Graphene Oxide and Nanocomposites: Strengthening Materials

Graphene Oxide Overview and Research Objectives

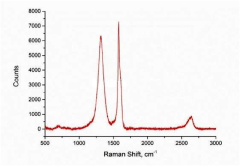

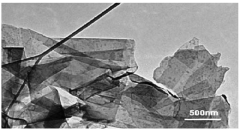

Graphene oxide (GO) has emerged as a revolutionary material in the field of materials science, offering exceptional mechanical, thermal, and electrical properties. This two-dimensional carbon-based nanomaterial is derived from graphene, the single layer of graphite, through oxidation processes. The unique structure of GO, consisting of a single layer of carbon atoms with oxygen-containing functional groups, provides it with remarkable versatility and potential for various applications.

The primary objective of this research is to explore the utilization of graphene oxide and its nanocomposites for strengthening materials. This goal aligns with the growing demand for lightweight yet robust materials in industries such as aerospace, automotive, and construction. By incorporating GO into existing materials or developing novel nanocomposites, we aim to enhance mechanical properties, including tensile strength, stiffness, and impact resistance.

The evolution of graphene oxide research has been marked by significant milestones since its initial discovery. Early studies focused on understanding its structure and developing efficient synthesis methods. As research progressed, attention shifted towards exploring GO's potential in various applications, with material strengthening emerging as a promising area.

Current trends in GO research for material strengthening include the development of GO-polymer nanocomposites, GO-reinforced metal matrix composites, and GO-enhanced cement and concrete. These applications leverage GO's high surface area, excellent mechanical properties, and ability to form strong interfacial bonds with matrix materials.

One of the key challenges in this field is achieving uniform dispersion of GO within matrix materials to maximize its reinforcing effect. Researchers are exploring various techniques, such as sonication, functionalization, and in-situ synthesis, to overcome this hurdle and optimize the performance of GO-based composites.

Looking ahead, the research aims to address several critical aspects. These include developing scalable and cost-effective production methods for GO and its nanocomposites, improving the compatibility between GO and different matrix materials, and enhancing the long-term stability of GO-reinforced materials under various environmental conditions.

Furthermore, this research seeks to explore the multifunctional properties of GO-based materials. Beyond mechanical reinforcement, we aim to investigate how GO can simultaneously enhance other material properties, such as thermal conductivity, electrical conductivity, and barrier properties, leading to the development of advanced multifunctional materials.

Market Analysis for Strengthened Materials

The market for strengthened materials, particularly those enhanced by graphene oxide and nanocomposites, has been experiencing significant growth and transformation in recent years. This surge is driven by the increasing demand for high-performance materials across various industries, including aerospace, automotive, construction, and electronics.

The global market for strengthened materials is projected to reach substantial figures in the coming years, with graphene-based products playing a crucial role in this expansion. The automotive sector, in particular, has shown keen interest in these advanced materials due to their potential to reduce vehicle weight while maintaining or improving structural integrity. This aligns with the industry's push towards fuel efficiency and electric vehicle development.

In the aerospace industry, the demand for lightweight yet durable materials has been a constant driver for innovation. Graphene oxide and nanocomposites offer promising solutions to meet these stringent requirements, potentially revolutionizing aircraft design and performance. The construction sector is also exploring these materials for their ability to enhance the strength and durability of building materials, potentially leading to more resilient and sustainable structures.

The electronics industry represents another significant market for strengthened materials. As devices become smaller and more powerful, the need for materials that can withstand high temperatures and provide excellent thermal management increases. Graphene-based composites are well-positioned to address these challenges, offering superior thermal conductivity and mechanical strength.

Market trends indicate a growing preference for multifunctional materials that not only provide strength but also offer additional properties such as electrical conductivity, thermal management, or self-healing capabilities. This trend is likely to further boost the demand for graphene oxide and nanocomposite-based solutions.

However, the market faces challenges in terms of scalability and cost-effectiveness. While the potential of graphene-based materials is widely recognized, the ability to produce them at scale and at competitive prices remains a hurdle. Overcoming these challenges could lead to widespread adoption across industries and potentially disrupt existing material markets.

Geographically, North America and Europe currently lead in research and development of graphene-based strengthened materials, but Asia-Pacific is rapidly emerging as a key player, driven by significant investments in nanotechnology and advanced materials research. This global distribution of innovation and production capabilities is likely to shape the competitive landscape of the strengthened materials market in the coming years.

Current Challenges in Graphene Oxide Nanocomposites

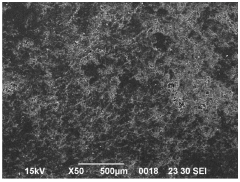

Despite the promising potential of graphene oxide (GO) nanocomposites for strengthening materials, several significant challenges persist in their development and application. One of the primary obstacles is achieving uniform dispersion of GO within the matrix material. The strong van der Waals forces between GO sheets often lead to agglomeration, reducing the effective surface area and compromising the mechanical properties of the composite.

Another critical challenge lies in the interfacial bonding between GO and the matrix material. While GO's oxygen-containing functional groups provide opportunities for chemical bonding, ensuring strong and stable interfaces across various matrix materials remains difficult. This interfacial weakness can result in reduced load transfer efficiency and diminished overall mechanical performance of the nanocomposite.

The scalability of GO nanocomposite production presents a substantial hurdle. Current laboratory-scale synthesis methods often prove challenging to translate into large-scale industrial processes without compromising quality and consistency. This scaling issue significantly impacts the commercial viability and widespread adoption of GO nanocomposites in real-world applications.

Environmental stability is another concern, particularly in terms of long-term performance. GO nanocomposites may exhibit sensitivity to moisture, temperature fluctuations, and UV radiation, potentially leading to degradation of mechanical properties over time. Addressing these durability issues is crucial for ensuring the reliability of GO-strengthened materials in various environmental conditions.

The high production cost of high-quality GO remains a significant barrier to widespread industrial adoption. The complex synthesis processes and the need for specialized equipment contribute to elevated expenses, making it challenging for GO nanocomposites to compete economically with traditional strengthening materials in many applications.

Furthermore, there are ongoing concerns regarding the potential toxicity and environmental impact of GO nanoparticles. While initial studies have shown promising results, more comprehensive long-term studies are needed to fully understand and mitigate any potential risks associated with the use and disposal of GO nanocomposites.

Lastly, the optimization of GO content in nanocomposites poses a challenge. While increasing GO concentration can enhance certain properties, it may also lead to brittleness or reduced ductility. Finding the optimal balance to maximize overall performance across various mechanical properties requires extensive research and fine-tuning for each specific application.

Existing Graphene Oxide Strengthening Solutions

01 Graphene oxide reinforcement in nanocomposites

Graphene oxide is used as a reinforcing material in nanocomposites to enhance their mechanical strength. The incorporation of graphene oxide into polymer matrices can significantly improve the tensile strength, modulus, and overall mechanical properties of the resulting nanocomposites.- Graphene oxide-based nanocomposites for enhanced strength: Graphene oxide is incorporated into various materials to create nanocomposites with improved mechanical properties. These nanocomposites exhibit enhanced strength, stiffness, and durability compared to their base materials. The unique structure of graphene oxide allows for effective load transfer and reinforcement within the composite matrix.

- Functionalization of graphene oxide for better compatibility: Chemical functionalization of graphene oxide is employed to improve its compatibility with different polymer matrices. This process enhances the interfacial bonding between graphene oxide and the host material, leading to superior mechanical properties in the resulting nanocomposites. Functionalized graphene oxide allows for better dispersion and integration within the composite structure.

- Graphene oxide-reinforced cement composites: Incorporation of graphene oxide into cement-based materials results in nanocomposites with significantly improved mechanical strength and durability. The addition of graphene oxide enhances the hydration process and microstructure of cement, leading to increased compressive and flexural strength. These nanocomposites show potential for use in high-performance construction applications.

- Graphene oxide/polymer nanocomposites for structural applications: Graphene oxide is used to reinforce various polymers, creating nanocomposites with enhanced mechanical properties suitable for structural applications. These nanocomposites exhibit improved tensile strength, modulus, and impact resistance. The high aspect ratio and surface area of graphene oxide contribute to effective stress transfer and reinforcement within the polymer matrix.

- Processing techniques for graphene oxide nanocomposites: Various processing techniques are developed to optimize the dispersion and integration of graphene oxide in nanocomposites. These methods include solution mixing, melt blending, and in-situ polymerization. Proper processing ensures uniform distribution of graphene oxide within the matrix, maximizing its reinforcing effect and resulting in nanocomposites with superior mechanical properties.

02 Functionalization of graphene oxide for improved compatibility

Chemical functionalization of graphene oxide is employed to improve its compatibility with various polymer matrices. This process enhances the interfacial bonding between graphene oxide and the polymer, leading to better dispersion and increased strength in the nanocomposite.Expand Specific Solutions03 Graphene oxide-based nanocomposites for structural applications

Graphene oxide-reinforced nanocomposites are developed for use in structural applications requiring high strength and lightweight properties. These materials show potential in aerospace, automotive, and construction industries due to their enhanced mechanical performance.Expand Specific Solutions04 Synergistic effects of graphene oxide with other nanomaterials

Combining graphene oxide with other nanomaterials, such as carbon nanotubes or nanoparticles, can create synergistic effects in nanocomposites. This approach leads to further improvements in strength and other mechanical properties compared to using graphene oxide alone.Expand Specific Solutions05 Processing techniques for graphene oxide nanocomposites

Various processing techniques are developed to optimize the dispersion and integration of graphene oxide in nanocomposites. These methods include solution mixing, melt blending, and in-situ polymerization, which aim to maximize the strength-enhancing effects of graphene oxide in the final nanocomposite material.Expand Specific Solutions

Key Players in Graphene Oxide Research and Industry

The research on graphene oxide and nanocomposites for strengthening materials is in a rapidly evolving phase, with significant market potential and technological advancements. The global market for graphene-based products is projected to grow substantially, driven by applications in various industries. The technology's maturity varies across different applications, with some areas more developed than others. Key players like Battelle Memorial Institute, China Petroleum & Chemical Corp., and The University of Manchester are at the forefront of research and development. Other notable contributors include XG Sciences, Inc., Samsung Electronics Co., Ltd., and several prestigious universities worldwide. The competitive landscape is characterized by a mix of established corporations, specialized startups, and academic institutions, each contributing to the advancement of graphene-based materials technology.

China Petroleum & Chemical Corp.

XG Sciences, Inc.

Core Innovations in Graphene Oxide Nanocomposites

- A process involving the preparation of a nanocomposite material with bidirectional carbon fibers and an epoxy matrix dispersed with graphene oxide in a weight percentage range of 1-3%, where graphene oxide is ultrasonicated to enhance dispersion, mixed with an epoxy hardener, and impregnated onto carbon fibers, followed by curing, to create a stable and homogeneous composite.

- The development of composite materials by combining jute mat fibre with an epoxy matrix and varying ratios of MWCNT and graphene, fabricated using the hand lay-up technique, to enhance hardness through optimized reinforcement distribution.

Environmental Impact of Graphene Oxide Production

The production of graphene oxide and its nanocomposites has raised significant environmental concerns due to the potential impacts on ecosystems and human health. The synthesis process of graphene oxide typically involves the oxidation of graphite using strong oxidizing agents, such as potassium permanganate and sulfuric acid, which can generate hazardous waste and toxic byproducts if not properly managed.

One of the primary environmental concerns is the release of nanomaterials into aquatic systems. Graphene oxide particles, due to their small size and unique properties, can potentially accumulate in water bodies and affect aquatic organisms. Studies have shown that these nanoparticles can interact with biological membranes, potentially causing cellular damage and disrupting ecosystem balance.

Air pollution is another significant issue associated with graphene oxide production. The manufacturing process may release fine particulate matter and volatile organic compounds into the atmosphere. These emissions can contribute to air quality degradation and pose respiratory risks to workers and nearby communities if adequate filtration and containment measures are not implemented.

The energy-intensive nature of graphene oxide production also contributes to its environmental footprint. The high temperatures and extended reaction times required for synthesis result in substantial energy consumption, often derived from fossil fuel sources, leading to increased greenhouse gas emissions and climate change concerns.

Waste management presents another challenge in the production of graphene oxide and its nanocomposites. The chemical processes involved generate acidic and toxic waste streams that require careful treatment and disposal. Improper handling of these wastes can lead to soil and groundwater contamination, potentially affecting local ecosystems and human health.

However, it is important to note that ongoing research is focused on developing more environmentally friendly production methods for graphene oxide. Green synthesis approaches, such as using plant extracts or biodegradable reducing agents, are being explored to minimize the use of harsh chemicals and reduce environmental impacts.

Additionally, the potential for graphene oxide to contribute to environmental remediation should be considered. Its high adsorption capacity and ability to remove contaminants from water and air could potentially offset some of the environmental costs associated with its production, if effectively harnessed in large-scale applications.

Scalability and Cost Analysis of Graphene Oxide Materials

The scalability and cost analysis of graphene oxide materials is a critical aspect in evaluating their potential for widespread application in strengthening materials. The production of graphene oxide (GO) has seen significant advancements in recent years, moving from laboratory-scale synthesis to industrial-scale manufacturing. However, challenges remain in achieving cost-effective, large-scale production while maintaining consistent quality.

Current production methods for GO, such as the modified Hummers method, have been optimized for larger batch sizes. Industrial-scale production can now yield hundreds of kilograms of GO per batch. Despite these improvements, the cost of high-quality GO remains relatively high, ranging from $50 to $200 per gram, depending on purity and production volume.

The scalability of GO production is primarily limited by the oxidation process, which requires careful control of reaction conditions and can be time-consuming. Efforts to address this bottleneck include the development of continuous flow reactors and microwave-assisted synthesis methods. These innovations have the potential to significantly increase production rates and reduce costs.

Another factor affecting scalability is the availability and cost of raw materials. High-quality graphite, the primary precursor for GO, can be expensive and subject to supply chain fluctuations. Research into alternative carbon sources, such as biomass-derived precursors, could potentially reduce raw material costs and improve sustainability.

The cost structure of GO production is dominated by raw materials, energy consumption, and purification processes. Innovations in green chemistry and process intensification are being explored to reduce energy requirements and minimize waste generation. Additionally, advancements in separation and purification technologies, such as membrane filtration and centrifugation, are crucial for improving yield and reducing production costs.

When considering the use of GO in nanocomposites for strengthening materials, the scalability and cost analysis must also account for the integration process. The uniform dispersion of GO in polymer matrices or other materials can be challenging at larger scales. Techniques such as solution mixing, melt blending, and in-situ polymerization are being optimized for industrial-scale production of GO-based nanocomposites.

The economic viability of GO-based strengthening materials depends on the value proposition they offer compared to existing solutions. While the superior mechanical properties of GO nanocomposites are well-documented, the cost-benefit analysis must consider factors such as durability, weight reduction, and multifunctionality. As production scales up and costs decrease, the range of economically viable applications for GO-strengthened materials is expected to expand.