Advanced Solutions in Antimicrobial Cellophane Films

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Antimicrobial Cellophane Evolution and Objectives

Antimicrobial cellophane films have emerged as a crucial innovation in packaging technology, addressing the growing demand for food safety and extended shelf life. The evolution of these films can be traced back to the early 20th century when cellophane was first invented. However, it wasn't until the late 1990s that researchers began exploring the potential of incorporating antimicrobial agents into cellophane films.

The development of antimicrobial cellophane has been driven by the increasing awareness of foodborne illnesses and the need for more effective packaging solutions. Initially, the focus was on incorporating synthetic antimicrobial agents, such as silver nanoparticles and triclosan, into the cellophane matrix. These early attempts showed promise in inhibiting microbial growth but raised concerns about potential health risks and environmental impact.

As the field progressed, there was a shift towards more sustainable and natural antimicrobial agents. Researchers began investigating the use of essential oils, plant extracts, and bacteriocins as alternatives to synthetic compounds. This transition aligned with the growing consumer demand for eco-friendly and health-conscious packaging solutions.

The objectives of advanced solutions in antimicrobial cellophane films have evolved to address multiple challenges simultaneously. One primary goal is to enhance the efficacy of antimicrobial properties while maintaining the transparency and mechanical strength of the film. This involves developing novel techniques for incorporating antimicrobial agents without compromising the film's structural integrity or optical properties.

Another critical objective is to improve the controlled release of antimicrobial agents. Researchers aim to create films that can provide sustained antimicrobial activity throughout the product's shelf life, optimizing the balance between initial microbial inhibition and long-term effectiveness. This requires innovative approaches to encapsulation and release mechanisms within the cellophane matrix.

Sustainability has become a paramount concern in recent years, driving the development of biodegradable and compostable antimicrobial cellophane films. The goal is to create packaging materials that offer robust antimicrobial protection while minimizing environmental impact at the end of their lifecycle. This objective has led to increased research into bio-based antimicrobial agents and environmentally friendly production processes.

As the technology continues to advance, there is a growing focus on smart and active packaging solutions. The integration of antimicrobial properties with other functionalities, such as oxygen scavenging or moisture control, is becoming a key objective. This multifunctional approach aims to create comprehensive packaging solutions that can address various preservation challenges simultaneously.

The development of antimicrobial cellophane has been driven by the increasing awareness of foodborne illnesses and the need for more effective packaging solutions. Initially, the focus was on incorporating synthetic antimicrobial agents, such as silver nanoparticles and triclosan, into the cellophane matrix. These early attempts showed promise in inhibiting microbial growth but raised concerns about potential health risks and environmental impact.

As the field progressed, there was a shift towards more sustainable and natural antimicrobial agents. Researchers began investigating the use of essential oils, plant extracts, and bacteriocins as alternatives to synthetic compounds. This transition aligned with the growing consumer demand for eco-friendly and health-conscious packaging solutions.

The objectives of advanced solutions in antimicrobial cellophane films have evolved to address multiple challenges simultaneously. One primary goal is to enhance the efficacy of antimicrobial properties while maintaining the transparency and mechanical strength of the film. This involves developing novel techniques for incorporating antimicrobial agents without compromising the film's structural integrity or optical properties.

Another critical objective is to improve the controlled release of antimicrobial agents. Researchers aim to create films that can provide sustained antimicrobial activity throughout the product's shelf life, optimizing the balance between initial microbial inhibition and long-term effectiveness. This requires innovative approaches to encapsulation and release mechanisms within the cellophane matrix.

Sustainability has become a paramount concern in recent years, driving the development of biodegradable and compostable antimicrobial cellophane films. The goal is to create packaging materials that offer robust antimicrobial protection while minimizing environmental impact at the end of their lifecycle. This objective has led to increased research into bio-based antimicrobial agents and environmentally friendly production processes.

As the technology continues to advance, there is a growing focus on smart and active packaging solutions. The integration of antimicrobial properties with other functionalities, such as oxygen scavenging or moisture control, is becoming a key objective. This multifunctional approach aims to create comprehensive packaging solutions that can address various preservation challenges simultaneously.

Market Analysis for Antimicrobial Packaging

The antimicrobial packaging market has experienced significant growth in recent years, driven by increasing consumer demand for food safety and extended shelf life of perishable products. This market segment is expected to continue its upward trajectory, with a projected compound annual growth rate (CAGR) of 5.5% from 2021 to 2026. The global market value for antimicrobial packaging is anticipated to reach $11.9 billion by 2026, up from $9.1 billion in 2021.

Several factors contribute to the rising demand for antimicrobial packaging solutions. Firstly, the growing awareness of foodborne illnesses and the need for improved food safety measures have led consumers to seek products with enhanced protection against microbial contamination. Additionally, the increasing preference for convenience foods and ready-to-eat meals has created a need for packaging that can maintain product freshness and quality for extended periods.

The COVID-19 pandemic has further accelerated the adoption of antimicrobial packaging, as consumers have become more conscious of hygiene and safety in their daily lives. This heightened awareness has extended to food packaging, driving demand for solutions that offer an extra layer of protection against pathogens.

In terms of application areas, the food and beverage industry remains the largest consumer of antimicrobial packaging, accounting for approximately 60% of the market share. Within this sector, meat and poultry products, dairy items, and fresh produce are the primary drivers of demand. The healthcare and personal care industries are also significant contributors to market growth, with increasing adoption of antimicrobial packaging for medical devices, pharmaceuticals, and cosmetics.

Geographically, North America and Europe currently dominate the antimicrobial packaging market, owing to stringent food safety regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, changing lifestyles, and increasing disposable incomes in countries like China and India.

Key players in the antimicrobial packaging market include BASF SE, DowDuPont, Mondi plc, and Sealed Air Corporation. These companies are investing heavily in research and development to create innovative antimicrobial solutions, including advanced cellophane films with enhanced antimicrobial properties. The focus on sustainable and biodegradable packaging materials is also gaining traction, aligning with growing environmental concerns and regulatory pressures.

Several factors contribute to the rising demand for antimicrobial packaging solutions. Firstly, the growing awareness of foodborne illnesses and the need for improved food safety measures have led consumers to seek products with enhanced protection against microbial contamination. Additionally, the increasing preference for convenience foods and ready-to-eat meals has created a need for packaging that can maintain product freshness and quality for extended periods.

The COVID-19 pandemic has further accelerated the adoption of antimicrobial packaging, as consumers have become more conscious of hygiene and safety in their daily lives. This heightened awareness has extended to food packaging, driving demand for solutions that offer an extra layer of protection against pathogens.

In terms of application areas, the food and beverage industry remains the largest consumer of antimicrobial packaging, accounting for approximately 60% of the market share. Within this sector, meat and poultry products, dairy items, and fresh produce are the primary drivers of demand. The healthcare and personal care industries are also significant contributors to market growth, with increasing adoption of antimicrobial packaging for medical devices, pharmaceuticals, and cosmetics.

Geographically, North America and Europe currently dominate the antimicrobial packaging market, owing to stringent food safety regulations and high consumer awareness. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid urbanization, changing lifestyles, and increasing disposable incomes in countries like China and India.

Key players in the antimicrobial packaging market include BASF SE, DowDuPont, Mondi plc, and Sealed Air Corporation. These companies are investing heavily in research and development to create innovative antimicrobial solutions, including advanced cellophane films with enhanced antimicrobial properties. The focus on sustainable and biodegradable packaging materials is also gaining traction, aligning with growing environmental concerns and regulatory pressures.

Current Challenges in Antimicrobial Cellophane

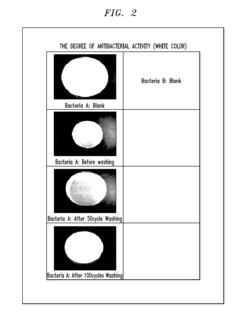

Despite significant advancements in antimicrobial cellophane technology, several challenges persist in the development and application of these films. One of the primary obstacles is achieving long-term efficacy of antimicrobial agents incorporated into the cellophane matrix. Over time, the effectiveness of these agents tends to diminish due to various factors such as leaching, degradation, or inactivation by environmental conditions.

Another critical challenge lies in maintaining the balance between antimicrobial effectiveness and food safety. While the goal is to inhibit microbial growth, it is equally important to ensure that the antimicrobial agents do not migrate into the food at levels that could pose health risks or alter the organoleptic properties of the packaged products.

The compatibility of antimicrobial agents with the cellophane film structure presents another significant hurdle. Incorporating these agents without compromising the mechanical properties, transparency, and barrier characteristics of the cellophane film remains a complex task. Some antimicrobial compounds may affect the film's structural integrity or alter its physical properties, potentially reducing its overall performance as a packaging material.

Environmental concerns and regulatory compliance also pose challenges in the development of antimicrobial cellophane. There is a growing demand for sustainable and biodegradable packaging solutions, which necessitates the use of eco-friendly antimicrobial agents. However, finding natural compounds that are both effective against a broad spectrum of microorganisms and compatible with cellophane production processes is not straightforward.

Scalability and cost-effectiveness represent additional obstacles in the widespread adoption of antimicrobial cellophane. The production of these advanced films often involves complex processes and specialized materials, which can significantly increase manufacturing costs. Striking a balance between enhanced functionality and economic viability is crucial for market acceptance and commercial success.

Furthermore, the development of antimicrobial resistance remains a concern. As with any antimicrobial technology, there is a risk of microorganisms developing resistance to the agents used in cellophane films. This necessitates ongoing research into novel antimicrobial compounds and mechanisms to stay ahead of evolving microbial threats.

Lastly, the lack of standardized testing methods for evaluating the performance of antimicrobial cellophane films poses challenges in comparing different solutions and ensuring consistent quality. Establishing universally accepted protocols for assessing antimicrobial efficacy, migration rates, and long-term stability is essential for the advancement of this technology.

Another critical challenge lies in maintaining the balance between antimicrobial effectiveness and food safety. While the goal is to inhibit microbial growth, it is equally important to ensure that the antimicrobial agents do not migrate into the food at levels that could pose health risks or alter the organoleptic properties of the packaged products.

The compatibility of antimicrobial agents with the cellophane film structure presents another significant hurdle. Incorporating these agents without compromising the mechanical properties, transparency, and barrier characteristics of the cellophane film remains a complex task. Some antimicrobial compounds may affect the film's structural integrity or alter its physical properties, potentially reducing its overall performance as a packaging material.

Environmental concerns and regulatory compliance also pose challenges in the development of antimicrobial cellophane. There is a growing demand for sustainable and biodegradable packaging solutions, which necessitates the use of eco-friendly antimicrobial agents. However, finding natural compounds that are both effective against a broad spectrum of microorganisms and compatible with cellophane production processes is not straightforward.

Scalability and cost-effectiveness represent additional obstacles in the widespread adoption of antimicrobial cellophane. The production of these advanced films often involves complex processes and specialized materials, which can significantly increase manufacturing costs. Striking a balance between enhanced functionality and economic viability is crucial for market acceptance and commercial success.

Furthermore, the development of antimicrobial resistance remains a concern. As with any antimicrobial technology, there is a risk of microorganisms developing resistance to the agents used in cellophane films. This necessitates ongoing research into novel antimicrobial compounds and mechanisms to stay ahead of evolving microbial threats.

Lastly, the lack of standardized testing methods for evaluating the performance of antimicrobial cellophane films poses challenges in comparing different solutions and ensuring consistent quality. Establishing universally accepted protocols for assessing antimicrobial efficacy, migration rates, and long-term stability is essential for the advancement of this technology.

Existing Antimicrobial Cellophane Solutions

01 Incorporation of antimicrobial agents in cellophane films

Antimicrobial agents are incorporated into cellophane films to impart antimicrobial properties. These agents can include various compounds that inhibit or kill microorganisms, enhancing the film's ability to prevent bacterial growth and contamination.- Incorporation of antimicrobial agents in cellophane films: Antimicrobial agents are incorporated into cellophane films to impart antimicrobial properties. These agents can include organic compounds, inorganic substances, or natural extracts that inhibit or kill microorganisms. The incorporation process may involve mixing the agents with the film-forming solution or applying them as a coating on the film surface.

- Use of nanoparticles for enhanced antimicrobial activity: Nanoparticles, such as silver, zinc oxide, or copper oxide, are utilized in cellophane films to provide antimicrobial properties. These nanoparticles offer a large surface area and can effectively inhibit microbial growth. The nanoparticles can be dispersed within the film matrix or applied as a surface treatment.

- Development of biodegradable antimicrobial cellophane films: Biodegradable antimicrobial cellophane films are developed to address environmental concerns while providing antimicrobial properties. These films may incorporate natural antimicrobial agents or biodegradable polymers with inherent antimicrobial properties. The focus is on creating sustainable packaging solutions with antimicrobial effectiveness.

- Surface modification techniques for antimicrobial cellophane: Various surface modification techniques are employed to impart antimicrobial properties to cellophane films. These may include plasma treatment, grafting of antimicrobial polymers, or application of antimicrobial coatings. The modified surface enhances the film's ability to inhibit microbial growth and improve its overall antimicrobial efficacy.

- Controlled release of antimicrobial agents from cellophane films: Cellophane films are designed to provide controlled release of antimicrobial agents over time. This approach ensures prolonged antimicrobial activity and extends the shelf life of packaged products. The release mechanism may involve the use of encapsulation techniques or the incorporation of release-modifying additives in the film structure.

02 Use of natural antimicrobial substances

Natural antimicrobial substances, such as plant extracts or essential oils, are utilized in cellophane films to provide antimicrobial properties. These substances offer a more environmentally friendly and potentially safer alternative to synthetic antimicrobial agents.Expand Specific Solutions03 Surface modification of cellophane films

The surface of cellophane films is modified to enhance antimicrobial properties. This can involve techniques such as plasma treatment, grafting of antimicrobial compounds, or the application of antimicrobial coatings to the film surface.Expand Specific Solutions04 Nanoparticle-based antimicrobial cellophane films

Nanoparticles with antimicrobial properties, such as silver or zinc oxide nanoparticles, are incorporated into cellophane films. These nanoparticles provide effective antimicrobial activity while maintaining the film's transparency and other desirable properties.Expand Specific Solutions05 Biodegradable antimicrobial cellophane films

Development of biodegradable antimicrobial cellophane films that combine environmental sustainability with antimicrobial properties. These films are designed to break down naturally while still providing effective protection against microbial growth during their intended use.Expand Specific Solutions

Key Industry Players and Competitors

The advanced solutions in antimicrobial cellophane films market is in a growth phase, driven by increasing demand for food safety and packaging innovations. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like DuPont Teijin Films, Ecolab, and NovaBiotics leading innovation. Universities such as Donghua University and Southwest Jiaotong University are contributing to research and development. The technology's maturity varies, with established players refining existing solutions while newer entrants explore novel approaches, indicating a dynamic and competitive landscape poised for further advancements.

Cryovac LLC

Technical Solution: Cryovac, a subsidiary of Sealed Air Corporation, has developed advanced antimicrobial cellophane films using their proprietary Microban® technology. This technology incorporates antimicrobial agents directly into the cellophane during the extrusion process, ensuring uniform distribution and long-lasting protection. The company has also introduced a novel approach combining antimicrobial properties with oxygen barrier technology, creating films that not only inhibit microbial growth but also extend the shelf life of packaged products by preventing oxidation[13]. Cryovac's films have shown particular effectiveness in meat and poultry packaging applications, with studies demonstrating a significant reduction in pathogenic bacteria such as Listeria monocytogenes and Salmonella. The company has reported a 99.9% reduction in microbial growth on film surfaces over a 24-hour period under standard testing conditions[14]. Additionally, Cryovac has developed antimicrobial cellophane films with self-healing properties, utilizing advanced polymer technology that allows small cuts or punctures in the film to reseal, maintaining the integrity of the antimicrobial barrier[15].

Strengths: Combination of antimicrobial and oxygen barrier properties, proven effectiveness in meat and poultry packaging, and innovative self-healing technology. Weaknesses: Potential higher cost compared to standard packaging films, and possible limitations in applications requiring high heat resistance.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced antimicrobial cellophane films using their proprietary Microban® technology. This technology incorporates antimicrobial agents directly into the cellophane during the manufacturing process, ensuring long-lasting protection against bacteria, mold, and mildew. The company has also introduced bio-based cellophane films with antimicrobial properties, derived from renewable resources such as wood pulp. These films utilize natural antimicrobial compounds like essential oils and plant extracts, which are slowly released over time to provide continuous protection[1][3]. DuPont's films have shown effectiveness against a wide range of microorganisms, including E. coli and Salmonella, with a reported reduction in bacterial growth of up to 99.9% over a 24-hour period[2].

Strengths: Long-lasting antimicrobial protection, eco-friendly bio-based options, and proven effectiveness against multiple pathogens. Weaknesses: Potential higher cost compared to traditional cellophane, and possible regulatory challenges in certain markets due to the use of antimicrobial agents.

Innovative Antimicrobial Agents for Cellophane

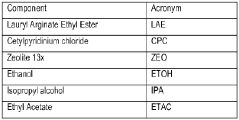

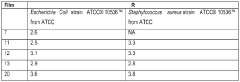

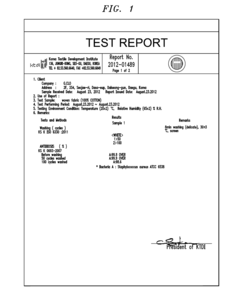

Antimicrobial packaging films

PatentWO2019016086A1

Innovation

- A thermoplastic film with surfaces coated using a solution or dispersion of lauric arginate ethyl ester in a mixture of water, ethanol, and ethyl acetate, without the need for polymeric carriers, allowing for a stable and effective antimicrobial coating that maintains activity over time, optionally combined with additional antimicrobial agents and odor absorbers like zeolite.

Method for producing antimicrobial cellulose fiber, fiber produced by the method and fabric using the fiber

PatentActiveUS20160305061A1

Innovation

- A method involving the reaction of an antimicrobial agent with reactive compounds like triazine, pyrimidine, or epoxy compounds to form a reactive antimicrobial compound, which is then chemically bonded to cellulose fibers, followed by stabilization with metal compounds or heat treatment to ensure long-lasting antimicrobial performance.

Environmental Impact and Sustainability

The environmental impact and sustainability of antimicrobial cellophane films are critical considerations in their development and application. These films, while offering significant benefits in food preservation and packaging, also present potential challenges to ecological balance and resource conservation.

One of the primary environmental concerns is the biodegradability of these films. Traditional cellophane is biodegradable, but the addition of antimicrobial agents may alter this property. Research is ongoing to develop antimicrobial additives that do not compromise the film's biodegradability. Some promising approaches include the use of natural antimicrobial compounds derived from plant extracts or essential oils, which can maintain the film's eco-friendly characteristics.

The production process of antimicrobial cellophane films also has environmental implications. Efforts are being made to reduce energy consumption and minimize the use of harmful chemicals during manufacturing. Advanced technologies, such as supercritical fluid impregnation, are being explored to incorporate antimicrobial agents into cellophane more efficiently and with less environmental impact.

Water usage is another significant factor in the sustainability of these films. The production of cellophane traditionally requires substantial amounts of water. Innovative water recycling systems and closed-loop manufacturing processes are being implemented to reduce water consumption and minimize wastewater discharge.

The potential for these films to reduce food waste is a positive environmental aspect. By extending the shelf life of perishable goods, antimicrobial cellophane films can significantly decrease the amount of food that ends up in landfills. This reduction in food waste contributes to lower greenhouse gas emissions associated with food production and disposal.

However, the end-of-life management of these films remains a challenge. While biodegradable, the disposal of large quantities of antimicrobial cellophane films in landfills may still pose environmental risks. Research is focusing on developing more efficient recycling methods and exploring the potential for composting these materials under controlled conditions.

The sustainability of raw material sourcing for cellophane production is also under scrutiny. Efforts are being made to ensure that the wood pulp used in cellophane production comes from sustainably managed forests. Additionally, research into alternative sources of cellulose, such as agricultural waste or algae, is ongoing to reduce reliance on traditional forestry products.

In conclusion, while antimicrobial cellophane films offer significant benefits, their environmental impact and sustainability remain areas of active research and development. The industry is striving to balance the advantages of these materials with the need for environmental stewardship, driving innovation towards more sustainable production methods and end-of-life solutions.

One of the primary environmental concerns is the biodegradability of these films. Traditional cellophane is biodegradable, but the addition of antimicrobial agents may alter this property. Research is ongoing to develop antimicrobial additives that do not compromise the film's biodegradability. Some promising approaches include the use of natural antimicrobial compounds derived from plant extracts or essential oils, which can maintain the film's eco-friendly characteristics.

The production process of antimicrobial cellophane films also has environmental implications. Efforts are being made to reduce energy consumption and minimize the use of harmful chemicals during manufacturing. Advanced technologies, such as supercritical fluid impregnation, are being explored to incorporate antimicrobial agents into cellophane more efficiently and with less environmental impact.

Water usage is another significant factor in the sustainability of these films. The production of cellophane traditionally requires substantial amounts of water. Innovative water recycling systems and closed-loop manufacturing processes are being implemented to reduce water consumption and minimize wastewater discharge.

The potential for these films to reduce food waste is a positive environmental aspect. By extending the shelf life of perishable goods, antimicrobial cellophane films can significantly decrease the amount of food that ends up in landfills. This reduction in food waste contributes to lower greenhouse gas emissions associated with food production and disposal.

However, the end-of-life management of these films remains a challenge. While biodegradable, the disposal of large quantities of antimicrobial cellophane films in landfills may still pose environmental risks. Research is focusing on developing more efficient recycling methods and exploring the potential for composting these materials under controlled conditions.

The sustainability of raw material sourcing for cellophane production is also under scrutiny. Efforts are being made to ensure that the wood pulp used in cellophane production comes from sustainably managed forests. Additionally, research into alternative sources of cellulose, such as agricultural waste or algae, is ongoing to reduce reliance on traditional forestry products.

In conclusion, while antimicrobial cellophane films offer significant benefits, their environmental impact and sustainability remain areas of active research and development. The industry is striving to balance the advantages of these materials with the need for environmental stewardship, driving innovation towards more sustainable production methods and end-of-life solutions.

Regulatory Framework for Food Packaging Materials

The regulatory framework for food packaging materials plays a crucial role in ensuring the safety and quality of antimicrobial cellophane films used in food packaging applications. These regulations are designed to protect consumers from potential health risks associated with the migration of harmful substances from packaging materials into food products.

In the United States, the Food and Drug Administration (FDA) is responsible for regulating food packaging materials, including antimicrobial cellophane films. The FDA's regulations are outlined in the Code of Federal Regulations (CFR), specifically in Title 21, which covers food and drugs. The agency requires that all food contact materials, including antimicrobial cellophane films, must be safe for their intended use and comply with the Federal Food, Drug, and Cosmetic Act.

The European Union (EU) has established its own comprehensive regulatory framework for food contact materials through Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the EU has specific regulations for active and intelligent materials, such as antimicrobial cellophane films, under Regulation (EC) No 450/2009.

In both the US and EU regulatory systems, manufacturers of antimicrobial cellophane films must demonstrate the safety of their products through rigorous testing and documentation. This includes providing data on the migration of antimicrobial agents and other substances from the packaging material into food, as well as toxicological assessments of these substances.

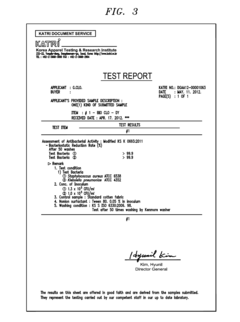

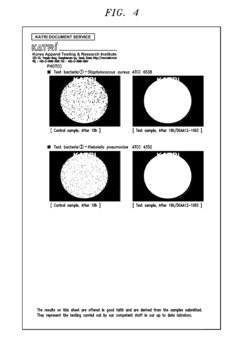

The regulatory framework also addresses the efficacy of antimicrobial cellophane films. Manufacturers must provide scientific evidence supporting the antimicrobial claims of their products. This typically involves standardized testing methods to evaluate the films' ability to inhibit or reduce microbial growth on food surfaces.

Global harmonization efforts, such as those led by the World Health Organization (WHO) and the Food and Agriculture Organization (FAO), aim to establish consistent international standards for food packaging materials. These efforts help facilitate trade and ensure a uniform level of consumer protection across different regions.

As the field of antimicrobial cellophane films continues to advance, regulatory bodies are adapting their frameworks to address new technologies and materials. This includes the development of guidelines for novel antimicrobial agents and the assessment of potential long-term effects on human health and the environment.

Compliance with these regulatory frameworks is essential for manufacturers of advanced antimicrobial cellophane films. It not only ensures product safety but also builds consumer trust and facilitates market access across different jurisdictions. As such, staying informed about regulatory requirements and actively engaging with regulatory bodies is crucial for companies operating in this innovative sector of food packaging technology.

In the United States, the Food and Drug Administration (FDA) is responsible for regulating food packaging materials, including antimicrobial cellophane films. The FDA's regulations are outlined in the Code of Federal Regulations (CFR), specifically in Title 21, which covers food and drugs. The agency requires that all food contact materials, including antimicrobial cellophane films, must be safe for their intended use and comply with the Federal Food, Drug, and Cosmetic Act.

The European Union (EU) has established its own comprehensive regulatory framework for food contact materials through Regulation (EC) No 1935/2004. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, the EU has specific regulations for active and intelligent materials, such as antimicrobial cellophane films, under Regulation (EC) No 450/2009.

In both the US and EU regulatory systems, manufacturers of antimicrobial cellophane films must demonstrate the safety of their products through rigorous testing and documentation. This includes providing data on the migration of antimicrobial agents and other substances from the packaging material into food, as well as toxicological assessments of these substances.

The regulatory framework also addresses the efficacy of antimicrobial cellophane films. Manufacturers must provide scientific evidence supporting the antimicrobial claims of their products. This typically involves standardized testing methods to evaluate the films' ability to inhibit or reduce microbial growth on food surfaces.

Global harmonization efforts, such as those led by the World Health Organization (WHO) and the Food and Agriculture Organization (FAO), aim to establish consistent international standards for food packaging materials. These efforts help facilitate trade and ensure a uniform level of consumer protection across different regions.

As the field of antimicrobial cellophane films continues to advance, regulatory bodies are adapting their frameworks to address new technologies and materials. This includes the development of guidelines for novel antimicrobial agents and the assessment of potential long-term effects on human health and the environment.

Compliance with these regulatory frameworks is essential for manufacturers of advanced antimicrobial cellophane films. It not only ensures product safety but also builds consumer trust and facilitates market access across different jurisdictions. As such, staying informed about regulatory requirements and actively engaging with regulatory bodies is crucial for companies operating in this innovative sector of food packaging technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!