Critical Review: Graphene Oxide and Antimicrobial Properties

Graphene Oxide Evolution

Graphene oxide (GO) has undergone a remarkable evolution since its initial discovery, transforming from a novel material to a promising candidate for antimicrobial applications. The journey of GO began with the groundbreaking work on graphene by Andre Geim and Konstantin Novoselov in 2004, which led to their Nobel Prize in Physics in 2010. However, it was the oxidized form of graphene that captured the attention of researchers in the field of antimicrobial materials.

The early stages of GO development focused primarily on its synthesis and characterization. The Hummers method, developed in 1958, became the foundation for GO production, with subsequent modifications improving yield and reducing environmental impact. As researchers delved deeper into GO's properties, they discovered its unique structural characteristics, including a high surface-to-volume ratio and abundant oxygen-containing functional groups, which hinted at its potential for antimicrobial applications.

The mid-2010s marked a turning point in GO research, with a surge in studies exploring its antimicrobial properties. Scientists began to unravel the mechanisms behind GO's ability to inhibit bacterial growth and destroy microbial cells. These investigations revealed that GO's sharp edges could physically disrupt bacterial cell membranes, while its oxidative stress-inducing properties further contributed to its antimicrobial efficacy.

As the understanding of GO's antimicrobial capabilities grew, researchers started to explore its potential in various applications. The medical field showed particular interest, with studies examining GO's use in wound dressings, implant coatings, and water purification systems. Concurrently, efforts to enhance GO's antimicrobial properties through functionalization and composite formation gained momentum, leading to the development of more potent and targeted antimicrobial materials.

Recent years have seen a shift towards addressing the challenges associated with GO's practical implementation. Researchers have focused on improving GO's stability in various environments, enhancing its selectivity towards harmful microorganisms, and ensuring its biocompatibility for medical applications. Additionally, the environmental impact and potential toxicity of GO have become important areas of study, prompting investigations into sustainable production methods and safe disposal practices.

The evolution of GO in the context of antimicrobial properties continues to accelerate, with emerging trends pointing towards the development of smart, responsive GO-based materials. These advanced materials aim to provide controlled release of antimicrobial agents and adapt to specific environmental triggers, potentially revolutionizing infection control strategies across various sectors.

Antimicrobial Market Needs

The antimicrobial market has experienced significant growth in recent years, driven by increasing concerns over infectious diseases, healthcare-associated infections, and the rise of antibiotic-resistant bacteria. This market encompasses a wide range of products, including antibiotics, antifungals, antivirals, and antiseptics, used across various sectors such as healthcare, food and beverage, and consumer goods.

In the healthcare sector, there is a pressing need for novel antimicrobial solutions to combat the growing threat of multidrug-resistant pathogens. Hospitals and healthcare facilities are seeking innovative materials and coatings that can prevent the spread of infections on surfaces and medical devices. This demand is further amplified by the global focus on infection control measures, especially in the wake of recent pandemics.

The food and beverage industry also presents a substantial market for antimicrobial technologies. Consumers are increasingly demanding safer, longer-lasting food products, driving the need for advanced packaging materials and preservatives that can inhibit microbial growth without compromising food quality or safety. Additionally, there is a growing interest in natural and eco-friendly antimicrobial solutions to align with consumer preferences for clean-label products.

In the consumer goods sector, antimicrobial properties are becoming a desirable feature in a wide range of products, from textiles and personal care items to household appliances. This trend is partly driven by heightened hygiene awareness among consumers, who are seeking products that offer protection against harmful microorganisms in their daily lives.

The ongoing COVID-19 pandemic has further accelerated the demand for antimicrobial solutions across all sectors. This has led to increased research and development efforts to create more effective and versatile antimicrobial materials and coatings that can be applied to various surfaces and products.

As environmental concerns grow, there is also a rising demand for sustainable antimicrobial solutions that do not contribute to pollution or ecological imbalance. This has sparked interest in developing bio-based antimicrobials and materials that offer both efficacy and environmental compatibility.

The global antimicrobial market is expected to continue its growth trajectory, with particular emphasis on innovative, broad-spectrum solutions that can address multiple pathogens simultaneously. There is also a growing need for antimicrobial technologies that can be easily integrated into existing manufacturing processes and products without significant cost increases or performance trade-offs.

GO Antimicrobial Challenges

Despite the promising antimicrobial properties of graphene oxide (GO), several challenges hinder its widespread application in this field. One of the primary concerns is the potential cytotoxicity of GO to human cells and tissues. While GO exhibits strong antimicrobial activity, it may also cause damage to healthy cells, limiting its use in biomedical applications. This toxicity is often dose-dependent and can vary based on the size, shape, and surface chemistry of GO particles.

Another significant challenge is the lack of standardization in GO production and characterization. The antimicrobial efficacy of GO can vary greatly depending on its synthesis method, oxidation degree, and lateral size. This variability makes it difficult to compare results across different studies and establish consistent protocols for antimicrobial applications.

The mechanism of GO's antimicrobial action is not fully understood, which poses challenges in optimizing its performance and addressing potential resistance development in microorganisms. While several theories exist, including physical disruption of cell membranes and oxidative stress induction, a comprehensive understanding of these mechanisms is still lacking.

The stability of GO in different environments presents another hurdle. In aqueous solutions or biological fluids, GO tends to aggregate, potentially reducing its antimicrobial efficacy and altering its interaction with microorganisms. This aggregation can also affect the long-term stability of GO-based antimicrobial coatings or materials.

Scalability and cost-effectiveness remain significant challenges for the commercial application of GO as an antimicrobial agent. The current production methods for high-quality GO are often expensive and difficult to scale up, limiting its potential for large-scale use in antimicrobial products.

Environmental concerns also pose challenges to the widespread use of GO. The potential release of GO into the environment and its long-term ecological impact are not fully understood. There are concerns about bioaccumulation and the effects on non-target organisms in ecosystems.

Regulatory hurdles present another obstacle. The novel nature of GO and its potential risks require thorough safety assessments before it can be approved for use in consumer products or medical applications. This regulatory process can be time-consuming and costly, potentially slowing down the commercialization of GO-based antimicrobial solutions.

Current GO Solutions

01 Antimicrobial properties of graphene oxide

Graphene oxide exhibits strong antimicrobial properties, making it effective against various microorganisms. Its large surface area and sharp edges can physically damage bacterial cell membranes, while its ability to generate reactive oxygen species contributes to its bactericidal effects. These properties make graphene oxide a promising material for developing antimicrobial coatings and materials.- Antimicrobial properties of graphene oxide: Graphene oxide exhibits strong antimicrobial properties, making it effective against various microorganisms. Its large surface area and sharp edges can physically damage bacterial cell membranes, while its ability to generate reactive oxygen species contributes to its bactericidal effects. This makes graphene oxide a promising material for developing antimicrobial coatings and materials.

- Graphene oxide-based antimicrobial composites: Graphene oxide can be incorporated into various composite materials to impart antimicrobial properties. These composites can include polymers, metals, or other nanomaterials, enhancing their overall antimicrobial efficacy. Such composites find applications in medical devices, water treatment systems, and food packaging materials.

- Functionalization of graphene oxide for enhanced antimicrobial activity: The antimicrobial properties of graphene oxide can be further enhanced through functionalization with various chemical groups or nanoparticles. This modification can improve its stability, dispersibility, and targeted antimicrobial action. Functionalized graphene oxide shows promise in developing advanced antimicrobial materials for diverse applications.

- Graphene oxide in water treatment and purification: Graphene oxide's antimicrobial properties make it an excellent candidate for water treatment and purification applications. It can be used in filtration membranes or as an adsorbent to remove microbial contaminants from water. The material's high surface area and ability to be functionalized allow for efficient water purification processes.

- Biomedical applications of antimicrobial graphene oxide: The antimicrobial properties of graphene oxide have led to its exploration in various biomedical applications. These include wound dressings, tissue engineering scaffolds, and drug delivery systems. The material's ability to inhibit bacterial growth while promoting tissue regeneration makes it particularly promising for wound healing applications.

02 Graphene oxide-based antimicrobial composites

Composites incorporating graphene oxide show enhanced antimicrobial activity. These composites can be formed by combining graphene oxide with polymers, metals, or other nanomaterials. The resulting materials often demonstrate synergistic effects, improving their overall antimicrobial efficacy and potentially expanding their range of applications in various fields such as healthcare, water treatment, and food packaging.Expand Specific Solutions03 Functionalization of graphene oxide for improved antimicrobial activity

Functionalization of graphene oxide can enhance its antimicrobial properties. This process involves modifying the surface of graphene oxide with various chemical groups or molecules, such as antibiotics, metal nanoparticles, or specific functional groups. Functionalization can improve the material's stability, dispersibility, and target specificity, leading to more effective antimicrobial performance.Expand Specific Solutions04 Graphene oxide in water treatment and purification

Graphene oxide's antimicrobial properties make it valuable for water treatment and purification applications. It can be used in filtration membranes or as an adsorbent to remove bacteria, viruses, and other contaminants from water. The material's high surface area and ability to be functionalized allow for efficient water purification processes, potentially addressing global clean water challenges.Expand Specific Solutions05 Biomedical applications of antimicrobial graphene oxide

The antimicrobial properties of graphene oxide have led to its exploration in various biomedical applications. These include wound dressings, implant coatings, drug delivery systems, and tissue engineering scaffolds. The material's ability to inhibit bacterial growth while potentially promoting tissue regeneration makes it a promising candidate for developing advanced medical devices and treatments.Expand Specific Solutions

Key GO Research Entities

The field of graphene oxide and its antimicrobial properties is in a rapidly evolving stage, with significant market potential due to increasing demand for advanced materials in healthcare and environmental applications. The global market for graphene-based products is expanding, driven by research advancements and industrial applications. Technological maturity varies among key players, with academic institutions like Northwestern University and University of California leading in fundamental research, while companies such as Nitto Denko Corp. and Eni SpA focus on commercial applications. Emerging players from diverse geographical regions, including Jinan Shengquan Group and Nantong Qiangsheng Graphene Technology, are contributing to the competitive landscape, indicating a growing interest in graphene oxide's antimicrobial potential across various industries.

Northwestern University

The Regents of the University of California

GO Antimicrobial Mechanisms

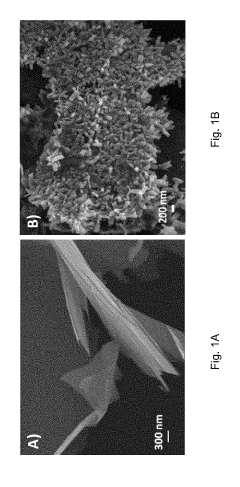

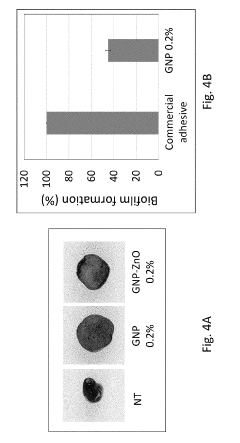

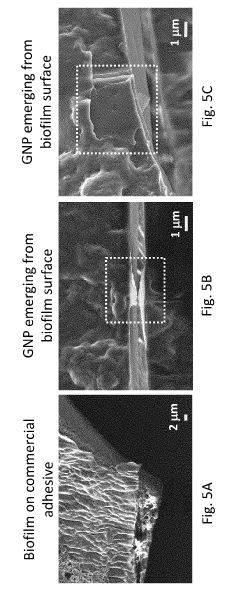

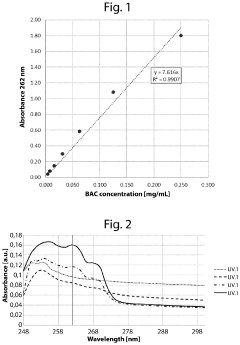

- A process for producing dental adhesives with uniformly dispersed graphene nanostructures, potentially decorated with zinc oxide nanorods, which exhibit antimicrobial and antibiofilm properties through mechanical interaction with bacteria, while maintaining mechanical properties and adhesion, and enhancing cure depth through UV radiation scattering.

- A process involving high shear mixing and oxidation of graphite using hydrogen peroxide and/or potassium hydroxide to produce graphene oxide with enhanced antimicrobial properties, eliminating potassium permanganate impurities and ensuring stability and reproducibility, allowing for extended antimicrobial action in rubber articles.

GO Safety Regulations

The safety regulations surrounding graphene oxide (GO) are evolving as research into its potential applications and risks continues. Currently, there is no specific regulatory framework exclusively for GO, but it falls under existing regulations for nanomaterials and chemical substances.

In the European Union, GO is subject to the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Manufacturers and importers of GO must register with the European Chemicals Agency (ECHA) if they produce or import more than one tonne per year. The registration process requires detailed information on the substance's properties, potential risks, and safe handling procedures.

The United States Environmental Protection Agency (EPA) regulates GO under the Toxic Substances Control Act (TSCA). Manufacturers and importers must submit a Pre-Manufacture Notice (PMN) to the EPA before producing or importing GO for commercial purposes. The EPA then evaluates the potential risks and may impose restrictions or require additional testing.

Occupational safety guidelines for handling GO are provided by organizations such as the National Institute for Occupational Safety and Health (NIOSH) in the US. These guidelines recommend using engineering controls, personal protective equipment, and proper handling procedures to minimize exposure risks.

In the context of antimicrobial applications, GO must also comply with regulations specific to biocidal products. In the EU, this falls under the Biocidal Products Regulation (BPR), which requires extensive safety and efficacy data before approval for use.

As research progresses, regulatory bodies are likely to develop more specific guidelines for GO. The Organization for Economic Co-operation and Development (OECD) has established a Working Party on Manufactured Nanomaterials, which is working to harmonize international approaches to nanomaterial safety assessment, including GO.

Researchers and manufacturers working with GO must stay informed about these evolving regulations and ensure compliance with relevant safety standards. This includes conducting thorough risk assessments, implementing appropriate safety measures, and providing accurate safety data sheets for GO-containing products.

GO Production Scalability

The scalability of graphene oxide (GO) production is a critical factor in its potential widespread application as an antimicrobial agent. Current production methods face significant challenges in scaling up to meet industrial demands while maintaining consistent quality and cost-effectiveness.

The most common method for GO production is the modified Hummers' method, which involves the oxidation of graphite using strong oxidizing agents. While this method is effective on a laboratory scale, it faces several obstacles when scaled up. The exothermic nature of the reaction makes temperature control difficult in large batches, potentially leading to inconsistent product quality. Additionally, the use of hazardous chemicals like sulfuric acid and potassium permanganate raises safety and environmental concerns in large-scale production.

To address these challenges, researchers are exploring alternative production methods. One promising approach is the electrochemical exfoliation of graphite, which offers better control over the oxidation process and reduces the use of harsh chemicals. This method has shown potential for scalability, but further optimization is needed to improve yield and consistency.

Another avenue being investigated is the use of continuous flow reactors for GO production. This approach allows for better control of reaction conditions and could potentially increase production rates. However, issues such as clogging and maintaining uniform oxidation across the graphite sheets need to be resolved before this method can be widely adopted.

The development of green synthesis methods for GO production is also gaining traction. These methods aim to reduce environmental impact by using less toxic reagents and minimizing waste. While promising, these approaches often result in lower yields and may require additional processing steps, which could limit their scalability.

A key challenge in scaling up GO production is maintaining consistent quality across large batches. The degree of oxidation, sheet size distribution, and the presence of defects can significantly affect GO's antimicrobial properties. Developing robust quality control measures and standardization protocols is essential for ensuring the reliability of GO-based antimicrobial products at an industrial scale.

In conclusion, while GO shows great promise as an antimicrobial agent, significant advancements in production scalability are needed to realize its full potential. Future research should focus on optimizing existing methods, developing new scalable approaches, and addressing quality control challenges to enable the large-scale production of GO for antimicrobial applications.