirable properties. This aligns with growing consumer demand for eco-friendly packaging solutions and helps companies meet increasingly stringent environmental regulations.

The evolution of cellophane technology also aims to expand its applications beyond traditional packaging. Research is underway to explore its potential in fields such as electronics, medical devices, and smart packaging. By diversifying its use cases, the cellophane industry seeks to enhance its market resilience and reduce dependency on any single sector.

In conclusion, the evolution of cellophane technology and its objectives are closely aligned with enhancing market resilience. By continuously improving its properties, expanding applications, and addressing sustainability concerns, cellophane solutions are poised to play a significant role in meeting future market demands across various industries.

The evolution of cellophane technology has been driven by the need for improved functionality, sustainability, and cost-effectiveness. Early developments focused on enhancing its barrier properties against moisture and gases, crucial for food packaging applications. The introduction of moisture-proof cellophane in the 1920s marked a significant milestone, extending the shelf life of packaged products.

As environmental concerns grew, the cellophane industry shifted its focus towards developing more sustainable production methods and biodegradable variants. This led to the exploration of alternative raw materials and the optimization of manufacturing processes to reduce environmental impact. Recent advancements have centered on improving cellophane's mechanical properties, such as tensile strength and flexibility, to broaden its application range.

The primary objective of cellophane technology evolution is to enhance market resilience by addressing key challenges in various sectors. In the food industry, the goal is to develop cellophane solutions that provide superior barrier properties while maintaining product freshness and extending shelf life. For the pharmaceutical sector, the focus is on creating cellophane packaging that ensures drug stability and prevents contamination.

Another crucial objective is to improve the cost-effectiveness of cellophane production without compromising quality. This involves optimizing manufacturing processes, exploring new raw material sources, and developing innovative production techniques. The aim is to make cellophane a more competitive option compared to synthetic alternatives, thereby increasing its market share and resilience.

Sustainability remains a central objective in cellophane technology evolution. Efforts are directed towards developing fully biodegradable cellophane variants that maintain the material's desirable properties. This aligns with growing consumer demand for eco-friendly packaging solutions and helps companies meet increasingly stringent environmental regulations.

The evolution of cellophane technology also aims to expand its applications beyond traditional packaging. Research is underway to explore its potential in fields such as electronics, medical devices, and smart packaging. By diversifying its use cases, the cellophane industry seeks to enhance its market resilience and reduce dependency on any single sector.

In conclusion, the evolution of cellophane technology and its objectives are closely aligned with enhancing market resilience. By continuously improving its properties, expanding applications, and addressing sustainability concerns, cellophane solutions are poised to play a significant role in meeting future market demands across various industries.

Market Demand Analysis for Resilient Packaging

The market demand for resilient packaging solutions, particularly those incorporating cellophane, has seen a significant uptick in recent years. This surge is driven by several factors, including the increasing focus on sustainability, the need for extended product shelf life, and the growing awareness of food safety concerns among consumers. The global packaging industry, valued at over $900 billion, is experiencing a shift towards more resilient and environmentally friendly materials.

Cellophane, a biodegradable and transparent material derived from regenerated cellulose, is gaining traction in the packaging sector due to its unique properties. Its ability to provide an effective barrier against moisture, gases, and bacteria while maintaining product visibility makes it an attractive option for food packaging, pharmaceuticals, and consumer goods. The cellophane market is expected to grow at a compound annual growth rate (CAGR) of 4.2% from 2021 to 2026, reflecting the increasing demand for resilient packaging solutions.

The food and beverage industry, in particular, is driving the demand for cellophane-based packaging. With consumers becoming more health-conscious and demanding longer shelf life for perishable goods, cellophane's ability to preserve freshness while allowing product visibility is highly valued. The pharmaceutical sector is another key driver, as cellophane's barrier properties make it suitable for protecting sensitive medications and medical devices from environmental factors.

E-commerce growth has further accelerated the need for resilient packaging solutions. As online shopping continues to expand, there is an increased emphasis on packaging that can withstand the rigors of shipping while maintaining product integrity. Cellophane's flexibility and durability make it an ideal component in multi-layer packaging designs that offer enhanced protection during transit.

Sustainability concerns are also shaping market demand. With growing environmental awareness and stricter regulations on plastic use, biodegradable materials like cellophane are gaining favor. Consumers are increasingly seeking eco-friendly packaging options, and brands are responding by incorporating sustainable materials into their packaging strategies. This trend is expected to continue, with the global sustainable packaging market projected to reach $412 billion by 2027.

The Asia-Pacific region is emerging as a key market for resilient packaging, driven by rapid industrialization, urbanization, and changing consumer lifestyles. Countries like China and India are witnessing a surge in demand for packaged goods, creating opportunities for innovative packaging solutions. North America and Europe remain significant markets, with a focus on advanced packaging technologies and stringent quality standards.

As the market evolves, there is a growing demand for cellophane solutions that offer enhanced functionality, such as improved barrier properties, antimicrobial features, and smart packaging capabilities. This presents opportunities for research and development in areas such as nanocomposite cellophane films and bio-based additives to further improve the material's performance and market appeal.

Cellophane, a biodegradable and transparent material derived from regenerated cellulose, is gaining traction in the packaging sector due to its unique properties. Its ability to provide an effective barrier against moisture, gases, and bacteria while maintaining product visibility makes it an attractive option for food packaging, pharmaceuticals, and consumer goods. The cellophane market is expected to grow at a compound annual growth rate (CAGR) of 4.2% from 2021 to 2026, reflecting the increasing demand for resilient packaging solutions.

The food and beverage industry, in particular, is driving the demand for cellophane-based packaging. With consumers becoming more health-conscious and demanding longer shelf life for perishable goods, cellophane's ability to preserve freshness while allowing product visibility is highly valued. The pharmaceutical sector is another key driver, as cellophane's barrier properties make it suitable for protecting sensitive medications and medical devices from environmental factors.

E-commerce growth has further accelerated the need for resilient packaging solutions. As online shopping continues to expand, there is an increased emphasis on packaging that can withstand the rigors of shipping while maintaining product integrity. Cellophane's flexibility and durability make it an ideal component in multi-layer packaging designs that offer enhanced protection during transit.

Sustainability concerns are also shaping market demand. With growing environmental awareness and stricter regulations on plastic use, biodegradable materials like cellophane are gaining favor. Consumers are increasingly seeking eco-friendly packaging options, and brands are responding by incorporating sustainable materials into their packaging strategies. This trend is expected to continue, with the global sustainable packaging market projected to reach $412 billion by 2027.

The Asia-Pacific region is emerging as a key market for resilient packaging, driven by rapid industrialization, urbanization, and changing consumer lifestyles. Countries like China and India are witnessing a surge in demand for packaged goods, creating opportunities for innovative packaging solutions. North America and Europe remain significant markets, with a focus on advanced packaging technologies and stringent quality standards.

As the market evolves, there is a growing demand for cellophane solutions that offer enhanced functionality, such as improved barrier properties, antimicrobial features, and smart packaging capabilities. This presents opportunities for research and development in areas such as nanocomposite cellophane films and bio-based additives to further improve the material's performance and market appeal.

Current Challenges in Cellophane Solutions

The cellophane industry faces several significant challenges in its quest to enhance market resilience. One of the primary issues is the increasing competition from alternative packaging materials, particularly plastic-based solutions. These alternatives often offer superior barrier properties, flexibility, and cost-effectiveness, putting pressure on cellophane manufacturers to innovate and improve their products.

Environmental concerns pose another major challenge for the cellophane market. While cellophane is biodegradable, its production process can be energy-intensive and involves the use of chemicals. This has led to growing scrutiny from environmentally conscious consumers and regulatory bodies, necessitating the development of more sustainable production methods and improved end-of-life solutions for cellophane products.

The volatility of raw material prices, particularly wood pulp, presents a significant challenge to the stability of the cellophane market. Fluctuations in these prices can impact production costs and, consequently, the competitiveness of cellophane solutions in the marketplace. This volatility requires manufacturers to implement robust supply chain management strategies and explore alternative raw material sources to maintain market resilience.

Technological limitations in cellophane production and processing also hinder market growth. Current manufacturing processes can be less efficient compared to those of synthetic alternatives, leading to higher production costs and limited scalability. Additionally, cellophane's inherent properties, such as its moisture sensitivity, can restrict its application in certain packaging scenarios, limiting market expansion opportunities.

The global shift towards digital and e-commerce platforms has created new challenges for cellophane packaging solutions. The material's performance under various shipping and handling conditions needs improvement to meet the rigorous demands of online retail and long-distance transportation. This requires significant research and development efforts to enhance cellophane's durability and protective qualities.

Regulatory compliance and changing standards across different regions present ongoing challenges for cellophane manufacturers. As food safety regulations and packaging standards evolve, companies must continuously adapt their products and processes to meet these requirements, which can be both time-consuming and costly.

Lastly, the cellophane industry faces challenges in consumer perception and education. Many consumers are unaware of cellophane's biodegradable properties and its differences from plastic films. This lack of awareness can lead to misconceptions about its environmental impact and hinder its adoption in eco-friendly packaging solutions. Overcoming these perception issues requires concerted marketing and educational efforts to highlight cellophane's unique benefits and sustainability credentials.

Environmental concerns pose another major challenge for the cellophane market. While cellophane is biodegradable, its production process can be energy-intensive and involves the use of chemicals. This has led to growing scrutiny from environmentally conscious consumers and regulatory bodies, necessitating the development of more sustainable production methods and improved end-of-life solutions for cellophane products.

The volatility of raw material prices, particularly wood pulp, presents a significant challenge to the stability of the cellophane market. Fluctuations in these prices can impact production costs and, consequently, the competitiveness of cellophane solutions in the marketplace. This volatility requires manufacturers to implement robust supply chain management strategies and explore alternative raw material sources to maintain market resilience.

Technological limitations in cellophane production and processing also hinder market growth. Current manufacturing processes can be less efficient compared to those of synthetic alternatives, leading to higher production costs and limited scalability. Additionally, cellophane's inherent properties, such as its moisture sensitivity, can restrict its application in certain packaging scenarios, limiting market expansion opportunities.

The global shift towards digital and e-commerce platforms has created new challenges for cellophane packaging solutions. The material's performance under various shipping and handling conditions needs improvement to meet the rigorous demands of online retail and long-distance transportation. This requires significant research and development efforts to enhance cellophane's durability and protective qualities.

Regulatory compliance and changing standards across different regions present ongoing challenges for cellophane manufacturers. As food safety regulations and packaging standards evolve, companies must continuously adapt their products and processes to meet these requirements, which can be both time-consuming and costly.

Lastly, the cellophane industry faces challenges in consumer perception and education. Many consumers are unaware of cellophane's biodegradable properties and its differences from plastic films. This lack of awareness can lead to misconceptions about its environmental impact and hinder its adoption in eco-friendly packaging solutions. Overcoming these perception issues requires concerted marketing and educational efforts to highlight cellophane's unique benefits and sustainability credentials.

Existing Cellophane Resilience Solutions

01 Improved manufacturing processes

Advancements in cellophane production techniques have enhanced the material's quality and efficiency. These improvements include optimized chemical processes, better control of film thickness, and innovative drying methods. Such enhancements contribute to the resilience of the cellophane market by increasing product consistency and reducing production costs.- Improved manufacturing processes: Advancements in cellophane production techniques have enhanced the material's quality and efficiency. These improvements include optimized chemical processes, better control systems, and innovative machinery, contributing to the market's resilience by increasing productivity and reducing costs.

- Eco-friendly and sustainable alternatives: The cellophane market has adapted to environmental concerns by developing biodegradable and sustainable variants. These eco-friendly alternatives maintain the desirable properties of traditional cellophane while addressing sustainability issues, thus ensuring market relevance and growth.

- Diversification of applications: Cellophane has found new applications beyond traditional packaging, including in electronics, medical devices, and specialty products. This diversification has strengthened the market's resilience by reducing dependence on a single industry and opening up new growth opportunities.

- Enhanced material properties: Research and development efforts have led to cellophane variants with improved properties such as increased strength, better barrier characteristics, and enhanced printability. These advancements have expanded the material's utility and maintained its competitiveness in various markets.

- Adaptation to changing market demands: The cellophane industry has demonstrated resilience by adapting to changing consumer preferences and regulatory requirements. This includes developing antimicrobial coatings, implementing smart packaging technologies, and creating customized solutions for specific industries.

02 Enhanced material properties

Research and development efforts have led to cellophane with improved physical and chemical properties. These enhancements include increased strength, better moisture resistance, and improved barrier properties. The resulting high-performance cellophane products cater to diverse industry needs, contributing to market resilience.Expand Specific Solutions03 Eco-friendly and sustainable solutions

The cellophane market has adapted to growing environmental concerns by developing biodegradable and sustainable alternatives. These innovations include bio-based cellophane materials and improved recycling processes, aligning with global sustainability trends and regulations, thus ensuring the market's long-term viability.Expand Specific Solutions04 Diversification of applications

The cellophane market has demonstrated resilience through the expansion of its applications across various industries. New uses in packaging, electronics, medical devices, and other sectors have been developed, broadening the market's customer base and reducing dependence on traditional applications.Expand Specific Solutions05 Technological integration and smart packaging

Integration of cellophane with advanced technologies has opened new market opportunities. This includes the development of smart packaging solutions incorporating sensors, RFID tags, and other intelligent features. Such innovations enhance the value proposition of cellophane products, contributing to market growth and resilience.Expand Specific Solutions

Key Players in Cellophane Industry

The market for cellophane solutions to enhance market resilience is in a growth phase, with increasing demand for sustainable packaging materials. The global cellophane market size is projected to expand significantly in the coming years, driven by eco-friendly consumer preferences and stringent regulations on plastic use. Technologically, cellophane solutions are evolving, with companies like Furukawa Electric, Nitto Denko, and Corning leading innovations in biodegradable and high-performance variants. These firms, along with others like International Paper and UPM-Kymmene, are investing in R&D to improve cellophane's properties and production efficiency. While the technology is mature, ongoing advancements in bio-based materials and manufacturing processes are enhancing cellophane's market competitiveness and environmental sustainability.

Furukawa Electric Co., Ltd.

Technical Solution: Furukawa Electric has developed advanced cellophane solutions to enhance market resilience. Their approach involves creating high-performance cellophane films with improved barrier properties and mechanical strength. The company utilizes a proprietary manufacturing process that incorporates nano-scale additives to enhance the film's properties[1]. This results in cellophane that offers superior moisture resistance and oxygen barrier capabilities, crucial for extending product shelf life and maintaining quality in various market sectors[2]. Additionally, Furukawa Electric has implemented sustainable practices in their cellophane production, using bio-based materials and reducing energy consumption, which aligns with growing market demands for eco-friendly packaging solutions[3].

Strengths: Superior barrier properties, enhanced mechanical strength, and sustainable production methods. Weaknesses: Potentially higher production costs and limited scalability for certain applications.

Nitto Denko Corp.

Technical Solution: Nitto Denko has developed innovative cellophane-based solutions to enhance market resilience. Their approach focuses on creating multi-functional cellophane films that combine optical clarity with advanced barrier properties. The company employs a unique coating technology that allows for the integration of multiple functional layers within a single cellophane film[4]. This results in products that offer enhanced UV protection, moisture resistance, and gas barrier properties while maintaining transparency[5]. Nitto Denko has also developed cellophane films with self-healing properties, which can repair minor scratches or damages, thus extending the product's lifespan and reducing waste in various industries[6]. Furthermore, the company has invested in recyclable cellophane solutions, addressing the growing market demand for sustainable packaging materials.

Strengths: Multi-functional properties, self-healing capabilities, and focus on recyclability. Weaknesses: Potentially higher costs due to advanced technologies and limited applicability in certain high-temperature environments.

Core Cellophane Enhancement Technologies

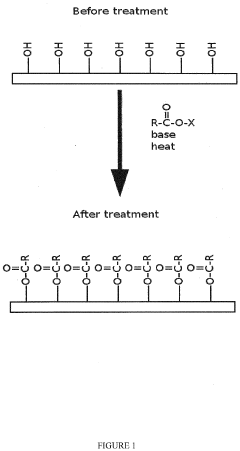

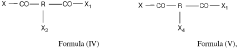

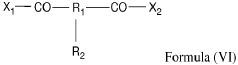

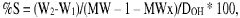

Methods for biodegradable derivatization of cellulosic surfaces

PatentActiveEP3628775A1

Innovation

- A method of esterifying available hydroxyl groups on cellulose using alkanoic acid derivatives and a base without Lewis acids or separate catalysts, creating a hydrophobic coating that is heat-resistant and biodegradable, applied through a composition that includes alkanoic acid derivatives, a base, and solvents, which crosslinks adjacent cellulose chains for enhanced mechanical and thermal stability.

Improved cellulose-based materials and containers made therefrom

PatentWO2022005768A1

Innovation

- Treating cellulosic fibers with both a dry strength chemistry preparation and a wet strength chemistry preparation to enhance the strength of cellulose-based materials and containers, providing a synergistic effect that improves performance in humid environments and allows for recyclability.

Environmental Impact of Cellophane Solutions

The environmental impact of cellophane solutions is a critical consideration in enhancing market resilience. Cellophane, a biodegradable material derived from cellulose, offers several advantages over traditional plastic packaging in terms of sustainability. However, its production and disposal still have environmental implications that must be carefully evaluated.

Cellophane production typically involves the use of wood pulp or cotton linters as raw materials. The manufacturing process requires chemical treatments and energy-intensive steps, which contribute to carbon emissions and potential water pollution if not properly managed. However, compared to petroleum-based plastics, cellophane's renewable source materials and biodegradability present a more environmentally friendly alternative.

One of the key environmental benefits of cellophane is its ability to decompose naturally in various environments. Unlike conventional plastics that persist for hundreds of years, cellophane can break down within a few months to a few years, depending on conditions. This characteristic significantly reduces the long-term accumulation of waste in landfills and oceans, addressing a major environmental concern associated with plastic packaging.

The biodegradability of cellophane also contributes to reduced microplastic pollution. As it decomposes, cellophane does not fragment into persistent microplastics that can harm marine life and enter the food chain. This aspect enhances the overall ecological safety of cellophane-based packaging solutions.

In terms of recycling, cellophane presents both opportunities and challenges. While it is technically recyclable, the infrastructure for collecting and processing cellophane waste is not as well-established as that for other materials. Improving recycling systems for cellophane could further enhance its environmental profile and contribute to a more circular economy.

The use of cellophane in packaging can also indirectly benefit the environment by extending the shelf life of perishable goods. This property helps reduce food waste, which is a significant contributor to greenhouse gas emissions when disposed of in landfills. By preserving food quality for longer periods, cellophane packaging can play a role in minimizing overall waste and its associated environmental impacts.

However, it is important to note that the environmental benefits of cellophane are maximized when the material is properly disposed of or composted. Educating consumers and implementing effective waste management systems are crucial to realizing the full potential of cellophane as an environmentally friendly packaging solution.

Cellophane production typically involves the use of wood pulp or cotton linters as raw materials. The manufacturing process requires chemical treatments and energy-intensive steps, which contribute to carbon emissions and potential water pollution if not properly managed. However, compared to petroleum-based plastics, cellophane's renewable source materials and biodegradability present a more environmentally friendly alternative.

One of the key environmental benefits of cellophane is its ability to decompose naturally in various environments. Unlike conventional plastics that persist for hundreds of years, cellophane can break down within a few months to a few years, depending on conditions. This characteristic significantly reduces the long-term accumulation of waste in landfills and oceans, addressing a major environmental concern associated with plastic packaging.

The biodegradability of cellophane also contributes to reduced microplastic pollution. As it decomposes, cellophane does not fragment into persistent microplastics that can harm marine life and enter the food chain. This aspect enhances the overall ecological safety of cellophane-based packaging solutions.

In terms of recycling, cellophane presents both opportunities and challenges. While it is technically recyclable, the infrastructure for collecting and processing cellophane waste is not as well-established as that for other materials. Improving recycling systems for cellophane could further enhance its environmental profile and contribute to a more circular economy.

The use of cellophane in packaging can also indirectly benefit the environment by extending the shelf life of perishable goods. This property helps reduce food waste, which is a significant contributor to greenhouse gas emissions when disposed of in landfills. By preserving food quality for longer periods, cellophane packaging can play a role in minimizing overall waste and its associated environmental impacts.

However, it is important to note that the environmental benefits of cellophane are maximized when the material is properly disposed of or composted. Educating consumers and implementing effective waste management systems are crucial to realizing the full potential of cellophane as an environmentally friendly packaging solution.

Regulatory Framework for Packaging Materials

The regulatory framework for packaging materials plays a crucial role in ensuring the safety, quality, and environmental sustainability of cellophane solutions in the market. As the demand for resilient packaging increases, understanding and adhering to these regulations becomes paramount for businesses seeking to enhance their market position.

At the global level, organizations such as the World Trade Organization (WTO) and the United Nations Environment Programme (UNEP) provide overarching guidelines for packaging materials. These guidelines often focus on reducing environmental impact, promoting recyclability, and ensuring food safety. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal also influences the regulatory landscape for packaging materials, including cellophane.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials, including cellophane, under the Federal Food, Drug, and Cosmetic Act. The FDA's regulations cover the composition, manufacturing processes, and intended use of packaging materials to ensure they do not adulterate food or pose health risks. Additionally, the Environmental Protection Agency (EPA) oversees regulations related to the environmental impact of packaging materials.

The European Union has implemented comprehensive regulations for food contact materials through the Framework Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Specific measures for cellophane are covered under Commission Directive 2007/42/EC, which outlines the requirements for cellulose film intended to come into contact with foodstuffs.

Many countries have adopted their own regulatory frameworks, often aligning with or exceeding international standards. For instance, Japan's Food Sanitation Act regulates food packaging materials, including cellophane, with a focus on chemical migration and safety. China's GB 9685-2016 standard governs the use of additives in food contact materials and articles, impacting the production and use of cellophane in the Chinese market.

To enhance market resilience with cellophane solutions, companies must navigate this complex regulatory landscape. This involves staying abreast of evolving regulations, investing in compliance measures, and potentially influencing policy development through industry associations. Companies that successfully adapt to and anticipate regulatory changes can gain a competitive advantage by offering compliant, high-quality cellophane products that meet both market demands and regulatory requirements.

Furthermore, the trend towards sustainable packaging is reflected in emerging regulations. Many jurisdictions are implementing extended producer responsibility (EPR) schemes, which could impact the lifecycle management of cellophane packaging. Companies developing cellophane solutions should consider these evolving regulatory frameworks to ensure long-term market viability and resilience.

At the global level, organizations such as the World Trade Organization (WTO) and the United Nations Environment Programme (UNEP) provide overarching guidelines for packaging materials. These guidelines often focus on reducing environmental impact, promoting recyclability, and ensuring food safety. The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal also influences the regulatory landscape for packaging materials, including cellophane.

In the United States, the Food and Drug Administration (FDA) regulates food contact materials, including cellophane, under the Federal Food, Drug, and Cosmetic Act. The FDA's regulations cover the composition, manufacturing processes, and intended use of packaging materials to ensure they do not adulterate food or pose health risks. Additionally, the Environmental Protection Agency (EPA) oversees regulations related to the environmental impact of packaging materials.

The European Union has implemented comprehensive regulations for food contact materials through the Framework Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Specific measures for cellophane are covered under Commission Directive 2007/42/EC, which outlines the requirements for cellulose film intended to come into contact with foodstuffs.

Many countries have adopted their own regulatory frameworks, often aligning with or exceeding international standards. For instance, Japan's Food Sanitation Act regulates food packaging materials, including cellophane, with a focus on chemical migration and safety. China's GB 9685-2016 standard governs the use of additives in food contact materials and articles, impacting the production and use of cellophane in the Chinese market.

To enhance market resilience with cellophane solutions, companies must navigate this complex regulatory landscape. This involves staying abreast of evolving regulations, investing in compliance measures, and potentially influencing policy development through industry associations. Companies that successfully adapt to and anticipate regulatory changes can gain a competitive advantage by offering compliant, high-quality cellophane products that meet both market demands and regulatory requirements.

Furthermore, the trend towards sustainable packaging is reflected in emerging regulations. Many jurisdictions are implementing extended producer responsibility (EPR) schemes, which could impact the lifecycle management of cellophane packaging. Companies developing cellophane solutions should consider these evolving regulatory frameworks to ensure long-term market viability and resilience.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!