HDPE's Role in Circular Economy: Opportunities and Challenges

HDPE Circular Economy Background and Objectives

High-density polyethylene (HDPE) has emerged as a crucial material in the global shift towards a circular economy. This transition represents a paradigm shift from the traditional linear "take-make-dispose" model to a more sustainable approach that emphasizes resource efficiency, waste reduction, and environmental preservation. The circular economy concept aims to keep products, materials, and resources in use for as long as possible, extracting maximum value before recovering and regenerating them at the end of their service life.

HDPE, a versatile and widely used plastic, plays a significant role in this circular economy model due to its recyclability and durability. As a thermoplastic, HDPE can be melted down and reformed multiple times without significant degradation of its properties, making it an ideal candidate for closed-loop recycling systems. This characteristic aligns perfectly with the circular economy's principles of resource conservation and waste minimization.

The evolution of HDPE's role in the circular economy can be traced back to the growing awareness of plastic pollution and the need for sustainable materials management. Initially developed in the 1950s, HDPE quickly became popular due to its strength, chemical resistance, and versatility. However, as environmental concerns grew, so did the focus on developing efficient recycling technologies and processes for HDPE.

In recent years, there has been a marked increase in research and development efforts aimed at improving HDPE recycling techniques, enhancing the quality of recycled HDPE, and expanding its applications in various industries. These advancements have been driven by a combination of regulatory pressures, consumer demand for eco-friendly products, and corporate sustainability initiatives.

The primary objective in exploring HDPE's role in the circular economy is to maximize its potential for recycling and reuse while minimizing its environmental impact. This involves addressing several key challenges, including improving collection and sorting systems, developing more efficient recycling technologies, and creating markets for recycled HDPE products. Additionally, there is a focus on designing HDPE products with circularity in mind, ensuring they are easily recyclable at the end of their life cycle.

Another critical goal is to reduce the reliance on virgin HDPE by increasing the use of recycled content in new products. This not only conserves resources but also reduces the carbon footprint associated with HDPE production. The circular economy approach also seeks to extend the lifespan of HDPE products through innovative design and repair strategies, further reducing waste and resource consumption.

As we delve deeper into HDPE's role in the circular economy, it becomes clear that realizing its full potential requires a multifaceted approach involving technological innovation, policy support, and shifts in consumer behavior. The journey towards a truly circular economy for HDPE presents both significant opportunities and formidable challenges, which will be explored in detail throughout this report.

Market Analysis for Recycled HDPE Products

The market for recycled HDPE products has been experiencing significant growth in recent years, driven by increasing environmental awareness and regulatory pressures to reduce plastic waste. The global recycled HDPE market size was valued at approximately $5.5 billion in 2020 and is projected to reach $10.3 billion by 2028, growing at a CAGR of 8.2% during the forecast period.

One of the key factors driving this market growth is the rising demand for sustainable packaging solutions across various industries. The packaging sector, including food and beverage, personal care, and household products, accounts for the largest share of recycled HDPE consumption. This trend is expected to continue as more companies commit to using recycled materials in their packaging to meet sustainability goals and consumer expectations.

The construction industry is another significant market for recycled HDPE products. Recycled HDPE is increasingly being used in applications such as pipes, lumber, and decking materials due to its durability, weather resistance, and cost-effectiveness. The automotive sector is also showing growing interest in recycled HDPE for non-structural components, contributing to the overall market expansion.

Geographically, North America and Europe are the leading markets for recycled HDPE products, owing to stringent environmental regulations and well-established recycling infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing environmental concerns in countries like China and India.

Despite the positive market outlook, several challenges persist in the recycled HDPE market. The quality and consistency of recycled HDPE can vary significantly, which can limit its use in certain high-performance applications. Additionally, the cost of recycled HDPE can fluctuate based on the availability of post-consumer waste and the efficiency of collection and processing systems.

The COVID-19 pandemic has had a mixed impact on the recycled HDPE market. While it initially disrupted supply chains and recycling programs, it has also accelerated the shift towards sustainable packaging solutions, potentially benefiting the market in the long term.

Looking ahead, technological advancements in recycling processes, such as chemical recycling and advanced sorting technologies, are expected to improve the quality and expand the applications of recycled HDPE. This, coupled with increasing corporate commitments to sustainability and circular economy principles, is likely to drive further growth in the recycled HDPE products market.

Current HDPE Recycling Technologies and Barriers

The current landscape of HDPE recycling technologies is characterized by a mix of established methods and emerging innovations, each with its own set of challenges and opportunities. Mechanical recycling remains the most widely used approach, involving the collection, sorting, cleaning, and reprocessing of HDPE waste into new products. This method is relatively cost-effective and energy-efficient, but it faces limitations in terms of maintaining material quality over multiple recycling cycles.

Advanced sorting technologies, such as near-infrared (NIR) spectroscopy and X-ray fluorescence, have significantly improved the efficiency of HDPE separation from mixed plastic waste streams. However, the effectiveness of these technologies is often hampered by contamination issues, particularly when HDPE products contain multi-layer materials or non-HDPE components.

Chemical recycling, including processes like pyrolysis and depolymerization, offers promising solutions for handling contaminated or low-quality HDPE waste. These technologies break down HDPE into its chemical building blocks, which can then be used to produce new plastics or other chemical products. While chemical recycling shows great potential for closing the loop in HDPE recycling, it currently faces challenges in terms of scalability and economic viability.

One of the primary barriers to effective HDPE recycling is the complexity of waste streams. HDPE products often contain additives, colorants, and other materials that complicate the recycling process and can degrade the quality of recycled material. This issue is particularly pronounced in food-grade HDPE packaging, where stringent quality requirements make it difficult to use recycled content.

Another significant challenge is the lack of standardization in HDPE product design and labeling. The wide variety of HDPE formulations and product designs makes it difficult to implement uniform recycling processes, leading to inefficiencies in collection and sorting systems. Additionally, inadequate consumer education about proper disposal and recycling practices contributes to contamination issues in recycling streams.

The economic barriers to HDPE recycling are also substantial. Fluctuations in oil prices can make virgin HDPE more cost-competitive than recycled material, discouraging investment in recycling infrastructure. Furthermore, the costs associated with collection, transportation, and processing of HDPE waste can be prohibitive, especially in regions with underdeveloped recycling systems.

Despite these challenges, innovative approaches are emerging to address these barriers. These include the development of compatibilizers to improve the quality of recycled HDPE blends, the use of blockchain technology for better traceability in recycling supply chains, and the implementation of extended producer responsibility schemes to incentivize recyclable product design and improve collection rates.

Existing HDPE Circular Economy Solutions

01 Composition and properties of HDPE

High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.- Composition and properties of HDPE: High-Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength, stiffness, and chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications in packaging, construction, and automotive industries.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.

- HDPE processing techniques: Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, blow molding, and rotational molding. Each method offers specific advantages and is suited for different product types. Advanced processing techniques can improve the material's performance or enable the production of complex shapes and structures.

- Recycling and sustainability of HDPE: HDPE is recyclable and can be reprocessed multiple times without significant loss of properties. Recycling processes for HDPE include mechanical recycling, chemical recycling, and energy recovery. Efforts are being made to improve recycling efficiency and develop more sustainable HDPE products to address environmental concerns.

- Applications of HDPE in various industries: HDPE finds applications in numerous industries due to its versatile properties. It is widely used in packaging for bottles, containers, and films. In construction, HDPE is used for pipes, geomembranes, and insulation. Other applications include automotive parts, toys, and household items. Ongoing research focuses on expanding HDPE's use in new areas and improving its performance in existing applications.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with fillers to enhance its properties. These blends and composites can improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, natural fibers, or inorganic particles, resulting in materials with tailored properties for specific applications.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, blow molding, and rotational molding. Each method offers unique advantages for producing different types of HDPE products, such as containers, pipes, films, or complex shapes. The choice of processing technique depends on the desired product characteristics and production requirements.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is widely recycled due to its thermoplastic nature, allowing it to be melted and reformed multiple times. Recycling processes for HDPE include mechanical recycling, chemical recycling, and energy recovery. Efforts are being made to improve the recycling efficiency and develop more sustainable HDPE products, addressing environmental concerns associated with plastic waste.Expand Specific Solutions05 HDPE applications in various industries

HDPE finds extensive use in diverse industries due to its versatile properties. It is commonly used in packaging for bottles, containers, and films. In construction, HDPE is utilized for pipes, geomembranes, and insulation. The automotive industry employs HDPE for fuel tanks and interior components. Other applications include household items, toys, and medical devices, showcasing the material's wide-ranging utility.Expand Specific Solutions

Key Players in HDPE Recycling Industry

The HDPE circular economy market is in its growth phase, with increasing demand for sustainable packaging solutions driving market expansion. The global HDPE recycling market is projected to grow significantly in the coming years, reflecting the industry's maturation. Technologically, HDPE recycling is advancing, with companies like Dow Global Technologies, Braskem, and SABIC leading innovations in chemical recycling and bio-based HDPE production. These advancements are improving the quality and scalability of recycled HDPE, addressing challenges such as contamination and material degradation. However, the industry still faces hurdles in collection infrastructure and consumer education. Companies like Borealis AG and ExxonMobil are investing in advanced sorting technologies and circular economy initiatives, indicating a strong commitment to overcoming these challenges and furthering HDPE's role in the circular economy.

Borealis AG

Dow Global Technologies LLC

Innovations in HDPE Recycling and Reuse

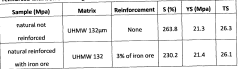

- A composite material comprising Ultra High Molecular Weight Polyethylene (UHMWPE) reinforced with iron ore tailings, which is processed through extrusion or pressing to enhance mechanical properties such as creep resistance, stiffness, and wear resistance, and reused in mining facilities to replace traditional HDPE and UHMWPE sheets.

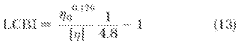

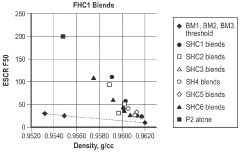

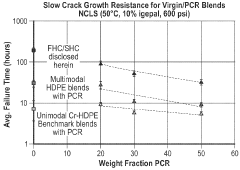

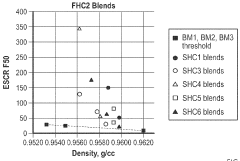

- A blend of two HDPE components with different molecular weights and densities is developed, where the first component has a lower molecular weight and higher density, and the second component has a higher molecular weight and lower density, with specific ranges for melt index, environmental stress crack resistance, and antioxidant content, to enhance the properties of the recyclate.

Environmental Impact of HDPE Recycling

The recycling of High-Density Polyethylene (HDPE) plays a crucial role in mitigating environmental impacts associated with plastic waste. When properly managed, HDPE recycling can significantly reduce greenhouse gas emissions, energy consumption, and the depletion of natural resources compared to the production of virgin HDPE.

One of the primary environmental benefits of HDPE recycling is the reduction in landfill waste. HDPE products, such as bottles and containers, can take hundreds of years to decompose naturally. By recycling these items, we can dramatically decrease the volume of plastic waste in landfills, thus preserving valuable land space and reducing the potential for soil and water contamination.

Furthermore, the recycling process for HDPE consumes less energy compared to the production of virgin HDPE. Studies have shown that recycling HDPE can save up to 66% of the energy required for new plastic production. This energy saving translates directly into reduced carbon emissions, contributing to the mitigation of climate change.

The recycling of HDPE also helps conserve non-renewable resources, particularly petroleum. As HDPE is derived from petroleum, each kilogram of recycled HDPE potentially saves approximately 1.75 kilograms of crude oil. This conservation of fossil fuels is crucial for sustainable development and reducing our dependence on non-renewable energy sources.

However, the environmental impact of HDPE recycling is not without challenges. The collection and transportation of HDPE waste for recycling can generate additional carbon emissions. Moreover, the cleaning process required for contaminated HDPE products can consume significant amounts of water and energy, potentially offsetting some of the environmental benefits.

Another concern is the potential release of microplastics during the recycling process. Mechanical recycling methods may generate small plastic particles that can enter waterways and ecosystems, posing risks to wildlife and potentially entering the food chain.

Despite these challenges, advancements in recycling technologies are continually improving the environmental performance of HDPE recycling. Innovations in sorting technologies, such as near-infrared spectroscopy, are enhancing the efficiency of separating different types of plastics, reducing contamination and improving the quality of recycled HDPE.

In conclusion, while HDPE recycling presents some environmental challenges, its overall impact is largely positive. The benefits of reduced landfill waste, energy savings, and resource conservation outweigh the potential drawbacks. As recycling technologies continue to advance, the environmental footprint of HDPE recycling is expected to improve further, reinforcing its importance in the circular economy and sustainable waste management practices.

Policy Landscape for Plastic Circularity

The policy landscape for plastic circularity has been evolving rapidly in recent years, driven by growing environmental concerns and the need for sustainable resource management. Governments worldwide are implementing various regulations and initiatives to promote the circular economy for plastics, with a particular focus on High-Density Polyethylene (HDPE) due to its widespread use and recyclability potential.

In the European Union, the Circular Economy Action Plan and the European Strategy for Plastics in a Circular Economy have set ambitious targets for plastic recycling and reuse. These policies aim to ensure that all plastic packaging is recyclable or reusable by 2030, with a specific emphasis on materials like HDPE. The EU has also introduced a plastic tax on non-recycled plastic packaging waste, incentivizing the use of recycled content in new products.

The United States has seen a patchwork of state-level policies addressing plastic circularity. California, for instance, has enacted legislation requiring all plastic bottles to contain at least 50% recycled content by 2030. Other states have implemented extended producer responsibility (EPR) programs, placing the onus on manufacturers to manage the entire lifecycle of their plastic products, including HDPE items.

In Asia, countries like Japan and South Korea have been at the forefront of implementing comprehensive recycling systems. Japan's Container and Packaging Recycling Law mandates the recycling of plastic containers and packaging, including HDPE products. South Korea has introduced a resource circulation policy framework that promotes the use of recycled materials in manufacturing processes.

Developing countries are also making strides in plastic circularity policies. India's Plastic Waste Management Rules aim to phase out single-use plastics and promote recycling infrastructure. Similarly, several African nations have implemented bans on single-use plastic bags, encouraging the use of more sustainable alternatives, including reusable HDPE products.

Global initiatives, such as the Ellen MacArthur Foundation's New Plastics Economy Global Commitment, have garnered support from governments and businesses worldwide. This initiative sets targets for reducing plastic waste and increasing the use of recycled content in packaging, including HDPE applications.

However, challenges remain in harmonizing policies across regions and ensuring effective implementation. Inconsistencies in recycling standards, labeling requirements, and waste management practices can hinder the development of a truly circular economy for plastics. Additionally, the lack of robust infrastructure for collecting, sorting, and processing plastic waste in many regions poses a significant barrier to achieving circularity goals.

As the policy landscape continues to evolve, there is a growing emphasis on life-cycle assessments, eco-design principles, and the development of innovative recycling technologies. These approaches aim to address the entire value chain of plastic products, from production to end-of-life management, ensuring that materials like HDPE can be effectively reintegrated into the circular economy.