How to Merge Industry Demands with Cellophane Innovation?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Innovation Landscape and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging and industrial applications for nearly a century. The innovation landscape for cellophane is currently at a critical juncture, driven by increasing environmental concerns and evolving industry demands. The primary objective of cellophane innovation is to address these challenges while maintaining its unique properties that have made it indispensable in various sectors.

The historical development of cellophane has seen significant advancements since its invention in 1908. Initially used for food packaging, its applications have expanded to include textiles, pharmaceuticals, and electronics. Recent technological trends in cellophane innovation focus on enhancing biodegradability, improving barrier properties, and reducing production costs. These trends align with the growing global emphasis on sustainable packaging solutions and circular economy principles.

Industry demands are rapidly shifting towards eco-friendly alternatives to traditional plastics. This presents both challenges and opportunities for cellophane innovation. The key objectives in this landscape include developing fully biodegradable cellophane variants, improving moisture resistance without compromising compostability, and exploring novel production methods that reduce energy consumption and chemical usage.

One of the primary goals is to merge cellophane's inherent benefits with cutting-edge material science. This involves exploring nanocomposite technologies to enhance cellophane's mechanical and barrier properties, investigating bio-based additives to improve functionality, and developing smart cellophane materials that can interact with their contents or environment.

Another critical objective is to align cellophane innovation with the broader sustainability goals of various industries. This includes creating cellophane products that are not only biodegradable but also sourced from renewable feedstocks, potentially expanding into agricultural waste or algae-based cellulose sources. Additionally, there is a push to develop cellophane that can be easily recycled or repurposed, contributing to closed-loop manufacturing systems.

The cellophane innovation landscape also aims to address specific industry needs, such as extending shelf life in food packaging, improving drug delivery systems in pharmaceuticals, and enhancing durability in electronic components. These sector-specific innovations require a deep understanding of the unique demands of each industry and the ability to tailor cellophane properties accordingly.

As we look towards the future, the cellophane innovation landscape is poised for significant breakthroughs. The convergence of biotechnology, nanotechnology, and materials science offers promising avenues for developing next-generation cellophane products. These innovations have the potential to not only meet current industry demands but also create new markets and applications, reinforcing cellophane's position as a versatile and sustainable material in the 21st century.

The historical development of cellophane has seen significant advancements since its invention in 1908. Initially used for food packaging, its applications have expanded to include textiles, pharmaceuticals, and electronics. Recent technological trends in cellophane innovation focus on enhancing biodegradability, improving barrier properties, and reducing production costs. These trends align with the growing global emphasis on sustainable packaging solutions and circular economy principles.

Industry demands are rapidly shifting towards eco-friendly alternatives to traditional plastics. This presents both challenges and opportunities for cellophane innovation. The key objectives in this landscape include developing fully biodegradable cellophane variants, improving moisture resistance without compromising compostability, and exploring novel production methods that reduce energy consumption and chemical usage.

One of the primary goals is to merge cellophane's inherent benefits with cutting-edge material science. This involves exploring nanocomposite technologies to enhance cellophane's mechanical and barrier properties, investigating bio-based additives to improve functionality, and developing smart cellophane materials that can interact with their contents or environment.

Another critical objective is to align cellophane innovation with the broader sustainability goals of various industries. This includes creating cellophane products that are not only biodegradable but also sourced from renewable feedstocks, potentially expanding into agricultural waste or algae-based cellulose sources. Additionally, there is a push to develop cellophane that can be easily recycled or repurposed, contributing to closed-loop manufacturing systems.

The cellophane innovation landscape also aims to address specific industry needs, such as extending shelf life in food packaging, improving drug delivery systems in pharmaceuticals, and enhancing durability in electronic components. These sector-specific innovations require a deep understanding of the unique demands of each industry and the ability to tailor cellophane properties accordingly.

As we look towards the future, the cellophane innovation landscape is poised for significant breakthroughs. The convergence of biotechnology, nanotechnology, and materials science offers promising avenues for developing next-generation cellophane products. These innovations have the potential to not only meet current industry demands but also create new markets and applications, reinforcing cellophane's position as a versatile and sustainable material in the 21st century.

Market Analysis for Advanced Cellophane Applications

The cellophane market has witnessed significant growth in recent years, driven by increasing demand for sustainable packaging solutions across various industries. As environmental concerns continue to rise, the market for advanced cellophane applications is expected to expand further, with a projected compound annual growth rate of 5.8% from 2021 to 2026. This growth is primarily attributed to the material's biodegradable and compostable properties, which align with the global shift towards eco-friendly packaging alternatives.

The food and beverage industry remains the largest consumer of cellophane, accounting for approximately 45% of the total market share. The material's excellent barrier properties against moisture, gases, and bacteria make it ideal for preserving food quality and extending shelf life. Additionally, the pharmaceutical sector has shown increased interest in cellophane for blister packaging and drug delivery systems, contributing to market expansion.

Emerging applications in the electronics industry, particularly for flexible displays and wearable devices, present new opportunities for cellophane innovation. The material's transparency, flexibility, and potential for functionalization make it an attractive option for next-generation electronic components. This diversification of applications is expected to drive market growth and stimulate further research and development efforts.

Geographically, Asia-Pacific dominates the cellophane market, with China and India leading in production and consumption. The region's rapid industrialization, growing population, and increasing disposable income contribute to the rising demand for packaged goods, subsequently boosting cellophane usage. North America and Europe follow, with a focus on high-value applications and sustainable packaging solutions.

Consumer preferences are shifting towards transparent packaging that allows product visibility while maintaining eco-friendliness. This trend has led to increased adoption of cellophane in the cosmetics and personal care industries, where product presentation is crucial. The material's ability to be easily printed and customized further enhances its appeal in these sectors.

Despite the positive market outlook, challenges such as competition from alternative materials like bioplastics and concerns over raw material sourcing persist. To address these issues, industry players are investing in research to improve cellophane's performance characteristics and develop more sustainable production methods. Innovations in cellulose-based nanocomposites and bio-based additives are expected to enhance cellophane's properties and expand its application range.

The market analysis reveals a growing demand for cellophane with advanced functionalities, such as antimicrobial properties, improved barrier performance, and enhanced biodegradability. These developments are crucial for meeting the evolving needs of various industries and maintaining cellophane's competitive edge in the packaging market.

The food and beverage industry remains the largest consumer of cellophane, accounting for approximately 45% of the total market share. The material's excellent barrier properties against moisture, gases, and bacteria make it ideal for preserving food quality and extending shelf life. Additionally, the pharmaceutical sector has shown increased interest in cellophane for blister packaging and drug delivery systems, contributing to market expansion.

Emerging applications in the electronics industry, particularly for flexible displays and wearable devices, present new opportunities for cellophane innovation. The material's transparency, flexibility, and potential for functionalization make it an attractive option for next-generation electronic components. This diversification of applications is expected to drive market growth and stimulate further research and development efforts.

Geographically, Asia-Pacific dominates the cellophane market, with China and India leading in production and consumption. The region's rapid industrialization, growing population, and increasing disposable income contribute to the rising demand for packaged goods, subsequently boosting cellophane usage. North America and Europe follow, with a focus on high-value applications and sustainable packaging solutions.

Consumer preferences are shifting towards transparent packaging that allows product visibility while maintaining eco-friendliness. This trend has led to increased adoption of cellophane in the cosmetics and personal care industries, where product presentation is crucial. The material's ability to be easily printed and customized further enhances its appeal in these sectors.

Despite the positive market outlook, challenges such as competition from alternative materials like bioplastics and concerns over raw material sourcing persist. To address these issues, industry players are investing in research to improve cellophane's performance characteristics and develop more sustainable production methods. Innovations in cellulose-based nanocomposites and bio-based additives are expected to enhance cellophane's properties and expand its application range.

The market analysis reveals a growing demand for cellophane with advanced functionalities, such as antimicrobial properties, improved barrier performance, and enhanced biodegradability. These developments are crucial for meeting the evolving needs of various industries and maintaining cellophane's competitive edge in the packaging market.

Technical Challenges in Cellophane Industry Integration

The integration of cellophane innovation with industry demands presents several technical challenges that require careful consideration and innovative solutions. One of the primary obstacles is the need to enhance the barrier properties of cellophane while maintaining its biodegradability. Traditional cellophane, while eco-friendly, often falls short in providing adequate moisture and oxygen barriers necessary for many industrial applications, particularly in food packaging.

Another significant challenge lies in improving the heat-sealing capabilities of cellophane. Unlike synthetic polymers, cellophane's natural composition makes it difficult to achieve strong, reliable seals without compromising its environmental benefits. This limitation restricts its use in certain packaging formats and automated production lines, where heat-sealing is a critical process.

The mechanical strength of cellophane also poses a challenge when integrating it into high-speed manufacturing processes. While cellophane offers good tensile strength, its tear resistance and puncture resistance may not meet the demands of some industrial applications. Enhancing these properties without resorting to non-biodegradable additives remains a complex technical hurdle.

Furthermore, the moisture sensitivity of cellophane presents difficulties in maintaining consistent performance across varying environmental conditions. This characteristic can lead to dimensional instability and changes in barrier properties, which are critical factors in many industrial uses. Developing moisture-resistant formulations that do not compromise cellophane's inherent biodegradability is a key technical challenge.

The printing and converting processes also face obstacles when working with cellophane. Its surface properties and heat sensitivity can make it challenging to achieve high-quality printing or apply certain coatings and adhesives. Adapting existing printing and converting technologies to work effectively with cellophane, or developing new ones, is essential for its widespread industrial adoption.

Lastly, scaling up the production of innovative cellophane formulations to meet industrial demands presents its own set of challenges. Ensuring consistent quality, optimizing production efficiency, and managing costs while incorporating new additives or processing techniques are critical aspects that need to be addressed. The industry must find ways to bridge the gap between laboratory innovations and large-scale manufacturing capabilities to make cellophane a viable alternative to synthetic plastics in various applications.

Another significant challenge lies in improving the heat-sealing capabilities of cellophane. Unlike synthetic polymers, cellophane's natural composition makes it difficult to achieve strong, reliable seals without compromising its environmental benefits. This limitation restricts its use in certain packaging formats and automated production lines, where heat-sealing is a critical process.

The mechanical strength of cellophane also poses a challenge when integrating it into high-speed manufacturing processes. While cellophane offers good tensile strength, its tear resistance and puncture resistance may not meet the demands of some industrial applications. Enhancing these properties without resorting to non-biodegradable additives remains a complex technical hurdle.

Furthermore, the moisture sensitivity of cellophane presents difficulties in maintaining consistent performance across varying environmental conditions. This characteristic can lead to dimensional instability and changes in barrier properties, which are critical factors in many industrial uses. Developing moisture-resistant formulations that do not compromise cellophane's inherent biodegradability is a key technical challenge.

The printing and converting processes also face obstacles when working with cellophane. Its surface properties and heat sensitivity can make it challenging to achieve high-quality printing or apply certain coatings and adhesives. Adapting existing printing and converting technologies to work effectively with cellophane, or developing new ones, is essential for its widespread industrial adoption.

Lastly, scaling up the production of innovative cellophane formulations to meet industrial demands presents its own set of challenges. Ensuring consistent quality, optimizing production efficiency, and managing costs while incorporating new additives or processing techniques are critical aspects that need to be addressed. The industry must find ways to bridge the gap between laboratory innovations and large-scale manufacturing capabilities to make cellophane a viable alternative to synthetic plastics in various applications.

Current Cellophane-Industry Merger Solutions

01 Cellophane production and modification

Various methods and processes for producing and modifying cellophane are described. These include techniques for improving the properties of cellophane, such as its strength, flexibility, and barrier characteristics. The production processes may involve chemical treatments, coating applications, or physical modifications to enhance the material's performance for different applications.- Cellophane in packaging applications: Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, where it can help preserve freshness and extend shelf life. Cellophane can be used alone or in combination with other materials to create various packaging solutions.

- Biodegradable cellophane alternatives: Research is being conducted to develop biodegradable alternatives to traditional cellophane. These new materials aim to maintain the desirable properties of cellophane while reducing environmental impact. Innovations in this area include the use of plant-based materials and modified production processes to enhance biodegradability.

- Cellophane in textile and fiber applications: Cellophane and its derivatives are used in various textile and fiber applications. This includes the production of regenerated cellulose fibers, which can be used to create fabrics with unique properties. Cellophane-based materials are also explored for use in technical textiles and specialty fibers.

- Modified cellophane for enhanced functionality: Researchers are developing modified forms of cellophane with enhanced functionality. These modifications can improve properties such as strength, barrier performance, and chemical resistance. Techniques include surface treatments, incorporation of additives, and chemical modifications of the cellulose structure.

- Cellophane in medical and pharmaceutical applications: Cellophane and its derivatives find applications in the medical and pharmaceutical fields. This includes use in drug delivery systems, wound dressings, and as a component in certain medical devices. The biocompatibility and barrier properties of cellophane make it suitable for these specialized applications.

02 Packaging applications of cellophane

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. The material is employed in food packaging, consumer goods packaging, and industrial packaging solutions. Innovations in this area focus on improving the sealing properties, printability, and compatibility with other materials to enhance the overall packaging performance.Expand Specific Solutions03 Biodegradable and eco-friendly cellophane

Research and development efforts are directed towards creating biodegradable and environmentally friendly versions of cellophane. These innovations aim to address sustainability concerns by developing cellophane-like materials that can decompose naturally or be recycled more easily. The focus is on maintaining the desirable properties of traditional cellophane while reducing its environmental impact.Expand Specific Solutions04 Cellophane in medical and pharmaceutical applications

Cellophane finds applications in the medical and pharmaceutical industries. It is used in various forms, such as films, membranes, or coatings, for drug delivery systems, wound dressings, and diagnostic devices. The material's biocompatibility and ability to be sterilized make it suitable for these specialized applications.Expand Specific Solutions05 Cellophane-based composite materials

Researchers are exploring the development of composite materials incorporating cellophane or its derivatives. These composites aim to combine the advantageous properties of cellophane with other materials to create novel products with enhanced characteristics. Applications may include advanced packaging, electronic components, or structural materials.Expand Specific Solutions

Key Players in Cellophane Innovation Ecosystem

The cellophane innovation market is in a growth phase, with increasing industry demands driving technological advancements. The competitive landscape is characterized by a mix of established players and emerging companies, reflecting the market's evolving nature. Key players like Novozymes A/S, Codexis, Inc., and AGC, Inc. are leveraging their expertise in biotechnology and materials science to develop innovative cellophane solutions. The market size is expanding as industries seek sustainable packaging alternatives. Technologically, cellophane innovation is progressing rapidly, with companies focusing on enhancing biodegradability, strength, and versatility. The involvement of research institutions and collaborations between industry and academia are accelerating the pace of innovation in this field.

Novozymes A/S

Technical Solution: Novozymes A/S has developed innovative enzyme solutions to enhance cellophane production and meet industry demands. Their approach involves using specialized cellulases and other enzymes to modify cellulose fibers during the manufacturing process. This enzymatic treatment improves cellophane's properties, such as increased strength, flexibility, and barrier properties[1]. The company has also focused on developing enzymes that can work efficiently at lower temperatures and pH levels, reducing energy consumption and chemical usage in cellophane production[2]. Additionally, Novozymes has explored the use of enzymes derived from extremophiles, which can withstand harsh industrial conditions, potentially revolutionizing the cellophane manufacturing process[3].

Strengths: Expertise in enzyme technology, sustainable solutions, improved product properties. Weaknesses: Potential higher initial costs, need for process modifications in existing manufacturing lines.

AGC, Inc. (Japan)

Technical Solution: AGC, Inc. has developed advanced coating technologies to enhance cellophane's functionality and meet evolving industry demands. Their approach involves applying ultra-thin, multi-layer coatings to cellophane substrates, improving barrier properties against moisture, oxygen, and UV light[4]. AGC has also introduced nano-scale surface treatments that enhance cellophane's printability and adhesion characteristics, making it more suitable for packaging applications[5]. Furthermore, the company has developed environmentally friendly coating materials derived from bio-based sources, aligning with the growing demand for sustainable packaging solutions[6]. AGC's innovations extend to incorporating active ingredients into cellophane coatings, such as antimicrobial agents, to create functional packaging materials that extend product shelf life[7].

Strengths: Advanced coating technologies, improved functionality, eco-friendly solutions. Weaknesses: Potentially higher production costs, limited to surface modifications rather than bulk material improvements.

Breakthrough Cellophane Technologies Analysis

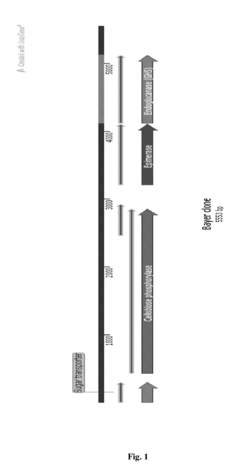

Compositions and methods of PGL for the increased production of isoprene

PatentWO2011079314A2

Innovation

- Integration of 6-phosphogluconolactonase (PGL) into E. coli strains, along with heterologous nucleic acids encoding isoprene synthase and other polypeptides, to enhance isoprene production, utilizing a recombinant cell system that integrates these genes into the E. coli chromosome, thereby increasing isoprene titer and specific productivity.

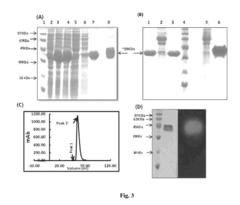

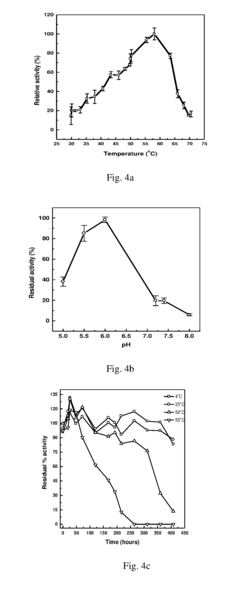

Cellulase derived from metagenomics

PatentInactiveUS20180371442A1

Innovation

- A novel endoglucanase gene from the soil metagenome, specifically a recombinant plasmid and host system for expressing a cellulase with high specific activity towards β-1,4 linkages in substrates like carboxy-methyl cellulose and barley-β-glucan, exhibiting enhanced thermal and pH stability, and tolerance to salts and chemicals.

Environmental Impact of Cellophane Innovations

The environmental impact of cellophane innovations is a critical consideration in the quest to merge industry demands with sustainable packaging solutions. Cellophane, a biodegradable material derived from cellulose, has been gaining renewed attention due to its potential to address environmental concerns associated with traditional plastic packaging.

One of the primary environmental benefits of cellophane innovations lies in its biodegradability. Unlike conventional plastics that persist in the environment for hundreds of years, cellophane can decompose naturally within a few months to a few years, depending on environmental conditions. This characteristic significantly reduces the long-term environmental burden and helps mitigate the issue of plastic pollution in landfills and oceans.

Moreover, cellophane production typically involves renewable resources, primarily wood pulp or cotton linters. This shift towards bio-based materials aligns with the growing demand for sustainable packaging solutions and contributes to reducing dependency on fossil fuel-derived plastics. The use of renewable resources also promotes a more circular economy approach, where materials can be regenerated and reused in natural cycles.

Recent innovations in cellophane technology have focused on enhancing its barrier properties and durability while maintaining its eco-friendly attributes. These advancements aim to expand cellophane's applicability across various industries, including food packaging, pharmaceuticals, and consumer goods. Improved moisture resistance and oxygen barrier properties, for instance, can extend the shelf life of products, potentially reducing food waste and the associated environmental impact.

However, it is essential to consider the entire lifecycle of cellophane products when assessing their environmental impact. While the material itself may be biodegradable, the production process can still have significant energy and water requirements. Innovations in manufacturing techniques, such as more efficient water recycling systems and the use of renewable energy sources, are crucial in minimizing the overall environmental footprint of cellophane production.

Additionally, the end-of-life management of cellophane products requires careful consideration. While biodegradable, improper disposal can still lead to environmental issues. Educating consumers about proper disposal methods and developing appropriate composting infrastructure are essential steps in maximizing the environmental benefits of cellophane innovations.

As industries strive to meet sustainability goals and consumer demands for eco-friendly packaging, cellophane innovations present a promising avenue. By continually improving the material's properties and production processes, cellophane has the potential to play a significant role in reducing the environmental impact of packaging materials while meeting the functional requirements of various industries.

One of the primary environmental benefits of cellophane innovations lies in its biodegradability. Unlike conventional plastics that persist in the environment for hundreds of years, cellophane can decompose naturally within a few months to a few years, depending on environmental conditions. This characteristic significantly reduces the long-term environmental burden and helps mitigate the issue of plastic pollution in landfills and oceans.

Moreover, cellophane production typically involves renewable resources, primarily wood pulp or cotton linters. This shift towards bio-based materials aligns with the growing demand for sustainable packaging solutions and contributes to reducing dependency on fossil fuel-derived plastics. The use of renewable resources also promotes a more circular economy approach, where materials can be regenerated and reused in natural cycles.

Recent innovations in cellophane technology have focused on enhancing its barrier properties and durability while maintaining its eco-friendly attributes. These advancements aim to expand cellophane's applicability across various industries, including food packaging, pharmaceuticals, and consumer goods. Improved moisture resistance and oxygen barrier properties, for instance, can extend the shelf life of products, potentially reducing food waste and the associated environmental impact.

However, it is essential to consider the entire lifecycle of cellophane products when assessing their environmental impact. While the material itself may be biodegradable, the production process can still have significant energy and water requirements. Innovations in manufacturing techniques, such as more efficient water recycling systems and the use of renewable energy sources, are crucial in minimizing the overall environmental footprint of cellophane production.

Additionally, the end-of-life management of cellophane products requires careful consideration. While biodegradable, improper disposal can still lead to environmental issues. Educating consumers about proper disposal methods and developing appropriate composting infrastructure are essential steps in maximizing the environmental benefits of cellophane innovations.

As industries strive to meet sustainability goals and consumer demands for eco-friendly packaging, cellophane innovations present a promising avenue. By continually improving the material's properties and production processes, cellophane has the potential to play a significant role in reducing the environmental impact of packaging materials while meeting the functional requirements of various industries.

Cross-Industry Collaboration Strategies

Cross-industry collaboration strategies are essential for merging industry demands with cellophane innovation. By fostering partnerships between cellophane manufacturers and diverse sectors, companies can unlock new applications and drive technological advancements. One key strategy is the formation of innovation clusters, bringing together researchers, manufacturers, and end-users from various industries. These clusters facilitate knowledge exchange, resource sharing, and joint problem-solving, accelerating the development of novel cellophane solutions.

Another effective approach is the establishment of open innovation platforms. These digital ecosystems enable companies to share challenges, ideas, and potential solutions related to cellophane technology. By inviting contributions from a wide range of industries, such platforms can lead to unexpected breakthroughs and cross-pollination of ideas. This collaborative model also helps identify new market opportunities and reduces the risk associated with individual research and development efforts.

Strategic alliances between cellophane producers and industry leaders in sectors such as packaging, electronics, and healthcare can drive targeted innovation. These partnerships allow for the co-development of specialized cellophane products that meet specific industry needs. By aligning research goals and sharing expertise, companies can accelerate the commercialization of new cellophane applications while ensuring market relevance.

Implementing cross-functional teams within organizations is another crucial strategy. These teams should include members from research and development, marketing, and customer-facing roles to ensure a holistic approach to innovation. By integrating diverse perspectives, companies can better anticipate market demands and develop cellophane solutions that address real-world challenges across multiple industries.

Collaborative research programs between academia and industry play a vital role in advancing cellophane technology. Universities can provide cutting-edge scientific knowledge and access to advanced research facilities, while industry partners offer practical insights and commercialization expertise. These partnerships can focus on fundamental research to improve cellophane properties or explore entirely new applications, fostering long-term innovation in the field.

Lastly, industry-wide consortia and standardization efforts are critical for aligning cellophane innovation with broader market needs. By establishing common standards and best practices, these initiatives can accelerate adoption across industries and create a more cohesive ecosystem for cellophane technology development. Such collaborative efforts also help address shared challenges, such as sustainability and regulatory compliance, ensuring that cellophane innovations meet evolving global requirements.

Another effective approach is the establishment of open innovation platforms. These digital ecosystems enable companies to share challenges, ideas, and potential solutions related to cellophane technology. By inviting contributions from a wide range of industries, such platforms can lead to unexpected breakthroughs and cross-pollination of ideas. This collaborative model also helps identify new market opportunities and reduces the risk associated with individual research and development efforts.

Strategic alliances between cellophane producers and industry leaders in sectors such as packaging, electronics, and healthcare can drive targeted innovation. These partnerships allow for the co-development of specialized cellophane products that meet specific industry needs. By aligning research goals and sharing expertise, companies can accelerate the commercialization of new cellophane applications while ensuring market relevance.

Implementing cross-functional teams within organizations is another crucial strategy. These teams should include members from research and development, marketing, and customer-facing roles to ensure a holistic approach to innovation. By integrating diverse perspectives, companies can better anticipate market demands and develop cellophane solutions that address real-world challenges across multiple industries.

Collaborative research programs between academia and industry play a vital role in advancing cellophane technology. Universities can provide cutting-edge scientific knowledge and access to advanced research facilities, while industry partners offer practical insights and commercialization expertise. These partnerships can focus on fundamental research to improve cellophane properties or explore entirely new applications, fostering long-term innovation in the field.

Lastly, industry-wide consortia and standardization efforts are critical for aligning cellophane innovation with broader market needs. By establishing common standards and best practices, these initiatives can accelerate adoption across industries and create a more cohesive ecosystem for cellophane technology development. Such collaborative efforts also help address shared challenges, such as sustainability and regulatory compliance, ensuring that cellophane innovations meet evolving global requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!