How to Enhance Thermal Stability with Graphene Oxide?

Graphene Oxide Thermal Stability Background

Graphene oxide (GO) has emerged as a revolutionary material in the field of nanotechnology, particularly in the context of thermal stability enhancement. The journey of GO began with the discovery of graphene in 2004, which sparked intense research into its derivatives. GO, a single-atomic-layered material, is produced by the oxidation of graphite, resulting in a structure with oxygen-containing functional groups on its basal planes and edges.

The thermal stability of materials has been a critical concern across various industries, from electronics to aerospace. As technologies advance and operating conditions become more extreme, the demand for thermally stable materials has intensified. GO has attracted significant attention due to its unique properties, including high surface area, excellent mechanical strength, and potential for functionalization.

The exploration of GO's thermal stability began in earnest in the early 2010s, with researchers investigating its behavior under different temperature conditions. Initial studies revealed that GO undergoes thermal reduction at elevated temperatures, leading to the partial restoration of the sp2 carbon network and the removal of oxygen-containing groups. This process, while altering the material's structure, also presented opportunities for tailoring its properties.

As research progressed, scientists discovered that the thermal stability of GO could be significantly enhanced through various methods. These include chemical functionalization, incorporation of nanoparticles, and the development of GO-based composites. The ability to modify GO's surface chemistry and structure opened up new avenues for creating materials with superior thermal resistance.

The quest to enhance GO's thermal stability has been driven by its potential applications in high-temperature environments. From thermal management in electronics to fire-retardant materials in construction, the improved thermal stability of GO-based materials promises to revolutionize multiple sectors. This has led to a surge in research efforts aimed at understanding the fundamental mechanisms of thermal degradation in GO and developing innovative strategies to mitigate these effects.

Recent years have seen remarkable advancements in GO thermal stability enhancement techniques. Researchers have explored the incorporation of metal oxides, the development of reduced GO (rGO) with preserved thermal properties, and the creation of hybrid structures that synergistically improve thermal resistance. These developments have not only expanded the potential applications of GO but have also contributed to our broader understanding of nanomaterial behavior under thermal stress.

Market Demand Analysis

The market demand for graphene oxide-enhanced thermal stability solutions has been steadily growing across various industries. This surge is primarily driven by the increasing need for high-performance materials in sectors such as electronics, aerospace, automotive, and energy storage. As electronic devices become more compact and powerful, the challenge of managing heat dissipation has become paramount, creating a significant market opportunity for graphene oxide-based thermal management solutions.

In the electronics industry, the demand for graphene oxide thermal management solutions is particularly strong. With the continuous miniaturization of electronic components and the rise of high-performance computing, traditional thermal management techniques are reaching their limits. Graphene oxide's exceptional thermal conductivity and ability to form thin, flexible films make it an attractive option for next-generation thermal interface materials and heat spreaders.

The aerospace and automotive sectors are also showing increased interest in graphene oxide for thermal stability applications. As these industries push for lighter, more fuel-efficient vehicles and aircraft, the need for advanced materials that can withstand high temperatures while maintaining structural integrity becomes crucial. Graphene oxide's potential to enhance the thermal stability of composites and coatings is driving research and development efforts in these fields.

Energy storage is another area where the market demand for graphene oxide thermal stability solutions is growing. The performance and safety of batteries, particularly lithium-ion batteries, are heavily influenced by thermal management. Graphene oxide's ability to improve heat dissipation and enhance the overall thermal stability of battery systems is attracting significant attention from battery manufacturers and researchers.

The construction industry is emerging as a potential growth market for graphene oxide thermal stability applications. With increasing focus on energy-efficient buildings and sustainable construction materials, graphene oxide-enhanced insulation and heat-reflective coatings are gaining traction. These materials offer the promise of improved thermal regulation in buildings, potentially reducing energy consumption for heating and cooling.

While the market potential for graphene oxide in thermal stability applications is substantial, it is important to note that the technology is still in its early stages of commercialization. Many applications are currently in the research and development phase, with a growing number of startups and established companies investing in bringing graphene oxide-based thermal management solutions to market. As manufacturing processes improve and costs decrease, the market is expected to expand rapidly in the coming years.

Current Challenges in Thermal Stability

Despite the promising potential of graphene oxide (GO) in enhancing thermal stability, several significant challenges persist in its practical application. One of the primary obstacles is the inconsistent quality and properties of GO produced through different synthesis methods. The variability in oxidation levels, sheet size, and functional groups can lead to unpredictable thermal behavior, making it difficult to achieve consistent results in thermal stability enhancement.

Another major challenge lies in the thermal reduction of GO at elevated temperatures. When exposed to high heat, GO tends to lose oxygen-containing functional groups, potentially altering its structure and properties. This thermal instability can compromise the very characteristics that make GO attractive for thermal stability applications, particularly in scenarios requiring prolonged exposure to high temperatures.

The agglomeration of GO sheets presents yet another hurdle. In many composite materials, GO has a tendency to stack and form aggregates due to strong van der Waals interactions between the sheets. This agglomeration can significantly reduce the effective surface area of GO, diminishing its ability to enhance thermal stability and potentially creating thermal weak points within the material.

Furthermore, the interface between GO and the matrix material in composites often poses challenges. Achieving strong interfacial bonding is crucial for effective heat transfer and overall thermal stability. However, the complex surface chemistry of GO can make it difficult to establish consistent and robust interfaces with various matrix materials, potentially limiting the thermal stability enhancement.

The scalability of GO production and integration into materials also presents significant challenges. While laboratory-scale experiments have shown promising results, translating these successes to industrial-scale production while maintaining consistent quality and performance remains a considerable obstacle. This scaling issue is particularly pertinent when considering the economic viability of GO-enhanced thermally stable materials for widespread commercial applications.

Additionally, the long-term stability and degradation of GO under various environmental conditions are not yet fully understood. Factors such as humidity, UV exposure, and chemical interactions can potentially alter the thermal stability properties of GO over time, raising concerns about the longevity and reliability of GO-enhanced materials in real-world applications.

Lastly, the environmental and health implications of GO production and use in thermal stability applications require further investigation. Concerns about the potential release of GO nanoparticles during material degradation or processing, and their subsequent environmental impact, need to be thoroughly addressed to ensure the sustainable and safe implementation of this technology.

Existing Thermal Enhancement Solutions

01 Thermal reduction of graphene oxide

Thermal reduction is a common method to improve the thermal stability of graphene oxide. This process involves heating graphene oxide at high temperatures, which removes oxygen-containing functional groups and restores the sp2 carbon network. The resulting reduced graphene oxide exhibits enhanced thermal stability compared to its precursor.- Thermal reduction of graphene oxide: Thermal reduction is a method used to improve the thermal stability of graphene oxide. This process involves heating graphene oxide at high temperatures, which removes oxygen-containing functional groups and restores the sp2 carbon network. The resulting reduced graphene oxide exhibits enhanced thermal stability compared to its precursor.

- Functionalization of graphene oxide: Functionalizing graphene oxide with various chemical groups or compounds can enhance its thermal stability. This approach involves attaching specific molecules or elements to the graphene oxide surface, which can alter its properties and improve resistance to thermal degradation.

- Composite materials with graphene oxide: Incorporating graphene oxide into composite materials can lead to improved thermal stability. By combining graphene oxide with polymers, ceramics, or other materials, the resulting composites often exhibit enhanced thermal properties compared to the individual components.

- Doping and modification of graphene oxide: Doping graphene oxide with various elements or modifying its structure can significantly impact its thermal stability. These processes can introduce new chemical bonds or alter the electronic structure of graphene oxide, leading to improved resistance to thermal degradation.

- Controlled synthesis for improved thermal stability: Optimizing the synthesis conditions and methods for producing graphene oxide can result in materials with enhanced thermal stability. This includes controlling factors such as oxidation degree, sheet size, and defect concentration during the production process to achieve desired thermal properties.

02 Functionalization of graphene oxide

Functionalizing graphene oxide with various chemical groups or compounds can improve its thermal stability. This approach involves attaching molecules or polymers to the graphene oxide surface, which can enhance its resistance to thermal degradation and improve overall stability at elevated temperatures.Expand Specific Solutions03 Composite materials with graphene oxide

Incorporating graphene oxide into composite materials can enhance their thermal stability. By dispersing graphene oxide in polymer matrices or combining it with other materials, the resulting composites often exhibit improved thermal properties, including increased decomposition temperatures and reduced thermal expansion.Expand Specific Solutions04 Controlled oxidation and reduction processes

Optimizing the oxidation and reduction processes of graphene oxide can lead to improved thermal stability. By carefully controlling the degree of oxidation and subsequent reduction, it is possible to tailor the thermal properties of graphene oxide-based materials for specific applications.Expand Specific Solutions05 Characterization and analysis of thermal stability

Various analytical techniques are employed to characterize and evaluate the thermal stability of graphene oxide and its derivatives. These methods include thermogravimetric analysis, differential scanning calorimetry, and spectroscopic techniques, which provide insights into the thermal behavior and degradation mechanisms of graphene oxide-based materials.Expand Specific Solutions

Key Players in Graphene Industry

The thermal stability enhancement using graphene oxide is an emerging field in advanced materials science, currently in its growth phase. The market for graphene oxide-based thermal management solutions is expanding rapidly, driven by increasing demand in electronics, aerospace, and energy sectors. The technology's maturity varies across applications, with some areas more developed than others. Key players like Harbin Institute of Technology, Shanghai Institute of Ceramics, and Penn State Research Foundation are leading research efforts, while companies such as Arkema France SA and BASF Corp. are focusing on commercial applications. The involvement of diverse institutions, from universities to major corporations, indicates a competitive landscape with significant potential for innovation and market growth.

Arkema France SA

Sumitomo Chemical Co., Ltd.

Core Innovations in Graphene Oxide

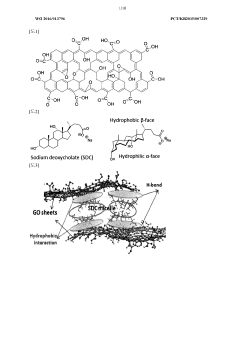

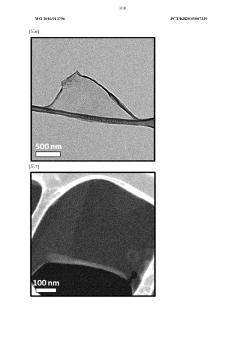

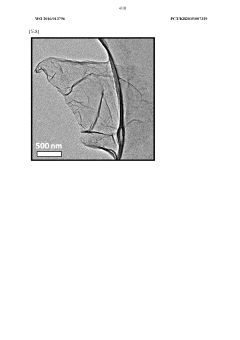

- A graphene oxide film coated with bile acids or bile salts is developed, utilizing a bile acid or bile salt as a coating layer to enhance adhesion between graphene oxide sheets, forming a stable layered structure with high mechanical strength and chemical stability against external stimuli.

- Introducing graphene as an additive into the ceramic matrix of SOFC plates to enhance thermal stability and mechanical properties.

- Using stored thermal energy for startup to reduce startup times and extreme thermal changes, controlling material creep and metallurgy reactions.

- Employing spark plasma sintering at 1650°C to densify graphene platelets (GPL) homogeneously dispersed with silicon nitride particles.

Environmental Impact Assessment

The environmental impact of enhancing thermal stability with graphene oxide (GO) is a critical consideration in the development and application of this technology. GO-based materials have shown promising potential for improving thermal stability in various applications, but their environmental implications must be carefully assessed.

One of the primary environmental concerns is the potential release of GO nanoparticles into ecosystems during production, use, or disposal. These nanoparticles may have unforeseen effects on aquatic and terrestrial organisms. Studies have shown that GO can accumulate in the gills and digestive tracts of fish, potentially causing oxidative stress and other adverse effects. Furthermore, the long-term persistence of GO in the environment is not yet fully understood, raising questions about its potential bioaccumulation in food chains.

The production process of GO also warrants environmental scrutiny. The synthesis of GO typically involves the use of strong oxidizing agents and acids, which can generate hazardous waste streams if not properly managed. However, recent advancements in green synthesis methods have shown promise in reducing the environmental footprint of GO production. These eco-friendly approaches utilize less toxic reagents and minimize waste generation, aligning with sustainable manufacturing principles.

On the positive side, the enhanced thermal stability provided by GO-based materials can contribute to improved energy efficiency and reduced resource consumption in various applications. For instance, in electronics and aerospace industries, GO-enhanced materials can lead to longer-lasting components that require less frequent replacement, potentially reducing electronic waste and resource depletion.

The use of GO in thermal management systems may also indirectly benefit the environment by improving the efficiency of heat dissipation in electronic devices and industrial processes. This could lead to reduced energy consumption and, consequently, lower greenhouse gas emissions associated with power generation.

However, the end-of-life management of GO-enhanced products presents another environmental challenge. The durability and stability of these materials, while beneficial during use, may complicate recycling processes. Research is needed to develop effective recycling methods that can safely recover and repurpose GO from composite materials without releasing nanoparticles into the environment.

In conclusion, while GO offers significant potential for enhancing thermal stability, its environmental impact is complex and multifaceted. Ongoing research is essential to fully understand and mitigate potential risks, while maximizing the environmental benefits of this technology. A life cycle assessment approach, considering all stages from production to disposal, will be crucial in developing environmentally responsible applications of GO for thermal stability enhancement.

Scalability and Cost Analysis

The scalability and cost analysis of enhancing thermal stability with graphene oxide (GO) is crucial for its practical implementation in various industries. The production of GO has seen significant advancements in recent years, moving from laboratory-scale synthesis to industrial-scale manufacturing. However, challenges remain in achieving consistent quality and cost-effective production at large scales.

Current production methods for GO, such as modified Hummers' method, can be scaled up to produce kilogram quantities. However, the process is still labor-intensive and time-consuming, which impacts the overall cost. The use of hazardous chemicals and the generation of toxic gases during production also pose challenges for large-scale manufacturing, requiring sophisticated safety measures and waste management systems.

The cost of GO production varies widely depending on the quality and production scale. High-quality GO can cost between $50 to $200 per gram, while lower-grade materials may be available for $10 to $30 per gram. As production scales increase, economies of scale are expected to drive down costs. However, the price of GO remains significantly higher than many conventional materials used for thermal stability enhancement.

Scalability also depends on the availability of high-quality graphite as a raw material. While graphite is abundant, the purity required for GO production can limit supply and increase costs. Developing alternative sources or improving purification methods for lower-grade graphite could enhance scalability and reduce raw material costs.

The application of GO for thermal stability enhancement requires additional processing steps, such as functionalization or incorporation into composite materials. These steps add to the overall cost and complexity of scaling up production. Developing more efficient and cost-effective methods for GO integration into final products is essential for widespread adoption.

Environmental considerations also play a role in scalability and cost analysis. The production of GO generates significant amounts of waste and consumes large quantities of water and energy. Implementing more sustainable production methods and recycling processes could improve the environmental footprint and potentially reduce long-term costs.

As research continues, novel production methods and applications of GO for thermal stability enhancement may emerge, potentially improving scalability and reducing costs. Innovations in continuous flow reactors, microwave-assisted synthesis, and electrochemical exfoliation show promise for more efficient GO production. Additionally, the development of GO-based materials with enhanced thermal properties at lower loadings could improve the cost-effectiveness of thermal stability solutions.