Latest Discoveries in High-Barrier Coatings on Cellophane

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Coating Evolution and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging since its invention in the early 20th century. The evolution of cellophane coatings has been driven by the need for improved barrier properties, particularly against moisture, gases, and odors. This progression has been crucial in extending the shelf life of packaged products and maintaining their quality.

The journey of cellophane coating technology began with simple moisture-resistant treatments. Early coatings were primarily focused on reducing water vapor transmission, which was essential for preserving food products. As the packaging industry advanced, the demand for more sophisticated barrier properties grew, leading to the development of multi-layer coatings that could provide protection against both moisture and gases.

In recent years, the focus has shifted towards creating high-barrier coatings that not only enhance the protective properties of cellophane but also address environmental concerns. This has led to the exploration of bio-based and biodegradable coating materials, aligning with the global push for sustainable packaging solutions.

The objectives of current research in high-barrier coatings for cellophane are multifaceted. Primarily, there is a drive to develop coatings that offer superior barrier properties against oxygen, water vapor, and other gases while maintaining the transparency and flexibility of cellophane. This is particularly crucial for extending the shelf life of sensitive food products and pharmaceuticals.

Another key objective is to enhance the heat-sealability of coated cellophane, allowing for more efficient packaging processes and improved package integrity. Researchers are also focusing on developing coatings that are resistant to oils and greases, expanding the range of products that can be safely packaged in cellophane.

Sustainability remains a central goal in the evolution of cellophane coatings. There is a concerted effort to create high-barrier coatings from renewable resources and ensure that the coated cellophane remains biodegradable or easily recyclable. This aligns with the growing consumer demand for environmentally friendly packaging solutions.

The latest discoveries in high-barrier coatings on cellophane are aimed at achieving these objectives through innovative approaches. These include the use of nanocomposites, plasma-enhanced chemical vapor deposition techniques, and the incorporation of natural polymers and biopolymers. The ultimate goal is to create a new generation of cellophane packaging that combines exceptional barrier properties with environmental sustainability, meeting the evolving needs of both industry and consumers.

The journey of cellophane coating technology began with simple moisture-resistant treatments. Early coatings were primarily focused on reducing water vapor transmission, which was essential for preserving food products. As the packaging industry advanced, the demand for more sophisticated barrier properties grew, leading to the development of multi-layer coatings that could provide protection against both moisture and gases.

In recent years, the focus has shifted towards creating high-barrier coatings that not only enhance the protective properties of cellophane but also address environmental concerns. This has led to the exploration of bio-based and biodegradable coating materials, aligning with the global push for sustainable packaging solutions.

The objectives of current research in high-barrier coatings for cellophane are multifaceted. Primarily, there is a drive to develop coatings that offer superior barrier properties against oxygen, water vapor, and other gases while maintaining the transparency and flexibility of cellophane. This is particularly crucial for extending the shelf life of sensitive food products and pharmaceuticals.

Another key objective is to enhance the heat-sealability of coated cellophane, allowing for more efficient packaging processes and improved package integrity. Researchers are also focusing on developing coatings that are resistant to oils and greases, expanding the range of products that can be safely packaged in cellophane.

Sustainability remains a central goal in the evolution of cellophane coatings. There is a concerted effort to create high-barrier coatings from renewable resources and ensure that the coated cellophane remains biodegradable or easily recyclable. This aligns with the growing consumer demand for environmentally friendly packaging solutions.

The latest discoveries in high-barrier coatings on cellophane are aimed at achieving these objectives through innovative approaches. These include the use of nanocomposites, plasma-enhanced chemical vapor deposition techniques, and the incorporation of natural polymers and biopolymers. The ultimate goal is to create a new generation of cellophane packaging that combines exceptional barrier properties with environmental sustainability, meeting the evolving needs of both industry and consumers.

High-Barrier Packaging Market Analysis

The high-barrier packaging market has experienced significant growth in recent years, driven by increasing demand for extended shelf life and improved product protection across various industries. This market segment is particularly crucial for food, beverage, pharmaceutical, and personal care sectors, where maintaining product integrity and freshness is paramount.

Global market trends indicate a steady increase in the adoption of high-barrier packaging solutions, with a notable shift towards sustainable and eco-friendly materials. The market is expected to continue its upward trajectory, fueled by changing consumer preferences, stringent regulations, and technological advancements in packaging materials.

In the food and beverage industry, which accounts for a substantial portion of the high-barrier packaging market, there is a growing emphasis on reducing food waste and extending product shelf life. This has led to increased demand for advanced barrier coatings, including those applied to cellophane substrates.

The pharmaceutical sector is another key driver of the high-barrier packaging market, with a focus on protecting sensitive medications from moisture, oxygen, and light. As the global population ages and healthcare needs expand, the demand for high-performance barrier packaging in this sector is projected to rise significantly.

Geographically, Asia-Pacific has emerged as a rapidly growing market for high-barrier packaging, driven by urbanization, changing lifestyles, and increased disposable income in countries like China and India. North America and Europe continue to be major markets, with a strong focus on innovation and sustainability in packaging solutions.

The market is characterized by intense competition among key players, including multinational corporations and specialized packaging companies. These companies are investing heavily in research and development to create innovative barrier coatings and materials that offer superior protection while addressing environmental concerns.

Consumer trends are also shaping the high-barrier packaging market, with a growing preference for convenience, portability, and sustainability. This has led to the development of lightweight, flexible packaging solutions with enhanced barrier properties, catering to on-the-go lifestyles while minimizing environmental impact.

As sustainability becomes increasingly important, there is a notable shift towards recyclable and biodegradable high-barrier packaging materials. This trend is driving research into bio-based barrier coatings and compostable packaging solutions, presenting both challenges and opportunities for market players.

Global market trends indicate a steady increase in the adoption of high-barrier packaging solutions, with a notable shift towards sustainable and eco-friendly materials. The market is expected to continue its upward trajectory, fueled by changing consumer preferences, stringent regulations, and technological advancements in packaging materials.

In the food and beverage industry, which accounts for a substantial portion of the high-barrier packaging market, there is a growing emphasis on reducing food waste and extending product shelf life. This has led to increased demand for advanced barrier coatings, including those applied to cellophane substrates.

The pharmaceutical sector is another key driver of the high-barrier packaging market, with a focus on protecting sensitive medications from moisture, oxygen, and light. As the global population ages and healthcare needs expand, the demand for high-performance barrier packaging in this sector is projected to rise significantly.

Geographically, Asia-Pacific has emerged as a rapidly growing market for high-barrier packaging, driven by urbanization, changing lifestyles, and increased disposable income in countries like China and India. North America and Europe continue to be major markets, with a strong focus on innovation and sustainability in packaging solutions.

The market is characterized by intense competition among key players, including multinational corporations and specialized packaging companies. These companies are investing heavily in research and development to create innovative barrier coatings and materials that offer superior protection while addressing environmental concerns.

Consumer trends are also shaping the high-barrier packaging market, with a growing preference for convenience, portability, and sustainability. This has led to the development of lightweight, flexible packaging solutions with enhanced barrier properties, catering to on-the-go lifestyles while minimizing environmental impact.

As sustainability becomes increasingly important, there is a notable shift towards recyclable and biodegradable high-barrier packaging materials. This trend is driving research into bio-based barrier coatings and compostable packaging solutions, presenting both challenges and opportunities for market players.

Current Challenges in Cellophane Barrier Coatings

Despite significant advancements in high-barrier coatings for cellophane, several challenges persist in achieving optimal performance and commercial viability. One of the primary obstacles is maintaining barrier properties under varying environmental conditions. Cellophane's inherent sensitivity to moisture and temperature fluctuations can compromise the effectiveness of barrier coatings, leading to reduced shelf life and product quality.

Another critical challenge lies in balancing barrier performance with other desirable properties such as transparency, flexibility, and printability. As coating technologies improve barrier characteristics, they often negatively impact these other essential attributes, creating a trade-off that limits widespread adoption in certain applications.

The scalability of advanced coating technologies presents a significant hurdle. While laboratory-scale experiments demonstrate promising results, translating these innovations to industrial-scale production remains problematic. Issues such as coating uniformity, adhesion, and process speed need to be addressed to ensure consistent quality in large-scale manufacturing.

Environmental concerns and regulatory pressures pose additional challenges. The industry faces increasing demand for sustainable and biodegradable packaging solutions. However, many high-performance barrier coatings rely on synthetic materials that are not easily recyclable or compostable, creating a conflict between performance and environmental responsibility.

Cost-effectiveness remains a persistent issue in the development of high-barrier coatings for cellophane. Advanced coating materials and processes often come with higher production costs, making it difficult to compete with traditional packaging options in price-sensitive markets.

The complexity of multi-layer coating systems presents challenges in terms of production efficiency and material compatibility. Ensuring proper adhesion between layers and preventing delamination during processing and use continues to be a focus area for researchers and manufacturers.

Lastly, the industry grapples with the need for improved testing and characterization methods. Current techniques may not accurately predict long-term barrier performance or simulate real-world conditions, leading to discrepancies between laboratory results and actual product performance. Developing more reliable and standardized testing protocols is crucial for advancing the field and building consumer confidence in cellophane-based packaging solutions.

Another critical challenge lies in balancing barrier performance with other desirable properties such as transparency, flexibility, and printability. As coating technologies improve barrier characteristics, they often negatively impact these other essential attributes, creating a trade-off that limits widespread adoption in certain applications.

The scalability of advanced coating technologies presents a significant hurdle. While laboratory-scale experiments demonstrate promising results, translating these innovations to industrial-scale production remains problematic. Issues such as coating uniformity, adhesion, and process speed need to be addressed to ensure consistent quality in large-scale manufacturing.

Environmental concerns and regulatory pressures pose additional challenges. The industry faces increasing demand for sustainable and biodegradable packaging solutions. However, many high-performance barrier coatings rely on synthetic materials that are not easily recyclable or compostable, creating a conflict between performance and environmental responsibility.

Cost-effectiveness remains a persistent issue in the development of high-barrier coatings for cellophane. Advanced coating materials and processes often come with higher production costs, making it difficult to compete with traditional packaging options in price-sensitive markets.

The complexity of multi-layer coating systems presents challenges in terms of production efficiency and material compatibility. Ensuring proper adhesion between layers and preventing delamination during processing and use continues to be a focus area for researchers and manufacturers.

Lastly, the industry grapples with the need for improved testing and characterization methods. Current techniques may not accurately predict long-term barrier performance or simulate real-world conditions, leading to discrepancies between laboratory results and actual product performance. Developing more reliable and standardized testing protocols is crucial for advancing the field and building consumer confidence in cellophane-based packaging solutions.

State-of-the-Art High-Barrier Coating Solutions

01 Coating composition for high barrier properties

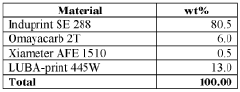

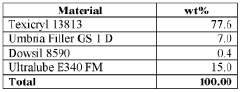

Advanced coating compositions are developed to enhance the barrier properties of cellophane. These compositions often include specific polymers, nanoparticles, or other additives that significantly improve resistance to moisture, oxygen, and other gases. The coatings are designed to maintain the transparency and flexibility of cellophane while providing superior barrier performance.- Coating composition for high barrier properties: Specialized coating compositions are developed to enhance the barrier properties of cellophane. These coatings typically include polymers, nanoparticles, or other materials that can significantly reduce gas and moisture permeability. The composition is carefully formulated to adhere well to cellophane while maintaining transparency and flexibility.

- Multi-layer barrier coating systems: Multi-layer coating systems are employed to achieve superior barrier properties on cellophane. Each layer in the system serves a specific function, such as adhesion promotion, moisture barrier, or gas barrier. The combination of different materials in a layered structure allows for customization of barrier properties to meet specific requirements.

- Nanocomposite coatings for enhanced barrier performance: Nanocomposite coatings incorporating nanomaterials such as clay, graphene, or metal oxides are used to improve the barrier properties of cellophane. These nanoparticles create a tortuous path for gas and moisture molecules, significantly reducing permeability. The nanocomposite coatings can achieve high barrier performance with minimal thickness.

- Plasma-enhanced coating techniques: Plasma-enhanced chemical vapor deposition (PECVD) or other plasma-based techniques are utilized to deposit thin, high-barrier coatings on cellophane. These methods allow for the creation of dense, pinhole-free coatings with excellent adhesion to the substrate. Plasma treatments can also be used to modify the surface of cellophane to improve coating adhesion.

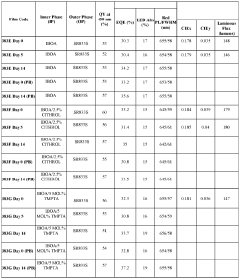

- Barrier property measurement and characterization: Advanced techniques and instruments are employed to measure and characterize the barrier properties of coated cellophane. These methods include gas permeability testing, moisture vapor transmission rate (MVTR) analysis, and surface analysis techniques. Accurate measurement of barrier properties is crucial for quality control and product development in high-barrier cellophane applications.

02 Multi-layer barrier coating structures

Multi-layer coating systems are employed to create high-barrier cellophane films. These structures typically consist of alternating layers of different materials, each contributing to specific barrier properties. The combination of layers can provide synergistic effects, resulting in enhanced overall barrier performance compared to single-layer coatings.Expand Specific Solutions03 Nanocomposite coatings for improved barrier properties

Nanocomposite coatings incorporating various nanoparticles are utilized to enhance the barrier properties of cellophane. These nanoparticles, such as clay, silica, or metal oxides, can significantly improve the film's resistance to gas and moisture permeation. The nanocomposite coatings often result in thinner films with superior barrier performance.Expand Specific Solutions04 Surface treatment techniques for coating adhesion

Various surface treatment methods are employed to improve the adhesion of high-barrier coatings to cellophane. These techniques may include plasma treatment, corona discharge, or chemical modifications of the cellophane surface. Enhanced adhesion ensures the durability and effectiveness of the barrier coatings over time.Expand Specific Solutions05 Evaluation and testing of barrier properties

Advanced methods and equipment are developed for evaluating and testing the barrier properties of coated cellophane films. These techniques include specialized permeation testing, microscopy analysis, and accelerated aging tests. Accurate assessment of barrier performance is crucial for quality control and further improvement of coating formulations.Expand Specific Solutions

Key Players in Cellophane Coating Industry

The field of high-barrier coatings on cellophane is in a growth phase, with increasing market demand driven by packaging innovations and sustainability concerns. The global market size for high-barrier coatings is expanding, estimated to reach several billion dollars in the coming years. Technologically, the sector is advancing rapidly, with companies like BASF, DIC Corp., and Stora Enso leading innovation. These firms are developing novel coating formulations and application techniques to enhance barrier properties while maintaining recyclability. Academic institutions such as Purdue Research Foundation and Chongqing University are contributing to fundamental research, pushing the boundaries of coating performance. The industry is seeing a shift towards bio-based and environmentally friendly solutions, with companies like Melodea Ltd. exploring nanocellulose-based coatings.

Sun Chemical Corp. (New Jersey)

Technical Solution: Sun Chemical has recently introduced a novel high-barrier coating for cellophane based on their SunBar® oxygen barrier coatings technology. This water-based coating system utilizes a blend of specially formulated resins and nanoparticles to create an effective oxygen barrier. The company has optimized the coating process to ensure uniform application on cellophane substrates, resulting in consistent barrier performance. Sun Chemical's latest innovation includes the incorporation of active barrier components that can scavenge oxygen molecules, further enhancing the overall barrier properties[3]. The coating is designed to be compatible with various printing processes, allowing for high-quality graphics on the packaged products[4].

Strengths: Excellent oxygen barrier, printability, and water-based formulation. Weaknesses: May require specialized application equipment and potential limitations in moisture barrier compared to some alternatives.

BASF SE

Technical Solution: BASF SE has developed advanced high-barrier coatings for cellophane using their proprietary Ultramid® polyamide technology. This coating system provides exceptional oxygen and moisture barrier properties, extending the shelf life of packaged products. The company has implemented a multi-layer coating approach, combining different functional layers to achieve optimal barrier performance[1]. BASF's coating technology incorporates nanocomposites, which enhance the barrier properties while maintaining transparency. The company has also focused on improving the heat-sealing properties of the coated cellophane, making it suitable for a wide range of packaging applications[2].

Strengths: Superior barrier properties, versatile applications, and improved heat-sealing. Weaknesses: Potentially higher cost compared to traditional coatings and limited biodegradability.

Breakthrough Innovations in Cellophane Coatings

Biomass-Origin Selective Coating, SUBJECTS INCLUDING THIS COVER, AND MATERIAL TREATMENT OF CELLULOZA MATERIALS IS ADJUSTABLE WITH THIS COVER

PatentPendingVN83965A

Innovation

- Development of a biodegradable barrier coating composed of prolamin and polyol fatty acid ester for cellulose materials.

- Increased oil and grease resistance of cellulose materials without compromising their biodegradability.

- Tunable treatment process allowing for adjustable hydrophobicity of cellulose materials.

Heat sealable barrier coating

PatentWO2018200783A1

Innovation

- A water-based coating composition comprising 5 wt% to 90 wt% acrylic polymer or copolymer emulsions, 2 wt% to 25 wt% melting waxes, and 5 wt% to 85 wt% water, which is heat-sealable and compostable, allowing for improved ecological impact and barrier properties without the need for additional materials or steps.

Environmental Impact of Cellophane Coatings

The environmental impact of cellophane coatings has become a significant concern in recent years, particularly as the demand for sustainable packaging solutions continues to grow. Traditional cellophane coatings, while effective in providing barrier properties, often rely on materials that can have detrimental effects on the environment throughout their lifecycle.

One of the primary environmental issues associated with cellophane coatings is their contribution to plastic pollution. Many conventional coatings are not biodegradable or compostable, leading to long-term accumulation in landfills and natural ecosystems. This persistence in the environment can harm wildlife and disrupt ecological balance.

The production process of cellophane coatings also raises environmental concerns. The manufacturing of these coatings often involves the use of petrochemical-based materials and energy-intensive processes, contributing to greenhouse gas emissions and resource depletion. Additionally, the chemicals used in some coating formulations may pose risks to water quality and soil health if not properly managed.

However, recent advancements in high-barrier coatings for cellophane have shown promising developments in mitigating these environmental impacts. Researchers and industry players are increasingly focusing on developing bio-based and biodegradable coating alternatives. These new formulations aim to maintain the high barrier properties required for food packaging while significantly reducing the environmental footprint.

One notable area of progress is the development of coatings derived from renewable resources such as plant-based polymers. These materials offer the potential for reduced carbon emissions during production and improved end-of-life biodegradability. Some innovative approaches include the use of cellulose nanocrystals and chitosan-based coatings, which have shown promising results in enhancing barrier properties while being more environmentally friendly.

Another important aspect of environmental impact reduction is the focus on improving the recyclability of coated cellophane. Traditional coatings often hinder the recycling process, but new technologies are emerging that allow for easier separation of coatings from the cellophane substrate. This advancement facilitates more efficient recycling and reduces the amount of waste sent to landfills.

The shift towards more sustainable coating solutions is also driving changes in packaging design. Manufacturers are exploring ways to minimize the amount of coating material used while maintaining necessary barrier properties. This approach not only reduces the environmental impact but also contributes to cost savings and resource efficiency.

As regulations and consumer preferences continue to evolve, the environmental impact of cellophane coatings remains a critical consideration for the packaging industry. The ongoing research and development in this field are crucial for balancing the need for effective packaging solutions with environmental sustainability goals.

One of the primary environmental issues associated with cellophane coatings is their contribution to plastic pollution. Many conventional coatings are not biodegradable or compostable, leading to long-term accumulation in landfills and natural ecosystems. This persistence in the environment can harm wildlife and disrupt ecological balance.

The production process of cellophane coatings also raises environmental concerns. The manufacturing of these coatings often involves the use of petrochemical-based materials and energy-intensive processes, contributing to greenhouse gas emissions and resource depletion. Additionally, the chemicals used in some coating formulations may pose risks to water quality and soil health if not properly managed.

However, recent advancements in high-barrier coatings for cellophane have shown promising developments in mitigating these environmental impacts. Researchers and industry players are increasingly focusing on developing bio-based and biodegradable coating alternatives. These new formulations aim to maintain the high barrier properties required for food packaging while significantly reducing the environmental footprint.

One notable area of progress is the development of coatings derived from renewable resources such as plant-based polymers. These materials offer the potential for reduced carbon emissions during production and improved end-of-life biodegradability. Some innovative approaches include the use of cellulose nanocrystals and chitosan-based coatings, which have shown promising results in enhancing barrier properties while being more environmentally friendly.

Another important aspect of environmental impact reduction is the focus on improving the recyclability of coated cellophane. Traditional coatings often hinder the recycling process, but new technologies are emerging that allow for easier separation of coatings from the cellophane substrate. This advancement facilitates more efficient recycling and reduces the amount of waste sent to landfills.

The shift towards more sustainable coating solutions is also driving changes in packaging design. Manufacturers are exploring ways to minimize the amount of coating material used while maintaining necessary barrier properties. This approach not only reduces the environmental impact but also contributes to cost savings and resource efficiency.

As regulations and consumer preferences continue to evolve, the environmental impact of cellophane coatings remains a critical consideration for the packaging industry. The ongoing research and development in this field are crucial for balancing the need for effective packaging solutions with environmental sustainability goals.

Regulatory Framework for Food Packaging Materials

The regulatory framework for food packaging materials, including high-barrier coatings on cellophane, is a complex and evolving landscape. In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing food packaging materials. The FDA's regulations are primarily codified in Title 21 of the Code of Federal Regulations (CFR), with specific sections addressing food contact substances and packaging materials.

For high-barrier coatings on cellophane, manufacturers must comply with FDA regulations for food contact substances. This includes demonstrating that the coating materials are safe for their intended use and do not migrate into food at levels that could pose health risks. The FDA's Food Contact Notification (FCN) program is often the preferred route for obtaining regulatory clearance for new food contact substances, including novel high-barrier coatings.

In the European Union, the European Food Safety Authority (EFSA) plays a crucial role in assessing the safety of food contact materials. The EU's regulatory framework is based on Regulation (EC) No 1935/2004, which sets out general principles for all food contact materials. For plastic materials, including certain high-barrier coatings, Regulation (EU) No 10/2011 provides specific requirements and a positive list of authorized substances.

Japan has its own regulatory system for food packaging materials, administered by the Ministry of Health, Labour and Welfare. The Japanese system includes a positive list of substances approved for use in food contact materials, which manufacturers must adhere to when developing new high-barrier coatings for cellophane.

Globally, there is a trend towards more stringent regulations and increased scrutiny of food packaging materials. This includes a focus on emerging contaminants, such as per- and polyfluoroalkyl substances (PFAS), which have been used in some food packaging applications for their barrier properties. As a result, manufacturers developing high-barrier coatings for cellophane must be aware of potential restrictions on certain chemicals and be prepared to demonstrate the safety and compliance of their products.

The regulatory landscape also increasingly emphasizes sustainability and recyclability. As such, developers of high-barrier coatings must consider not only the performance and safety of their products but also their environmental impact and end-of-life disposal. This may influence the choice of materials and technologies used in coating formulations.

For high-barrier coatings on cellophane, manufacturers must comply with FDA regulations for food contact substances. This includes demonstrating that the coating materials are safe for their intended use and do not migrate into food at levels that could pose health risks. The FDA's Food Contact Notification (FCN) program is often the preferred route for obtaining regulatory clearance for new food contact substances, including novel high-barrier coatings.

In the European Union, the European Food Safety Authority (EFSA) plays a crucial role in assessing the safety of food contact materials. The EU's regulatory framework is based on Regulation (EC) No 1935/2004, which sets out general principles for all food contact materials. For plastic materials, including certain high-barrier coatings, Regulation (EU) No 10/2011 provides specific requirements and a positive list of authorized substances.

Japan has its own regulatory system for food packaging materials, administered by the Ministry of Health, Labour and Welfare. The Japanese system includes a positive list of substances approved for use in food contact materials, which manufacturers must adhere to when developing new high-barrier coatings for cellophane.

Globally, there is a trend towards more stringent regulations and increased scrutiny of food packaging materials. This includes a focus on emerging contaminants, such as per- and polyfluoroalkyl substances (PFAS), which have been used in some food packaging applications for their barrier properties. As a result, manufacturers developing high-barrier coatings for cellophane must be aware of potential restrictions on certain chemicals and be prepared to demonstrate the safety and compliance of their products.

The regulatory landscape also increasingly emphasizes sustainability and recyclability. As such, developers of high-barrier coatings must consider not only the performance and safety of their products but also their environmental impact and end-of-life disposal. This may influence the choice of materials and technologies used in coating formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!