Eco-Excellence in Tomorrow's Cellophane Applications

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Evolution and Eco-Goals

Cellophane, a transparent film made from regenerated cellulose, has undergone significant evolution since its invention in the early 20th century. Initially developed as a moisture-proof coating for textiles, cellophane quickly found applications in packaging due to its unique properties. The journey of cellophane from its inception to its current state reflects the changing priorities of industry and society.

In the early stages, the focus was primarily on improving the material's barrier properties and manufacturing efficiency. As environmental concerns gained prominence, the cellophane industry began to shift its attention towards sustainability. This transition marked a crucial turning point in the material's development trajectory, aligning it with the growing global emphasis on eco-friendly solutions.

The evolution of cellophane has been characterized by continuous improvements in its production process and performance characteristics. Researchers have worked tirelessly to enhance its biodegradability, reduce the environmental impact of its manufacturing, and explore renewable sources for its raw materials. These efforts have led to the development of new variants of cellophane with improved ecological profiles.

Looking towards the future, the eco-goals for cellophane are ambitious and multifaceted. One primary objective is to achieve complete biodegradability without compromising the material's functional properties. This involves fine-tuning the molecular structure of cellophane to ensure it breaks down rapidly in natural environments while maintaining its strength and barrier qualities during use.

Another critical eco-goal is the transition to fully renewable and sustainable raw material sources. While cellophane is already derived from cellulose, a naturally occurring polymer, there is a push to explore alternative plant-based sources that do not compete with food crops or contribute to deforestation. This includes investigating the potential of agricultural waste, algae, and other non-traditional cellulose sources.

Reducing the energy and water consumption in cellophane production is another key focus area. Researchers are exploring innovative manufacturing techniques, such as using enzymes for cellulose processing, which could significantly lower the environmental footprint of cellophane production. Additionally, there is a growing interest in developing closed-loop systems that minimize waste and maximize resource efficiency throughout the cellophane lifecycle.

The pursuit of these eco-goals is driving collaboration between material scientists, environmental experts, and industry stakeholders. As cellophane continues to evolve, the aim is to position it as a leading sustainable packaging solution, capable of meeting the stringent environmental standards of the future while fulfilling the diverse needs of modern consumers and industries.

In the early stages, the focus was primarily on improving the material's barrier properties and manufacturing efficiency. As environmental concerns gained prominence, the cellophane industry began to shift its attention towards sustainability. This transition marked a crucial turning point in the material's development trajectory, aligning it with the growing global emphasis on eco-friendly solutions.

The evolution of cellophane has been characterized by continuous improvements in its production process and performance characteristics. Researchers have worked tirelessly to enhance its biodegradability, reduce the environmental impact of its manufacturing, and explore renewable sources for its raw materials. These efforts have led to the development of new variants of cellophane with improved ecological profiles.

Looking towards the future, the eco-goals for cellophane are ambitious and multifaceted. One primary objective is to achieve complete biodegradability without compromising the material's functional properties. This involves fine-tuning the molecular structure of cellophane to ensure it breaks down rapidly in natural environments while maintaining its strength and barrier qualities during use.

Another critical eco-goal is the transition to fully renewable and sustainable raw material sources. While cellophane is already derived from cellulose, a naturally occurring polymer, there is a push to explore alternative plant-based sources that do not compete with food crops or contribute to deforestation. This includes investigating the potential of agricultural waste, algae, and other non-traditional cellulose sources.

Reducing the energy and water consumption in cellophane production is another key focus area. Researchers are exploring innovative manufacturing techniques, such as using enzymes for cellulose processing, which could significantly lower the environmental footprint of cellophane production. Additionally, there is a growing interest in developing closed-loop systems that minimize waste and maximize resource efficiency throughout the cellophane lifecycle.

The pursuit of these eco-goals is driving collaboration between material scientists, environmental experts, and industry stakeholders. As cellophane continues to evolve, the aim is to position it as a leading sustainable packaging solution, capable of meeting the stringent environmental standards of the future while fulfilling the diverse needs of modern consumers and industries.

Market Demand for Sustainable Packaging

The global packaging industry is experiencing a significant shift towards sustainable solutions, driven by increasing environmental concerns and regulatory pressures. This trend has created a robust market demand for eco-friendly packaging materials, with cellophane emerging as a promising candidate due to its biodegradable and renewable properties. The market for sustainable packaging is projected to grow substantially in the coming years, as consumers become more environmentally conscious and businesses seek to reduce their carbon footprint.

Cellophane, a transparent film made from regenerated cellulose, aligns well with the sustainability goals of many industries. Its potential applications span various sectors, including food packaging, personal care products, and industrial packaging. The food industry, in particular, shows strong interest in cellophane due to its excellent barrier properties against moisture and gases, which help extend the shelf life of products while maintaining a commitment to sustainability.

Consumer preferences are playing a crucial role in driving the demand for sustainable packaging. A growing segment of consumers is willing to pay a premium for products packaged in environmentally friendly materials. This shift in consumer behavior is compelling brands to reevaluate their packaging strategies and invest in sustainable alternatives like cellophane. Retailers are also responding to this trend by setting ambitious targets for reducing plastic packaging and increasing the use of recyclable or biodegradable materials in their supply chains.

The regulatory landscape is another significant factor influencing the market demand for sustainable packaging. Governments worldwide are implementing stricter regulations on single-use plastics and promoting the use of biodegradable materials. These policies are creating a favorable environment for the adoption of cellophane and other eco-friendly packaging solutions. As regulations continue to evolve, the demand for sustainable packaging is expected to accelerate further, providing a strong impetus for innovation in cellophane applications.

The market potential for cellophane extends beyond traditional packaging applications. Emerging trends in smart packaging and active packaging systems present new opportunities for cellophane to be integrated with advanced technologies. This convergence of sustainability and innovation is likely to open up new market segments and drive further growth in the demand for eco-friendly cellophane-based solutions.

However, challenges remain in fully realizing the market potential of cellophane. These include the need for improved performance characteristics to match or exceed those of conventional plastics, as well as the development of more efficient production processes to reduce costs. Addressing these challenges will be crucial in meeting the growing market demand for sustainable packaging and positioning cellophane as a leading material in the eco-friendly packaging landscape.

Cellophane, a transparent film made from regenerated cellulose, aligns well with the sustainability goals of many industries. Its potential applications span various sectors, including food packaging, personal care products, and industrial packaging. The food industry, in particular, shows strong interest in cellophane due to its excellent barrier properties against moisture and gases, which help extend the shelf life of products while maintaining a commitment to sustainability.

Consumer preferences are playing a crucial role in driving the demand for sustainable packaging. A growing segment of consumers is willing to pay a premium for products packaged in environmentally friendly materials. This shift in consumer behavior is compelling brands to reevaluate their packaging strategies and invest in sustainable alternatives like cellophane. Retailers are also responding to this trend by setting ambitious targets for reducing plastic packaging and increasing the use of recyclable or biodegradable materials in their supply chains.

The regulatory landscape is another significant factor influencing the market demand for sustainable packaging. Governments worldwide are implementing stricter regulations on single-use plastics and promoting the use of biodegradable materials. These policies are creating a favorable environment for the adoption of cellophane and other eco-friendly packaging solutions. As regulations continue to evolve, the demand for sustainable packaging is expected to accelerate further, providing a strong impetus for innovation in cellophane applications.

The market potential for cellophane extends beyond traditional packaging applications. Emerging trends in smart packaging and active packaging systems present new opportunities for cellophane to be integrated with advanced technologies. This convergence of sustainability and innovation is likely to open up new market segments and drive further growth in the demand for eco-friendly cellophane-based solutions.

However, challenges remain in fully realizing the market potential of cellophane. These include the need for improved performance characteristics to match or exceed those of conventional plastics, as well as the development of more efficient production processes to reduce costs. Addressing these challenges will be crucial in meeting the growing market demand for sustainable packaging and positioning cellophane as a leading material in the eco-friendly packaging landscape.

Current Eco-Cellophane Challenges

The current eco-cellophane industry faces several significant challenges that hinder its widespread adoption and environmental impact. One of the primary obstacles is the high production cost associated with eco-friendly cellophane alternatives. Traditional cellophane, derived from wood pulp, remains more economically viable, making it difficult for sustainable options to compete in the market.

Another major challenge is the limited biodegradability of existing eco-cellophane products. While improvements have been made, many current solutions still do not fully decompose in natural environments within a reasonable timeframe. This shortcoming undermines the environmental benefits and circular economy potential of eco-cellophane applications.

The performance characteristics of eco-cellophane also present challenges. Achieving the same level of transparency, flexibility, and barrier properties as conventional cellophane has proven difficult. This performance gap limits the adoption of eco-friendly alternatives in certain industries, particularly in food packaging where these properties are crucial.

Scalability remains a significant hurdle for eco-cellophane production. Many innovative solutions developed in laboratories face difficulties when transitioning to large-scale manufacturing processes. This scaling issue affects both the consistency of product quality and the ability to meet growing market demands.

The sourcing of sustainable raw materials for eco-cellophane production is another challenge. Ensuring a stable supply chain of renewable resources without compromising food security or contributing to deforestation requires careful management and often involves complex logistics.

Regulatory compliance and certification processes pose additional challenges. The lack of standardized definitions and testing methods for biodegradability and compostability across different regions creates confusion and hinders market acceptance of eco-cellophane products.

Consumer education and awareness represent a significant challenge in the eco-cellophane sector. Many consumers are unfamiliar with the benefits of eco-friendly cellophane alternatives or are skeptical about their effectiveness, leading to slower adoption rates in the market.

Lastly, the end-of-life management of eco-cellophane products remains problematic. The lack of appropriate recycling or composting infrastructure in many regions means that even biodegradable cellophane often ends up in landfills or incineration facilities, negating its environmental benefits.

Another major challenge is the limited biodegradability of existing eco-cellophane products. While improvements have been made, many current solutions still do not fully decompose in natural environments within a reasonable timeframe. This shortcoming undermines the environmental benefits and circular economy potential of eco-cellophane applications.

The performance characteristics of eco-cellophane also present challenges. Achieving the same level of transparency, flexibility, and barrier properties as conventional cellophane has proven difficult. This performance gap limits the adoption of eco-friendly alternatives in certain industries, particularly in food packaging where these properties are crucial.

Scalability remains a significant hurdle for eco-cellophane production. Many innovative solutions developed in laboratories face difficulties when transitioning to large-scale manufacturing processes. This scaling issue affects both the consistency of product quality and the ability to meet growing market demands.

The sourcing of sustainable raw materials for eco-cellophane production is another challenge. Ensuring a stable supply chain of renewable resources without compromising food security or contributing to deforestation requires careful management and often involves complex logistics.

Regulatory compliance and certification processes pose additional challenges. The lack of standardized definitions and testing methods for biodegradability and compostability across different regions creates confusion and hinders market acceptance of eco-cellophane products.

Consumer education and awareness represent a significant challenge in the eco-cellophane sector. Many consumers are unfamiliar with the benefits of eco-friendly cellophane alternatives or are skeptical about their effectiveness, leading to slower adoption rates in the market.

Lastly, the end-of-life management of eco-cellophane products remains problematic. The lack of appropriate recycling or composting infrastructure in many regions means that even biodegradable cellophane often ends up in landfills or incineration facilities, negating its environmental benefits.

Existing Eco-Cellophane Solutions

01 Biodegradable cellophane materials

Development of eco-friendly cellophane materials that are biodegradable and compostable. These materials aim to reduce environmental impact while maintaining the functional properties of traditional cellophane. Innovations focus on using renewable resources and improving end-of-life disposal options.- Biodegradable cellophane materials: Development of eco-friendly cellophane materials that are biodegradable and compostable. These materials aim to reduce environmental impact while maintaining the functional properties of traditional cellophane. Innovations in this area focus on using renewable resources and improving end-of-life disposal options.

- Improved production processes for eco-cellophane: Advancements in manufacturing techniques to produce more environmentally friendly cellophane. These processes may involve reducing energy consumption, minimizing waste, or utilizing greener chemicals. The focus is on creating a more sustainable production chain for cellophane materials.

- Eco-packaging solutions using cellophane: Innovative packaging designs that incorporate eco-friendly cellophane to reduce plastic waste. These solutions may include compostable food packaging, biodegradable wraps, or recyclable product packaging. The emphasis is on maintaining product protection while enhancing environmental sustainability.

- Recycling and upcycling of cellophane products: Development of methods and systems for effectively recycling or upcycling used cellophane products. This includes innovations in collection, sorting, and processing of cellophane waste to create new products or materials, thereby reducing environmental impact and promoting a circular economy.

- Eco-excellence certification and standards for cellophane: Establishment of certification processes and standards to evaluate and promote the eco-excellence of cellophane products. This includes developing criteria for assessing environmental impact, biodegradability, and sustainability throughout the product lifecycle, as well as creating guidelines for manufacturers to improve their cellophane products' eco-performance.

02 Improved manufacturing processes for cellophane

Advancements in cellophane production methods to enhance eco-excellence. These processes aim to reduce energy consumption, minimize waste, and utilize more sustainable raw materials. Innovations include optimizing chemical treatments and developing more efficient drying techniques.Expand Specific Solutions03 Cellophane packaging solutions

Development of innovative cellophane-based packaging solutions that prioritize environmental sustainability. These solutions focus on reducing material usage, improving recyclability, and enhancing the overall eco-friendliness of packaging products while maintaining their protective properties.Expand Specific Solutions04 Recycling and upcycling of cellophane

Advancements in recycling and upcycling technologies for cellophane products. These innovations aim to extend the lifecycle of cellophane materials, reduce waste, and create new value-added products from recycled cellophane, contributing to a more circular economy.Expand Specific Solutions05 Eco-friendly additives and coatings for cellophane

Development of environmentally friendly additives and coatings to enhance the properties of cellophane. These innovations focus on improving barrier properties, extending shelf life, and adding functionality to cellophane products while maintaining their eco-excellence and recyclability.Expand Specific Solutions

Key Players in Eco-Cellophane Industry

The research on eco-excellence in tomorrow's cellophane applications is in an emerging phase, with the market showing significant growth potential due to increasing environmental concerns. The global market size for eco-friendly packaging materials is expanding rapidly, driven by consumer demand and regulatory pressures. Technologically, the field is evolving, with companies like Novozymes, DSM IP Assets BV, and SCHOTT AG leading innovation in bio-based and biodegradable materials. These firms are developing advanced enzymatic and polymer technologies to enhance cellophane's eco-properties. Other players such as LG Electronics and Samsung Display are exploring applications in flexible displays, indicating a broadening scope for eco-cellophane beyond traditional packaging.

Danisco US, Inc.

Technical Solution: Danisco, now part of IFF (International Flavors & Fragrances), has been researching bio-based packaging solutions as alternatives to traditional cellophane. Their approach focuses on developing cellulose-based films with enhanced barrier properties using enzyme technology[7]. The company has made significant progress in creating films that are both biodegradable and compostable while maintaining the transparency and flexibility of cellophane. Danisco's research also includes the incorporation of antimicrobial agents into these films to extend the shelf life of packaged products[8]. They are exploring the use of agricultural waste as a raw material source to further improve the sustainability profile of their cellophane alternatives[9].

Strengths: Strong expertise in enzyme technology and bio-based materials. Weaknesses: Potential challenges in achieving cost parity with traditional cellophane at scale.

Novozymes A/S

Technical Solution: Novozymes, a leader in biological solutions, is applying its enzyme technology to develop eco-friendly alternatives to cellophane. Their research focuses on creating biodegradable films using cellulose and other bio-based polymers[10]. The company has developed enzymatic processes that can modify cellulose structures to improve film properties such as water resistance and mechanical strength[11]. Novozymes is also exploring the use of agricultural residues and food waste as raw materials for their cellophane alternatives, aiming to create a circular economy approach to packaging[12]. Their technology allows for the production of films with tailored properties for specific applications, potentially surpassing the versatility of traditional cellophane.

Strengths: Cutting-edge enzyme technology and strong focus on sustainability. Weaknesses: May face challenges in scaling up production to meet large-scale demand.

Innovative Eco-Cellophane Patents

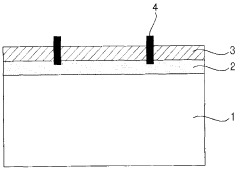

Electrode paste for solar cell, solar cell using the paste, and fabrication method of the solar cell

PatentWO2011005003A2

Innovation

- An electrode paste comprising silver or silver alloys, zinc, leaded or lead-free glass frit, and a resin binder is used, with specific weight percentages, to form a conductive semiconductor layer with a depth of 100 nm to 500 nm, allowing for the formation of a high sheet resistance emitter layer and preventing short circuits during the firing process.

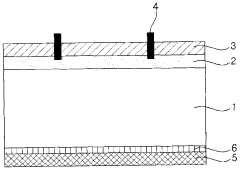

Electrode paste for solar cell, solar cell using the paste, and fabrication method of the solar cell

PatentInactiveEP2452366A2

Innovation

- An electrode paste comprising silver or silver alloys, zinc, leaded or lead-free glass frit, and a resin binder is used, with specific weight percentages, to form a conductive semiconductor layer with a depth of 100 nm to 500 nm, allowing for the formation of a high sheet resistance emitter layer and preventing short circuits during the firing process.

Biodegradability and Recycling

Cellophane, a biodegradable and compostable material derived from renewable resources, has gained renewed interest in the pursuit of eco-friendly packaging solutions. The biodegradability and recyclability of cellophane are crucial factors in its potential to address environmental concerns associated with conventional plastics.

Cellophane's biodegradability is attributed to its cellulose-based composition, which allows it to break down naturally in various environments. Under optimal conditions, cellophane can decompose within a few months to a year, significantly faster than traditional petroleum-based plastics. This rapid biodegradation process reduces the accumulation of waste in landfills and minimizes the risk of environmental pollution.

The biodegradation of cellophane occurs through the action of microorganisms, such as bacteria and fungi, which secrete enzymes capable of breaking down the cellulose molecules. This process results in the conversion of cellophane into water, carbon dioxide, and biomass, leaving no harmful residues in the environment. However, the rate of biodegradation can vary depending on factors such as temperature, humidity, and the presence of specific microorganisms.

In terms of recycling, cellophane presents both opportunities and challenges. While it is technically recyclable, the current recycling infrastructure is not widely equipped to handle cellophane separately from other materials. As a result, cellophane often ends up in general waste streams or contaminates other recycling processes.

To improve the recyclability of cellophane, efforts are being made to develop specialized recycling processes and infrastructure. One approach involves the chemical recycling of cellophane, which breaks down the material into its basic components for reuse in new products. Another strategy focuses on enhancing the compatibility of cellophane with existing recycling streams, such as paper recycling.

The eco-excellence of cellophane in future applications will depend on advancements in both biodegradability and recycling technologies. Research is ongoing to optimize the biodegradation process, ensuring that cellophane breaks down efficiently in various environments without leaving microplastics or other harmful residues. This includes the development of additives that can accelerate biodegradation while maintaining the material's functional properties.

Simultaneously, efforts are being made to improve the recyclability of cellophane through the design of easily separable multi-layer structures and the development of compatible coatings that do not hinder the recycling process. These innovations aim to create a closed-loop system for cellophane, where the material can be effectively recycled or composted at the end of its life cycle.

As the demand for sustainable packaging solutions continues to grow, the focus on enhancing the biodegradability and recyclability of cellophane will play a crucial role in positioning it as a viable alternative to conventional plastics. The success of these efforts will contribute significantly to the eco-excellence of cellophane in tomorrow's applications, aligning with global sustainability goals and circular economy principles.

Cellophane's biodegradability is attributed to its cellulose-based composition, which allows it to break down naturally in various environments. Under optimal conditions, cellophane can decompose within a few months to a year, significantly faster than traditional petroleum-based plastics. This rapid biodegradation process reduces the accumulation of waste in landfills and minimizes the risk of environmental pollution.

The biodegradation of cellophane occurs through the action of microorganisms, such as bacteria and fungi, which secrete enzymes capable of breaking down the cellulose molecules. This process results in the conversion of cellophane into water, carbon dioxide, and biomass, leaving no harmful residues in the environment. However, the rate of biodegradation can vary depending on factors such as temperature, humidity, and the presence of specific microorganisms.

In terms of recycling, cellophane presents both opportunities and challenges. While it is technically recyclable, the current recycling infrastructure is not widely equipped to handle cellophane separately from other materials. As a result, cellophane often ends up in general waste streams or contaminates other recycling processes.

To improve the recyclability of cellophane, efforts are being made to develop specialized recycling processes and infrastructure. One approach involves the chemical recycling of cellophane, which breaks down the material into its basic components for reuse in new products. Another strategy focuses on enhancing the compatibility of cellophane with existing recycling streams, such as paper recycling.

The eco-excellence of cellophane in future applications will depend on advancements in both biodegradability and recycling technologies. Research is ongoing to optimize the biodegradation process, ensuring that cellophane breaks down efficiently in various environments without leaving microplastics or other harmful residues. This includes the development of additives that can accelerate biodegradation while maintaining the material's functional properties.

Simultaneously, efforts are being made to improve the recyclability of cellophane through the design of easily separable multi-layer structures and the development of compatible coatings that do not hinder the recycling process. These innovations aim to create a closed-loop system for cellophane, where the material can be effectively recycled or composted at the end of its life cycle.

As the demand for sustainable packaging solutions continues to grow, the focus on enhancing the biodegradability and recyclability of cellophane will play a crucial role in positioning it as a viable alternative to conventional plastics. The success of these efforts will contribute significantly to the eco-excellence of cellophane in tomorrow's applications, aligning with global sustainability goals and circular economy principles.

Life Cycle Assessment of Cellophane

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental impact of cellophane throughout its entire lifecycle. This comprehensive analysis begins with the extraction of raw materials, primarily wood pulp or cotton linters, and extends through the manufacturing process, use phase, and eventual disposal or recycling of cellophane products.

The production phase of cellophane involves several energy-intensive steps, including the dissolution of cellulose in alkali and carbon disulfide, followed by regeneration in an acid bath. This process contributes significantly to the overall environmental footprint of cellophane. Energy consumption and chemical usage during manufacturing are key factors that need to be carefully assessed and optimized to improve the eco-profile of cellophane.

During the use phase, cellophane's biodegradability and potential for composting present advantages over conventional plastics. However, the actual environmental benefits depend on proper disposal and the availability of industrial composting facilities. The LCA must account for various end-of-life scenarios, including landfilling, incineration, and composting, to provide a holistic view of cellophane's environmental impact.

Water usage is another critical aspect of cellophane's life cycle. The production process requires substantial amounts of water, and the treatment of wastewater from manufacturing plants is an important consideration in the overall environmental assessment. Innovations in water recycling and purification technologies can significantly reduce the water footprint of cellophane production.

Transportation and distribution of cellophane products also contribute to their environmental impact. The LCA should consider the emissions associated with transporting raw materials to production facilities and finished products to end-users. Optimizing logistics and exploring more sustainable transportation methods can help mitigate these impacts.

Comparing cellophane's life cycle performance with alternative packaging materials is essential for understanding its relative environmental benefits. This comparison should include factors such as resource depletion, greenhouse gas emissions, water consumption, and end-of-life management. Such analysis can guide decision-making in packaging selection and highlight areas where cellophane excels or needs improvement.

Advancements in bio-based and renewable feedstocks for cellophane production offer promising avenues for enhancing its eco-profile. Exploring alternative raw materials and production methods that reduce reliance on fossil fuels and minimize chemical inputs can lead to significant improvements in cellophane's life cycle performance.

The production phase of cellophane involves several energy-intensive steps, including the dissolution of cellulose in alkali and carbon disulfide, followed by regeneration in an acid bath. This process contributes significantly to the overall environmental footprint of cellophane. Energy consumption and chemical usage during manufacturing are key factors that need to be carefully assessed and optimized to improve the eco-profile of cellophane.

During the use phase, cellophane's biodegradability and potential for composting present advantages over conventional plastics. However, the actual environmental benefits depend on proper disposal and the availability of industrial composting facilities. The LCA must account for various end-of-life scenarios, including landfilling, incineration, and composting, to provide a holistic view of cellophane's environmental impact.

Water usage is another critical aspect of cellophane's life cycle. The production process requires substantial amounts of water, and the treatment of wastewater from manufacturing plants is an important consideration in the overall environmental assessment. Innovations in water recycling and purification technologies can significantly reduce the water footprint of cellophane production.

Transportation and distribution of cellophane products also contribute to their environmental impact. The LCA should consider the emissions associated with transporting raw materials to production facilities and finished products to end-users. Optimizing logistics and exploring more sustainable transportation methods can help mitigate these impacts.

Comparing cellophane's life cycle performance with alternative packaging materials is essential for understanding its relative environmental benefits. This comparison should include factors such as resource depletion, greenhouse gas emissions, water consumption, and end-of-life management. Such analysis can guide decision-making in packaging selection and highlight areas where cellophane excels or needs improvement.

Advancements in bio-based and renewable feedstocks for cellophane production offer promising avenues for enhancing its eco-profile. Exploring alternative raw materials and production methods that reduce reliance on fossil fuels and minimize chemical inputs can lead to significant improvements in cellophane's life cycle performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!