HDPE in Geomembrane Applications: Technical Insights

HDPE Geomembrane Evolution and Objectives

High-density polyethylene (HDPE) geomembranes have revolutionized the field of environmental protection and waste containment since their introduction in the 1980s. The evolution of HDPE geomembranes has been driven by the increasing demand for more effective and durable barriers in various applications, including landfills, mining operations, and water containment structures.

Initially, HDPE geomembranes were primarily used as simple liners in landfills. However, as environmental regulations became more stringent and the need for long-term containment solutions grew, the technology behind HDPE geomembranes rapidly advanced. The development of improved manufacturing processes and material formulations led to enhanced physical and chemical properties, making HDPE geomembranes more resistant to environmental stresses and chemical degradation.

One of the key milestones in the evolution of HDPE geomembranes was the introduction of textured surfaces in the 1990s. This innovation significantly improved the interface friction between the geomembrane and adjacent materials, enhancing slope stability and reducing the risk of sliding failures in containment systems. The textured surface also provided better anchorage for cover soils and increased the overall performance of the liner system.

Another significant advancement was the development of multi-layer HDPE geomembranes. These composite structures combine the strength and chemical resistance of HDPE with additional layers that provide specific functionalities, such as improved UV resistance or enhanced gas barrier properties. This innovation expanded the application range of HDPE geomembranes to more challenging environments and specialized containment needs.

The primary objectives driving the continued evolution of HDPE geomembranes include improving long-term durability, enhancing chemical resistance, and increasing overall system performance. Researchers and manufacturers are focusing on developing HDPE formulations that can withstand extreme temperatures, resist oxidation, and maintain their physical properties over extended periods, often exceeding 100 years.

Additionally, there is a growing emphasis on sustainability and environmental impact. Current research aims to develop HDPE geomembranes that are more easily recyclable at the end of their service life, as well as exploring bio-based alternatives that maintain the performance characteristics of traditional HDPE while reducing the reliance on fossil fuels.

The future evolution of HDPE geomembranes is likely to involve smart technologies, such as integrated sensors for real-time monitoring of liner integrity and performance. This would allow for proactive maintenance and early detection of potential issues, further enhancing the reliability and longevity of containment systems.

Market Analysis for HDPE Geomembranes

The HDPE geomembrane market has experienced significant growth in recent years, driven by increasing environmental regulations and the need for effective containment solutions across various industries. The global market size for HDPE geomembranes was valued at approximately $2.1 billion in 2020 and is projected to reach $3.5 billion by 2027, growing at a CAGR of around 7.5% during the forecast period.

The demand for HDPE geomembranes is primarily fueled by their extensive use in waste management, water containment, and mining applications. In the waste management sector, stringent environmental regulations regarding landfill construction and management have led to increased adoption of HDPE geomembranes as an effective barrier system. The water containment segment, including applications in reservoirs, canals, and artificial lakes, has also witnessed substantial growth due to water scarcity concerns and the need for efficient water conservation solutions.

The mining industry represents another significant market for HDPE geomembranes, particularly in applications such as heap leach pads, tailing ponds, and process water containment. As mining activities expand globally, the demand for reliable and durable containment solutions continues to rise, benefiting the HDPE geomembrane market.

Geographically, North America and Europe have been the dominant markets for HDPE geomembranes, owing to strict environmental regulations and well-established waste management practices. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental awareness in countries like China and India.

The market is characterized by the presence of several key players, including GSE Environmental, Solmax International, Agru America, and Naue GmbH & Co. KG. These companies are focusing on product innovations, such as developing geomembranes with enhanced chemical resistance and improved installation techniques, to gain a competitive edge in the market.

Despite the positive growth outlook, the HDPE geomembrane market faces challenges such as fluctuating raw material prices and competition from alternative materials like PVC and LLDPE geomembranes. However, the superior properties of HDPE geomembranes, including high tensile strength, excellent chemical resistance, and long-term durability, continue to make them the preferred choice for many applications.

HDPE Geomembrane Technical Challenges

High-density polyethylene (HDPE) geomembranes have become a cornerstone in environmental protection and containment applications. However, their widespread use has also revealed several technical challenges that require ongoing research and innovation. One of the primary concerns is the long-term durability of HDPE geomembranes under various environmental conditions. Exposure to UV radiation, extreme temperatures, and chemical agents can lead to degradation of the material over time, potentially compromising its barrier properties.

Another significant challenge lies in the installation process. HDPE geomembranes require precise seaming techniques to ensure a watertight barrier. The quality of these seams is critical to the overall performance of the geomembrane system. Factors such as ambient temperature, surface cleanliness, and operator skill can all affect seam integrity, making consistent high-quality installation a persistent challenge in the field.

Stress cracking is a phenomenon that continues to pose problems for HDPE geomembranes. This occurs when the material is subjected to constant stress, particularly at points of folding or bending. The development of stress cracks can lead to premature failure of the geomembrane, necessitating ongoing research into improving the stress crack resistance of HDPE formulations.

The interface friction between HDPE geomembranes and adjacent materials is another area of concern. In landfill applications, for instance, the stability of the entire waste containment system depends on the frictional characteristics between the geomembrane and surrounding soil or geotextiles. Achieving the right balance between low friction for ease of installation and high friction for slope stability remains a challenge for engineers and material scientists.

Gas permeation through HDPE geomembranes, particularly in landfill applications, presents another technical hurdle. While HDPE is highly effective at containing liquids, certain gases can slowly diffuse through the material. This can lead to issues such as odor release or the escape of greenhouse gases, necessitating the development of enhanced barrier properties or complementary gas management systems.

The detection and location of leaks in installed HDPE geomembranes continue to be a significant challenge. Current methods for leak detection can be time-consuming, costly, and not always reliable, especially for large installations. There is an ongoing need for more efficient and accurate leak detection technologies to ensure the integrity of geomembrane systems throughout their operational life.

Lastly, the recycling and end-of-life management of HDPE geomembranes present environmental and technical challenges. As these materials reach the end of their service life, finding sustainable ways to recycle or dispose of them without contributing to environmental pollution is becoming increasingly important. This challenge intersects with broader issues of plastic waste management and circular economy principles in the construction and environmental protection sectors.

Current HDPE Geomembrane Solutions

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and industrial products.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.

- HDPE processing techniques: Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Advanced processing techniques can improve the material's performance or enable the creation of complex shapes and structures.

- Recycling and sustainability of HDPE: HDPE is recyclable and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in various applications. This includes developing new recycling technologies, improving the quality of recycled HDPE, and finding innovative uses for recycled material. Sustainability initiatives also focus on reducing the environmental impact of HDPE production and use.

- HDPE applications in specific industries: HDPE finds applications in numerous industries due to its versatile properties. In the construction sector, it is used for pipes, geomembranes, and insulation. In packaging, HDPE is utilized for bottles, containers, and films. The automotive industry employs HDPE for fuel tanks and interior components. Other applications include medical devices, toys, and household items.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, or specific mechanical properties. The resulting materials find applications in diverse industries, including automotive, construction, and consumer goods.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are employed to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Innovations in processing techniques focus on improving efficiency, reducing cycle times, and enhancing product quality.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is highly recyclable, making it an environmentally friendly material. Recycling processes for HDPE involve collection, sorting, cleaning, and reprocessing into new products. Innovations in this area focus on improving recycling efficiency, developing new recycling technologies, and finding novel applications for recycled HDPE to promote circular economy principles.Expand Specific Solutions05 HDPE applications in specific industries

HDPE finds extensive use in various industries due to its versatile properties. In the packaging industry, it is used for bottles, containers, and films. In construction, HDPE is employed for pipes, geomembranes, and insulation. Other applications include automotive parts, toys, and medical devices. Ongoing research focuses on expanding HDPE's use in specialized applications and improving its performance in existing ones.Expand Specific Solutions

Key HDPE Geomembrane Manufacturers

The HDPE geomembrane market is in a growth phase, driven by increasing environmental regulations and infrastructure development. The global market size is expanding, with projections indicating significant growth in the coming years. Technologically, HDPE geomembranes are relatively mature, but ongoing innovations focus on enhancing durability, chemical resistance, and installation efficiency. Key players like Solmax International, Inc., Dow Global Technologies LLC, and Borealis AG are at the forefront of these advancements. Companies such as GSE Environmental (now part of Solmax) and Agru/America, Inc. are also contributing to technological improvements. The competitive landscape is characterized by a mix of large multinational corporations and specialized geosynthetics manufacturers, with increasing emphasis on sustainable and high-performance solutions.

Dow Global Technologies LLC

Borealis AG

HDPE Geomembrane Patent Analysis

- An ethylene-based interpolymer with a density of 0.910 to 0.930 g/cc, a melt index of 0.1 to 0.5 g/10 min, and a high density fraction in the ATREF short chain branch distribution curve eluting above 92°C, comprising greater than 10% to less than 28% of the total ATREF SCBD curve area, is developed, which is polymerized using a chrome catalyst and does not involve blending with other polymers or chemical modification.

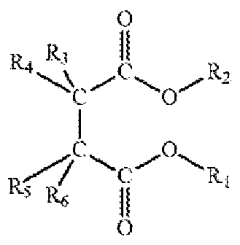

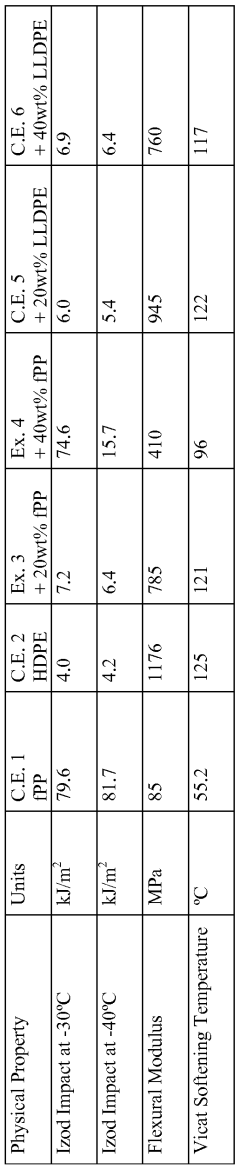

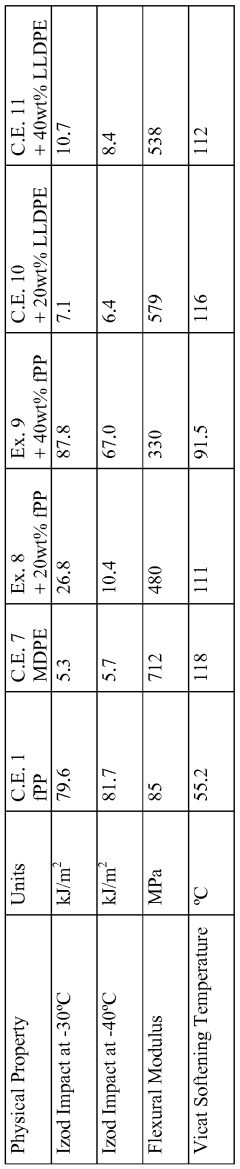

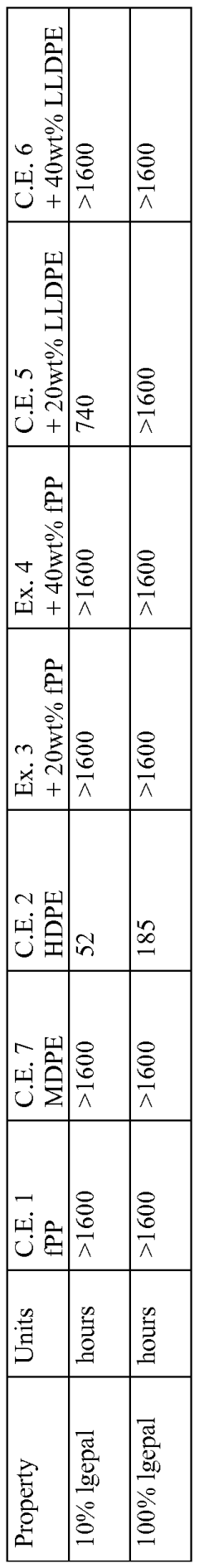

- A polyolefin composition comprising a thermoplastic olefin polymer and polyethylene, with the thermoplastic olefin polymer present in amounts of 10-50 weight percent, having a density of 0.85-0.92 g/cm3 and a flexural modulus of less than 700 MPa, and comprising polypropylene and an olefin copolymer, combined with MDPE or HDPE in amounts of 50-90 weight percent, to enhance the physical properties of geomembranes.

Environmental Impact Assessment

The environmental impact assessment of HDPE geomembranes in various applications reveals both positive and negative effects on ecosystems and natural resources. On the positive side, HDPE geomembranes play a crucial role in environmental protection by preventing soil and groundwater contamination. Their use in landfills, waste containment facilities, and mining operations significantly reduces the risk of hazardous materials leaching into surrounding ecosystems.

HDPE geomembranes also contribute to water conservation efforts. When used in irrigation systems and water reservoirs, they minimize water loss through seepage, thereby conserving this precious resource in water-scarce regions. Additionally, their application in aquaculture helps maintain water quality and prevents the escape of farmed species into natural habitats.

However, the production and disposal of HDPE geomembranes present environmental challenges. The manufacturing process of HDPE involves the use of fossil fuels and energy-intensive processes, contributing to greenhouse gas emissions and climate change. The extraction of raw materials for HDPE production can lead to habitat destruction and biodiversity loss in mining areas.

End-of-life management of HDPE geomembranes is another significant environmental concern. While HDPE is recyclable, the recycling process for geomembranes can be complicated due to contamination from their use in waste containment and other applications. Improper disposal can lead to long-term environmental pollution, as HDPE does not biodegrade easily and can persist in the environment for hundreds of years.

The installation of HDPE geomembranes may also have short-term impacts on local ecosystems. Site preparation and installation processes can disrupt habitats and cause soil compaction. However, these impacts are generally temporary and can be mitigated through proper planning and restoration efforts.

In terms of long-term environmental benefits, HDPE geomembranes contribute to the reduction of soil erosion and sedimentation in water bodies when used in erosion control applications. This helps maintain water quality and protect aquatic ecosystems. Furthermore, their use in agricultural applications can lead to more efficient use of fertilizers and pesticides, reducing the overall environmental impact of farming practices.

HDPE Geomembrane Quality Control

Quality control is a critical aspect of HDPE geomembrane production and installation to ensure the material's performance and longevity in various applications. The quality control process begins at the manufacturing stage, where strict protocols are implemented to maintain consistent material properties. This includes regular testing of raw materials, monitoring of extrusion parameters, and continuous inspection of the finished product.

During production, key parameters such as thickness, density, and melt flow index are closely monitored. Thickness measurements are typically taken at regular intervals along the length and width of the geomembrane to ensure uniformity. Density testing is crucial as it directly relates to the material's strength and chemical resistance. The melt flow index is monitored to ensure proper molecular weight distribution, which affects the geomembrane's long-term performance.

On-site quality control is equally important during installation. Before deployment, each roll of geomembrane undergoes visual inspection for defects such as pinholes, tears, or foreign inclusions. Destructive and non-destructive testing methods are employed to verify seam integrity. Destructive tests involve cutting samples from the installed geomembrane and testing them for peel and shear strength. Non-destructive methods, such as air channel testing for dual-track fusion welds or vacuum box testing for extrusion welds, are used to check seam continuity without compromising the liner.

Environmental factors are also considered in quality control procedures. Temperature and humidity are monitored during installation, as extreme conditions can affect seaming quality. Subgrade preparation is inspected to ensure a smooth, compacted surface free of sharp objects that could puncture the geomembrane.

Documentation plays a vital role in quality control. Detailed records of manufacturing data, installation procedures, and test results are maintained. This documentation serves as a reference for future maintenance and provides a traceable history of the geomembrane's quality assurance process.

Advanced technologies are increasingly being incorporated into quality control processes. Automated thickness measurement systems, infrared cameras for detecting thermal anomalies in seams, and GPS-enabled documentation of installation progress are examples of innovations enhancing the precision and efficiency of quality control measures.

Continuous improvement in quality control methods is driven by evolving industry standards and regulations. Organizations such as the Geosynthetic Institute (GSI) and ASTM International regularly update their guidelines to reflect advancements in materials and installation techniques, ensuring that quality control practices remain current and effective.