Efficient HDPE Production: Best Practices and Techniques

HDPE Production Evolution and Objectives

High-density polyethylene (HDPE) production has undergone significant evolution since its inception in the 1950s. Initially developed by Karl Ziegler using a catalyst system, HDPE quickly gained prominence due to its superior properties compared to low-density polyethylene. The primary objective of HDPE production has consistently been to create a versatile, durable, and cost-effective plastic material suitable for a wide range of applications.

Over the decades, the focus of HDPE production has shifted towards improving efficiency, reducing environmental impact, and enhancing product quality. Early production methods relied heavily on energy-intensive processes and had limited control over polymer properties. However, advancements in catalyst technology, particularly the development of Ziegler-Natta and metallocene catalysts, have revolutionized HDPE production, allowing for greater control over molecular weight distribution and polymer structure.

The industry has witnessed a continuous drive towards process optimization, with the introduction of gas-phase and slurry processes replacing the original high-pressure methods. These innovations have significantly reduced energy consumption and improved overall production efficiency. Additionally, the integration of advanced process control systems and real-time monitoring technologies has further enhanced production consistency and quality.

In recent years, sustainability has become a key objective in HDPE production. Manufacturers are increasingly focusing on reducing carbon footprint, minimizing waste, and exploring bio-based feedstocks. The development of catalysts that enable lower operating temperatures and pressures has contributed to energy savings and reduced greenhouse gas emissions.

Another significant trend in HDPE production is the pursuit of enhanced material properties. Research efforts are directed towards developing HDPE grades with improved strength, chemical resistance, and processability. This includes the exploration of nanocomposites and the fine-tuning of molecular architecture to meet specific application requirements.

Looking ahead, the objectives for HDPE production are multifaceted. There is a growing emphasis on circular economy principles, with increased efforts to improve recyclability and incorporate recycled content into new HDPE products. The industry is also exploring novel polymerization techniques and catalyst systems that could potentially revolutionize production processes, further improving efficiency and sustainability.

As global demand for HDPE continues to rise, driven by its versatility and performance in various sectors, the industry faces the challenge of scaling up production while adhering to increasingly stringent environmental regulations. This necessitates ongoing innovation in process technology, catalysts, and product design to ensure that HDPE production remains economically viable and environmentally responsible.

HDPE Market Demand Analysis

The global High-Density Polyethylene (HDPE) market has been experiencing steady growth, driven by increasing demand across various industries. HDPE's versatility, durability, and cost-effectiveness have made it a preferred material in packaging, construction, automotive, and consumer goods sectors.

In the packaging industry, HDPE is widely used for bottles, containers, and films. The growing e-commerce sector and the shift towards sustainable packaging solutions have further boosted HDPE demand. The construction industry also contributes significantly to HDPE market growth, with applications in pipes, fittings, and geomembranes.

The automotive sector has been increasingly adopting HDPE for lightweight components, fuel tanks, and interior parts, driven by the need for fuel efficiency and reduced emissions. Consumer goods manufacturers utilize HDPE in household products, toys, and personal care items, capitalizing on its chemical resistance and impact strength.

Geographically, Asia-Pacific leads the HDPE market, with China and India as major consumers and producers. The region's rapid industrialization, urbanization, and growing middle-class population contribute to increased HDPE demand. North America and Europe follow, with mature markets focusing on technological advancements and sustainable HDPE production methods.

The market demand for HDPE is influenced by several factors, including economic growth, urbanization rates, and environmental regulations. The push for circular economy practices has led to increased interest in recycled HDPE, creating new market opportunities and challenges for producers.

Despite the overall positive outlook, the HDPE market faces challenges such as fluctuating raw material prices and environmental concerns regarding plastic waste. These factors are driving innovation in production techniques and recycling technologies, shaping the future of HDPE demand and production.

Industry analysts project continued growth in the HDPE market, with a focus on developing bio-based alternatives and improving recycling capabilities. The demand for efficient HDPE production techniques is expected to rise as manufacturers seek to optimize costs and reduce environmental impact while meeting the growing market needs.

HDPE Production Challenges

High-density polyethylene (HDPE) production faces several significant challenges that impact efficiency, quality, and overall productivity. One of the primary issues is the high energy consumption required for the polymerization process. The reaction typically occurs at elevated temperatures and pressures, demanding substantial energy input, which not only increases production costs but also raises environmental concerns.

Another challenge lies in catalyst efficiency and selectivity. The choice and performance of catalysts play a crucial role in HDPE production. Inefficient catalysts can lead to lower yields, increased impurities, and inconsistent product properties. Developing and optimizing catalysts that offer high activity, selectivity, and stability under various reaction conditions remains an ongoing challenge for manufacturers.

Process control and product consistency pose additional difficulties. HDPE production involves complex reactions and multiple variables that need precise control to maintain product quality. Fluctuations in temperature, pressure, or monomer concentration can result in variations in molecular weight distribution, density, and other critical properties of the final product. Achieving consistent quality across different production batches is essential for meeting customer specifications and regulatory requirements.

The management of by-products and waste streams presents another significant challenge. The polymerization process can generate various by-products and unreacted monomers that need to be separated, recycled, or disposed of properly. Efficient separation and purification techniques are crucial for maximizing yield and minimizing environmental impact.

Raw material variability and supply chain management also contribute to production challenges. The quality and consistency of ethylene feedstock can vary, affecting the polymerization process and final product properties. Ensuring a stable supply of high-quality raw materials while managing inventory and logistics adds complexity to HDPE production operations.

Furthermore, equipment reliability and maintenance pose ongoing challenges. HDPE production facilities operate under harsh conditions, subjecting equipment to wear, corrosion, and potential fouling. Regular maintenance and equipment upgrades are necessary to prevent unplanned shutdowns and ensure continuous operation, but these activities can impact production schedules and costs.

Lastly, meeting evolving regulatory requirements and sustainability goals presents additional challenges. Manufacturers must adapt to changing environmental regulations, implement cleaner production technologies, and explore ways to reduce carbon footprint. This includes efforts to improve energy efficiency, reduce emissions, and develop more sustainable production processes, all while maintaining product quality and economic viability.

Current HDPE Production Methods

01 Improved HDPE production processes

Various methods to enhance the efficiency of HDPE production have been developed. These include optimizing polymerization conditions, using advanced catalysts, and implementing innovative reactor designs. Such improvements lead to increased productivity, reduced energy consumption, and better control over the polymer properties.- Improved HDPE production processes: Various methods to enhance the efficiency of HDPE production have been developed. These include optimizing polymerization conditions, using advanced catalysts, and implementing innovative reactor designs. Such improvements lead to increased productivity, reduced energy consumption, and better control over the polymer properties.

- HDPE blends and composites: Blending HDPE with other materials or creating HDPE-based composites can significantly improve its efficiency and performance. These formulations often result in enhanced mechanical properties, better processability, and increased resistance to environmental factors, making the material more suitable for specific applications.

- Recycling and upcycling of HDPE: Efficient recycling and upcycling processes for HDPE have been developed to improve its overall lifecycle efficiency. These methods focus on maintaining or enhancing the properties of recycled HDPE, reducing waste, and creating value-added products from post-consumer or post-industrial HDPE materials.

- HDPE modification techniques: Various modification techniques have been invented to enhance the efficiency of HDPE for specific applications. These include surface treatments, chemical modifications, and the incorporation of additives or nanoparticles. Such modifications can improve properties like barrier performance, printability, and adhesion.

- HDPE processing and manufacturing efficiency: Innovations in HDPE processing and manufacturing techniques have led to improved efficiency in terms of energy consumption, material utilization, and product quality. These advancements include optimized extrusion and molding processes, as well as novel equipment designs for HDPE product manufacturing.

02 HDPE blends and composites

Blending HDPE with other materials or creating HDPE-based composites can significantly improve its efficiency and performance. These formulations can enhance mechanical properties, thermal stability, and processability of HDPE, making it suitable for a wider range of applications.Expand Specific Solutions03 Recycling and upcycling of HDPE

Efficient recycling and upcycling processes for HDPE have been developed to improve its overall lifecycle efficiency. These methods include advanced sorting techniques, chemical recycling, and the development of new applications for recycled HDPE, contributing to a more sustainable use of the material.Expand Specific Solutions04 HDPE processing techniques

Innovative processing techniques have been introduced to enhance the efficiency of HDPE manufacturing and shaping. These include advanced extrusion methods, injection molding optimizations, and novel forming processes that improve product quality while reducing energy consumption and material waste.Expand Specific Solutions05 HDPE additives and modifications

The use of specific additives and chemical modifications can significantly improve the efficiency and performance of HDPE. These enhancements can include improved UV resistance, increased strength, better processability, and enhanced barrier properties, expanding the range of applications for HDPE.Expand Specific Solutions

Key HDPE Manufacturers

The HDPE production market is in a mature stage, with a global market size expected to reach $84 billion by 2026. The technology for efficient HDPE production is well-established, with ongoing innovations focusing on sustainability and cost reduction. Key players like Dow Global Technologies, SABIC, and ExxonMobil are at the forefront of technological advancements, investing heavily in R&D to improve production efficiency and product quality. Emerging companies from China, such as Sinopec and China Petroleum & Chemical Corp., are rapidly gaining market share by leveraging advanced technologies and economies of scale. The competitive landscape is characterized by a mix of established multinational corporations and rising regional players, driving continuous improvement in HDPE production techniques.

Dow Global Technologies LLC

China Petroleum & Chemical Corp.

Innovative HDPE Catalysts

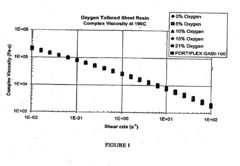

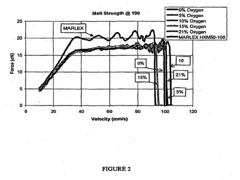

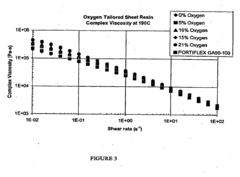

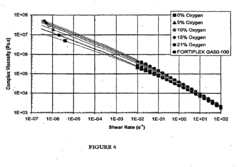

- The use of oxygen tailoring to introduce limited long chain branching in chromium-catalyzed HDPE resins during the extrusion process, enhancing melt strength without compromising extensibility, by exposing the resin to low levels of oxygen in the extruder's second melt zone and subsequent antioxidant treatment.

- A process involving the use of two continuous stirred tank reactors in series, where the first reactor homopolymerizes ethylene in the presence of hydrogen and a Ziegler-Natta catalyst, and the second reactor copolymerizes ethylene with an α-olefinic comonomer, producing a bimodal HDPE with a specific molecular weight distribution, density, and mechanical properties.

Environmental Impact of HDPE

The environmental impact of High-Density Polyethylene (HDPE) production and usage is a critical consideration in the plastics industry. HDPE, while offering numerous benefits in terms of durability and versatility, also poses significant environmental challenges throughout its lifecycle.

During the production phase, HDPE manufacturing contributes to greenhouse gas emissions and energy consumption. The process relies heavily on fossil fuels, both as raw materials and energy sources. Ethylene, the primary feedstock for HDPE, is typically derived from natural gas or petroleum, contributing to the depletion of non-renewable resources. The cracking and polymerization processes involved in HDPE production are energy-intensive, leading to substantial carbon dioxide emissions.

Water pollution is another concern associated with HDPE production. The manufacturing process generates wastewater containing various chemicals and pollutants, which, if not properly treated, can contaminate local water sources. Additionally, the production of catalysts and additives used in HDPE manufacturing may involve hazardous substances that require careful handling and disposal.

The environmental impact of HDPE extends beyond its production phase. While HDPE is recyclable, a significant portion of HDPE products end up in landfills or as litter in the environment. HDPE's resistance to degradation, a quality that makes it valuable for many applications, also means that it persists in the environment for hundreds of years. This persistence contributes to the growing problem of plastic pollution in terrestrial and marine ecosystems.

In marine environments, HDPE products can break down into microplastics, which pose a threat to marine life. These tiny plastic particles can be ingested by marine organisms, potentially entering the food chain and affecting human health. The accumulation of HDPE and other plastics in oceans also contributes to the formation of large garbage patches, disrupting marine ecosystems and navigation.

The recycling of HDPE, while beneficial, also has environmental implications. The recycling process requires energy and can produce emissions, although these are generally lower than those associated with virgin HDPE production. Additionally, the quality of recycled HDPE may degrade over multiple recycling cycles, limiting its long-term recyclability.

To mitigate the environmental impact of HDPE, various strategies are being explored and implemented. These include improving production efficiency to reduce energy consumption and emissions, developing bio-based alternatives to traditional HDPE, enhancing recycling technologies and infrastructure, and promoting circular economy principles in HDPE product design and lifecycle management.

HDPE Quality Control

Quality control is a critical aspect of efficient HDPE production, ensuring that the final product meets industry standards and customer specifications. The quality control process for HDPE typically involves several key steps and techniques.

One of the primary quality control measures is the monitoring of melt flow index (MFI), which indicates the polymer's molecular weight and flow characteristics. Regular MFI testing helps maintain consistency in the production process and ensures that the HDPE meets the required specifications for various applications. This test is typically performed using a melt flow indexer, where the rate of extrusion of molten polymer through a die under specified conditions is measured.

Density testing is another crucial quality control parameter for HDPE. The density of the polymer directly affects its mechanical properties, such as stiffness and impact resistance. Density measurements are usually conducted using a density gradient column or a density meter, allowing for precise determination of the HDPE's density and ensuring it falls within the specified range for the intended application.

Tensile strength and elongation tests are essential for evaluating the mechanical properties of HDPE. These tests involve stretching a sample of the material until it breaks, providing information on its strength, ductility, and overall performance under stress. The results of these tests help ensure that the HDPE meets the required mechanical specifications for its intended use.

Environmental stress crack resistance (ESCR) testing is particularly important for HDPE products that will be exposed to harsh environments or chemicals. This test evaluates the material's resistance to cracking under stress and in the presence of specific chemicals, helping to predict its long-term performance and durability in various applications.

Thermal analysis techniques, such as differential scanning calorimetry (DSC), are used to assess the thermal properties of HDPE. DSC measurements provide information on the polymer's melting point, crystallization behavior, and overall thermal stability. This data is crucial for ensuring consistent processing conditions and predicting the material's performance in different temperature environments.

Visual inspection and dimensional checks are also integral parts of HDPE quality control. These assessments help identify any surface defects, color inconsistencies, or dimensional variations that may affect the product's appearance or functionality. Advanced imaging technologies and automated inspection systems are often employed to enhance the accuracy and efficiency of these visual quality checks.

Implementing a robust statistical process control (SPC) system is essential for maintaining consistent HDPE quality. SPC involves the continuous monitoring of key process parameters and quality metrics, allowing for early detection of trends or deviations that may impact product quality. This proactive approach helps minimize variability and reduce the likelihood of producing out-of-specification material.