Enhancing HDPE's UV Resistance for Outdoor Use

HDPE UV Resistance Background and Objectives

High-density polyethylene (HDPE) has been a cornerstone material in various industries since its commercial introduction in the 1950s. Its exceptional strength-to-density ratio, chemical resistance, and versatility have made it a preferred choice for numerous applications. However, when exposed to outdoor environments, HDPE faces a significant challenge: ultraviolet (UV) radiation degradation.

The evolution of HDPE's UV resistance technology has been driven by the growing demand for durable outdoor products. Initially, HDPE was primarily used for indoor applications due to its poor UV stability. As the material's potential for outdoor use became apparent, researchers and manufacturers began exploring ways to enhance its UV resistance.

The primary objective in enhancing HDPE's UV resistance is to extend the material's service life in outdoor applications while maintaining its desirable mechanical and chemical properties. This involves developing strategies to prevent or slow down the photo-oxidation process that occurs when HDPE is exposed to UV radiation.

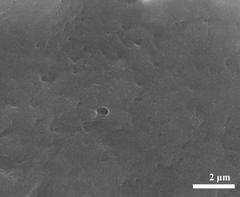

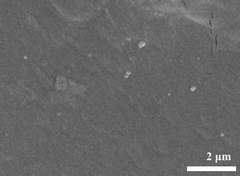

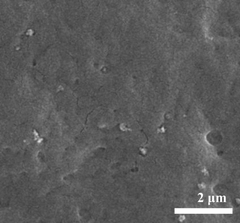

UV degradation in HDPE manifests as surface cracking, discoloration, and a reduction in mechanical properties. These effects are caused by the breaking of polymer chains and the formation of free radicals, which lead to further degradation. The challenge lies in interrupting this process without compromising the inherent properties that make HDPE valuable.

Over the years, several approaches have been explored to enhance HDPE's UV resistance. These include the incorporation of UV stabilizers, such as hindered amine light stabilizers (HALS) and UV absorbers, into the polymer matrix. Another strategy involves the use of carbon black as a UV-blocking agent, which has proven effective but limits color options.

Recent technological advancements have focused on developing more sophisticated UV stabilization systems. These include synergistic combinations of different types of stabilizers, nanocomposite technologies, and surface treatments. The goal is to achieve long-term UV stability without significantly altering the material's cost or processability.

The current technological landscape presents both opportunities and challenges. While significant progress has been made in UV stabilization techniques, there is still room for improvement in terms of efficiency, cost-effectiveness, and environmental sustainability. The development of bio-based UV stabilizers and the exploration of novel polymer architectures are emerging areas of research that hold promise for future innovations.

As we look towards the future, the objectives for enhancing HDPE's UV resistance are multifaceted. They include developing more effective and environmentally friendly stabilization methods, improving the prediction and modeling of long-term outdoor performance, and creating tailored solutions for specific application requirements. These efforts aim to expand HDPE's use in demanding outdoor applications, from construction materials to agricultural products, ultimately contributing to more durable and sustainable plastic solutions.

Market Analysis for UV-Resistant HDPE Products

The market for UV-resistant HDPE products has been experiencing significant growth in recent years, driven by the increasing demand for durable outdoor materials across various industries. The global UV-resistant HDPE market is projected to expand at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2026, reaching a market value of $3.2 billion by the end of the forecast period.

The construction industry remains the largest consumer of UV-resistant HDPE products, accounting for approximately 40% of the market share. This sector utilizes UV-resistant HDPE in applications such as outdoor furniture, playground equipment, and building materials. The growing emphasis on sustainable and long-lasting construction materials has further boosted the demand for UV-resistant HDPE in this sector.

The agriculture industry is another significant consumer of UV-resistant HDPE products, particularly for greenhouse coverings, irrigation systems, and storage containers. The market share for agricultural applications is expected to grow at a CAGR of 7.2% during the forecast period, driven by the increasing adoption of precision farming techniques and the need for weather-resistant materials.

Geographically, North America and Europe currently dominate the UV-resistant HDPE market, collectively accounting for over 60% of the global market share. However, the Asia-Pacific region is expected to witness the highest growth rate, with a CAGR of 8.1% from 2021 to 2026. This growth is attributed to rapid industrialization, urbanization, and increasing investments in infrastructure development in countries like China and India.

The automotive industry is emerging as a promising market for UV-resistant HDPE products, particularly in the manufacturing of exterior components such as bumpers, trims, and body panels. The lightweight and durable nature of UV-resistant HDPE aligns well with the automotive industry's focus on fuel efficiency and sustainability.

Key market trends include the development of advanced UV stabilizers and additives to enhance the performance of HDPE in outdoor applications. Manufacturers are investing in research and development to create HDPE formulations that offer improved UV resistance without compromising other material properties such as strength and flexibility.

The market is also witnessing a shift towards bio-based and recycled UV-resistant HDPE products, driven by growing environmental concerns and stringent regulations on plastic usage. This trend is expected to create new opportunities for market players and reshape the competitive landscape in the coming years.

Current Challenges in HDPE UV Protection

High-density polyethylene (HDPE) is widely used in outdoor applications due to its excellent mechanical properties and chemical resistance. However, its susceptibility to UV degradation poses significant challenges for long-term outdoor use. The current challenges in HDPE UV protection stem from several factors that limit the effectiveness of existing solutions.

One of the primary challenges is the inherent chemical structure of HDPE. The polymer's long hydrocarbon chains are susceptible to photo-oxidation when exposed to UV radiation, leading to chain scission and subsequent deterioration of mechanical properties. This vulnerability is particularly pronounced in outdoor environments where prolonged exposure to sunlight is inevitable.

The effectiveness of traditional UV stabilizers is another area of concern. While hindered amine light stabilizers (HALS) and UV absorbers have been widely used, their long-term performance in HDPE remains suboptimal. These additives can migrate to the surface over time, reducing their protective capacity and potentially leaching into the environment. Additionally, the high loadings required for effective protection can negatively impact the material's mechanical properties and processability.

Color stability presents another challenge in HDPE UV protection. Many outdoor HDPE products require specific colors for aesthetic or functional purposes. However, UV exposure can cause significant color fading or yellowing, compromising both appearance and performance. Developing UV-stable colorants that maintain their integrity over extended periods remains a technical hurdle.

The heterogeneous nature of HDPE products further complicates UV protection strategies. Different parts of a product may experience varying levels of UV exposure, leading to uneven degradation. This non-uniform deterioration can result in localized weak points and premature failure of the entire product.

Environmental factors also play a crucial role in the challenges faced by HDPE UV protection. Extreme temperatures, humidity, and pollutants can interact with UV radiation, accelerating the degradation process. Developing UV protection systems that remain effective across a wide range of environmental conditions is a significant challenge.

Cost considerations present an additional obstacle. While more advanced UV protection technologies exist, their implementation often comes at a premium. Balancing the need for enhanced UV resistance with economic viability is a constant challenge for manufacturers, particularly in competitive markets where price sensitivity is high.

Lastly, the regulatory landscape surrounding UV stabilizers and additives is becoming increasingly stringent. Concerns over the environmental impact and potential health effects of certain UV protection chemicals have led to restrictions or bans in some regions. This regulatory pressure necessitates the development of new, environmentally friendly UV protection solutions that comply with evolving standards while maintaining effectiveness.

Existing UV Stabilization Methods for HDPE

01 UV stabilizers and antioxidants

Incorporating UV stabilizers and antioxidants into HDPE formulations enhances its resistance to UV radiation. These additives protect the polymer chains from degradation caused by sunlight exposure, extending the material's lifespan and maintaining its mechanical properties over time.- UV stabilizers and antioxidants for HDPE: Incorporating UV stabilizers and antioxidants into HDPE formulations enhances its resistance to UV radiation. These additives protect the polymer chains from degradation caused by sunlight exposure, extending the material's lifespan and maintaining its mechanical properties over time.

- Nanocomposite HDPE materials: Developing nanocomposite HDPE materials by incorporating nanoparticles or nanoclays improves UV resistance. These nanofillers can act as UV absorbers or scatterers, providing enhanced protection against UV-induced degradation while maintaining or improving other material properties.

- Surface treatments and coatings: Applying surface treatments or UV-resistant coatings to HDPE products enhances their UV resistance. These treatments can include plasma treatment, chemical modification, or the application of specialized UV-blocking coatings, creating a protective layer on the HDPE surface.

- Blending with other polymers: Blending HDPE with other UV-resistant polymers or elastomers can improve its overall UV resistance. This approach combines the desirable properties of HDPE with the UV-resistant characteristics of other materials, resulting in a more durable composite.

- Optimized processing techniques: Employing optimized processing techniques during HDPE manufacturing can enhance its UV resistance. This includes controlling processing parameters such as temperature, pressure, and cooling rates to achieve a more uniform and stable polymer structure that is less susceptible to UV degradation.

02 Nanocomposite materials

Developing HDPE nanocomposites by adding nanoparticles or nanofillers improves UV resistance. These nanocomposites can enhance the material's barrier properties against UV radiation, resulting in better long-term performance in outdoor applications.Expand Specific Solutions03 Surface treatments and coatings

Applying surface treatments or UV-resistant coatings to HDPE products can significantly improve their UV resistance. These treatments create a protective layer that absorbs or reflects UV radiation, preventing it from penetrating and damaging the underlying material.Expand Specific Solutions04 Polymer blending and copolymerization

Blending HDPE with other UV-resistant polymers or copolymerizing it with monomers that have inherent UV resistance can enhance the overall UV stability of the material. This approach combines the desirable properties of HDPE with improved UV resistance.Expand Specific Solutions05 Optimized processing techniques

Employing specialized processing techniques during HDPE manufacturing can improve its UV resistance. These techniques may include controlled cooling rates, orientation processes, or the use of specific catalysts that promote the formation of UV-resistant molecular structures within the polymer.Expand Specific Solutions

Key Players in UV-Resistant HDPE Industry

The market for enhancing HDPE's UV resistance for outdoor use is in a growth phase, driven by increasing demand for durable outdoor products. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like DSM IP Assets BV, ExxonMobil Chemical Patents, Inc., and NOVA Chemicals Corp. leading innovation. These firms are developing advanced UV stabilizers and additives to improve HDPE's performance. Other players such as Sinopec Yangzi Petrochemical Co., Ltd. and Braskem SA are also contributing to technological advancements, focusing on enhancing HDPE's long-term outdoor durability and weatherability.

DSM IP Assets BV

China Petroleum & Chemical Corp.

Innovative UV Resistance Technologies for HDPE

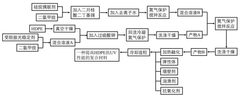

- By introducing light stabilizers, silane cross-linking technology and melt blending technology, HDPE materials are modified to improve their UV resistance, mechanical properties, water resistance, flexibility and braidability. Specific methods include chemical grafting to firmly bind the light stabilizer to the HDPE molecular structure, enhancing the mechanical properties and waterproofness of the material through silane cross-linking technology, and improving the flexibility and impact resistance of the material through a melt blending process.

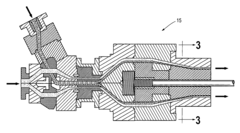

- A twin-layer polyethylene pipe is produced through co-extrusion, with a UV-resistant and oxidation-resistant outer layer and an inner layer protected by an inert gas blanket during and after extrusion, minimizing antioxidant usage and preventing oxygen-induced degradation.

Environmental Impact of UV-Resistant HDPE

The environmental impact of UV-resistant HDPE is a critical consideration in the development and application of this enhanced material. While improving the durability and longevity of HDPE products for outdoor use, the addition of UV-resistant properties also introduces new environmental factors that must be carefully evaluated.

One of the primary environmental benefits of UV-resistant HDPE is the extended lifespan of products made from this material. By reducing degradation caused by UV radiation, these products remain functional for longer periods, potentially reducing the need for frequent replacements. This longevity can lead to a decrease in overall plastic waste generation and the associated environmental burdens of production and disposal.

However, the addition of UV stabilizers to HDPE raises concerns about the potential release of these additives into the environment. As UV-resistant HDPE products weather over time, there is a risk that the stabilizing compounds may leach out and contaminate soil or water systems. The ecological impact of these additives on various organisms and ecosystems requires thorough investigation to ensure that the benefits of UV resistance do not come at the cost of introducing harmful substances into the environment.

The recyclability of UV-resistant HDPE is another important environmental consideration. While HDPE is generally recyclable, the presence of UV stabilizers may complicate the recycling process or affect the quality of recycled materials. It is crucial to assess whether the addition of UV-resistant properties impacts the material's ability to be effectively recycled and reused, as this could influence the overall sustainability of UV-resistant HDPE products.

The production process for UV-resistant HDPE may also have environmental implications. The synthesis and incorporation of UV stabilizers could potentially increase energy consumption or require additional chemical processes, leading to a larger carbon footprint compared to standard HDPE production. A comprehensive life cycle assessment is necessary to quantify these impacts and compare them to the environmental benefits gained from the material's extended lifespan.

Furthermore, the improved durability of UV-resistant HDPE may have indirect environmental effects. For instance, in agricultural applications, longer-lasting materials could reduce the frequency of plastic film replacement, potentially decreasing soil disturbance and associated environmental impacts. Similarly, in construction and infrastructure, the use of more durable materials could lead to reduced maintenance and replacement activities, potentially lowering overall resource consumption and emissions associated with these processes.

As the adoption of UV-resistant HDPE increases, it is essential to monitor its long-term environmental performance. This includes studying the material's degradation patterns in various environmental conditions, assessing the fate of UV stabilizers in different ecosystems, and evaluating the material's impact on wildlife and habitats. Such ongoing research will be crucial in refining the formulation of UV-resistant HDPE to minimize negative environmental impacts while maximizing its beneficial properties.

Cost-Benefit Analysis of Enhanced UV-Resistant HDPE

The cost-benefit analysis of enhanced UV-resistant HDPE is a critical consideration for manufacturers and end-users alike. The primary benefit of incorporating UV resistance into HDPE products is the significant extension of their service life when exposed to outdoor conditions. This increased durability translates to reduced replacement frequency, resulting in long-term cost savings for consumers and businesses.

Initial production costs for UV-resistant HDPE are typically higher due to the addition of UV stabilizers and other protective additives. These additives can increase raw material costs by 5-15%, depending on the level of UV protection required. However, this upfront investment is often offset by the extended lifespan of the products, which can be two to three times longer than standard HDPE in outdoor applications.

The enhanced UV resistance also contributes to maintaining the mechanical properties of HDPE over time. This preservation of strength and flexibility reduces the risk of product failure, potentially lowering liability costs and improving safety in various applications, such as outdoor furniture, playground equipment, and construction materials.

From an environmental perspective, UV-resistant HDPE offers benefits in terms of reduced waste generation. The longer lifespan of these products means fewer replacements and less plastic waste entering landfills or recycling streams. This aligns with growing consumer demand for more sustainable products and can enhance a company's environmental credentials.

Market analysis indicates that consumers are increasingly willing to pay a premium for products with enhanced durability and UV resistance, particularly in regions with high UV exposure. This trend suggests that the higher initial costs of UV-resistant HDPE can be passed on to consumers without significantly impacting demand.

For manufacturers, the adoption of UV-resistant HDPE technology may require some initial investment in production processes and quality control measures. However, these costs are typically outweighed by the potential for product differentiation and access to premium market segments.

In sectors such as agriculture and outdoor infrastructure, the use of UV-resistant HDPE can lead to substantial savings in maintenance and replacement costs. For example, UV-resistant HDPE pipes used in irrigation systems or outdoor electrical conduits can remain functional for decades, reducing the need for frequent excavation and replacement.

Overall, while the initial costs of producing UV-resistant HDPE are higher, the long-term benefits in terms of product longevity, reduced maintenance, and enhanced sustainability make it an economically viable option for many outdoor applications. The cost-benefit ratio improves significantly when considering the full lifecycle of the products and the potential for increased market share in premium segments.