Breakthrough Innovations in Heat-Resistant Cellophane

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Heat-Resistant Cellophane Evolution and Objectives

Heat-resistant cellophane has undergone significant evolution since its inception in the early 20th century. Initially developed as a transparent packaging material, cellophane's heat resistance properties have been continuously improved to meet the growing demands of various industries. The journey began with the basic cellulose-based film, which had limited heat resistance capabilities.

As the need for more durable packaging solutions grew, researchers focused on enhancing cellophane's thermal stability. This led to the development of coatings and treatments that could withstand higher temperatures without compromising the material's transparency or flexibility. The 1960s and 1970s saw major breakthroughs in heat-resistant cellophane technology, with the introduction of new polymer blends and manufacturing processes.

The evolution of heat-resistant cellophane has been driven by several factors, including the food packaging industry's requirements for materials that can withstand microwave heating and hot-filling processes. Additionally, the electronics and automotive sectors have pushed for cellophane variants capable of enduring high-temperature applications in their manufacturing processes.

Recent advancements in nanotechnology and material science have opened up new possibilities for further improving the heat resistance of cellophane. Researchers are exploring the integration of nanoparticles and novel polymer structures to create cellophane films with unprecedented thermal stability and mechanical properties.

The primary objectives in the development of heat-resistant cellophane are multifaceted. Firstly, there is a continuous effort to increase the maximum temperature that cellophane can withstand without degradation or loss of its desirable properties. This includes maintaining transparency, flexibility, and barrier properties at elevated temperatures.

Secondly, researchers aim to expand the range of applications for heat-resistant cellophane by tailoring its properties to specific industry needs. This involves developing variants that can resist not only high temperatures but also chemical exposure and mechanical stress under thermal conditions.

Another crucial objective is to improve the sustainability of heat-resistant cellophane production. This includes developing bio-based alternatives and enhancing the recyclability of the material without compromising its heat-resistant qualities. The goal is to align the production and use of heat-resistant cellophane with global sustainability initiatives and circular economy principles.

Lastly, there is a focus on cost-effective manufacturing processes that can produce heat-resistant cellophane at scale. This objective is critical for widespread adoption across various industries and applications, ensuring that the advanced material remains economically viable for both producers and consumers.

As the need for more durable packaging solutions grew, researchers focused on enhancing cellophane's thermal stability. This led to the development of coatings and treatments that could withstand higher temperatures without compromising the material's transparency or flexibility. The 1960s and 1970s saw major breakthroughs in heat-resistant cellophane technology, with the introduction of new polymer blends and manufacturing processes.

The evolution of heat-resistant cellophane has been driven by several factors, including the food packaging industry's requirements for materials that can withstand microwave heating and hot-filling processes. Additionally, the electronics and automotive sectors have pushed for cellophane variants capable of enduring high-temperature applications in their manufacturing processes.

Recent advancements in nanotechnology and material science have opened up new possibilities for further improving the heat resistance of cellophane. Researchers are exploring the integration of nanoparticles and novel polymer structures to create cellophane films with unprecedented thermal stability and mechanical properties.

The primary objectives in the development of heat-resistant cellophane are multifaceted. Firstly, there is a continuous effort to increase the maximum temperature that cellophane can withstand without degradation or loss of its desirable properties. This includes maintaining transparency, flexibility, and barrier properties at elevated temperatures.

Secondly, researchers aim to expand the range of applications for heat-resistant cellophane by tailoring its properties to specific industry needs. This involves developing variants that can resist not only high temperatures but also chemical exposure and mechanical stress under thermal conditions.

Another crucial objective is to improve the sustainability of heat-resistant cellophane production. This includes developing bio-based alternatives and enhancing the recyclability of the material without compromising its heat-resistant qualities. The goal is to align the production and use of heat-resistant cellophane with global sustainability initiatives and circular economy principles.

Lastly, there is a focus on cost-effective manufacturing processes that can produce heat-resistant cellophane at scale. This objective is critical for widespread adoption across various industries and applications, ensuring that the advanced material remains economically viable for both producers and consumers.

Market Analysis for Advanced Packaging Materials

The global market for advanced packaging materials has been experiencing significant growth, driven by increasing demand for sustainable and high-performance packaging solutions across various industries. Heat-resistant cellophane, as a breakthrough innovation in this sector, is poised to capture a substantial share of this expanding market.

The packaging industry has been evolving rapidly to meet the changing needs of consumers and businesses alike. With a growing emphasis on environmental sustainability, food safety, and extended shelf life, there is a rising demand for advanced packaging materials that can withstand high temperatures while maintaining product integrity. Heat-resistant cellophane addresses these market requirements, offering a unique combination of thermal stability, transparency, and biodegradability.

Market research indicates that the global advanced packaging materials market is expected to grow at a compound annual growth rate (CAGR) of over 10% in the next five years. This growth is primarily attributed to the increasing adoption of innovative packaging solutions in the food and beverage, pharmaceutical, and electronics industries. Heat-resistant cellophane, with its enhanced thermal properties, is well-positioned to capitalize on this trend.

The food packaging segment, in particular, presents a significant opportunity for heat-resistant cellophane. As consumers increasingly opt for convenience foods and ready-to-eat meals, there is a growing need for packaging materials that can withstand microwave heating and hot-fill processes. Heat-resistant cellophane offers a viable solution to this challenge, potentially revolutionizing the packaging of heat-sensitive products.

In the pharmaceutical industry, the demand for heat-resistant packaging materials is driven by the need to protect temperature-sensitive drugs and medical devices during sterilization processes. Heat-resistant cellophane's ability to maintain its structural integrity at high temperatures makes it an attractive option for pharmaceutical packaging applications.

The electronics industry is another key market for heat-resistant cellophane. With the increasing miniaturization of electronic components and the rise of flexible electronics, there is a growing demand for packaging materials that can withstand high temperatures during manufacturing and operation. Heat-resistant cellophane's thermal stability and flexibility make it a promising candidate for various electronic packaging applications.

Geographically, Asia-Pacific is expected to be the fastest-growing market for advanced packaging materials, including heat-resistant cellophane. This growth is driven by rapid industrialization, increasing disposable incomes, and changing consumer preferences in countries like China and India. North America and Europe are also significant markets, with a strong focus on sustainable packaging solutions and stringent regulations driving the adoption of innovative materials.

The packaging industry has been evolving rapidly to meet the changing needs of consumers and businesses alike. With a growing emphasis on environmental sustainability, food safety, and extended shelf life, there is a rising demand for advanced packaging materials that can withstand high temperatures while maintaining product integrity. Heat-resistant cellophane addresses these market requirements, offering a unique combination of thermal stability, transparency, and biodegradability.

Market research indicates that the global advanced packaging materials market is expected to grow at a compound annual growth rate (CAGR) of over 10% in the next five years. This growth is primarily attributed to the increasing adoption of innovative packaging solutions in the food and beverage, pharmaceutical, and electronics industries. Heat-resistant cellophane, with its enhanced thermal properties, is well-positioned to capitalize on this trend.

The food packaging segment, in particular, presents a significant opportunity for heat-resistant cellophane. As consumers increasingly opt for convenience foods and ready-to-eat meals, there is a growing need for packaging materials that can withstand microwave heating and hot-fill processes. Heat-resistant cellophane offers a viable solution to this challenge, potentially revolutionizing the packaging of heat-sensitive products.

In the pharmaceutical industry, the demand for heat-resistant packaging materials is driven by the need to protect temperature-sensitive drugs and medical devices during sterilization processes. Heat-resistant cellophane's ability to maintain its structural integrity at high temperatures makes it an attractive option for pharmaceutical packaging applications.

The electronics industry is another key market for heat-resistant cellophane. With the increasing miniaturization of electronic components and the rise of flexible electronics, there is a growing demand for packaging materials that can withstand high temperatures during manufacturing and operation. Heat-resistant cellophane's thermal stability and flexibility make it a promising candidate for various electronic packaging applications.

Geographically, Asia-Pacific is expected to be the fastest-growing market for advanced packaging materials, including heat-resistant cellophane. This growth is driven by rapid industrialization, increasing disposable incomes, and changing consumer preferences in countries like China and India. North America and Europe are also significant markets, with a strong focus on sustainable packaging solutions and stringent regulations driving the adoption of innovative materials.

Current Challenges in Heat-Resistant Cellophane Production

The production of heat-resistant cellophane faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the difficulty in maintaining the transparency and clarity of cellophane while enhancing its heat resistance properties. Traditional methods of improving heat resistance often result in a compromise on the material's optical qualities, which are crucial for many applications.

Another major challenge lies in the development of cost-effective production processes. Current techniques for manufacturing heat-resistant cellophane often involve complex chemical treatments or the incorporation of expensive additives, leading to higher production costs. This economic barrier limits the material's competitiveness in the market, especially when compared to alternative packaging solutions.

The environmental impact of heat-resistant cellophane production is also a growing concern. Many of the chemicals used in the manufacturing process can be harmful to the environment, and the disposal of these materials presents additional challenges. Developing eco-friendly production methods and ensuring the biodegradability of the final product are critical issues that need to be addressed.

Scalability remains a significant hurdle in the industry. While laboratory-scale production of heat-resistant cellophane has shown promising results, translating these processes to large-scale industrial production presents numerous technical and logistical challenges. Maintaining consistent quality and properties across large batches is particularly difficult.

The limited temperature range of current heat-resistant cellophane is another area requiring improvement. While existing products can withstand higher temperatures than standard cellophane, they still fall short of the heat resistance needed for certain high-temperature applications, such as microwave cooking or industrial processes.

Achieving a balance between heat resistance and other desirable properties, such as flexibility, strength, and barrier properties, poses a complex challenge. Enhancing heat resistance often comes at the cost of reduced flexibility or decreased barrier properties against moisture and gases, which are critical for many packaging applications.

Lastly, regulatory compliance and safety standards present ongoing challenges. As new additives and production processes are developed to enhance heat resistance, they must undergo rigorous testing and approval processes to ensure they meet food safety and environmental regulations. This can be a time-consuming and costly process, potentially slowing down innovation in the field.

Another major challenge lies in the development of cost-effective production processes. Current techniques for manufacturing heat-resistant cellophane often involve complex chemical treatments or the incorporation of expensive additives, leading to higher production costs. This economic barrier limits the material's competitiveness in the market, especially when compared to alternative packaging solutions.

The environmental impact of heat-resistant cellophane production is also a growing concern. Many of the chemicals used in the manufacturing process can be harmful to the environment, and the disposal of these materials presents additional challenges. Developing eco-friendly production methods and ensuring the biodegradability of the final product are critical issues that need to be addressed.

Scalability remains a significant hurdle in the industry. While laboratory-scale production of heat-resistant cellophane has shown promising results, translating these processes to large-scale industrial production presents numerous technical and logistical challenges. Maintaining consistent quality and properties across large batches is particularly difficult.

The limited temperature range of current heat-resistant cellophane is another area requiring improvement. While existing products can withstand higher temperatures than standard cellophane, they still fall short of the heat resistance needed for certain high-temperature applications, such as microwave cooking or industrial processes.

Achieving a balance between heat resistance and other desirable properties, such as flexibility, strength, and barrier properties, poses a complex challenge. Enhancing heat resistance often comes at the cost of reduced flexibility or decreased barrier properties against moisture and gases, which are critical for many packaging applications.

Lastly, regulatory compliance and safety standards present ongoing challenges. As new additives and production processes are developed to enhance heat resistance, they must undergo rigorous testing and approval processes to ensure they meet food safety and environmental regulations. This can be a time-consuming and costly process, potentially slowing down innovation in the field.

Existing Heat-Resistant Cellophane Solutions

01 Heat-resistant cellophane composition

Development of cellophane compositions with improved heat resistance through the incorporation of specific additives or modifications to the cellulose structure. These compositions can withstand higher temperatures without degradation or loss of mechanical properties.- Heat-resistant cellophane composition: Development of cellophane compositions with improved heat resistance through the incorporation of specific additives or modifications to the cellulose structure. These compositions can withstand higher temperatures without degradation or loss of mechanical properties.

- Coating techniques for enhancing heat resistance: Application of heat-resistant coatings or treatments to cellophane surfaces to improve their thermal stability. These coatings can include inorganic materials or specialized polymers that provide a protective barrier against high temperatures.

- Heat-resistant cellophane packaging solutions: Development of packaging solutions using heat-resistant cellophane for applications requiring exposure to elevated temperatures. These solutions may include multi-layer structures or specialized sealing techniques to maintain package integrity under thermal stress.

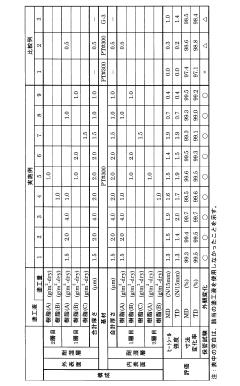

- Manufacturing processes for heat-resistant cellophane: Innovative manufacturing techniques and process modifications to produce cellophane with enhanced heat resistance. These may include adjustments to the cellulose regeneration process, incorporation of cross-linking agents, or post-treatment methods to improve thermal stability.

- Testing and characterization of heat-resistant cellophane: Development of methods and equipment for testing and characterizing the heat resistance of cellophane materials. These techniques may include thermal analysis, mechanical property measurements at elevated temperatures, and accelerated aging tests to evaluate long-term performance.

02 Coating techniques for enhancing heat resistance

Application of heat-resistant coatings or treatments to cellophane surfaces to improve their thermal stability. These coatings can include inorganic materials, polymers, or specialized compounds that form a protective layer against heat.Expand Specific Solutions03 Multi-layer cellophane structures for heat resistance

Creation of multi-layer cellophane structures that combine different materials to enhance overall heat resistance. These structures may include layers of heat-resistant polymers or inorganic materials sandwiched between cellophane layers.Expand Specific Solutions04 Chemical modification of cellophane for heat stability

Chemical treatments or modifications of cellophane to improve its heat resistance properties. This can involve cross-linking, grafting, or introducing heat-stable functional groups to the cellulose structure.Expand Specific Solutions05 Heat-resistant cellophane packaging solutions

Development of specialized cellophane-based packaging solutions designed for high-temperature applications. These packaging materials maintain their integrity and barrier properties when exposed to heat during processing or use.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The heat-resistant cellophane market is in a growth phase, driven by increasing demand for sustainable packaging solutions across various industries. The global market size is projected to expand significantly in the coming years, fueled by innovations in material science and manufacturing processes. Technologically, the field is advancing rapidly, with companies like Toray Industries, Asahi Kasei, and Dai Nippon Printing leading research efforts. These firms are developing novel formulations and production techniques to enhance cellophane's heat resistance and overall performance. Emerging players such as Unifrax and NICHIAS are also contributing to the technological progress, focusing on specialized applications in high-temperature environments.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a breakthrough heat-resistant cellophane using advanced polymer technology. Their approach involves incorporating nano-scale ceramic particles into the cellophane matrix, significantly enhancing its thermal stability[1]. The company has also implemented a proprietary cross-linking process that creates stronger bonds between polymer chains, further improving heat resistance[3]. Additionally, Toray has developed a multi-layer structure for their cellophane, with each layer optimized for different properties such as heat resistance, barrier properties, and mechanical strength[5]. This innovative approach allows for a cellophane product that can withstand temperatures up to 200°C while maintaining flexibility and transparency[7].

Strengths: Superior heat resistance, maintained flexibility, and transparency. Multi-functional properties due to layered structure. Weaknesses: Potentially higher production costs, may require specialized equipment for manufacturing.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has made significant strides in heat-resistant cellophane technology through their proprietary "Thermylon" process. This innovative method involves the controlled partial dehydration of cellulose molecules, resulting in a more thermally stable structure[2]. The company has also developed a unique coating technology that applies a thin, heat-resistant layer to conventional cellophane, enhancing its thermal properties without significantly altering its other characteristics[4]. Furthermore, Asahi Kasei has incorporated flame-retardant additives into their cellophane formulation, creating a product that not only resists high temperatures but also provides improved fire safety[6]. Their latest research focuses on bio-based additives to enhance heat resistance while maintaining the biodegradability of the cellophane[8].

Strengths: Improved thermal stability without sacrificing traditional cellophane properties, enhanced fire safety, potential for biodegradable solutions. Weaknesses: The coating process may add complexity to manufacturing, potential for reduced clarity due to additives.

Core Innovations in Thermal Stability Enhancement

Cellophane laminate

PatentPendingJP2024001514A

Innovation

- A cellophane laminate with moisture-resistant layers of specific thickness and composition, made from olefin, aliphatic, or alicyclic hydrocarbon resins, applied directly to both surfaces without an anchor coat or adhesive, providing heat-sealability and moisture resistance.

Microporous membranes, methods for making such membranes, and the use of such membranes as battery separator film

PatentWO2010147801A2

Innovation

- A microporous membrane comprising a polymer mixture of polymethylpentene, first polyethylene with specific molecular weight and terminal unsaturation, and second polyethylene, which is extruded, stretched, and then treated to achieve a meltdown temperature above 180°C, a shutdown temperature below 131°C, and minimal heat shrinkage of less than 30% at 170°C, maintaining high permeability and strength.

Environmental Impact and Sustainability Considerations

The development of heat-resistant cellophane presents both challenges and opportunities in terms of environmental impact and sustainability. As the demand for advanced packaging materials grows, it is crucial to consider the ecological footprint of these innovations throughout their lifecycle.

Heat-resistant cellophane production typically involves energy-intensive processes and the use of chemical additives to enhance thermal stability. This raises concerns about increased carbon emissions and potential environmental contamination. However, recent breakthroughs in manufacturing techniques have shown promise in reducing energy consumption and minimizing the use of harmful substances.

One significant environmental benefit of heat-resistant cellophane is its potential to extend the shelf life of perishable goods. By providing superior protection against temperature fluctuations, this material can help reduce food waste, a major contributor to greenhouse gas emissions. Additionally, the improved durability of heat-resistant cellophane may lead to a decrease in overall packaging material consumption.

Recyclability remains a key consideration in the development of heat-resistant cellophane. While traditional cellophane is biodegradable, the addition of heat-resistant properties may affect its decomposition rate. Researchers are exploring bio-based alternatives and composite materials that maintain heat resistance while preserving biodegradability.

The sustainability of heat-resistant cellophane also depends on its sourcing and production methods. Efforts are underway to develop cellulose-based materials derived from sustainable forestry practices or agricultural waste, reducing reliance on petroleum-based resources. These initiatives align with circular economy principles and contribute to a more sustainable packaging industry.

Water usage in the production of heat-resistant cellophane is another critical environmental factor. Innovations in water recycling systems and dry manufacturing processes are being implemented to minimize water consumption and reduce the environmental impact of production facilities.

As regulations on single-use plastics become more stringent globally, heat-resistant cellophane may offer a viable alternative in certain applications. However, its widespread adoption must be balanced with comprehensive life cycle assessments to ensure that the environmental benefits outweigh the potential drawbacks.

In conclusion, while heat-resistant cellophane presents promising solutions for packaging challenges, its environmental impact and sustainability considerations are complex and multifaceted. Ongoing research and development efforts must prioritize eco-friendly production methods, recyclability, and responsible sourcing to ensure that these innovations contribute positively to global sustainability goals.

Heat-resistant cellophane production typically involves energy-intensive processes and the use of chemical additives to enhance thermal stability. This raises concerns about increased carbon emissions and potential environmental contamination. However, recent breakthroughs in manufacturing techniques have shown promise in reducing energy consumption and minimizing the use of harmful substances.

One significant environmental benefit of heat-resistant cellophane is its potential to extend the shelf life of perishable goods. By providing superior protection against temperature fluctuations, this material can help reduce food waste, a major contributor to greenhouse gas emissions. Additionally, the improved durability of heat-resistant cellophane may lead to a decrease in overall packaging material consumption.

Recyclability remains a key consideration in the development of heat-resistant cellophane. While traditional cellophane is biodegradable, the addition of heat-resistant properties may affect its decomposition rate. Researchers are exploring bio-based alternatives and composite materials that maintain heat resistance while preserving biodegradability.

The sustainability of heat-resistant cellophane also depends on its sourcing and production methods. Efforts are underway to develop cellulose-based materials derived from sustainable forestry practices or agricultural waste, reducing reliance on petroleum-based resources. These initiatives align with circular economy principles and contribute to a more sustainable packaging industry.

Water usage in the production of heat-resistant cellophane is another critical environmental factor. Innovations in water recycling systems and dry manufacturing processes are being implemented to minimize water consumption and reduce the environmental impact of production facilities.

As regulations on single-use plastics become more stringent globally, heat-resistant cellophane may offer a viable alternative in certain applications. However, its widespread adoption must be balanced with comprehensive life cycle assessments to ensure that the environmental benefits outweigh the potential drawbacks.

In conclusion, while heat-resistant cellophane presents promising solutions for packaging challenges, its environmental impact and sustainability considerations are complex and multifaceted. Ongoing research and development efforts must prioritize eco-friendly production methods, recyclability, and responsible sourcing to ensure that these innovations contribute positively to global sustainability goals.

Regulatory Framework for Food Packaging Materials

The regulatory framework for food packaging materials plays a crucial role in ensuring the safety and quality of heat-resistant cellophane innovations. In the United States, the Food and Drug Administration (FDA) oversees the regulation of food contact materials, including cellophane. The FDA's Food Contact Substance Notification Program requires manufacturers to submit detailed information about new food contact substances, including their chemical composition, intended use, and safety data.

In the European Union, the European Food Safety Authority (EFSA) is responsible for evaluating the safety of food contact materials. The EU's Regulation (EC) No 1935/2004 provides the general principles for all food contact materials, while specific measures for plastic materials are outlined in Regulation (EU) No 10/2011. These regulations establish migration limits for substances that may transfer from packaging to food, ensuring consumer safety.

Japan's regulatory system for food packaging materials is governed by the Food Sanitation Act, which sets standards for various food contact materials, including cellophane. The Japanese government requires manufacturers to comply with specific positive lists of approved substances and migration limits.

International standards, such as those developed by the International Organization for Standardization (ISO), also influence the regulatory landscape for heat-resistant cellophane. ISO 22000 provides guidelines for food safety management systems, which can be applied to packaging material production.

As breakthrough innovations in heat-resistant cellophane emerge, regulatory bodies must adapt their frameworks to address new technologies and materials. This may involve updating existing regulations or developing new guidelines to ensure the safety and efficacy of novel heat-resistant cellophane products.

Manufacturers of heat-resistant cellophane must navigate these complex regulatory environments to bring their innovations to market. This often requires extensive testing and documentation to demonstrate compliance with safety standards and migration limits. Additionally, as sustainability becomes increasingly important, regulations may evolve to address environmental concerns related to packaging materials.

The global nature of the food packaging industry necessitates harmonization efforts between different regulatory bodies. Initiatives such as the Global Food Safety Initiative (GFSI) aim to promote convergence in food safety standards worldwide, which can impact the regulatory landscape for heat-resistant cellophane and other food packaging materials.

In the European Union, the European Food Safety Authority (EFSA) is responsible for evaluating the safety of food contact materials. The EU's Regulation (EC) No 1935/2004 provides the general principles for all food contact materials, while specific measures for plastic materials are outlined in Regulation (EU) No 10/2011. These regulations establish migration limits for substances that may transfer from packaging to food, ensuring consumer safety.

Japan's regulatory system for food packaging materials is governed by the Food Sanitation Act, which sets standards for various food contact materials, including cellophane. The Japanese government requires manufacturers to comply with specific positive lists of approved substances and migration limits.

International standards, such as those developed by the International Organization for Standardization (ISO), also influence the regulatory landscape for heat-resistant cellophane. ISO 22000 provides guidelines for food safety management systems, which can be applied to packaging material production.

As breakthrough innovations in heat-resistant cellophane emerge, regulatory bodies must adapt their frameworks to address new technologies and materials. This may involve updating existing regulations or developing new guidelines to ensure the safety and efficacy of novel heat-resistant cellophane products.

Manufacturers of heat-resistant cellophane must navigate these complex regulatory environments to bring their innovations to market. This often requires extensive testing and documentation to demonstrate compliance with safety standards and migration limits. Additionally, as sustainability becomes increasingly important, regulations may evolve to address environmental concerns related to packaging materials.

The global nature of the food packaging industry necessitates harmonization efforts between different regulatory bodies. Initiatives such as the Global Food Safety Initiative (GFSI) aim to promote convergence in food safety standards worldwide, which can impact the regulatory landscape for heat-resistant cellophane and other food packaging materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!