Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Octenyl succinic anhydride-modified starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of low-viscosity octenyl succinic anhydride modified starch

InactiveCN102532329ARaise the temperature of esterificationShort reaction timeDistilled waterSuccinic acid

The invention relates to a preparation method of low-viscosity octenyl succinic anhydride modified starch. The method comprises the following steps of: (1) adjusting the pH value of a starch emulsion to 8.0-8.5, adding an H2O2 solution, adding a hydrochloric acid solution for neutralizing the starch emulsion till the pH value is 6.5-7.0, washing and drying to obtain low-viscosity oxidized starch; and (2) mixing the low-viscosity oxidized starch with distilled water to obtain a starch emulsion, continually stirring in a constant-temperature water bath, adjusting the pH value to 8.0-8.5, adding 2 mol / L of an MgSO4 solution which accounts for 1 percent of the weight of the starch emulsion, slowly adding octenyl succinic anhydride which accounts for 2-3 percent of the total mass of the low-viscosity oxidized starch obtained in the step (2), adjusting the pH value to 5.5-6.5, washing with water and ethanol respectively twice, and drying to obtain a white finished product. The product has the advantages of stable performance, simple and environmentally-friendly process steps, reduction in preparation time, no residue of oxidant and increase in production efficiency.

Owner:天津市轻工业化学研究所有限公司 +1

Acid-heat degradation and enzymolysis preparation method of low-viscosity octenyl succinic anhydride modified starch

The invention discloses an acid-heat degradation and enzymolysis preparation method of low-viscosity octenyl succinic anhydride modified starch. The method comprises the following steps: raw starch is prepared into a slurry; alkaline liquid is added; octenyl succinic anhydride is fed; an esterification reaction is allowed; neutralization and liquid-removal are carried out; washing refining is carried out; a filter cake is prepared into a slurry; the pH value is regulated; an acid hydrolysis reaction is carried out; a continuous-ejection high-temperature acid-heat treatment is carried out; laminar-flow thermal insulation is carried out; cooling is carried out; a saturated calcium hydroxide solution is added; the mixture is stirred such that neutralization is carried out; pullulanase is added for carrying out debranching enzymolysis; active carbon is added; temperature is increased and decolorization is carried out; pressure filtration is carried out; the filtrate is concentrated under vacuum; fine filtration is carried out; spray drying is carried out; and cooling and packaging are carried out, such that a product is obtained. The product is suitable to be used as an emulsifier of foods and daily chemicals, or as a microencapsulation material. With the method, the low-viscosity water-soluble octenyl succinic anhydride modified starch product can be produced, and good economical benefit can be achieved. With a pullulanase debranching effect upon modified starch molecules, more products with linear or low-branch-degree molecular structures can be produced, such that product emulsifying and film-forming properties can be improved.

Owner:SOUTH CHINA UNIV OF TECH

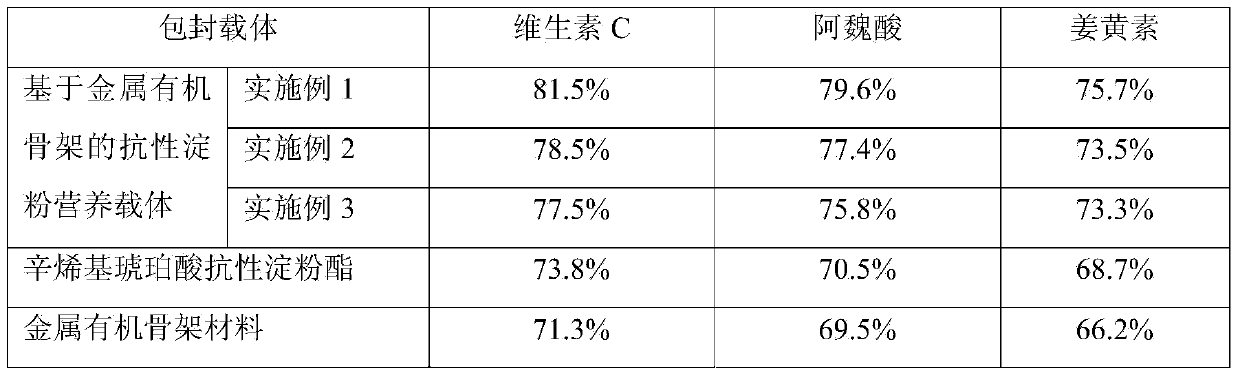

Preparation method of resistant starch nutritional carrier based on metal-organic framework as well as product thereof

InactiveCN103549635AGood health effectGood self-aggregation performanceFood shapingFood preparationFood additiveMetal-organic framework

The invention discloses a preparation method of a resistant starch nutritional carrier based on a metal-organic framework as well as a product thereof. The preparation method of the resistant starch nutritional carrier comprises the step of adsorbing metal-organic framework structured gamma-cyclodextrin on the surface of octenyl succinic anhydride modified starch (OSA-S) by taking the OSA-S prepared by performing esterification on octenyl succinic anhydride and resistant starch as a base material and under the effects of hydrogen bond, electrostatic force and the like, thus constructing the nutritional carrier with a porous network structure. The nutritional carrier has favorable solution self-aggregation performance; by virtue of the great load quantity of the relatively single OSA-S and the metal-organic framework structured gamma-cyclodextrin, functional substances such as nutritional elements can be embedded in a solid state mode, so that the damage caused by light irradiation, oxygen as well as acid-base and the like is prevented effectively, and a certain slow-release effect is achieved; the resistant starch also has a good health protection effect, and thus the nutritional carrier is expected to be a safe functional food additive applied to the food processing field.

Owner:SOUTHWEST UNIVERSITY

Alum-free sweet potato noodles

The invention discloses alum-free sweet potato noodles, which are prepared from the following raw materials in part by weight: 99 to 100 parts of starch, 0.05 to 0.5 part of octenyl succinic anhydride modified starch, 0.05 to 0.5 part of soybean lecithin, 0.02 to 0.5 part of konjac glucomannan, 0.02 to 0.5 part of D-sodium erythorbate, 0.05 to 2 parts of vegetable oil and 30 to 35 parts of water. A method for preparing the alum-free sweet potato noodles comprises the following steps of: mixing powder at first, then mixing each component of the raw materials in a specified proportion, uniformly stirring to obtain a mixture, curing the mixture for molding, and processing the uniformly-mixed mixture to form noodles or flakes. The noodles or flakes produced by the method maintains non-sticking, non-breaking and non-muddling characteristics, and are softer, tender and pliable; and the product quality is obviously improved.

Owner:界首市天瑞食品有限公司

Acer truncatum seed oil nanometer microcapsule for middle-aged and elderly health-care eating, and preparation method thereof

InactiveCN106901373APromote absorptionPrevent or reduce morbidityFood shapingLipidic food ingredientsSequelaMonoglyceride

The invention discloses an acer truncatum seed oil nanometer microcapsule for middle-aged and elderly health-care eating, and a preparation method thereof. The preparation method comprises the following steps: by taking acer truncatum seed oil as a core material, octenyl succinic anhydride-modified gum arabic, octenyl succinic anhydride modified starch and oligosaccharide syrup as wall materials, and fatty acid monoglyceride and fatty acid biglyceride as a core material emulsifier, performing dynamic high-pressure microjetting, and spray drying to be powdery to obtain the acer truncatum seed oil nanometer microcapsule product. The prepared acer truncatum seed oil nanometer microcapsule is safe and non-toxic, low in cost, simple in preparation technology, and suitable for large-scale production. Furthermore, the acer truncatum seed oil nanometer microcapsule is rich in nervonic acid and alpha-linolenic acid, thus having the functions of reducing blood fat and blood pressure, inhibiting senile dementia and parkinson's disease, improving sequela of cerebral apoplexy and hypomnesis, prolonging aging and the like. In addition, the acer truncatum seed oil nanometer microcapsule is a nanometer microcapsule product, and the bioavailability of nutritional substances in the acer truncatum seed oil can be effectively improved through the absorption of nanoparticles.

Owner:NANCHANG UNIV

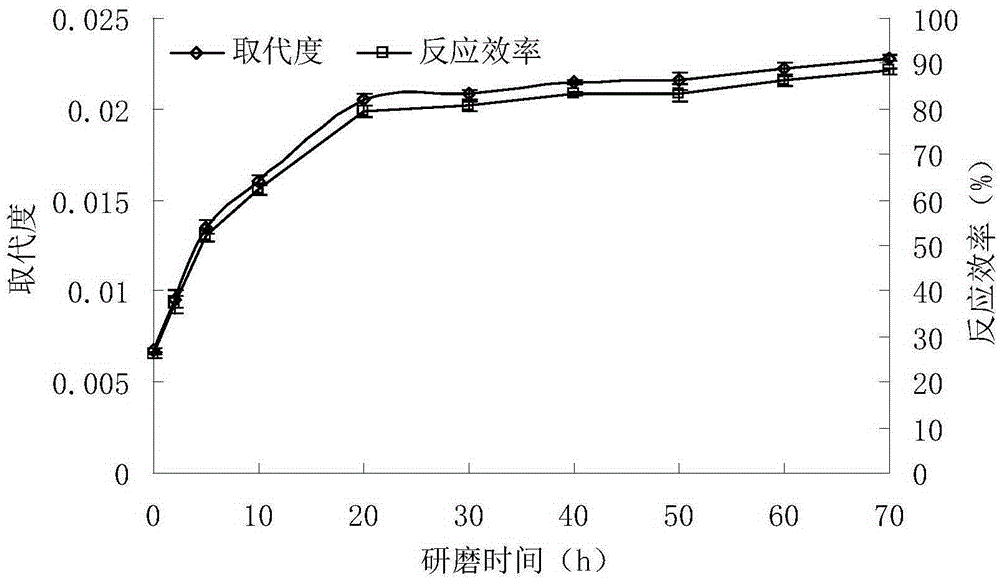

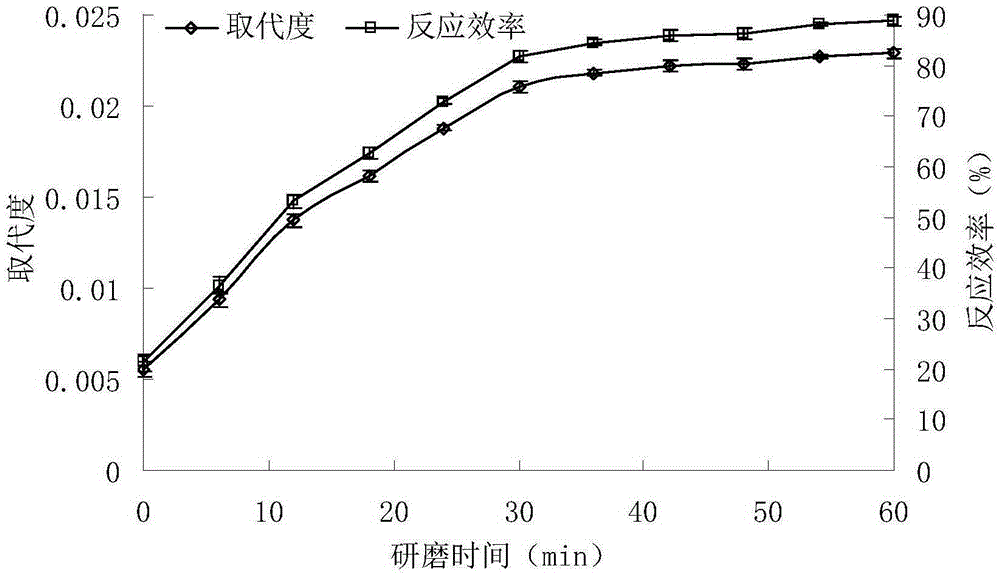

Octenyl succinic anhydride modified starch prepared through dry mechanical force induction of esterification reaction and application thereof

InactiveCN105348399AOvercome the disadvantages of not being easy to mix evenly and prone to local severe reactionsEdible oils/fats ingredientsFrozen sweetsMaterials preparationOCTENYLSUCCINIC ACID

The invention relates to octenyl succinic anhydride modified starch prepared through dry mechanical force induction of an esterification reaction and an application thereof. A method comprises the steps: (1) adopting a secondary mixing-process material preparation method, mixing an NaOH solution and octenyl succinic anhydride with an appropriate mass ratio, to obtain an alkaline octenyl succinic anhydride solution, then sprinkling the solution on starch with an appropriate mass ratio of the solution to the starch and blending uniformly, to obtain a mixture A, and carrying out secondary uniform blending of the mixture A and starch with an appropriate mass ratio, to obtain a mixture B; and (2) putting the mixture B in a ball milling pot, and grinding under appropriate parameters to obtain micro-fine esterified starch; or placing the mixture B in a Raymond mill, and grinding under appropriate parameters to obtain micro-fine octenyl succinic anhydride modified starch. The shortcomings that materials are not easy to mix evenly and are easily subjected to a local sharp reaction in dry-process preparation of octenyl succinic anhydride modified starch are overcome, and at the same time, the shortcomings of insufficient mechanical force strength and long reaction time are overcome.

Owner:HUAZHONG AGRI UNIV

Preparation method of low viscosity octenyl succinic anhydride modified starch (OSA-starch) by oxidative degradation and enzymolysis

The invention discloses a preparation method of low viscosity octenyl succinic anhydride modified starch (OSA-starch) by oxidative degradation and enzymolysis. The method comprises the following steps: pulping original starch, adding alkali liquor, feeding alkenyl succinic anhydride for esterification, and reacting for 6.0-20.0 hours; feeding a calcium hypochlorite solution for oxidization, and reacting for 2.0-4.0 hours; carrying out high-heat treatment for continuous injection, and insulating by a laminar flow; cooling, reducing by a reducing agent, then adding an oxalic acid solution, stirring and neutralizing to adjust the pH value, and adding pullulanase for debranched enzymolysis; adding active carbon, raising temperature and decoloring, and carrying out filter pressing; and carrying out vacuum concentration on the filtrate, finely filtering, spray-drying, cooling and packaging to obtain a water soluble low viscosity OSA-starch product which is suitable for emulsifiers or microcapsule embedding materials for chemical products such as pesticides, articles for daily use, and the like.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing double-enzyme enzymatic hydrolysis octenyl succinic anhydride modified starch ester

The invention discloses a method for preparing double-enzyme enzymatic hydrolysis octenyl succinic anhydride modified starch ester. The method includes preparing octenyl succinic anhydride starch ester; carrying out amylase enzymatic hydrolysis, to be more specific, regulating the pH (potential of hydrogen) until the acidity is indicated, dissolving amylase by buffer solution, then adding the amylase into the octenyl succinic anhydride starch ester and carrying out reaction under stirring conditions. Compared with the traditional methods, the method has the advantages that surface tension, theviscosity and the molecular weight of the prepared octenyl succinic anhydride modified starch ester are changed, the octenyl succinic anhydride starch ester produced by means of alpha-beta double-amylase enzymatic hydrolysis is good in emulsifying stability as compared with products prepared by the aid of the traditional processes, the application has extremely high theoretical research value andpractical application significance, starch is endowed with novel performance and functionality, the application fields of the starch can be expanded, and a novel way can be provided for improvement of the application performance of the starch and processes for producing starch derivative emulsifiers.

Owner:JIANGNAN UNIV

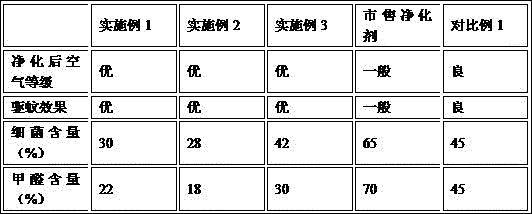

Air purifying agent and preparation method thereof

ActiveCN106139817ANatural materialsImprove air purification effectBiocideGas treatmentAbsorption capacityRaw material

The invention discloses an air purifying agent and a preparation method thereof. The air purifying agent is prepared from the following raw materials: 23 to 40 parts of tea leaves, pearl powder, active carbon powder, sodium chlorite, folium artemisiae argyi, deionized water, menthol, octenyl succinic anhydride modified starch and honeysuckle. The preparation method comprises the following steps: weighing the required raw materials, putting the tea leaves, the folium artemisiae argyi and the honeysuckle into the deionized water, heating to 80 to 90 DEG C, and filtering to obtain an extracting solution; then immersing the active carbon powder, the pearl powder and the menthol into the extracting solution for refrigeration at the temperature of 0 to 5 DEG C for 12 to 24 hours, then taking out the materials, adding the sodium chlorite and the octenyl succinic anhydride modified starch, and performing spray drying to obtain a semi-finished product; finally, putting the semi-finished product into a clean filter bag to obtain the air purifying agent. The air purifying agent disclosed by the invention is good in purification effect, can kill bacteria and expel mosquitoes, and is high in formaldehyde absorption capacity; the materials are natural; the preparation process is simple; the air purifying agent is suitable for industrialization.

Owner:广东得天生物科技有限公司

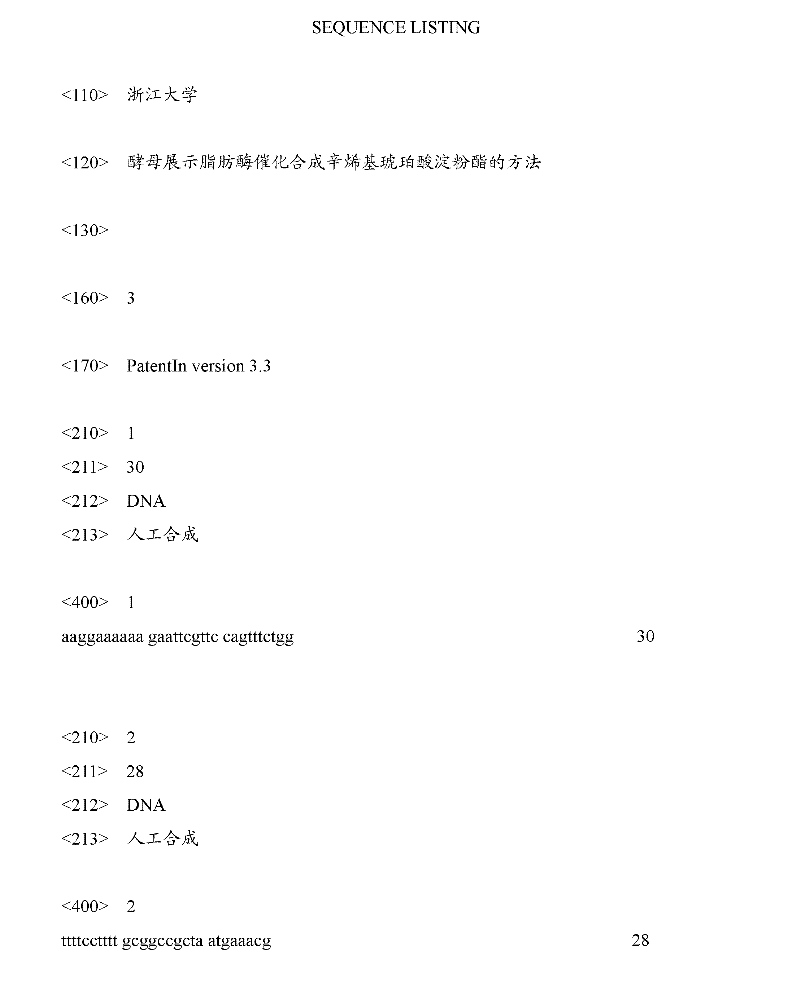

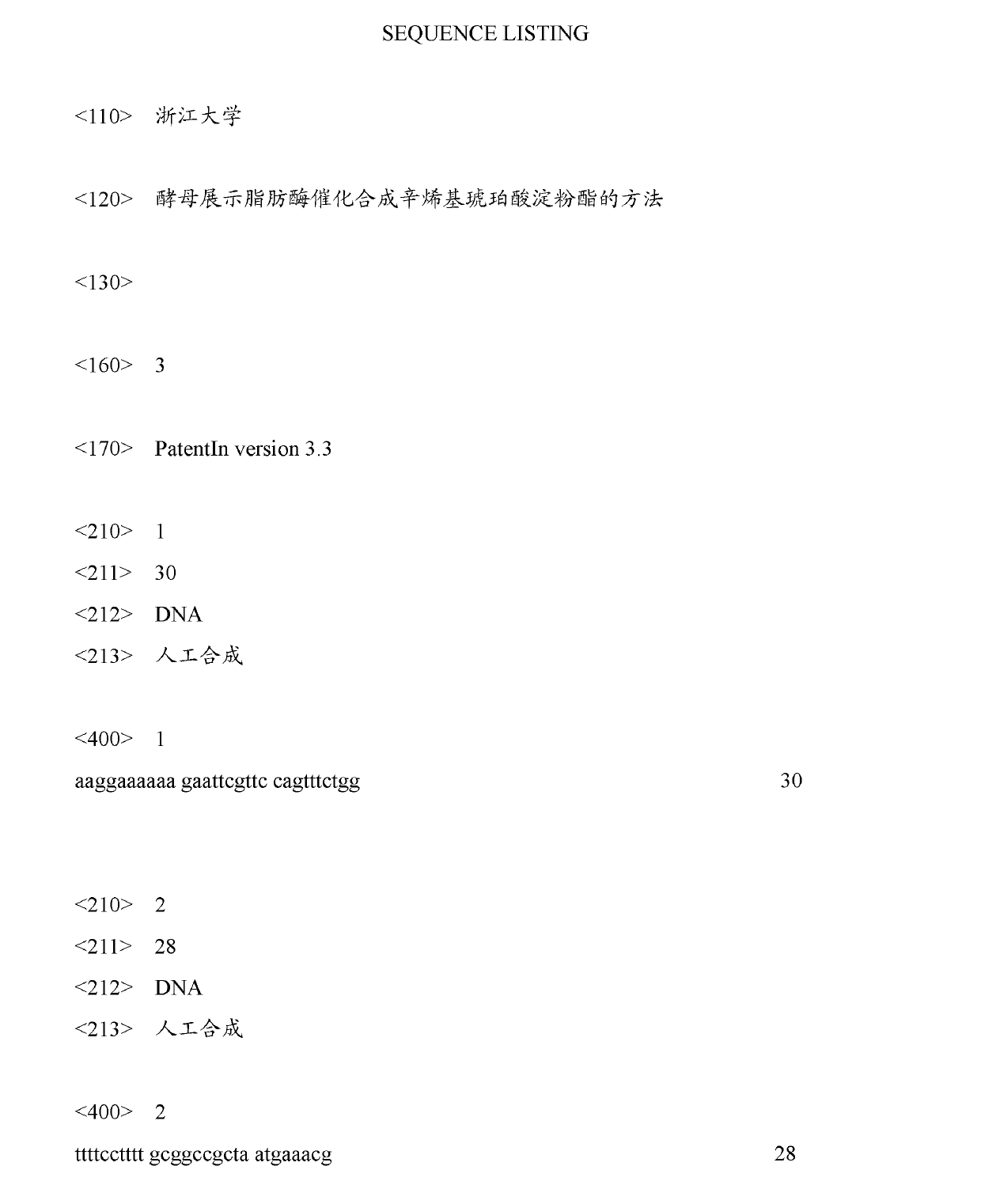

Method for catalyzing and synthesizing octenyl succinic anhydride modified starch ester through yeast show lipase

InactiveCN102212583AReduce manufacturing costHigh Catalytic Synthesis Conversion EfficiencyFungiHydrolasesPichia pastorisTransformation efficiency

The invention discloses a method for catalyzing and synthesizing octenyl succinic anhydride modified starch ester through yeast show lipase, comprising the following steps of: dissolving grain starch in water; after imbibition, adding octenyl succinic anhydride and the yeast show lipase; stirring and reacting at 34-36 degrees centigrade for 1-1.5 h; and separating and purifying to obtain starch sodium ester sodium octenyl succinate. A method for preparing the yeast show lipase comprises the following steps of: transforming linearly treated recombinant plasmids into pichia pastoris GS115; inoculating the obtained transformant into a BMMY (buffered methanol-complex medium) culture medium; after inducing and culturing for 72-144 h, centrifugally collecting thallus; and washing, biologically imprinting, freezing and drying the thallus so as to obtain the yeast show lipase. By showing the lipase outside cells, the octenyl succinic anhydride modified starch ester is catalyzed and synthesized through the lipase preparation. By means of the method disclosed by the invention, the transformation efficiency is improved; furthermore, the reaction time is shortened; and the production cost is reduced.

Owner:ZHEJIANG UNIV

Preparation method for composite polymer resin foam adhesive

The invention discloses a preparation method for a composite polymer resin foam adhesive, belonging to the technical field of polymeric materials. The preparation method provided by the invention comprises the following steps: mixing octenyl succinic anhydride modified starch, a natural macromolecular organic matter and water under stirring, carrying out standing and swelling, carrying out heatingunder stirring, carrying out dissolving so as to obtain a mixed solution, then adding linseed oil into the mixed solution, and carrying out stirring at a high speed so as to obtain an emulsion; and subjecting (N-amidino)dodecyl acrylamide, polyethylene glycol phosphate and an additive to a reaction under stirring at a constant temperature so as to prepare a self-prepared surfactant, then mixing the emulsion, the self-prepared surfactant and an anionic polyacrylamide dispersion under stirring, adding a cross-linking agent, carrying out a reaction under stirring at a constant temperature, thensuccessively adding a sodium silicate solution and a polyurethane performed polymer, carrying out mixing under stirring, and carrying out standing and foaming so as to obtain the composite polymer resin foam adhesive. The composite polymer resin foam adhesive prepared by using the preparation method provided by the invention has excellent bonding strength, and does not generate the phenomenon of layering when in storage due to excellent foam stability.

Owner:CHANGZHOU AMANTE CHEM CO LTD

Acid-heat degradation preparation method of low-viscosity octenyl succinic anhydride modified starch

The invention discloses an acid-heat degradation preparation method of a low-viscosity water-soluble octenyl succinic anhydride modified starch product. The method comprises the following steps: raw starch is prepared into a slurry; alkaline liquid is added; under a starch gelatinization temperature, octenyl succinic anhydride is fed, and an esterification reaction is allowed for more than 8 hours; neutralization and liquid-removal are carried out; purified water is used for washing and refining; a filter cake is prepared into a slurry with water; the pH value is regulated by using an oxalic acid solution; an acid hydrolysis reaction is carried out; a high-temperature acid-heat treatment is carried out under continuous ejection under a temperature of 125-130 DEG C by using a hydrothermal device; laminar-flow thermal insulation is carried out; cooling is carried out; a saturated calcium hydroxide solution is added, or a calcium carbonate emulsion and a sodium carbonate solution are added; the mixture is stirred such that neutralization is carried out; active carbon is added; pressure filtration is carried out; the filtrate is concentrated under vacuum; fine filtration is carried out; spray drying is carried out; and the product is cooled and packaged. With the method, the low-viscosity water-soluble octenyl succinic anhydride modified starch product is obtained. The product is suitable to be used as an emulsifier of foods and daily chemicals, or as a microencapsulation material. With the method, the low-viscosity water-soluble octenyl succinic anhydride modified starch product can be produced, and good economical benefit can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

Novel preparation method of octenyl succinic starch ester

The present invention relates to a novel preparation method of starch octenyl succinate, the main technical point of which is to carry out hot alkali pretreatment on starch, and then adopt two methods of direct modification or modification after freeze-drying and then carry out octenyl Synthesis of starch octenyl succinate to improve the emulsification performance of the final product starch octenyl succinate. The invention has simple operation steps and low cost, and the octenyl succinic acid starch ester treated with hot alkali freeze-intervention has a higher degree of substitution and better emulsifying performance than the starch ester without pretreatment.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production process of octenyl succinic anhydride modified starch (OSA Starch)

The invention discloses a production process of octenyl succinic anhydride modified starch (OSA Starch). The production process comprises the steps as follows: after esterification, performing filtration and obtaining the OSA starch and a filtrate; rinsing, recovering and obtaining a washes; combining the washes and the filtrate, separating alcohol via reduced pressure distillation, and recovering and obtaining a micro-saturated concentrated salt solution; cooling and filtering the micro-saturated concentrated salt solution; performing separation and obtaining octenylsuccinic anhydride and a salt solution; adding ammonium hydrogencarbonate into the salt solution for reaction; performing filtration, recovering, and obtaining dicarbonate and a salmak solution; performing reaction of the ammonium hydrogencarbonate and sodium hydroxide and obtaining a soda solution; performing the reaction of the soda solution and the calcium hydroxide, filtering, and obtaining a sodium hydroxide solution. Therefore, the sodium chloride of the filtrate obtained after the esterification is separated; besides, the prepared sodium hydroxide can be reused as a pH regulator of the esterification, so as to lower the production cost of the OSA starch.

Owner:GUANGXI GAOYUAN STARCH

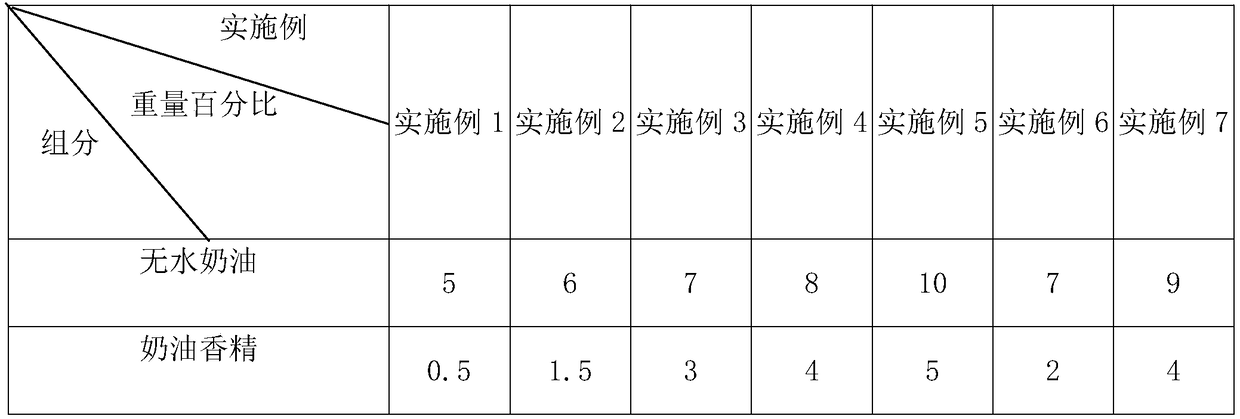

Butterfat flavor reinforcing agent and preparation method thereof

InactiveCN109247559AEnhances fat tasteAdd flavorFood ingredient as taste affecting agentFood ingredient as pH modification agentFlavorButterfat

The invention discloses a butterfat flavor reinforcing agent and a preparation method thereof, which relate to the technical field of edible essence, and solve the technical problem that the existingessence has obvious sour flavour and leads to poor cream flavor. The butterfat flavor reinforcing agent comprises the following components by weight percentage: 5-10% of anhydrous butter; 0.5-5% of cream essence; 10-50% of DATEM; 1-10% of octenyl succinic anhydride modified starch; 0.1-2% of trisodium phosphate; and 0.001-0.01% of butyl p-hydroxybenzoate sodium; water is supplied to 100%; whereinthe DATEM is Liquid. The preparation method adopts the liquid DATEM to enhance the fat taste of dairy products, and the effect can be enhanced by adding the anhydrous butter, the stable liquid butterfat flavor reinforcing agent is prepared, is easy to use and uses trisodium phosphate to adjust the sour degree to enhance the taste, and the product is more suitable for the dairy products such as icecream, dairy beverage, yogurt and cheese.

Owner:上海华宝孔雀香精有限公司

Method for preparing powdered oil by compounding octenylsuccinic anhydride (OSA) modified starch with xanthan gum

InactiveCN110583801ANovel and reasonable designSimple processing methodEdible oils/fatsWater bathsSlurry

The invention discloses a method for preparing powdered oil by compounding octenylsuccinic anhydride (OSA) modified starch with xanthan gum, and belongs to the field of micro-encapsulated powdered oilpreparation. By selecting a mixture of the OSA modified starch and the xanthan gum as a wall material, the method for preparing the powdered oil by compounding the OSA modified starch with the xanthan gum is capable of solving the technical problems of low encapsulation efficiency, poor stability and the like of the micro-encapsulated powdered oil. The method for preparing the powdered oil by compounding the OSA modified starch with the xanthan gum comprises the following steps: step one, dispersing corn starch in an HCl solution of which the concentration is 0.65M, carrying out reaction in water bath at 50 DEG C for 0-24 hours so as to obtain a mixed solution, adjusting pH value of the mixed solution to neutral, terminating acid hydrolysis reaction, and carrying out centrifuging-drying so as to obtain hydrolyzed starch; step two, dispersing the hydrolyzed starch in an aqueous solution so as to obtain starch slurry, adding an OSA solution into the starch slurry within 2 hours with thepH value of the starch slurry kept at 8.5, continuing reaction for 1 hour, adjusting the pH value of the starch slurry to 6.5, Performing centrifugal water-washing on the starch slurry, and carryingout drying so as to obtain OSA modified starch; step three, mixing the OSA modified starch with the xanthan gum at room temperature for 24 hours so as to obtain wall material suspension liquid; step four, adding soybean oil into the wall material suspension liquid obtained in the step three, carrying out homogenization, and carrying out high-pressure homogenization for 2 times; and step five, carrying out spray-drying so as to obtain the powdered oil. The method for preparing the powdered oil by compounding the OSA modified starch with the xanthan gum is novel and rational in design, as well as simple in process; and moreover, the method also has the characteristics of being capable of significantly improving encapsulation rate of the powdered oil, enhancing product stability and so on.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

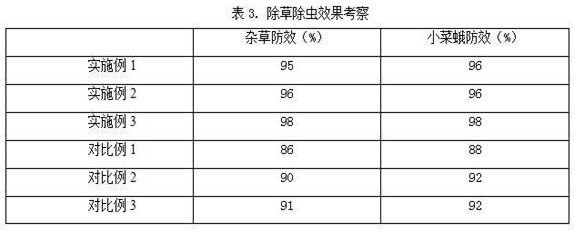

Efficient environment-friendly mulching film with weeding and deinsectization effects and preparation method thereof

ActiveCN112430395AGood weed control and pest controlGuaranteed mechanical propertiesClimate change adaptationWeed killersCellulosePolyvinyl alcohol

The invention provides an efficient environment-friendly mulching film with weeding and deinsectization effects and a preparation method of the mulching film. According to the preparation method, firstly, a herbicide and a deinsectization agent are mixed to prepare microcapsules, then the microcapsules are mixed with a biodegradable material, and film blowing processing is conducted to obtain themulching film, wherein the microcapsules are prepared by the following steps: taking rapeseed oil as an oil phase, mixing octenyl succinic anhydride modified starch and a sodium carboxymethyl cellulose aqueous solution to prepare a water phase, correspondingly adding the oil phase or the water phase according to the oil solubility or water solubility of herbicides and insecticides, conducting uniform stirring and mixing, finally conducting stirring and emulsifying, conducting homogenizing under high pressure, and conducting drying. The biodegradable material is prepared by modifying sludge powder with fresh corn stalk juice to obtain modified sludge powder, and then mixing the modified sludge powder with polyvinyl alcohol partially modified soybean meal and epoxy chloropropane for reaction. The mulching film has good weeding and deinsectization effects, and is biodegradable, safe and environment-friendly.

Owner:甘肃济洋塑料有限公司

Starch gel rich in fat-soluble nutritional component, preparation method for starch gel and application of starch gel.

ActiveCN111938136AImprove stabilityGood dispersionLipidic food ingredientsFood ingredient as emulsifierBiotechnologyFish oil

The invention belongs to the technical field of health product processing, and particularly relates to starch gel rich in fat-soluble component, a preparation method for the starch gel and applicationof the starch gel. The starch gel comprises the following raw materials in parts by weight: 20 parts of starch, 10-20 parts of pregelatinized waxy starch, 1-3 parts of deep-sea fish oil, 0.2-0.5 partof vitamin E, 0.2-0.5 part of octenyl succinic anhydride modified starch and 0.2-0.5 part of 1,3-butanediol. The starch gel with strong gel performance is obtained, and the pregelatinized waxy starchand the octenyl succinic anhydride modified starch can interact, so that oil drops are fixed better, and movement of the oil drops is reduced. The concentration of pregelatinized waxy starch is controlled, so that dispersion liquid has certain viscosity, starch granules added later are suspended in a mixed solution, and stirring is not needed during reheating, and thus, a firmer starch gel network structure of in-situ water absorption is formed. The process is simple, and operation is easy, thus being conducive to industrial production.

Owner:QILU UNIV OF TECH

Fructo-oligosaccharide tablet excipient, medicine tablet and preparation method of medicine tablet

InactiveCN102671206AImprove emulsion stabilityGood thickening effectInorganic non-active ingredientsPill deliverySolubilityAdditive ingredient

The invention discloses a fructo-oligosaccharide tablet excipient which includes, by weight, 88% to 96% of fructo-oligosaccharide, 1% to 5% of an octenyl succinic anhydride modified starch, 1% to 5% of silicon dioxide and 1% to 5% of kaolin. The fructo-oligosaccharide tablet excipient is good in liquidity, molding, and demoulding, and can be used for preparing medicine tablets with medicine and water through direct compression. The invention further discloses a medicine tablet which includes, by weight, 75% to 85% of an active pharmaceutical ingredient, 5% to 15% of the fructo-oligosaccharidetablet excipient and 5% to 15% of water. The fructo-oligosaccharide tablet excipient and the active pharmaceutical ingredient have no incompatibility and reaction, have good dissolubility and liquidity, and are suitable for direct compression of various medicines. The invention further discloses a preparation method of the medicine tablet. The preparation method is simple, and easy to implement, operate and control.

Owner:安吉东来药用辅料有限责任公司

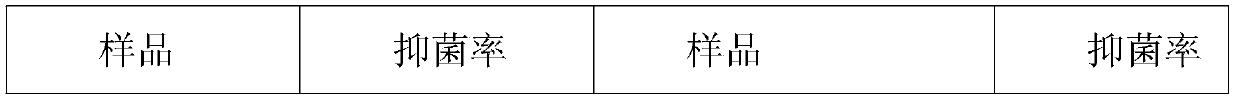

Medicine microcapsule slow-release filtering material composition for epidemic prevention functional type gauze mask

InactiveCN111228335AWith active epidemic prevention functionImprove the effect of epidemic preventionAntibacterial agentsBiocideBiotechnologyAjowan oil

The invention discloses a medicine microcapsule slow-release filtering material composition for an epidemic prevention functional type gauze mask, and belongs to the technical field of antibacterial and antivirus gauze masks. The formula medicine components are attached to the surface of a nonwoven material to prepare a medicine microcapsule filtering material layer, so that the gauze mask has active epidemic prevention function for resisting pathogenic microorganisms, and can improve the respiratory system immunity of users wearing the gauze mask in different degrees. The medicine filtering material layer comprises the composition of following medicine raw materials in parts by weight of 1-20 parts of atractylis oil, 1-30 parts of palchouli oil, 1-40 parts of radix angelicae oil, 1-20 parts of fortune eupatorium herb oil, 1-10 parts of oleum cinnamomi, 1-10 parts of camphor oil, 1-25 parts of clove oil, 1-30 parts of folium eucalypti oil, 1-10 parts of peppermint oil, 1-10 parts of a2000ppm nanosilver solution and 8-40 parts of octenyl succinic anhydride modified starch. The medicine raw materials are combined to prepare medicine microcapsules and then are adhered to the surfacesof nonwovens to prepare the medicine filtering material layer. The medicine microcapsule slow-release filtering material layer for the epidemic prevention functional type gauze mask has high adsorption and pathogenic microorganism killing properties, and besides, the hygroscopicity and the air permeability are good.

Owner:湖南华瑞康源科技有限公司

Starch esters and method of preparation

Owner:KANSAS STATE UNIV RES FOUND

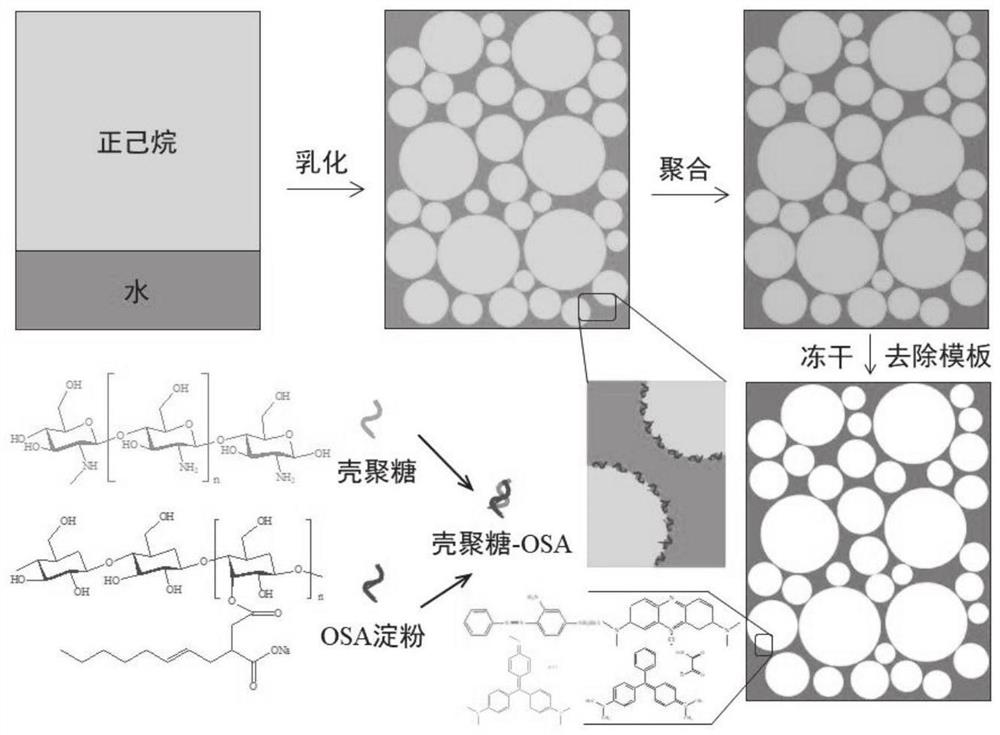

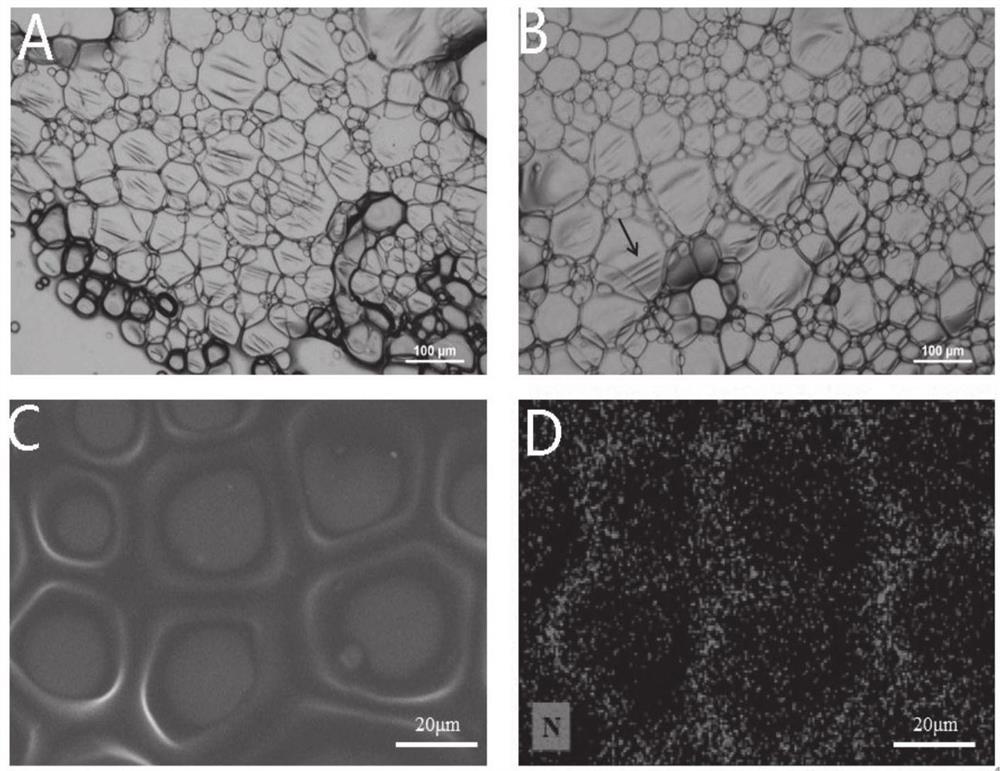

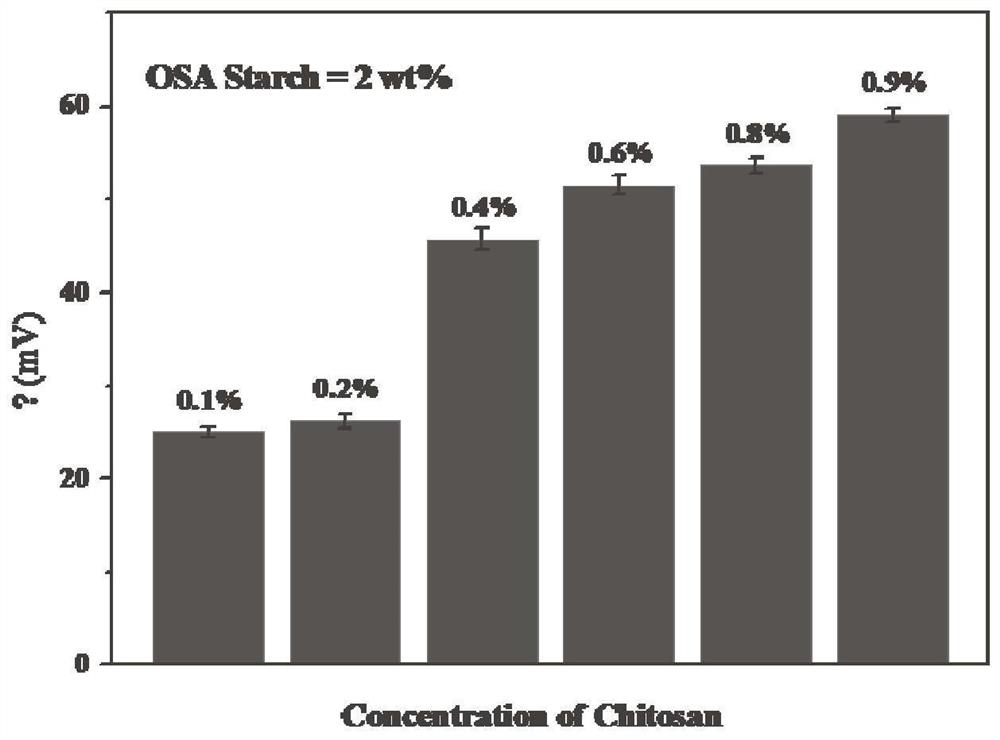

Method for preparing macroporous aerogel by using high-internal-phase Pickering emulsion as template and application of macroporous aerogel

ActiveCN113578282AHigh modulus of elasticityIncreased viscous modulusOther chemical processesWater contaminantsPolymer scienceOctene

The invention belongs to the technical field of aerogel adsorption material preparation, and relates to a method for preparing macroporous aerogel by taking a high internal phase Pickering emulsion as a template and application of the macroporous aerogel. A stabilizer of the high internal phase Pickering emulsion is a polysaccharide compound formed by mixing chitosan and 2-octenyl succinic anhydride modified starch, an external phase is water, and an internal phase is n-hexane. The Pickering emulsion disclosed by the invention has relatively high stability. Then, by taking the high-internal-phase Pickering emulsion as a template, a monomer acrylic acid is added into the external phase, ultraviolet-initiated external phase polymerization is conducted, the internal phase is removed, and freeze-drying is conducted to obtain the aerogel adsorption material. The aerogel adsorption material has relatively high mechanical strength and a better dye adsorption effect.

Owner:SHANDONG UNIV

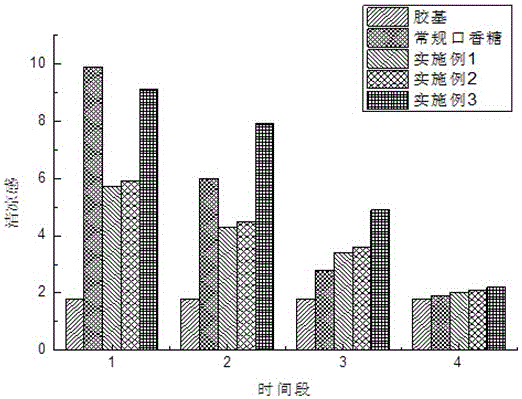

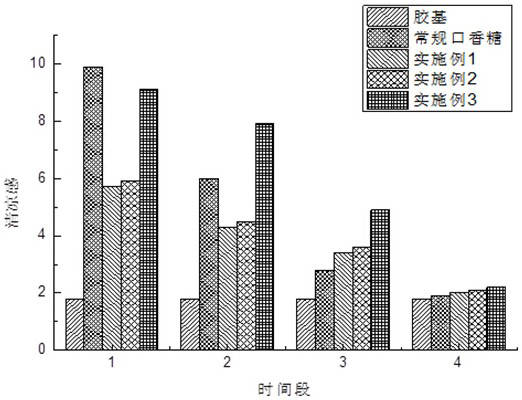

Chewing gum containing gelatin-octenyl succinic anhydride modified starch-L-menthol microcapsules and preparation method thereof

ActiveCN106561963AProceduralExtended release timeSugar food ingredientsChewing gumGlycerolHigh fructose

The invention discloses chewing gum containing gelatin-octenyl succinic anhydride modified starch-L-menthol microcapsules. The chewing gum is prepared from the following components in parts by weight: 10-20 parts of polyvinyl acetate, 10-20 parts of high fructose syrup, 50-60 parts of sorbitol, 1-3 parts of glycerinum and 1-5 parts of the gelatin-octenyl succinic anhydride modified starch-L-menthol microcapsules. The invention further provides a method for preparing the chewing gum. The method comprises the following steps of respectively adding auxiliaries into softened the polyvinyl acetate; conducting mixing and stirring; adding the gelatin-octenyl succinic anhydride modified starch-L-menthol microcapsules into the mixture; conducting heating to 80-90 DEG C; conducting condensation and cooling; conducting extrusion in an extruding machine; and conducting cut-forming, packaging, cooling and aging to obtain a finished product. The chewing gum has long duration in the oral cavity with more cool feeling. Furthermore, the preparation method is simple, has relatively low production cost, and is suitable for industrial production.

Owner:上海松皓生物科技有限公司

A kind of preparation method of non-crystalline high emulsification active starch

The invention discloses a non-crystalline high-emulsification activity starch preparation method, and belongs to the field of food processing. According to the preparation method, octenyl succinic anhydride modified starch is gelatinized at high temperature, starch granules and crystalline areas are broken, amylose and amylopectin are released, starch gelatinization solution is prepared and treated by a high-speed shearing machine and a high-pressure homogenizer, polymerization between starch molecular chains is broken, viscosity is reduced, dispersity and emulsibility of molecules are furtherimproved, and high-solvency and high-emulsibility non-crystalline starch is prepared by a spray-drying technology. Compared with a chemistry method, a biology method and the like, the preparation method is a purely physical modified starch method, adding of any reagent is omitted, and the method is convenient to operate and popularize and high in repeatability.

Owner:THE SUIZHOU ER YUE FENG FOOD

Preparation method of low-viscosity octenyl succinic acid starch ester by acid-thermal degradation and enzymatic hydrolysis

ActiveCN104086662BDE value decreasedImprove emulsification and film-forming performanceFermentationThermal insulationSuccinic acid

The invention discloses an acid-heat degradation and enzymolysis preparation method of low-viscosity octenyl succinic anhydride modified starch. The method comprises the following steps: raw starch is prepared into a slurry; alkaline liquid is added; octenyl succinic anhydride is fed; an esterification reaction is allowed; neutralization and liquid-removal are carried out; washing refining is carried out; a filter cake is prepared into a slurry; the pH value is regulated; an acid hydrolysis reaction is carried out; a continuous-ejection high-temperature acid-heat treatment is carried out; laminar-flow thermal insulation is carried out; cooling is carried out; a saturated calcium hydroxide solution is added; the mixture is stirred such that neutralization is carried out; pullulanase is added for carrying out debranching enzymolysis; active carbon is added; temperature is increased and decolorization is carried out; pressure filtration is carried out; the filtrate is concentrated under vacuum; fine filtration is carried out; spray drying is carried out; and cooling and packaging are carried out, such that a product is obtained. The product is suitable to be used as an emulsifier of foods and daily chemicals, or as a microencapsulation material. With the method, the low-viscosity water-soluble octenyl succinic anhydride modified starch product can be produced, and good economical benefit can be achieved. With a pullulanase debranching effect upon modified starch molecules, more products with linear or low-branch-degree molecular structures can be produced, such that product emulsifying and film-forming properties can be improved.

Owner:SOUTH CHINA UNIV OF TECH

Fructo-oligosaccharide tablet excipient, medicine tablet and preparation method of medicine tablet

InactiveCN102671206BPromote degradationGood biocompatibilityInorganic non-active ingredientsPill deliverySolubilityOCTENYLSUCCINIC ACID

The invention discloses a fructo-oligosaccharide tablet excipient which includes, by weight, 88% to 96% of fructo-oligosaccharide, 1% to 5% of an octenyl succinic anhydride modified starch, 1% to 5% of silicon dioxide and 1% to 5% of kaolin. The fructo-oligosaccharide tablet excipient is good in liquidity, molding, and demoulding, and can be used for preparing medicine tablets with medicine and water through direct compression. The invention further discloses a medicine tablet which includes, by weight, 75% to 85% of an active pharmaceutical ingredient, 5% to 15% of the fructo-oligosaccharidetablet excipient and 5% to 15% of water. The fructo-oligosaccharide tablet excipient and the active pharmaceutical ingredient have no incompatibility and reaction, have good dissolubility and liquidity, and are suitable for direct compression of various medicines. The invention further discloses a preparation method of the medicine tablet. The preparation method is simple, and easy to implement, operate and control.

Owner:安吉东来药用辅料有限责任公司

Fiberglass rigid communications tube

The invention relates to a fiberglass rigid communications tube, made from the following components: metallocene polyethylene, isobornyl propionate, sodium allysulfonate, alkyl diphenyl phosphate, polypropylene glycol adipate, praseodymium oxide powder, diethylene glycol monobutyl ether acetate, phosphonitrilic chloride trimer, pyromellitic dianhydride, benzothiazole, monostearin, polyarylene ether nitrile, octenyl Succinic Anhydride modified starch, sulfur trioxide, bismaleimide resin, sodium bicarbonate, dibutyl maleate, carbon powder, chromium oxide powder, zinc oxide, fiberglass powder, sodium alginate, and hydroxymethyl cellulose. The various materials are mixed together to form the novel composite toughened reinforced system has good toughness, rigidity and elasticity modulus performance indexes, the aging resistance and service performance of the tube are greatly improved, and good corrosion resistance is provided; the tube has good comprehensive performance and service effect.

Owner:华蓥友达精密模具制造有限公司

A kind of acid heat degradation preparation method of low-viscosity octenyl succinic acid starch ester

The invention discloses an acid-heat degradation preparation method of a low-viscosity water-soluble octenyl succinic anhydride modified starch product. The method comprises the following steps: raw starch is prepared into a slurry; alkaline liquid is added; under a starch gelatinization temperature, octenyl succinic anhydride is fed, and an esterification reaction is allowed for more than 8 hours; neutralization and liquid-removal are carried out; purified water is used for washing and refining; a filter cake is prepared into a slurry with water; the pH value is regulated by using an oxalic acid solution; an acid hydrolysis reaction is carried out; a high-temperature acid-heat treatment is carried out under continuous ejection under a temperature of 125-130 DEG C by using a hydrothermal device; laminar-flow thermal insulation is carried out; cooling is carried out; a saturated calcium hydroxide solution is added, or a calcium carbonate emulsion and a sodium carbonate solution are added; the mixture is stirred such that neutralization is carried out; active carbon is added; pressure filtration is carried out; the filtrate is concentrated under vacuum; fine filtration is carried out; spray drying is carried out; and the product is cooled and packaged. With the method, the low-viscosity water-soluble octenyl succinic anhydride modified starch product is obtained. The product is suitable to be used as an emulsifier of foods and daily chemicals, or as a microencapsulation material. With the method, the low-viscosity water-soluble octenyl succinic anhydride modified starch product can be produced, and good economical benefit can be achieved.

Owner:SOUTH CHINA UNIV OF TECH

A kind of chewing gum containing gelatin-octenyl starch succinate-l-menthol microcapsules and preparation method thereof

ActiveCN106561963BProceduralExtended release timeSugar food ingredientsChewing gumBiotechnologyMenthol

The invention discloses chewing gum containing gelatin-octenyl succinic anhydride modified starch-L-menthol microcapsules. The chewing gum is prepared from the following components in parts by weight: 10-20 parts of polyvinyl acetate, 10-20 parts of high fructose syrup, 50-60 parts of sorbitol, 1-3 parts of glycerinum and 1-5 parts of the gelatin-octenyl succinic anhydride modified starch-L-menthol microcapsules. The invention further provides a method for preparing the chewing gum. The method comprises the following steps of respectively adding auxiliaries into softened the polyvinyl acetate; conducting mixing and stirring; adding the gelatin-octenyl succinic anhydride modified starch-L-menthol microcapsules into the mixture; conducting heating to 80-90 DEG C; conducting condensation and cooling; conducting extrusion in an extruding machine; and conducting cut-forming, packaging, cooling and aging to obtain a finished product. The chewing gum has long duration in the oral cavity with more cool feeling. Furthermore, the preparation method is simple, has relatively low production cost, and is suitable for industrial production.

Owner:上海松皓生物科技有限公司

Method for catalyzing and synthesizing octenyl succinic anhydride modified starch ester through yeast show lipase

InactiveCN102212583BReduce manufacturing costHigh Catalytic Synthesis Conversion EfficiencyFungiHydrolasesPichia pastorisTransformation efficiency

The invention discloses a method for catalyzing and synthesizing octenyl succinic anhydride modified starch ester through yeast show lipase, comprising the following steps of: dissolving grain starch in water; after imbibition, adding octenyl succinic anhydride and the yeast show lipase; stirring and reacting at 34-36 degrees centigrade for 1-1.5 h; and separating and purifying to obtain starch sodium ester sodium octenyl succinate. A method for preparing the yeast show lipase comprises the following steps of: transforming linearly treated recombinant plasmids into pichia pastoris GS115; inoculating the obtained transformant into a BMMY (buffered methanol-complex medium) culture medium; after inducing and culturing for 72-144 h, centrifugally collecting thallus; and washing, biologically imprinting, freezing and drying the thallus so as to obtain the yeast show lipase. By showing the lipase outside cells, the octenyl succinic anhydride modified starch ester is catalyzed and synthesized through the lipase preparation. By means of the method disclosed by the invention, the transformation efficiency is improved; furthermore, the reaction time is shortened; and the production cost is reduced.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com