HDPE and 3D Printing: Exploring New Possibilities

HDPE 3D Printing Background and Objectives

High-density polyethylene (HDPE) has been a staple material in various industries for decades, known for its durability, chemical resistance, and versatility. As 3D printing technology continues to evolve, the exploration of HDPE as a potential material for additive manufacturing has gained significant attention. This convergence of a well-established polymer with cutting-edge fabrication techniques presents an exciting frontier in materials science and manufacturing.

The journey of HDPE in 3D printing began with the recognition of its potential to overcome limitations associated with traditional 3D printing materials. HDPE's unique properties, including its high strength-to-density ratio, excellent chemical resistance, and low cost, make it an attractive candidate for a wide range of applications. However, the challenges associated with processing HDPE for 3D printing have historically limited its widespread adoption in this field.

Recent technological advancements have reignited interest in HDPE 3D printing, driven by the growing demand for sustainable and recyclable materials in additive manufacturing. The ability to repurpose common HDPE products, such as milk jugs and detergent bottles, into 3D printing filament aligns with global efforts to reduce plastic waste and promote circular economy principles.

The primary objective of exploring HDPE in 3D printing is to develop robust, cost-effective, and environmentally friendly manufacturing solutions. Researchers and industry professionals aim to optimize printing parameters, enhance material properties, and expand the range of applications for HDPE-printed objects. This includes improving print quality, increasing dimensional accuracy, and developing new composite materials that leverage HDPE's unique characteristics.

Another key goal is to address the technical challenges associated with HDPE 3D printing, such as warping, poor layer adhesion, and inconsistent extrusion. Overcoming these obstacles requires innovative approaches to filament production, printer design, and post-processing techniques. Success in these areas could potentially revolutionize the use of HDPE in additive manufacturing, opening up new possibilities in industries ranging from automotive and aerospace to consumer goods and medical devices.

As the field progresses, there is a growing focus on understanding the relationship between HDPE's molecular structure, processing conditions, and the resulting properties of 3D printed objects. This fundamental research is crucial for developing predictive models and design guidelines that will enable the widespread adoption of HDPE in 3D printing applications.

Market Analysis for HDPE 3D Printing Applications

The market for HDPE 3D printing applications is experiencing significant growth, driven by the material's unique properties and the expanding capabilities of additive manufacturing technologies. High-Density Polyethylene (HDPE) offers excellent chemical resistance, durability, and low cost, making it an attractive option for various industries seeking to leverage 3D printing for prototyping and production.

In the automotive sector, HDPE 3D printing is gaining traction for producing lightweight, durable parts such as fluid containers, ducting components, and interior trim pieces. The material's resistance to chemicals and impact makes it ideal for these applications, potentially reducing vehicle weight and improving fuel efficiency.

The packaging industry is another key market for HDPE 3D printing. Custom packaging solutions, including containers, caps, and closures, can be rapidly prototyped and produced in small batches. This flexibility allows for quick design iterations and cost-effective production of specialized packaging for niche markets or limited product runs.

Medical device manufacturers are exploring HDPE 3D printing for creating custom orthotics, prosthetics, and anatomical models. The material's biocompatibility and ability to be sterilized make it suitable for certain medical applications, although regulatory considerations must be carefully addressed.

The construction industry is showing interest in large-scale HDPE 3D printing for creating formwork, temporary structures, and even permanent building components. The material's weather resistance and durability make it attractive for outdoor applications, potentially reducing construction time and labor costs.

Consumer goods represent another growing market for HDPE 3D printing. Custom household items, toys, and sporting goods can be produced on-demand, allowing for personalization and small-scale manufacturing of niche products. This sector benefits from HDPE's food-safe properties and resistance to wear and tear.

The marine industry is exploring HDPE 3D printing for producing corrosion-resistant parts, buoys, and small watercraft components. The material's buoyancy and UV resistance make it well-suited for marine applications, potentially reducing maintenance costs and extending product lifespans.

As 3D printing technologies continue to advance, the market for HDPE applications is expected to expand further. Improved printing speeds, larger build volumes, and enhanced material properties will likely open up new opportunities in industries such as aerospace, energy, and agriculture. However, challenges such as warping, shrinkage, and surface finish quality will need to be addressed to fully realize the potential of HDPE in 3D printing across these diverse markets.

Current Challenges in HDPE 3D Printing

Despite the promising potential of HDPE in 3D printing, several significant challenges currently hinder its widespread adoption and optimal utilization. One of the primary obstacles is the high shrinkage rate of HDPE during cooling, which can lead to warping and dimensional inaccuracies in printed parts. This issue is particularly pronounced in larger prints, where uneven cooling can cause severe deformation and compromise the structural integrity of the final product.

Another major challenge is the poor layer adhesion of HDPE prints. The material's low surface energy and high crystallinity make it difficult for successive layers to bond effectively, resulting in weak interlayer strength and potential delamination. This limitation significantly impacts the mechanical properties and overall durability of HDPE 3D printed objects, restricting their use in applications that require high strength and reliability.

The high melting point of HDPE, typically around 130-137°C, poses additional difficulties in the printing process. It necessitates higher nozzle temperatures, which can lead to increased energy consumption and potential degradation of the material during prolonged printing sessions. Moreover, the higher temperatures required can cause issues with thermal management in 3D printers, potentially affecting other components and reducing overall print quality.

HDPE's low viscosity when melted presents challenges in achieving precise extrusion control. This can result in inconsistent filament deposition and difficulties in creating fine details or intricate geometries. The material's tendency to string or ooze during printing further complicates the production of clean, high-quality prints, often requiring extensive post-processing to achieve desired surface finishes.

The limited availability of HDPE filaments specifically designed for 3D printing is another significant hurdle. Most commercially available HDPE filaments are not optimized for 3D printing applications, leading to inconsistent print quality and unreliable results. This scarcity of suitable materials hampers research and development efforts in exploring HDPE's full potential in additive manufacturing.

Furthermore, the environmental impact of HDPE in 3D printing remains a concern. While HDPE is recyclable, the process of recycling 3D printed HDPE objects is not straightforward due to potential contamination and the need for specialized recycling facilities. This challenge contradicts the sustainability goals often associated with 3D printing technologies.

Addressing these challenges requires concerted efforts in materials science, printer hardware development, and process optimization. Innovations in HDPE formulations, such as the incorporation of additives to improve layer adhesion and reduce shrinkage, are crucial. Additionally, advancements in printer design, including enhanced cooling systems and more precise extrusion mechanisms, are necessary to overcome the current limitations and unlock the full potential of HDPE in 3D printing applications.

Existing HDPE 3D Printing Solutions

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and industrial products.- Composition and manufacturing of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer produced from ethylene monomers. Its manufacturing process involves various catalysts and polymerization techniques to achieve desired properties such as high density, strength, and chemical resistance. Different compositions and additives can be incorporated to enhance specific characteristics for various applications.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to create composites with improved properties. These blends and composites often exhibit enhanced mechanical strength, thermal stability, or specific functional characteristics. The combination of HDPE with other polymers or additives allows for tailored material properties suitable for diverse applications.

- HDPE recycling and sustainability: Recycling processes for HDPE have been developed to address environmental concerns and promote sustainability. These methods involve collecting, sorting, cleaning, and reprocessing HDPE products to create new materials. Innovations in recycling techniques aim to maintain or improve the properties of recycled HDPE, making it suitable for various applications and reducing environmental impact.

- HDPE applications in packaging and containers: HDPE is widely used in packaging and container applications due to its excellent chemical resistance, durability, and moisture barrier properties. It is commonly employed in the production of bottles, drums, tanks, and various types of packaging materials. Innovations in this area focus on improving design, reducing material usage, and enhancing functionality for specific storage and transportation needs.

- HDPE in construction and infrastructure: HDPE finds extensive use in construction and infrastructure applications due to its durability, corrosion resistance, and flexibility. It is utilized in the production of pipes, geomembranes, and various construction materials. Research in this area focuses on improving the material's long-term performance, resistance to environmental factors, and suitability for specific construction requirements.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functionalities. Examples include HDPE mixed with natural fibers, nanoparticles, or other polymers to create materials with tailored characteristics for specific applications.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Advancements in processing technology focus on improving efficiency, reducing cycle times, and enhancing the quality of the final products.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is recyclable and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in new products. This includes developing better sorting and cleaning methods for post-consumer HDPE, as well as finding ways to maintain or enhance the properties of recycled HDPE for various applications. Sustainability initiatives also focus on reducing the environmental impact of HDPE production and use.Expand Specific Solutions05 Novel applications of HDPE

Researchers and industries are exploring new applications for HDPE, leveraging its unique properties. This includes using HDPE in 3D printing, developing HDPE-based composites for specialized industrial applications, and creating innovative packaging solutions. These novel applications aim to expand the use of HDPE in various sectors, from construction to healthcare.Expand Specific Solutions

Key Players in HDPE 3D Printing Industry

The HDPE and 3D printing market is in a growth phase, with increasing adoption across various industries. The market size is expanding rapidly, driven by advancements in material properties and printing technologies. Technical maturity is progressing, with companies like Dow Global Technologies LLC, HP Development Co. LP, and Braskem America, Inc. leading innovation. Chinese institutions, including the Chinese Academy of Science Institute of Chemistry and China Petroleum & Chemical Corp., are also making significant contributions. The competitive landscape is diverse, featuring collaborations between material suppliers, printer manufacturers, and research institutions, all working to overcome challenges in HDPE printing, such as warping and layer adhesion, to unlock new possibilities in additive manufacturing.

HP Development Co. LP

Braskem America, Inc.

Innovative HDPE 3D Printing Techniques

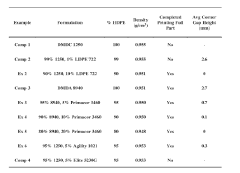

- A composite material comprising a polymer matrix blend of polypropylene (PP) and polyethylene (PE) with natural cellulosic nanofibers is developed, which slows crystallization rates and enhances mechanical properties, allowing for improved dimensional stability and reduced shrinkage during the 3D printing process.

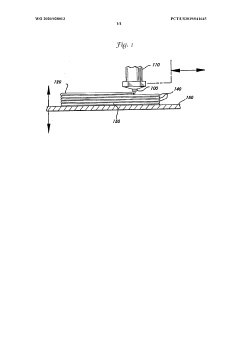

- A thermoplastic blend comprising high-density polyethylene (HDPE) and a second thermoplastic polymer, such as low-density polyethylene or functionalized polyolefin, with a weight ratio of HDPE to second polymer ranging from 1.5/1 to 20/1, is used, which is heated and extruded through a nozzle to form layers with improved adhesion and minimal warpage.

Environmental Impact of HDPE 3D Printing

The environmental impact of HDPE 3D printing is a complex issue that requires careful consideration. While 3D printing technology offers numerous advantages in terms of customization and on-demand production, its environmental implications, particularly when using High-Density Polyethylene (HDPE), are significant.

HDPE is a thermoplastic polymer derived from petroleum, which raises concerns about its carbon footprint and sustainability. The production process of HDPE involves the extraction and refining of fossil fuels, contributing to greenhouse gas emissions and environmental degradation. However, when used in 3D printing, HDPE presents some unique environmental challenges and opportunities.

One of the primary environmental benefits of HDPE 3D printing is the potential for reduced waste. Traditional manufacturing methods often result in significant material waste, whereas 3D printing allows for precise material usage, minimizing excess. Additionally, HDPE is highly recyclable, which can contribute to a more circular economy if proper recycling systems are in place.

The energy consumption of HDPE 3D printing is another crucial factor to consider. While 3D printers generally consume less energy than traditional manufacturing equipment, the specific energy requirements can vary depending on the printer model and the complexity of the printed object. It's essential to optimize printer settings and design parameters to minimize energy usage without compromising print quality.

The durability and longevity of HDPE-printed products can have positive environmental implications. HDPE is known for its strength and resistance to chemicals and weathering, which means products made from this material may have extended lifespans, reducing the need for frequent replacements and, consequently, lowering overall resource consumption and waste generation.

However, the end-of-life management of HDPE-printed products remains a challenge. While HDPE is recyclable, the presence of additives and colorants used in 3D printing filaments can complicate the recycling process. Developing effective recycling methods for 3D-printed HDPE objects is crucial to fully realize the material's environmental potential.

The transportation impact of HDPE 3D printing should also be considered. On-demand, localized production can potentially reduce the need for long-distance shipping of finished products, thereby decreasing transportation-related emissions. However, this benefit may be offset if the raw HDPE filament needs to be transported over long distances to reach local 3D printing facilities.

In conclusion, while HDPE 3D printing offers some environmental advantages, such as reduced waste and potential for localized production, it also presents challenges related to raw material sourcing, energy consumption, and end-of-life management. To maximize the environmental benefits of this technology, it is essential to focus on sustainable sourcing of HDPE, optimizing printer efficiency, and developing robust recycling systems for 3D-printed objects.

Material Properties and Performance Analysis

High-density polyethylene (HDPE) has emerged as a promising material for 3D printing applications, offering unique properties that expand the possibilities of additive manufacturing. HDPE is known for its excellent chemical resistance, high impact strength, and low moisture absorption, making it an attractive option for various industries. When used in 3D printing, HDPE exhibits good layer adhesion and minimal warping, contributing to the production of durable and dimensionally stable parts.

The mechanical properties of HDPE in 3D printing applications are noteworthy. Printed HDPE parts demonstrate high tensile strength, typically ranging from 22 to 31 MPa, depending on the printing parameters and post-processing techniques. The material also exhibits good elongation at break, often exceeding 300%, which contributes to its toughness and ability to withstand deformation without failure. These characteristics make HDPE particularly suitable for applications requiring flexibility and impact resistance.

Thermal performance is another crucial aspect of HDPE in 3D printing. With a melting point around 130-137°C, HDPE offers a relatively low printing temperature compared to some other engineering plastics. This property can lead to reduced energy consumption during the printing process and potentially extend the lifespan of printing equipment. However, it's important to note that HDPE's low glass transition temperature of approximately -110°C means that parts may experience creep under sustained loads at room temperature.

The chemical resistance of HDPE is a significant advantage in 3D printing applications. Printed HDPE parts show excellent resistance to a wide range of chemicals, including acids, bases, and organic solvents. This property makes HDPE an ideal choice for manufacturing components that come into contact with harsh chemicals or are used in corrosive environments. Additionally, HDPE's low moisture absorption rate, typically less than 0.01% over 24 hours, ensures dimensional stability and consistent performance in humid conditions.

Surface properties of 3D printed HDPE parts present both challenges and opportunities. The material tends to have a relatively low surface energy, which can result in poor adhesion to other materials or coatings. However, this property also contributes to HDPE's non-stick characteristics, making it suitable for applications where easy release or self-cleaning surfaces are desired. Various surface treatment methods, such as plasma treatment or chemical etching, can be employed to modify the surface properties of HDPE and improve its adhesion capabilities when necessary.

In terms of environmental performance, HDPE offers several advantages. The material is recyclable, allowing for the reuse of failed prints or end-of-life parts in new printing processes. This recyclability contributes to the sustainability of 3D printing operations using HDPE. Furthermore, HDPE's low density (approximately 0.94-0.97 g/cm³) results in lightweight parts, which can be beneficial in applications where weight reduction is crucial, such as in the automotive or aerospace industries.