HDPE: Innovations in Film Manufacturing Techniques

HDPE Film Evolution

High-density polyethylene (HDPE) film has undergone significant evolution since its introduction in the 1950s. Initially, HDPE film manufacturing relied on basic extrusion techniques, producing films with limited properties and applications. The early films were primarily used for simple packaging solutions and had relatively poor optical and mechanical characteristics.

As demand for more versatile and higher-quality films grew, manufacturers began to explore innovative techniques to enhance HDPE film properties. The 1960s and 1970s saw the development of blown film extrusion, which allowed for better control over film thickness and improved mechanical properties. This technique enabled the production of thinner films with enhanced strength, leading to increased use in packaging applications.

The 1980s marked a significant milestone in HDPE film evolution with the introduction of multi-layer co-extrusion technology. This innovation allowed manufacturers to combine different materials in a single film, creating products with tailored properties for specific applications. Multi-layer HDPE films offered improved barrier properties, enhanced printability, and better sealing characteristics, expanding their use in food packaging and industrial applications.

In the 1990s and early 2000s, advancements in polymer science and processing technology led to the development of metallocene-catalyzed HDPE resins. These new materials offered improved clarity, toughness, and processability, further expanding the range of applications for HDPE films. Simultaneously, improvements in extrusion die design and process control systems enabled manufacturers to produce films with more consistent quality and enhanced properties.

Recent years have seen a focus on sustainability and recyclability in HDPE film manufacturing. Innovations in this area include the development of mono-material structures that are easier to recycle, as well as the incorporation of post-consumer recycled content into new films. Additionally, advancements in nano-technology have led to the creation of HDPE nanocomposite films with improved barrier properties and mechanical strength.

The evolution of HDPE film manufacturing techniques has also been driven by the need for increased productivity and energy efficiency. Modern extrusion lines feature advanced automation systems, in-line quality control measures, and energy-efficient motors and heating systems. These improvements have resulted in higher production speeds, reduced waste, and lower energy consumption per unit of film produced.

Looking ahead, the future of HDPE film evolution is likely to focus on further enhancing sustainability, improving film performance, and expanding into new application areas. Emerging technologies such as 3D printing and smart packaging solutions may also play a role in shaping the next generation of HDPE film products and manufacturing techniques.

Market Demand Analysis

The market demand for HDPE film manufacturing techniques has been steadily growing, driven by the increasing need for flexible packaging solutions across various industries. The global HDPE film market is experiencing robust growth, with a significant portion attributed to innovations in manufacturing techniques. This growth is primarily fueled by the rising demand in sectors such as food packaging, consumer goods, and industrial applications.

In the food packaging industry, there is a growing preference for HDPE films due to their excellent moisture barrier properties, chemical resistance, and durability. The shift towards sustainable packaging solutions has also contributed to the increased demand for HDPE films, as they are recyclable and can be manufactured using eco-friendly processes. This trend is particularly evident in developed markets where environmental concerns are driving packaging choices.

The consumer goods sector is another key driver of market demand for HDPE film manufacturing innovations. As e-commerce continues to expand, there is a heightened need for protective packaging materials that can withstand the rigors of shipping and handling. HDPE films, with their high tensile strength and puncture resistance, are well-suited for this application, leading to increased adoption in the packaging of consumer electronics, apparel, and other retail products.

Industrial applications represent a significant growth area for HDPE film manufacturing techniques. The construction industry, in particular, has seen an uptick in the use of HDPE films for vapor barriers, temporary enclosures, and protective coverings. The automotive sector is also contributing to market demand, utilizing HDPE films in various components due to their lightweight properties and chemical resistance.

Geographically, Asia-Pacific is emerging as a key market for HDPE film manufacturing innovations, driven by rapid industrialization, urbanization, and changing consumer preferences. North America and Europe continue to be significant markets, with a focus on high-performance and sustainable HDPE film solutions.

The market demand is also being shaped by technological advancements in HDPE film manufacturing techniques. Innovations in extrusion technology, such as multi-layer co-extrusion and blown film processes, are enabling the production of HDPE films with enhanced properties and performance characteristics. This has opened up new application areas and is driving demand for more sophisticated manufacturing solutions.

Furthermore, the ongoing trend towards lightweight packaging and material reduction is fueling research and development in HDPE film manufacturing. There is a growing demand for thinner films that maintain or improve upon the performance of their thicker counterparts, driving innovations in polymer science and processing techniques.

Technical Challenges

High-density polyethylene (HDPE) film manufacturing faces several technical challenges that hinder innovation and efficiency in the production process. One of the primary obstacles is achieving consistent film thickness across the entire width of the film. Variations in thickness can lead to quality issues and increased material waste, impacting both product performance and production costs.

Another significant challenge lies in enhancing the film's mechanical properties without compromising its optical clarity. As HDPE films are widely used in packaging applications, maintaining transparency while improving strength and puncture resistance remains a complex balancing act. This challenge is particularly acute when developing films for specialized applications that demand both high clarity and superior mechanical performance.

The extrusion process itself presents several technical hurdles. Controlling the melt temperature and flow rate throughout the extrusion line is critical for producing high-quality films. Fluctuations in these parameters can result in inconsistencies in film properties and surface defects. Additionally, die design and optimization continue to be areas of focus, as they directly impact film uniformity and production efficiency.

Addressing the issue of gel formation during the extrusion process is another ongoing challenge. These microscopic imperfections can compromise the film's appearance and mechanical properties, leading to customer rejections and increased scrap rates. Developing more effective filtration systems and optimizing resin formulations are key areas of research in combating this problem.

The increasing demand for sustainable packaging solutions has introduced new technical challenges in HDPE film manufacturing. Incorporating recycled content while maintaining film performance and processability is a complex task. Engineers must overcome issues related to contamination, degradation of mechanical properties, and color consistency when working with recycled HDPE.

Furthermore, the push for thinner films to reduce material usage presents its own set of challenges. As film thickness decreases, maintaining adequate barrier properties and mechanical strength becomes more difficult. This necessitates innovations in polymer chemistry and processing techniques to achieve the desired performance in ultra-thin films.

Lastly, the industry faces challenges in scaling up new technologies from laboratory to industrial production. Many promising innovations struggle to make the transition due to issues with process stability, equipment compatibility, and cost-effectiveness at larger scales. Overcoming these scaling hurdles is crucial for bringing new HDPE film manufacturing techniques to market and driving industry-wide advancements.

Current Techniques

01 Extrusion techniques for HDPE film production

Various extrusion techniques are employed in the manufacturing of HDPE films. These methods include blown film extrusion, cast film extrusion, and sheet extrusion. Each technique offers specific advantages in terms of film properties, production speed, and thickness control. The choice of extrusion method depends on the desired film characteristics and application requirements.- Extrusion techniques for HDPE film production: Various extrusion techniques are employed in the manufacturing of HDPE films. These include blown film extrusion, cast film extrusion, and sheet extrusion. Each method offers specific advantages in terms of film properties, production speed, and thickness control. The choice of extrusion technique depends on the desired film characteristics and application requirements.

- Additives and blending for enhanced HDPE film properties: Incorporating additives and blending HDPE with other polymers can significantly improve film properties. Common additives include antioxidants, UV stabilizers, and processing aids. Blending HDPE with other polyolefins or specialty polymers can enhance specific properties such as strength, flexibility, or barrier performance. The selection and proportion of additives and blend components are crucial for achieving desired film characteristics.

- Process optimization and control in HDPE film manufacturing: Optimizing and controlling various process parameters is essential for producing high-quality HDPE films. Key factors include temperature control, cooling rates, draw ratios, and line speed. Advanced process control systems and real-time monitoring techniques are employed to maintain consistent film quality and maximize production efficiency. Proper optimization can lead to improved film uniformity, reduced defects, and enhanced overall performance.

- Surface treatment and modification of HDPE films: Surface treatment and modification techniques are used to enhance the properties of HDPE films. These methods include corona treatment, plasma treatment, and chemical modification. Such treatments can improve the film's printability, adhesion characteristics, and compatibility with coatings or laminates. Surface modification can also be used to impart specific functionalities, such as antimicrobial properties or improved barrier performance.

- Recycling and sustainability in HDPE film production: Incorporating recycled HDPE and developing sustainable manufacturing processes are becoming increasingly important in HDPE film production. This includes the use of post-consumer recycled HDPE, the development of mono-material structures for improved recyclability, and the implementation of energy-efficient production methods. Advances in recycling technologies and the adoption of circular economy principles are driving innovations in sustainable HDPE film manufacturing.

02 Additives and blending for enhanced HDPE film properties

Incorporating additives and blending HDPE with other polymers can significantly improve film properties. Common additives include antioxidants, UV stabilizers, and processing aids. Blending HDPE with other polyolefins or specialty polymers can enhance specific characteristics such as strength, flexibility, or barrier properties. The selection and proportion of additives and blends are crucial in achieving desired film performance.Expand Specific Solutions03 Process optimization and control in HDPE film manufacturing

Optimizing process parameters and implementing advanced control systems are essential for producing high-quality HDPE films. Key factors include temperature control, cooling rates, draw ratios, and line speed. Utilizing sensors, real-time monitoring, and automated adjustments can improve film consistency and reduce defects. Process optimization also focuses on energy efficiency and waste reduction in film production.Expand Specific Solutions04 Surface treatment and modification of HDPE films

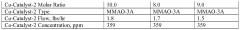

Various surface treatment techniques are applied to HDPE films to enhance their properties and functionality. These include corona treatment, plasma treatment, and chemical modification. Such treatments improve the film's printability, adhesion characteristics, and compatibility with coatings or laminates. Surface modification can also alter the film's barrier properties or introduce specific functionalities for specialized applications.Expand Specific Solutions05 Multilayer HDPE film structures and co-extrusion

Developing multilayer HDPE film structures through co-extrusion is a key technique for creating films with enhanced properties. This method allows for the combination of HDPE with other materials in a single film, offering improved barrier properties, strength, or specialized functionalities. Co-extrusion techniques enable the production of films tailored for specific applications, such as packaging or industrial use, by leveraging the strengths of different materials in each layer.Expand Specific Solutions

Industry Leaders

The HDPE film manufacturing industry is in a mature stage, characterized by steady growth and ongoing technological advancements. The global market size for HDPE films is substantial, driven by increasing demand in packaging, agriculture, and construction sectors. Technological maturity varies among key players, with companies like ExxonMobil Chemical Patents, Inc., Dow Global Technologies LLC, and NOVA Chemicals Corp. leading in innovation. These firms, along with others such as Borealis AG and LG Chem Ltd., are investing heavily in R&D to develop novel manufacturing techniques, focusing on improving film properties, reducing production costs, and enhancing sustainability. The competitive landscape is intense, with both established multinationals and emerging regional players vying for market share through product differentiation and process optimization.

ExxonMobil Chemical Patents, Inc.

Dow Global Technologies LLC

Key Innovations

- A method for preparing high modulus, high density polyethylene films by machine direction orientation of blown films with a draw-down ratio greater than 10:1, using polyethylene resins with specific molecular weight and density ranges, and processing techniques like high-stalk or in-pocket blown extrusion, followed by uniaxial stretching and annealing.

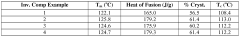

- A multi-layered shrink film comprising at least three layers, including two skin layers and one core layer, where at least one layer is made from an ethylene-based polymer composition with specific properties such as Comonomer Distribution Constant (CDC) between 75 to 220, vinyl unsaturation of 30 to 100 vinyls per million carbon atoms, zero shear viscosity ratio (ZSVR) from 2.5 to 15, density between 0.924 to 0.940 g/cm3, and molecular weight distributions, which enhances stiffness and clarity.

Environmental Impact

The environmental impact of HDPE film manufacturing techniques has become a critical concern in recent years, prompting innovations aimed at reducing the ecological footprint of this widely used material. Traditional HDPE film production methods often involve energy-intensive processes and generate significant waste, contributing to greenhouse gas emissions and plastic pollution.

One of the primary environmental challenges in HDPE film manufacturing is the high energy consumption required for extrusion and cooling processes. Recent innovations have focused on developing more energy-efficient machinery and optimizing production lines to reduce overall energy usage. Advanced heat recovery systems and improved insulation techniques have been implemented to minimize energy loss during the manufacturing process.

Waste reduction has been another key area of focus in improving the environmental performance of HDPE film production. Innovative recycling technologies have been developed to reprocess production scrap and off-spec materials, significantly reducing the amount of waste sent to landfills. Closed-loop manufacturing systems have been implemented in some facilities, allowing for the continuous recycling of materials within the production process.

Water consumption and contamination have also been addressed through recent innovations. Water-based cooling systems have been optimized to reduce overall water usage, while advanced filtration and treatment technologies have been employed to minimize the release of pollutants into local water systems. Some manufacturers have even implemented zero-liquid discharge systems, eliminating wastewater discharge entirely.

The use of bio-based and recycled materials in HDPE film production has gained traction as a means of reducing reliance on fossil fuels and promoting a circular economy. Innovations in this area include the development of HDPE resins derived from renewable sources, such as sugarcane or other plant-based feedstocks. Additionally, advancements in recycling technologies have enabled the incorporation of post-consumer recycled HDPE into new film products without compromising quality or performance.

Efforts to reduce the carbon footprint of HDPE film manufacturing have also led to innovations in transportation and logistics. Manufacturers are increasingly adopting lightweight packaging solutions and optimizing shipping routes to minimize fuel consumption and emissions associated with product distribution. Some companies have invested in on-site renewable energy generation, such as solar panels or wind turbines, to power their manufacturing facilities with clean energy.

As environmental regulations become more stringent and consumer demand for sustainable products grows, the HDPE film industry continues to invest in research and development of eco-friendly manufacturing techniques. These ongoing innovations not only aim to mitigate the environmental impact of HDPE film production but also seek to enhance the material's recyclability and overall sustainability throughout its lifecycle.

Regulatory Landscape

The regulatory landscape surrounding HDPE film manufacturing techniques is complex and multifaceted, encompassing environmental, safety, and quality standards. Environmental regulations play a significant role in shaping the industry, with a focus on reducing plastic waste and promoting sustainability. Many countries have implemented strict guidelines for plastic production and disposal, encouraging manufacturers to adopt more eco-friendly practices and develop recyclable or biodegradable HDPE films.

Safety regulations are equally important in the HDPE film manufacturing sector. These regulations typically address worker safety, equipment standards, and the handling of chemicals used in the production process. Manufacturers must comply with occupational health and safety standards, ensuring proper ventilation, personal protective equipment, and safe operating procedures for machinery.

Quality standards are crucial for maintaining the integrity and performance of HDPE films. Various international and regional bodies have established specifications for HDPE film properties, including thickness, tensile strength, and barrier properties. Compliance with these standards is often mandatory for market access and customer acceptance.

The regulatory landscape also extends to food contact applications, where HDPE films must meet stringent requirements to ensure they do not contaminate food products. Regulations such as the FDA's Food Contact Substance Notification program in the United States and the European Union's Regulation (EC) No 1935/2004 govern the use of HDPE films in food packaging.

As innovations in HDPE film manufacturing techniques continue to emerge, regulatory bodies are adapting to keep pace. New regulations are being developed to address novel production methods, additives, and film properties. For instance, the use of nanotechnology in HDPE film production has prompted regulatory agencies to consider potential health and environmental impacts, leading to the development of specific guidelines for nanomaterials in plastics.

The global nature of the HDPE film industry necessitates harmonization of regulations across different regions. Efforts are underway to align standards and create a more unified regulatory framework, facilitating international trade and ensuring consistent quality and safety worldwide. However, disparities in regulations between countries can still pose challenges for manufacturers operating in multiple markets.