Benefits of HDPE in Food Packaging Safety

HDPE Food Packaging Evolution

The evolution of High-Density Polyethylene (HDPE) in food packaging represents a significant advancement in ensuring food safety and quality. Initially introduced in the 1950s, HDPE quickly gained prominence in the packaging industry due to its superior properties and versatility.

In the early stages, HDPE was primarily used for simple containers and bottles. However, as manufacturing techniques improved, its applications in food packaging expanded rapidly. The 1960s and 1970s saw the development of more sophisticated HDPE packaging solutions, including multi-layer structures that enhanced barrier properties and extended shelf life.

The 1980s marked a turning point in HDPE food packaging with the introduction of advanced extrusion and molding technologies. These innovations allowed for the production of thinner, yet stronger packaging materials, reducing material usage while maintaining or even improving performance. This period also saw the emergence of HDPE as a preferred material for milk bottles, replacing glass in many markets.

Throughout the 1990s and early 2000s, the focus shifted towards enhancing the sustainability of HDPE packaging. Manufacturers began incorporating recycled HDPE into new packaging, creating a more circular economy for plastic materials. Simultaneously, advancements in polymer science led to the development of HDPE grades with improved clarity and barrier properties, further expanding its use in transparent food packaging applications.

The late 2000s and 2010s witnessed a surge in research on HDPE's safety profile, particularly concerning its interaction with food. Studies consistently demonstrated HDPE's low migration potential and inertness, reinforcing its position as a safe material for food contact. This period also saw the development of antimicrobial HDPE formulations, offering additional protection against foodborne pathogens.

Recent years have seen a focus on enhancing HDPE's environmental profile. Innovations in bio-based HDPE, derived from renewable resources such as sugarcane, have emerged as a promising alternative to traditional petroleum-based HDPE. These developments aim to address growing consumer concerns about plastic's environmental impact while maintaining the material's excellent food safety properties.

The evolution of HDPE in food packaging continues to be driven by demands for improved safety, sustainability, and functionality. Ongoing research focuses on developing HDPE with enhanced barrier properties, improved recyclability, and reduced environmental footprint. As regulatory standards for food packaging become increasingly stringent, HDPE's evolution ensures its continued relevance in safeguarding food quality and safety.

Market Demand Analysis

The market demand for HDPE in food packaging safety has been steadily increasing due to its superior properties and growing consumer awareness of food safety issues. HDPE, or High-Density Polyethylene, offers excellent barrier properties against moisture, chemicals, and gases, making it an ideal choice for preserving food quality and extending shelf life.

In recent years, the global food packaging market has experienced significant growth, driven by changing consumer lifestyles, urbanization, and the rise of e-commerce in the food sector. The HDPE segment within this market has shown particularly strong performance, with a compound annual growth rate (CAGR) exceeding that of the overall packaging industry.

Consumer preferences have shifted towards safer, more sustainable packaging options, with HDPE meeting many of these requirements. Its ability to withstand high temperatures during sterilization processes and resist chemical interactions with food contents has made it a preferred choice for manufacturers and consumers alike. This trend is especially pronounced in developed markets where food safety regulations are stringent.

The COVID-19 pandemic has further accelerated the demand for safe food packaging solutions. Consumers have become more health-conscious and are seeking products that offer enhanced protection against contamination. HDPE's ability to maintain food freshness and prevent bacterial growth aligns well with these evolving consumer priorities.

In the beverage industry, HDPE bottles have gained significant market share, particularly in milk packaging. The material's opacity protects milk from light exposure, preserving its nutritional value and taste. This application alone represents a substantial portion of the HDPE food packaging market.

Emerging economies are presenting new growth opportunities for HDPE food packaging. As these markets develop and adopt more sophisticated food safety standards, the demand for high-quality packaging materials like HDPE is expected to surge. This is particularly evident in countries with rapidly expanding middle-class populations and increasing disposable incomes.

Environmental concerns have also influenced market dynamics. While plastic waste remains a global issue, HDPE's recyclability gives it an advantage over some other packaging materials. Many companies are investing in recycling technologies and circular economy initiatives, which could further boost the appeal of HDPE in food packaging applications.

The market for HDPE in food packaging is not without challenges. Competition from alternative materials, such as PET and biodegradable plastics, poses a threat to market growth. However, ongoing innovations in HDPE formulations and manufacturing processes are helping to maintain its competitive edge in terms of cost-effectiveness and performance.

HDPE Technical Challenges

While High-Density Polyethylene (HDPE) has proven to be a valuable material in food packaging, it still faces several technical challenges that need to be addressed to enhance its performance and sustainability. One of the primary concerns is the potential migration of chemical compounds from HDPE packaging into food products. Although HDPE is generally considered safe, there is ongoing research to minimize any potential leaching of additives or degradation products, especially under high-temperature conditions or prolonged storage periods.

Another significant challenge lies in improving the barrier properties of HDPE. While it provides excellent moisture resistance, its gas barrier properties, particularly against oxygen and carbon dioxide, are not as effective as some other packaging materials. This limitation can affect the shelf life of certain food products, especially those sensitive to oxidation. Researchers are exploring various methods to enhance these barrier properties, such as incorporating nanocomposites or developing multi-layer structures.

The recyclability of HDPE food packaging also presents technical hurdles. While HDPE is recyclable, the presence of food residues, labels, and other contaminants can complicate the recycling process. Developing more efficient cleaning and sorting technologies for recycled HDPE, as well as improving the quality of recycled HDPE for food-contact applications, remains an ongoing challenge for the industry.

Furthermore, there is a growing demand for bio-based and biodegradable alternatives to traditional HDPE. Creating bio-based HDPE with properties comparable to petroleum-based HDPE, while ensuring cost-effectiveness and scalability, is a significant technical challenge. Similarly, developing HDPE that can biodegrade under specific conditions without compromising its performance during use is an area of active research.

The optimization of HDPE's mechanical properties for specific food packaging applications also presents ongoing challenges. Balancing factors such as strength, flexibility, and impact resistance while maintaining the material's lightweight nature requires continuous innovation in polymer science and processing technologies.

Lastly, the industry faces the challenge of reducing the environmental footprint of HDPE production and processing. This includes developing more energy-efficient manufacturing processes, reducing waste during production, and exploring alternative feedstocks that can lower the carbon footprint of HDPE without compromising its performance in food packaging applications.

Current HDPE Solutions

01 Chemical resistance and safety of HDPE

High-Density Polyethylene (HDPE) exhibits excellent chemical resistance, making it safe for use in various applications. Its inert nature prevents chemical reactions with most substances, ensuring the safety of stored contents and reducing the risk of contamination. This property makes HDPE suitable for packaging hazardous materials and chemicals.- Chemical resistance and safety of HDPE: High-Density Polyethylene (HDPE) exhibits excellent chemical resistance, making it safe for use in various applications. It is resistant to many solvents, acids, and bases, which contributes to its safety profile in chemical storage and handling. This property also makes HDPE suitable for use in food packaging and medical devices, as it does not leach harmful chemicals into the contents.

- Thermal stability and fire safety of HDPE: HDPE demonstrates good thermal stability, maintaining its structural integrity over a wide range of temperatures. While it is combustible, it can be formulated with flame retardants to improve its fire safety characteristics. This makes it suitable for use in construction materials and electrical applications where fire resistance is important.

- Environmental safety and recyclability of HDPE: HDPE is considered environmentally safe due to its recyclability and non-toxicity. It does not release harmful substances into the environment during normal use or disposal. HDPE can be recycled multiple times without significant loss of properties, contributing to its sustainability and reducing environmental impact.

- Mechanical properties and safety in structural applications: The high strength-to-density ratio of HDPE contributes to its safety in structural applications. It has good impact resistance and durability, making it suitable for use in protective equipment, containers, and construction materials. These properties help prevent breakage and potential hazards associated with material failure.

- Food contact safety and medical applications of HDPE: HDPE is widely used in food packaging and medical applications due to its safety profile. It is inert, does not support bacterial growth, and does not interact with most substances it comes into contact with. This makes it safe for storing food, pharmaceuticals, and for use in medical devices, where maintaining product integrity and preventing contamination are crucial.

02 HDPE in food packaging and safety

HDPE is widely used in food packaging due to its safety profile. It does not leach harmful chemicals into food or beverages, maintaining the quality and safety of the contents. The material's durability and resistance to moisture make it ideal for preserving food freshness and preventing contamination, contributing to food safety standards.Expand Specific Solutions03 Environmental safety and recyclability of HDPE

HDPE is considered environmentally safe due to its recyclability. It can be recycled multiple times without significant degradation in quality, reducing waste and environmental impact. The recycling process of HDPE is energy-efficient and produces minimal emissions, contributing to its overall environmental safety profile.Expand Specific Solutions04 HDPE in medical and pharmaceutical applications

HDPE's safety properties make it suitable for medical and pharmaceutical applications. Its resistance to bacteria and chemicals, coupled with its ability to maintain the purity of contents, makes it ideal for medical packaging, drug containers, and prosthetics. The material's biocompatibility ensures it can be safely used in contact with the human body.Expand Specific Solutions05 Safety improvements in HDPE manufacturing

Advancements in HDPE manufacturing processes have led to improved safety features. These include the development of additives that enhance UV resistance, flame retardancy, and antistatic properties. Such improvements increase the safety of HDPE products in various applications, from construction materials to consumer goods, ensuring better protection against environmental factors and potential hazards.Expand Specific Solutions

Key HDPE Manufacturers

The market for HDPE in food packaging safety is in a mature growth stage, with a significant global market size driven by increasing demand for safe and durable packaging solutions. The technology has reached a high level of maturity, with key players like Dow Global Technologies, LG Chem, and DuPont de Nemours leading innovation. Companies such as Equistar Chemicals, Borealis AG, and Chevron Phillips Chemical are also making substantial contributions to the field. The competitive landscape is characterized by ongoing research and development efforts focused on enhancing HDPE properties, improving sustainability, and expanding applications in the food packaging industry. This has led to a diverse range of HDPE products tailored for specific food packaging needs, with companies like Graham Packaging and Sonoco Development specializing in innovative packaging solutions.

Dow Global Technologies LLC

LG Chem Ltd.

HDPE Safety Innovations

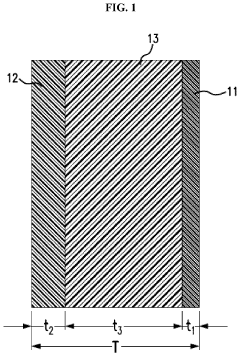

- A molded multilayer polymer structure comprising a body wall with a first layer of copolymer HDPE, a second layer of homopolymer HDPE, and a third layer that combines both, with a total weight content of homopolymer HDPE at least 30 wt-%, including regrind and post-consumer resin, to achieve improved mechanical and ESCR properties without costly processes.

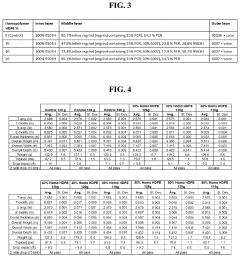

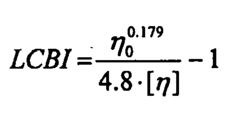

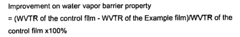

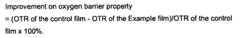

- Incorporating a nucleating agent into substantially linear HDPE with a long chain branching index (LCBI) less than or equal to 0.5 and a melt flow ratio (MFR) less than or equal to 65 to produce a film with enhanced water vapor and oxygen barrier properties, specifically achieving at least a 15% improvement.

Regulatory Compliance

Regulatory compliance is a critical aspect of HDPE food packaging safety, ensuring that manufacturers adhere to stringent standards set by various governing bodies. In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating food contact materials, including HDPE. The FDA's Code of Federal Regulations Title 21, specifically Part 177, outlines the requirements for polymers used in food packaging. HDPE must meet these regulations to be considered safe for food contact applications.

The European Union has established its own set of regulations through the European Food Safety Authority (EFSA). The EU Regulation No. 10/2011 on plastic materials and articles intended to come into contact with food provides comprehensive guidelines for HDPE and other polymers. This regulation includes specific migration limits for various substances and overall migration limits to ensure the safety of food packaging materials.

Global harmonization efforts, such as those led by the World Health Organization (WHO) and the Food and Agriculture Organization (FAO), have resulted in the development of international standards for food packaging materials. The Codex Alimentarius Commission, a joint WHO/FAO initiative, has established guidelines that many countries use as a basis for their national regulations.

Compliance with these regulations often requires extensive testing and documentation. Manufacturers must conduct migration studies to demonstrate that HDPE packaging does not transfer harmful substances to food at levels exceeding regulatory limits. These tests typically involve simulating various food types and storage conditions to assess the potential for chemical migration over the product's intended shelf life.

Third-party certification programs, such as those offered by NSF International and Intertek, provide additional assurance of regulatory compliance. These programs often involve rigorous testing and auditing processes, resulting in certifications that can enhance consumer confidence and facilitate market access for HDPE food packaging products.

Regulatory bodies also focus on the recyclability and environmental impact of HDPE packaging. Many jurisdictions have implemented regulations aimed at promoting the use of recyclable materials and reducing plastic waste. Manufacturers must consider these environmental regulations alongside food safety requirements when developing HDPE packaging solutions.

As scientific understanding of food safety evolves, regulatory frameworks continue to adapt. Ongoing research into potential endocrine disruptors and nanomaterials has led to increased scrutiny of plastic packaging materials. Manufacturers must stay informed about emerging regulations and scientific findings to ensure continued compliance and maintain consumer trust in the safety of HDPE food packaging.

Environmental Impact

The environmental impact of HDPE (High-Density Polyethylene) in food packaging is a complex issue that requires careful consideration. While HDPE offers significant benefits in terms of food safety and preservation, its environmental footprint has been a subject of concern and ongoing research.

HDPE is widely used in food packaging due to its durability, chemical resistance, and ability to maintain food quality. However, the production and disposal of HDPE packaging contribute to environmental challenges. The manufacturing process of HDPE relies heavily on fossil fuels, leading to greenhouse gas emissions and energy consumption. This aspect of HDPE production aligns with broader concerns about the petrochemical industry's environmental impact.

Despite these production-related concerns, HDPE's durability presents both advantages and disadvantages from an environmental perspective. Its long-lasting nature means that HDPE packaging can be reused multiple times, potentially reducing the overall demand for new plastic production. However, this same durability becomes problematic when HDPE products are improperly disposed of, as they can persist in the environment for hundreds of years.

Recycling offers a partial solution to the environmental challenges posed by HDPE. The material is highly recyclable, and many recycling programs accept HDPE products. When properly recycled, HDPE can be repurposed into new products, reducing the need for virgin plastic production and minimizing waste. However, the effectiveness of recycling programs varies globally, and a significant portion of HDPE still ends up in landfills or the natural environment.

In recent years, there has been increased focus on developing more environmentally friendly alternatives to traditional HDPE. Bio-based HDPE, derived from renewable resources such as sugarcane, offers a promising direction. These alternatives aim to reduce reliance on fossil fuels and decrease the carbon footprint associated with HDPE production. However, the scalability and cost-effectiveness of these solutions remain challenges to widespread adoption.

The marine impact of HDPE packaging is another critical environmental concern. When improperly disposed of, HDPE products can find their way into oceans and waterways, contributing to plastic pollution. While HDPE does not break down into microplastics as readily as some other plastics, its presence in marine environments can still harm wildlife and ecosystems.

Efforts to mitigate the environmental impact of HDPE in food packaging are ongoing. These include improving recycling infrastructure, developing more efficient production processes, and exploring biodegradable additives that could accelerate HDPE breakdown in natural environments. Additionally, there is a growing emphasis on circular economy principles, aiming to create closed-loop systems where HDPE packaging is consistently reused or recycled, minimizing waste and environmental impact.