Emerging Cellophane Applications in the Cosmetic Industry

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane in Cosmetics: Background and Objectives

Cellophane, a thin, transparent sheet made from regenerated cellulose, has been a staple in various industries for decades. However, its application in the cosmetic industry is a relatively recent development that has gained significant traction in recent years. The evolution of cellophane in cosmetics can be traced back to the early 2000s when beauty brands began exploring innovative packaging solutions to enhance product appeal and functionality.

The primary objective of incorporating cellophane in cosmetics is to revolutionize product presentation, protection, and application. As consumers increasingly prioritize eco-friendly and visually appealing products, cellophane has emerged as a versatile material that addresses these demands while offering unique benefits to both manufacturers and end-users.

In the context of the cosmetic industry, cellophane has found applications in various forms, including packaging materials, face masks, and even as a component in certain cosmetic formulations. Its transparency allows for clear product visibility, which is crucial in an industry where visual appeal plays a significant role in consumer decision-making. Moreover, cellophane's barrier properties provide excellent protection against moisture and contaminants, ensuring product integrity and extending shelf life.

The technological advancements in cellophane production have led to the development of bio-based and biodegradable variants, aligning with the growing demand for sustainable cosmetic packaging solutions. This shift towards eco-friendly alternatives has been driven by increasing environmental awareness and stringent regulations on plastic usage in the cosmetic industry.

As the cosmetic industry continues to evolve, the integration of cellophane is expected to expand beyond traditional applications. Emerging trends indicate potential uses in smart packaging, where cellophane could be combined with sensors or color-changing properties to indicate product freshness or provide interactive experiences for consumers. Additionally, research is underway to explore cellophane's potential as a delivery system for active ingredients in skincare products.

The adoption of cellophane in cosmetics is not without challenges. Manufacturers must address concerns related to scalability, cost-effectiveness, and compatibility with various cosmetic formulations. Furthermore, as the industry moves towards more sustainable practices, there is a growing need to develop cellophane production methods that minimize environmental impact while maintaining the material's desirable properties.

In conclusion, the emergence of cellophane applications in the cosmetic industry represents a convergence of technological innovation, consumer preferences, and sustainability goals. As research and development efforts continue, cellophane is poised to play an increasingly significant role in shaping the future of cosmetic packaging and product formulations, offering new possibilities for both aesthetic appeal and functional benefits.

The primary objective of incorporating cellophane in cosmetics is to revolutionize product presentation, protection, and application. As consumers increasingly prioritize eco-friendly and visually appealing products, cellophane has emerged as a versatile material that addresses these demands while offering unique benefits to both manufacturers and end-users.

In the context of the cosmetic industry, cellophane has found applications in various forms, including packaging materials, face masks, and even as a component in certain cosmetic formulations. Its transparency allows for clear product visibility, which is crucial in an industry where visual appeal plays a significant role in consumer decision-making. Moreover, cellophane's barrier properties provide excellent protection against moisture and contaminants, ensuring product integrity and extending shelf life.

The technological advancements in cellophane production have led to the development of bio-based and biodegradable variants, aligning with the growing demand for sustainable cosmetic packaging solutions. This shift towards eco-friendly alternatives has been driven by increasing environmental awareness and stringent regulations on plastic usage in the cosmetic industry.

As the cosmetic industry continues to evolve, the integration of cellophane is expected to expand beyond traditional applications. Emerging trends indicate potential uses in smart packaging, where cellophane could be combined with sensors or color-changing properties to indicate product freshness or provide interactive experiences for consumers. Additionally, research is underway to explore cellophane's potential as a delivery system for active ingredients in skincare products.

The adoption of cellophane in cosmetics is not without challenges. Manufacturers must address concerns related to scalability, cost-effectiveness, and compatibility with various cosmetic formulations. Furthermore, as the industry moves towards more sustainable practices, there is a growing need to develop cellophane production methods that minimize environmental impact while maintaining the material's desirable properties.

In conclusion, the emergence of cellophane applications in the cosmetic industry represents a convergence of technological innovation, consumer preferences, and sustainability goals. As research and development efforts continue, cellophane is poised to play an increasingly significant role in shaping the future of cosmetic packaging and product formulations, offering new possibilities for both aesthetic appeal and functional benefits.

Market Analysis for Cellophane-Based Cosmetic Products

The global cosmetic industry has been experiencing steady growth, with a market value projected to reach $463.5 billion by 2027. Within this expanding sector, there is a growing demand for innovative packaging solutions that are both sustainable and functional. Cellophane, a biodegradable and transparent material derived from cellulose, has emerged as a promising candidate for cosmetic packaging applications.

The market for cellophane-based cosmetic products is driven by several key factors. Firstly, the increasing consumer awareness of environmental issues has led to a preference for eco-friendly packaging materials. Cellophane's biodegradability aligns well with this trend, making it an attractive option for environmentally conscious consumers. Secondly, the transparency of cellophane allows for clear product visibility, which is crucial in the cosmetic industry where visual appeal plays a significant role in purchasing decisions.

The Asia-Pacific region is expected to be the fastest-growing market for cellophane-based cosmetic products, driven by the rising middle-class population and increasing disposable incomes. North America and Europe are also significant markets, with a strong focus on sustainable packaging solutions. The market is segmented into various product categories, including skincare, haircare, makeup, and fragrances, each presenting unique opportunities for cellophane applications.

In terms of market trends, there is a growing interest in customizable cellophane packaging solutions that allow brands to differentiate their products. Additionally, the development of advanced cellophane formulations with enhanced barrier properties and durability is opening up new possibilities for its use in premium cosmetic products.

However, the market for cellophane-based cosmetic products also faces challenges. The higher cost of cellophane compared to traditional plastic packaging materials may limit its adoption, particularly in price-sensitive market segments. Furthermore, the performance limitations of cellophane in terms of moisture resistance and shelf life may restrict its use in certain cosmetic formulations.

Despite these challenges, the market outlook for cellophane-based cosmetic products remains positive. The increasing regulatory pressure on plastic reduction and the growing consumer demand for sustainable packaging are expected to drive the adoption of cellophane in the cosmetic industry. As technology advances and production scales up, the cost-effectiveness of cellophane is likely to improve, further boosting its market potential.

The market for cellophane-based cosmetic products is driven by several key factors. Firstly, the increasing consumer awareness of environmental issues has led to a preference for eco-friendly packaging materials. Cellophane's biodegradability aligns well with this trend, making it an attractive option for environmentally conscious consumers. Secondly, the transparency of cellophane allows for clear product visibility, which is crucial in the cosmetic industry where visual appeal plays a significant role in purchasing decisions.

The Asia-Pacific region is expected to be the fastest-growing market for cellophane-based cosmetic products, driven by the rising middle-class population and increasing disposable incomes. North America and Europe are also significant markets, with a strong focus on sustainable packaging solutions. The market is segmented into various product categories, including skincare, haircare, makeup, and fragrances, each presenting unique opportunities for cellophane applications.

In terms of market trends, there is a growing interest in customizable cellophane packaging solutions that allow brands to differentiate their products. Additionally, the development of advanced cellophane formulations with enhanced barrier properties and durability is opening up new possibilities for its use in premium cosmetic products.

However, the market for cellophane-based cosmetic products also faces challenges. The higher cost of cellophane compared to traditional plastic packaging materials may limit its adoption, particularly in price-sensitive market segments. Furthermore, the performance limitations of cellophane in terms of moisture resistance and shelf life may restrict its use in certain cosmetic formulations.

Despite these challenges, the market outlook for cellophane-based cosmetic products remains positive. The increasing regulatory pressure on plastic reduction and the growing consumer demand for sustainable packaging are expected to drive the adoption of cellophane in the cosmetic industry. As technology advances and production scales up, the cost-effectiveness of cellophane is likely to improve, further boosting its market potential.

Current Challenges in Cellophane Cosmetic Applications

The cosmetic industry's adoption of cellophane faces several significant challenges that hinder its widespread implementation. One of the primary obstacles is the material's limited biodegradability. While cellophane is derived from natural sources, its production process often involves chemical treatments that can impede its decomposition in the environment. This poses a sustainability concern for cosmetic companies striving to meet increasing consumer demands for eco-friendly packaging solutions.

Another challenge lies in the moisture sensitivity of cellophane. When exposed to high humidity or direct contact with water, cellophane tends to lose its structural integrity, potentially compromising the protection and preservation of cosmetic products. This characteristic limits its application in certain product categories, particularly those with high water content or those requiring long-term storage in humid environments.

The cost factor also presents a significant hurdle for widespread adoption. Although cellophane is relatively inexpensive compared to some synthetic alternatives, the specialized manufacturing processes required for cosmetic-grade cellophane can drive up production costs. This economic consideration may deter some companies, especially smaller brands or those operating in price-sensitive markets, from fully embracing cellophane-based packaging solutions.

Technical limitations in cellophane's barrier properties pose another challenge. While it provides excellent resistance to oils and greases, its permeability to gases and certain volatile compounds can be problematic for cosmetic formulations that require stringent protection against oxidation or fragrance loss. This necessitates additional protective measures or limits the types of products that can be packaged using cellophane.

The printing and decoration capabilities of cellophane also present challenges in the highly competitive cosmetic market. Achieving high-quality, vibrant prints on cellophane surfaces can be more difficult compared to some synthetic materials, potentially limiting brand expression and product differentiation through packaging design.

Regulatory compliance adds another layer of complexity to cellophane adoption in cosmetics. Ensuring that cellophane-based packaging meets various international safety standards and regulations for cosmetic products requires extensive testing and documentation, which can be time-consuming and resource-intensive for companies.

Lastly, the integration of cellophane into existing manufacturing and packaging processes presents operational challenges. Many cosmetic companies have established production lines optimized for traditional packaging materials. Adapting these systems to accommodate cellophane's unique handling requirements and physical properties may require significant investments in equipment and training.

Another challenge lies in the moisture sensitivity of cellophane. When exposed to high humidity or direct contact with water, cellophane tends to lose its structural integrity, potentially compromising the protection and preservation of cosmetic products. This characteristic limits its application in certain product categories, particularly those with high water content or those requiring long-term storage in humid environments.

The cost factor also presents a significant hurdle for widespread adoption. Although cellophane is relatively inexpensive compared to some synthetic alternatives, the specialized manufacturing processes required for cosmetic-grade cellophane can drive up production costs. This economic consideration may deter some companies, especially smaller brands or those operating in price-sensitive markets, from fully embracing cellophane-based packaging solutions.

Technical limitations in cellophane's barrier properties pose another challenge. While it provides excellent resistance to oils and greases, its permeability to gases and certain volatile compounds can be problematic for cosmetic formulations that require stringent protection against oxidation or fragrance loss. This necessitates additional protective measures or limits the types of products that can be packaged using cellophane.

The printing and decoration capabilities of cellophane also present challenges in the highly competitive cosmetic market. Achieving high-quality, vibrant prints on cellophane surfaces can be more difficult compared to some synthetic materials, potentially limiting brand expression and product differentiation through packaging design.

Regulatory compliance adds another layer of complexity to cellophane adoption in cosmetics. Ensuring that cellophane-based packaging meets various international safety standards and regulations for cosmetic products requires extensive testing and documentation, which can be time-consuming and resource-intensive for companies.

Lastly, the integration of cellophane into existing manufacturing and packaging processes presents operational challenges. Many cosmetic companies have established production lines optimized for traditional packaging materials. Adapting these systems to accommodate cellophane's unique handling requirements and physical properties may require significant investments in equipment and training.

Existing Cellophane-Based Cosmetic Solutions

01 Cellophane in packaging applications

Cellophane is widely used in packaging applications due to its transparency, flexibility, and barrier properties. It is particularly useful for food packaging, providing protection against moisture and gases while allowing visibility of the product. Cellophane can be combined with other materials to enhance its properties for specific packaging needs.- Cellophane production and processing: Various methods and techniques for producing and processing cellophane, including improvements in manufacturing processes, chemical treatments, and modifications to enhance its properties for specific applications.

- Packaging applications of cellophane: Utilization of cellophane in packaging solutions, including food packaging, consumer goods packaging, and specialized packaging for industrial products. This covers innovations in cellophane-based packaging materials and designs.

- Cellophane in composite materials: Integration of cellophane into composite materials for various applications, including reinforced plastics, laminates, and multi-layer films. This involves combining cellophane with other materials to create products with enhanced properties.

- Biodegradable and eco-friendly cellophane: Development of biodegradable and environmentally friendly cellophane variants, focusing on sustainable production methods and improved end-of-life characteristics to address environmental concerns.

- Cellophane in medical and pharmaceutical applications: Use of cellophane in medical and pharmaceutical fields, including drug delivery systems, wound dressings, and diagnostic tools. This covers modifications to cellophane for biocompatibility and controlled release properties.

02 Cellophane production and processing

Various methods and technologies are employed in the production and processing of cellophane. This includes techniques for improving its physical properties, such as strength and flexibility, as well as methods for modifying its surface characteristics. Innovations in cellophane production focus on enhancing efficiency and reducing environmental impact.Expand Specific Solutions03 Cellophane in biomedical applications

Cellophane has found applications in biomedical fields due to its biocompatibility and unique properties. It can be used in various medical devices, drug delivery systems, and as a substrate for cell culture. Research is ongoing to expand its use in regenerative medicine and tissue engineering.Expand Specific Solutions04 Cellophane-based composites and blends

Cellophane can be combined with other materials to create composites or blends with enhanced properties. These combinations can improve mechanical strength, barrier properties, or add functionalities such as antimicrobial activity. Such composites find applications in packaging, textiles, and other industries.Expand Specific Solutions05 Recycling and biodegradation of cellophane

As environmental concerns grow, there is increasing focus on the recycling and biodegradation of cellophane. Research is being conducted on improving the biodegradability of cellophane and developing efficient recycling processes. This includes methods for separating cellophane from other materials in composite packaging and converting it back into usable raw materials.Expand Specific Solutions

Key Players in Cellophane-Infused Cosmetics

The emerging cellophane applications in the cosmetic industry are in the early stages of development, with a growing market potential driven by increasing demand for sustainable packaging solutions. The market size is expanding as major players like L'Oréal SA and Shiseido Co., Ltd. explore innovative uses for cellophane in cosmetic products. The technology's maturity is progressing, with companies such as Shin-Etsu Chemical Co., Ltd. and Eastman Chemical Co. investing in research and development to enhance cellophane's properties for cosmetic applications. While still evolving, the competitive landscape is becoming more diverse as both established cosmetic brands and specialty chemical manufacturers recognize the potential of cellophane in addressing consumer preferences for eco-friendly packaging solutions.

L'Oréal SA

Technical Solution: L'Oréal has developed innovative cellophane-based applications for cosmetic packaging and product delivery systems. Their approach includes using biodegradable cellophane films infused with active ingredients for sheet masks and patches[1]. These films dissolve upon contact with skin, releasing encapsulated skincare compounds. L'Oréal has also explored cellophane-based microfluidic devices for personalized cosmetic formulations, allowing precise control over ingredient ratios and delivery[3]. Additionally, they've incorporated cellophane into smart packaging solutions that can indicate product freshness and provide usage instructions through color-changing properties[5].

Strengths: Biodegradability, controlled release of active ingredients, potential for personalization. Weaknesses: Higher production costs, potential shelf-life limitations compared to traditional packaging.|

Shin-Etsu Chemical Co., Ltd.

Technical Solution: Shin-Etsu Chemical has developed advanced cellophane formulations specifically tailored for cosmetic applications. Their proprietary cellophane films feature enhanced barrier properties against moisture and oxygen, crucial for preserving sensitive cosmetic formulations[2]. The company has also introduced cellophane variants with adjustable transparency and gloss levels, allowing cosmetic brands to create visually appealing packaging[4]. Shin-Etsu's cellophane technology incorporates antimicrobial properties, extending the shelf life of cosmetic products without additional preservatives[6]. Furthermore, they've developed cellophane films with controlled permeability, enabling the gradual release of fragrances in perfume packaging.

Strengths: Superior barrier properties, customizable aesthetics, antimicrobial features. Weaknesses: Potentially higher cost compared to standard cellophane, limited biodegradability in some formulations.|

Innovative Cellophane Technologies in Cosmetics

method of forming an emulsion

PatentActiveFR3050109A1

Innovation

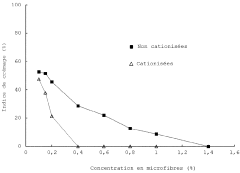

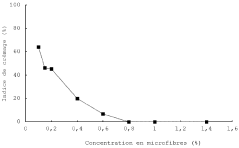

- A process involving cationization and in-situ fibrillation of cellulose fibers during emulsion formation, using cationized cellulose fibers as emulsifiers derived from plant sources like oats, achieving homogeneous and stable emulsions without additional preservatives.

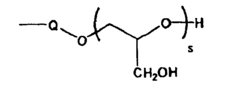

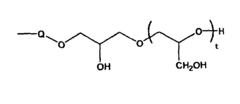

Polyhydric alcohol-modified silicone and cosmetic material containing same

PatentInactiveEP1213316B1

Innovation

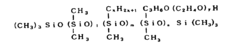

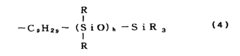

- A polyhydric alcohol-modified silicone compound is developed, which undergoes an addition reaction with an organohydrogen polysiloxane to enhance affinity with silicone oil bases and improve emulsifying power, stability, and skin compatibility, reducing viscosity and stickiness while maintaining water repellence.

Environmental Impact of Cellophane in Cosmetics

The environmental impact of cellophane in cosmetics is a growing concern as the industry increasingly adopts this material for packaging and product applications. Cellophane, derived from renewable wood pulp, offers a seemingly eco-friendly alternative to traditional plastic packaging. However, its environmental footprint is complex and multifaceted, requiring careful consideration.

One of the primary environmental advantages of cellophane is its biodegradability. Unlike conventional plastics, cellophane can decompose naturally in the environment, potentially reducing long-term pollution. This characteristic aligns with the cosmetic industry's growing emphasis on sustainability and eco-conscious consumer preferences. However, the biodegradation process may release methane, a potent greenhouse gas, if not properly managed in landfill conditions.

The production of cellophane also raises environmental concerns. The manufacturing process involves chemical treatments, including the use of carbon disulfide, which can have negative impacts on air and water quality if not properly controlled. Additionally, the energy-intensive nature of cellophane production contributes to its carbon footprint, potentially offsetting some of its environmental benefits.

Water usage in cellophane production is another significant environmental factor. The process requires substantial amounts of water, which can strain local water resources, especially in regions where water scarcity is a concern. This aspect necessitates careful consideration of production locations and water management practices.

The recyclability of cellophane in cosmetic packaging presents both opportunities and challenges. While technically recyclable, the infrastructure for cellophane recycling is not as widespread as that for other materials, potentially limiting its practical recyclability. Furthermore, when used in multi-layer packaging or combined with other materials in cosmetic products, cellophane can become difficult to separate and recycle effectively.

As the cosmetic industry explores innovative applications for cellophane, such as in face masks, hair wraps, and other beauty products, the environmental impact extends beyond packaging. The potential for microfiber shedding during use and disposal of these products raises concerns about microplastic pollution in aquatic environments, despite cellophane's biodegradable nature.

The end-of-life management of cellophane-based cosmetic products and packaging is crucial in determining their overall environmental impact. While biodegradable, cellophane may not decompose efficiently in all disposal environments, particularly in modern landfills designed to minimize degradation. This highlights the importance of developing appropriate waste management strategies and consumer education on proper disposal methods.

In conclusion, while cellophane offers certain environmental advantages over traditional plastics in cosmetic applications, its overall environmental impact is nuanced. The cosmetic industry must carefully weigh the benefits against the potential drawbacks, considering the entire lifecycle of cellophane-based products and packaging. Continued research and innovation in production methods, recycling technologies, and end-of-life management are essential to maximize the environmental benefits of cellophane in cosmetics while mitigating its negative impacts.

One of the primary environmental advantages of cellophane is its biodegradability. Unlike conventional plastics, cellophane can decompose naturally in the environment, potentially reducing long-term pollution. This characteristic aligns with the cosmetic industry's growing emphasis on sustainability and eco-conscious consumer preferences. However, the biodegradation process may release methane, a potent greenhouse gas, if not properly managed in landfill conditions.

The production of cellophane also raises environmental concerns. The manufacturing process involves chemical treatments, including the use of carbon disulfide, which can have negative impacts on air and water quality if not properly controlled. Additionally, the energy-intensive nature of cellophane production contributes to its carbon footprint, potentially offsetting some of its environmental benefits.

Water usage in cellophane production is another significant environmental factor. The process requires substantial amounts of water, which can strain local water resources, especially in regions where water scarcity is a concern. This aspect necessitates careful consideration of production locations and water management practices.

The recyclability of cellophane in cosmetic packaging presents both opportunities and challenges. While technically recyclable, the infrastructure for cellophane recycling is not as widespread as that for other materials, potentially limiting its practical recyclability. Furthermore, when used in multi-layer packaging or combined with other materials in cosmetic products, cellophane can become difficult to separate and recycle effectively.

As the cosmetic industry explores innovative applications for cellophane, such as in face masks, hair wraps, and other beauty products, the environmental impact extends beyond packaging. The potential for microfiber shedding during use and disposal of these products raises concerns about microplastic pollution in aquatic environments, despite cellophane's biodegradable nature.

The end-of-life management of cellophane-based cosmetic products and packaging is crucial in determining their overall environmental impact. While biodegradable, cellophane may not decompose efficiently in all disposal environments, particularly in modern landfills designed to minimize degradation. This highlights the importance of developing appropriate waste management strategies and consumer education on proper disposal methods.

In conclusion, while cellophane offers certain environmental advantages over traditional plastics in cosmetic applications, its overall environmental impact is nuanced. The cosmetic industry must carefully weigh the benefits against the potential drawbacks, considering the entire lifecycle of cellophane-based products and packaging. Continued research and innovation in production methods, recycling technologies, and end-of-life management are essential to maximize the environmental benefits of cellophane in cosmetics while mitigating its negative impacts.

Regulatory Framework for Cellophane in Cosmetics

The regulatory framework for cellophane in cosmetics is a complex and evolving landscape that requires careful navigation by manufacturers and industry stakeholders. As cellophane finds increasing applications in the cosmetic industry, regulatory bodies worldwide are adapting their guidelines to ensure consumer safety and product efficacy.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of cosmetic products and their ingredients, including cellophane. Under the Federal Food, Drug, and Cosmetic Act, cellophane used in cosmetics must be safe for its intended use and properly labeled. The FDA does not require pre-market approval for cosmetic products or ingredients, but it does have the authority to take action against products that are adulterated or misbranded.

The European Union, through its Cosmetic Regulation (EC) No 1223/2009, has established a comprehensive framework for cosmetic products. While cellophane is not explicitly listed in the regulation's annexes, it falls under the general safety assessment requirements for cosmetic ingredients. Manufacturers must ensure that cellophane used in cosmetic products does not pose any risk to human health when applied under normal or reasonably foreseeable conditions of use.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetics under the Pharmaceutical Affairs Law. Cellophane, when used in cosmetic applications, must comply with the standards set forth in the Japanese Standards of Quasi-Drug Ingredients. These standards outline specific requirements for purity, quality, and safety of cosmetic ingredients.

Globally, the International Organization for Standardization (ISO) has developed standards that are relevant to cellophane use in cosmetics, such as ISO 22716:2007 for Good Manufacturing Practices (GMP) in the cosmetics industry. These standards help ensure the quality and safety of cosmetic products, including those incorporating cellophane.

As the use of cellophane in cosmetics expands, regulatory bodies are likely to develop more specific guidelines. Industry associations, such as the Personal Care Products Council in the U.S. and Cosmetics Europe, play a crucial role in working with regulators to establish appropriate standards and best practices for emerging materials like cellophane in cosmetic applications.

Manufacturers and formulators must stay informed about the latest regulatory developments and conduct thorough safety assessments to ensure compliance. This includes evaluating the potential for allergenicity, irritation, and long-term effects of cellophane when used in various cosmetic formulations. Additionally, as sustainability becomes increasingly important in regulatory considerations, the environmental impact of cellophane production and disposal may also factor into future regulatory frameworks for its use in cosmetics.

In the United States, the Food and Drug Administration (FDA) oversees the regulation of cosmetic products and their ingredients, including cellophane. Under the Federal Food, Drug, and Cosmetic Act, cellophane used in cosmetics must be safe for its intended use and properly labeled. The FDA does not require pre-market approval for cosmetic products or ingredients, but it does have the authority to take action against products that are adulterated or misbranded.

The European Union, through its Cosmetic Regulation (EC) No 1223/2009, has established a comprehensive framework for cosmetic products. While cellophane is not explicitly listed in the regulation's annexes, it falls under the general safety assessment requirements for cosmetic ingredients. Manufacturers must ensure that cellophane used in cosmetic products does not pose any risk to human health when applied under normal or reasonably foreseeable conditions of use.

In Japan, the Ministry of Health, Labour and Welfare regulates cosmetics under the Pharmaceutical Affairs Law. Cellophane, when used in cosmetic applications, must comply with the standards set forth in the Japanese Standards of Quasi-Drug Ingredients. These standards outline specific requirements for purity, quality, and safety of cosmetic ingredients.

Globally, the International Organization for Standardization (ISO) has developed standards that are relevant to cellophane use in cosmetics, such as ISO 22716:2007 for Good Manufacturing Practices (GMP) in the cosmetics industry. These standards help ensure the quality and safety of cosmetic products, including those incorporating cellophane.

As the use of cellophane in cosmetics expands, regulatory bodies are likely to develop more specific guidelines. Industry associations, such as the Personal Care Products Council in the U.S. and Cosmetics Europe, play a crucial role in working with regulators to establish appropriate standards and best practices for emerging materials like cellophane in cosmetic applications.

Manufacturers and formulators must stay informed about the latest regulatory developments and conduct thorough safety assessments to ensure compliance. This includes evaluating the potential for allergenicity, irritation, and long-term effects of cellophane when used in various cosmetic formulations. Additionally, as sustainability becomes increasingly important in regulatory considerations, the environmental impact of cellophane production and disposal may also factor into future regulatory frameworks for its use in cosmetics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!