Graphene Oxide: Revolutionizing Sensor Technologies

Graphene Oxide Sensor Evolution and Objectives

Graphene oxide has emerged as a revolutionary material in the field of sensor technologies, marking a significant milestone in the evolution of advanced sensing devices. The journey of graphene oxide in sensor applications began with the discovery of graphene in 2004, which sparked intense research into its derivatives. As scientists explored the potential of graphene-based materials, graphene oxide quickly gained attention due to its unique properties and versatility.

The development of graphene oxide sensors has been driven by the increasing demand for highly sensitive, rapid, and cost-effective sensing solutions across various industries. From environmental monitoring to healthcare diagnostics, the need for advanced sensor technologies has propelled the exploration of graphene oxide's capabilities. The material's exceptional surface area, tunable electronic properties, and abundant functional groups have positioned it as a promising candidate for next-generation sensors.

Over the past decade, researchers have made significant strides in harnessing the potential of graphene oxide for sensor applications. Early efforts focused on understanding the fundamental properties of graphene oxide and developing methods for its synthesis and functionalization. As the field progressed, scientists began to explore various sensing mechanisms, including electrochemical, optical, and field-effect sensing, leveraging the unique characteristics of graphene oxide.

The evolution of graphene oxide sensors has been marked by several key objectives. Firstly, researchers have aimed to enhance the sensitivity and selectivity of these sensors, pushing the boundaries of detection limits and specificity. Secondly, efforts have been directed towards improving the stability and reproducibility of graphene oxide-based sensing platforms, addressing challenges related to long-term performance and reliability. Additionally, there has been a focus on developing scalable and cost-effective production methods to facilitate the commercialization of graphene oxide sensors.

Looking ahead, the objectives for graphene oxide sensor technologies continue to evolve. Current research is aimed at expanding the range of detectable analytes, exploring novel sensing mechanisms, and integrating graphene oxide sensors into multifunctional devices. There is also a growing emphasis on developing flexible and wearable sensors, leveraging the mechanical properties of graphene oxide. Furthermore, researchers are exploring the potential of hybrid materials, combining graphene oxide with other nanomaterials to create synergistic sensing platforms with enhanced performance and functionality.

Market Demand for Advanced Sensor Technologies

The market demand for advanced sensor technologies has been experiencing significant growth in recent years, driven by the increasing need for more accurate, sensitive, and versatile sensing capabilities across various industries. This demand is particularly evident in sectors such as healthcare, environmental monitoring, industrial automation, and consumer electronics.

In the healthcare sector, there is a growing requirement for advanced biosensors capable of detecting minute quantities of biomarkers, pathogens, and other biological molecules. These sensors are crucial for early disease detection, personalized medicine, and continuous health monitoring. The global biosensors market is expected to expand rapidly, with a focus on wearable and implantable devices for real-time health tracking.

Environmental monitoring is another area driving the demand for advanced sensors. With increasing concerns about air and water quality, climate change, and pollution, there is a pressing need for sensors that can detect and measure various pollutants and environmental parameters with high precision. This includes sensors for detecting greenhouse gases, particulate matter, and water contaminants.

In the industrial sector, the rise of Industry 4.0 and the Internet of Things (IoT) has created a surge in demand for smart sensors capable of real-time data collection and analysis. These sensors are essential for predictive maintenance, process optimization, and quality control in manufacturing and other industrial applications. The industrial sensor market is projected to grow substantially as more companies adopt smart manufacturing practices.

The consumer electronics industry is also a significant driver of demand for advanced sensor technologies. Smartphones, wearables, and smart home devices increasingly rely on sophisticated sensors for features such as facial recognition, gesture control, and environmental sensing. The trend towards more immersive and interactive user experiences is pushing the boundaries of sensor capabilities in consumer products.

Automotive and transportation sectors are witnessing a rising demand for advanced sensors, particularly with the development of autonomous vehicles and advanced driver assistance systems (ADAS). These applications require a wide array of sensors, including LiDAR, radar, and various types of optical sensors for navigation, obstacle detection, and safety features.

The emergence of smart cities and infrastructure projects is creating new opportunities for sensor technologies. There is a growing need for sensors that can monitor traffic flow, energy consumption, structural health of buildings and bridges, and various urban environmental parameters.

As the demand for advanced sensor technologies continues to grow, there is an increasing focus on developing sensors with improved sensitivity, selectivity, and reliability. This has led to significant research and development efforts in materials science, nanotechnology, and advanced manufacturing techniques to create next-generation sensors that can meet these evolving market needs.

Current Graphene Oxide Sensor Challenges

Despite the promising potential of graphene oxide (GO) in sensor technologies, several significant challenges currently hinder its widespread adoption and optimal performance. One of the primary issues is the lack of consistency in GO production methods, leading to variations in material quality and properties. This inconsistency affects sensor reproducibility and reliability, making it difficult to standardize GO-based sensors for commercial applications.

Another major challenge lies in the stability of GO sensors under various environmental conditions. GO is highly sensitive to humidity and temperature changes, which can alter its electrical and mechanical properties. This sensitivity, while beneficial for certain sensing applications, can also lead to false readings or reduced sensor longevity in real-world environments.

The selectivity of GO sensors remains a significant hurdle, particularly in complex matrices. While GO exhibits high sensitivity to various analytes, it often lacks the ability to discriminate between similar molecules effectively. This limitation can result in cross-reactivity and false positives, especially in applications requiring precise detection of specific compounds in mixed samples.

Signal-to-noise ratio optimization is another critical challenge in GO sensor development. The high surface area and abundant functional groups of GO, while advantageous for sensing, can also lead to increased background noise. This issue is particularly pronounced in electrochemical and optical sensing platforms, where distinguishing true signals from background interference is crucial for accurate measurements.

The scalability of GO sensor production presents both technical and economic challenges. While laboratory-scale synthesis and sensor fabrication have shown promising results, translating these processes to industrial-scale production while maintaining quality and cost-effectiveness remains difficult. This scalability issue is a significant barrier to the widespread commercialization of GO-based sensors.

Furthermore, the long-term stability and durability of GO sensors are areas of ongoing concern. GO's tendency to agglomerate over time and its susceptibility to chemical and physical changes can lead to sensor degradation and reduced performance. Developing strategies to enhance the long-term stability of GO-based sensing platforms is crucial for their practical implementation in real-world applications.

Lastly, the integration of GO sensors with existing electronic systems and readout technologies poses significant challenges. Developing compatible interfaces and signal processing methods that can effectively harness the unique properties of GO while seamlessly integrating with current sensing infrastructures is an area requiring further research and development.

Existing Graphene Oxide Sensor Solutions

01 Graphene oxide-based gas sensors

Graphene oxide is utilized in the development of highly sensitive gas sensors. These sensors can detect various gases and volatile organic compounds with high selectivity and fast response times. The unique properties of graphene oxide, such as its large surface area and tunable electronic properties, make it an ideal material for gas sensing applications.- Graphene oxide-based gas sensors: Graphene oxide is utilized in the development of highly sensitive gas sensors. These sensors can detect various gases and volatile organic compounds with high selectivity and fast response times. The unique properties of graphene oxide, such as its large surface area and excellent electrical conductivity, make it an ideal material for gas sensing applications.

- Graphene oxide-based biosensors: Graphene oxide is employed in the creation of biosensors for detecting biological molecules and pathogens. These biosensors offer high sensitivity and specificity in detecting various biomolecules, including proteins, DNA, and enzymes. The functionalization of graphene oxide with specific recognition elements enhances its biosensing capabilities.

- Graphene oxide-based electrochemical sensors: Electrochemical sensors utilizing graphene oxide demonstrate enhanced performance in detecting various analytes. These sensors exhibit improved electron transfer rates and electrocatalytic activity, leading to higher sensitivity and lower detection limits. The incorporation of graphene oxide in electrodes also increases the stability and durability of the sensors.

- Graphene oxide-based optical sensors: Optical sensors based on graphene oxide exploit its unique optical properties for sensing applications. These sensors utilize phenomena such as fluorescence quenching or enhancement, surface plasmon resonance, and Raman scattering to detect various analytes. The optical properties of graphene oxide can be tuned by controlling its oxidation state and functionalization.

- Graphene oxide sensor fabrication techniques: Various fabrication techniques are employed to produce graphene oxide-based sensors with improved performance and reproducibility. These methods include chemical vapor deposition, solution-based processing, and printing techniques. The development of scalable and cost-effective fabrication processes is crucial for the widespread adoption of graphene oxide sensors in practical applications.

02 Graphene oxide-based biosensors

Graphene oxide is employed in the creation of biosensors for detecting biomolecules and monitoring biological processes. These sensors can be used for various applications, including medical diagnostics, environmental monitoring, and food safety. The high sensitivity and biocompatibility of graphene oxide make it suitable for detecting proteins, nucleic acids, and other biological molecules.Expand Specific Solutions03 Graphene oxide-based electrochemical sensors

Electrochemical sensors utilizing graphene oxide are developed for detecting various analytes in liquid environments. These sensors offer high sensitivity, wide linear range, and low detection limits for applications in environmental monitoring, pharmaceutical analysis, and industrial process control. The excellent electrical conductivity and large surface area of graphene oxide contribute to improved sensor performance.Expand Specific Solutions04 Functionalization of graphene oxide for sensor applications

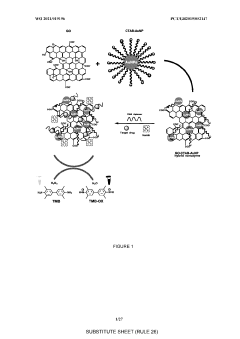

Various methods are employed to functionalize graphene oxide, enhancing its sensing capabilities and selectivity towards specific target molecules. Functionalization techniques include chemical modification, doping with heteroatoms, and incorporation of nanoparticles or biomolecules. These modifications improve the sensor's performance, stability, and specificity for different analytes.Expand Specific Solutions05 Graphene oxide-based flexible and wearable sensors

Graphene oxide is utilized in the development of flexible and wearable sensors for various applications, including health monitoring, environmental sensing, and human-machine interfaces. The mechanical flexibility and electrical properties of graphene oxide enable the creation of sensors that can be integrated into clothing, skin patches, or other wearable devices, providing real-time monitoring capabilities.Expand Specific Solutions

Key Players in Graphene Oxide Sensor Industry

The field of graphene oxide sensor technologies is in a dynamic growth phase, with a rapidly expanding market and increasing technological maturity. The global market for graphene-based sensors is projected to reach significant scale, driven by applications in electronics, healthcare, and environmental monitoring. Technological advancements are accelerating, with key players like The University of Manchester, Naval Research Laboratory, and Shanghai Integrated Circuit Research & Development Center leading innovation. Companies such as Flextrapower, Inc. and Archer Materials Ltd. are commercializing these technologies, while academic institutions like the Indian Institute of Science and University of Electronic Science & Technology of China are pushing the boundaries of research. The collaboration between industry and academia is fostering rapid progress, indicating a competitive yet collaborative landscape.

The University of Manchester

Naval Research Laboratory

Core Innovations in Graphene Oxide Sensors

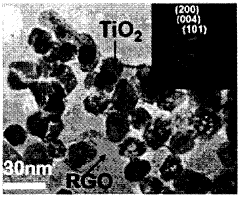

- A device based on a hydrophilic and reduced graphene oxide matrix decorated with TiO2, ZnO, and iron oxide nanoparticles, where the graphene-based nanocomposite material is deposited on a suitable substrate to detect heavy-metal complexes through selective surface complexation and charge-based interactions, utilizing modified Hummer's method for synthesis and one-pot reduction for grafting nanoparticles, enhancing detection capabilities.

- Development of hybrid nanozyme materials combining graphene oxide and metal nanoparticles with aptamer molecules, which catalyze chromogenic substrates in the presence of hydrogen peroxide, enabling selective and sensitive colorimetric detection of illicit substances without the need for external receptors.

Environmental Impact of Graphene Oxide Sensors

The environmental impact of graphene oxide sensors is a critical consideration as this technology gains prominence in various applications. Graphene oxide, while offering exceptional sensing capabilities, also presents potential environmental concerns that must be carefully evaluated.

One of the primary environmental advantages of graphene oxide sensors is their potential to reduce overall material consumption. Due to their high sensitivity and efficiency, these sensors can often replace larger, more resource-intensive devices. This reduction in material usage can lead to decreased environmental footprints in manufacturing processes and waste generation.

However, the production of graphene oxide itself raises environmental questions. The synthesis of graphene oxide typically involves the use of strong oxidizing agents and acids, which can generate hazardous waste if not properly managed. Efforts are underway to develop more environmentally friendly production methods, such as electrochemical exfoliation or green reduction processes, which could significantly mitigate these concerns.

The disposal of graphene oxide sensors at the end of their lifecycle is another important environmental consideration. While graphene oxide is generally considered non-toxic, its nanoscale size raises concerns about potential bioaccumulation in ecosystems if improperly disposed of. Research is ongoing to understand the long-term environmental fate of graphene oxide and to develop safe disposal or recycling methods.

On the positive side, graphene oxide sensors have the potential to contribute significantly to environmental monitoring and protection. Their high sensitivity and versatility make them excellent tools for detecting pollutants, monitoring air and water quality, and tracking environmental changes. This capability could lead to more effective environmental management strategies and early warning systems for ecological threats.

The energy efficiency of graphene oxide sensors is another environmental benefit. These sensors often require less power to operate compared to traditional sensing technologies, potentially reducing energy consumption in various applications. This energy efficiency could translate to lower carbon footprints for sensor-equipped devices and systems.

As research progresses, the focus is increasingly on developing graphene oxide sensors that are not only high-performing but also environmentally sustainable throughout their lifecycle. This includes exploring biodegradable substrates, environmentally friendly functionalization methods, and designs that facilitate easy recycling or safe disposal.

In conclusion, while graphene oxide sensors offer significant potential for environmental monitoring and resource efficiency, their overall environmental impact depends on responsible production, use, and disposal practices. Ongoing research and development efforts are crucial to maximizing the environmental benefits of this technology while minimizing potential risks.

Graphene Oxide Sensor Fabrication Techniques

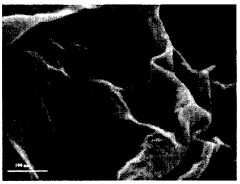

Graphene oxide (GO) sensor fabrication techniques have evolved rapidly in recent years, offering innovative approaches to create highly sensitive and selective sensing devices. The most common methods include solution-based processes, such as drop-casting, spin-coating, and spray coating. These techniques allow for the deposition of GO onto various substrates, forming thin films with controllable thickness and uniformity.

Drop-casting involves depositing a GO solution onto a substrate and allowing it to dry naturally or under controlled conditions. This method is simple and cost-effective but may result in non-uniform film thickness. Spin-coating, on the other hand, utilizes centrifugal force to spread the GO solution evenly across the substrate, producing more uniform films with precise thickness control. Spray coating offers the advantage of covering large areas and complex geometries, making it suitable for industrial-scale production.

Another widely used technique is the Langmuir-Blodgett (LB) method, which enables the formation of highly ordered GO monolayers or multilayers. This approach involves spreading GO sheets on a liquid surface and compressing them to form a densely packed layer, which is then transferred onto a solid substrate. The LB method allows for precise control over film thickness and orientation of GO sheets.

Electrophoretic deposition (EPD) has gained attention for its ability to create uniform GO coatings on conductive substrates. In this process, an electric field is applied to a GO suspension, causing the negatively charged GO sheets to migrate towards the positively charged electrode and deposit on its surface. EPD offers advantages such as rapid deposition, good control over film thickness, and the ability to coat complex geometries.

Layer-by-layer (LbL) assembly is another promising technique for GO sensor fabrication. This method involves the sequential deposition of oppositely charged polyelectrolytes and GO sheets, allowing for precise control over film thickness and composition. LbL assembly enables the incorporation of additional functional materials, enhancing the sensor's performance and versatility.

Recent advancements in 3D printing technologies have also been applied to GO sensor fabrication. Direct ink writing and stereolithography techniques using GO-based inks have been developed to create complex 3D structures with high precision. These methods offer unprecedented flexibility in sensor design and enable the fabrication of customized sensing devices for specific applications.

In conclusion, the diverse range of GO sensor fabrication techniques provides researchers and manufacturers with a versatile toolbox to create tailored sensing devices. The choice of fabrication method depends on factors such as desired sensor performance, substrate compatibility, scalability, and cost-effectiveness. As research in this field continues to advance, new and improved fabrication techniques are likely to emerge, further expanding the potential applications of GO-based sensors.