HDPE's Role in Eliminating Single-Use Plastics

HDPE Evolution and Objectives

High-density polyethylene (HDPE) has emerged as a pivotal material in the global effort to eliminate single-use plastics. The evolution of HDPE technology can be traced back to the 1950s when it was first synthesized by Karl Ziegler. Since then, HDPE has undergone significant advancements in terms of its production processes, properties, and applications.

The primary objective in HDPE's role in eliminating single-use plastics is to provide a more sustainable alternative that maintains the functionality and convenience of traditional plastics while reducing environmental impact. This goal aligns with the growing global awareness of plastic pollution and the urgent need for eco-friendly solutions.

HDPE's evolution has been marked by continuous improvements in its mechanical properties, such as increased strength, durability, and chemical resistance. These enhancements have expanded its potential applications, making it suitable for a wide range of products that can replace single-use plastics. The development of advanced catalysts and polymerization techniques has also contributed to more efficient and cost-effective production methods.

One of the key objectives in HDPE's evolution is to improve its recyclability. Unlike many single-use plastics, HDPE can be recycled multiple times without significant degradation of its properties. This characteristic makes it an attractive option for creating a circular economy in plastic usage. Ongoing research aims to further enhance HDPE's recyclability and develop more efficient recycling processes.

Another important goal is to reduce the carbon footprint associated with HDPE production. This involves exploring bio-based feedstocks and developing more energy-efficient manufacturing processes. The industry is also focusing on increasing the use of recycled HDPE in new products, thereby closing the loop in the material's lifecycle.

The development of HDPE alternatives to single-use plastics extends to various sectors, including packaging, consumer goods, and industrial applications. Researchers and manufacturers are working on innovative HDPE formulations that can mimic the properties of different types of single-use plastics, such as flexible packaging films and disposable cutlery.

As the technology continues to evolve, there is a growing emphasis on creating HDPE products that are not only recyclable but also biodegradable under specific conditions. This research aims to address concerns about plastic accumulation in the environment while maintaining the material's beneficial properties.

In conclusion, the evolution of HDPE technology and its objectives in eliminating single-use plastics represent a significant shift towards more sustainable materials. The ongoing advancements in HDPE production, properties, and applications demonstrate its potential to play a crucial role in addressing the global plastic pollution crisis while meeting the functional needs of various industries and consumers.

Market Demand Analysis

The market demand for High-Density Polyethylene (HDPE) as a solution to single-use plastics has been steadily increasing in recent years. This growth is driven by a combination of environmental concerns, regulatory pressures, and consumer preferences for more sustainable packaging options.

Environmental awareness has become a significant factor in shaping market demand. As the detrimental effects of single-use plastics on ecosystems and marine life have gained widespread attention, consumers and businesses alike are seeking alternatives. HDPE, being recyclable and more durable than many single-use plastics, has emerged as a viable option to address these concerns.

Regulatory initiatives worldwide have also played a crucial role in driving market demand for HDPE. Many countries and regions have implemented or are considering bans on single-use plastics, creating a need for alternative materials. This regulatory landscape has prompted industries to explore HDPE as a compliant and sustainable solution, further boosting market demand.

The packaging industry, in particular, has shown significant interest in HDPE as a replacement for single-use plastics. HDPE's versatility allows it to be used in various applications, from food packaging to personal care products. This adaptability has expanded its potential market across multiple sectors, contributing to its growing demand.

Consumer preferences have shifted towards more environmentally friendly products, influencing purchasing decisions and brand loyalty. Companies that adopt HDPE packaging can leverage this trend to enhance their brand image and appeal to eco-conscious consumers. This shift in consumer behavior has created a ripple effect, encouraging more businesses to consider HDPE alternatives and further stimulating market demand.

The durability and reusability of HDPE products have also contributed to their market appeal. Unlike single-use plastics, HDPE items can be used multiple times, aligning with the growing trend of circular economy principles. This aspect has made HDPE particularly attractive in sectors such as retail, where reusable shopping bags made from HDPE have gained popularity.

Market analysis indicates that the demand for HDPE in replacing single-use plastics is not limited to developed economies. Emerging markets are also showing increased interest, driven by growing environmental awareness and the need for cost-effective, sustainable solutions. This global demand is expected to fuel further innovation and development in HDPE technologies and applications.

The potential for HDPE to reduce plastic waste and its associated environmental impacts has garnered attention from both the public and private sectors. Investments in research and development to improve HDPE's properties and expand its applications are likely to further drive market growth and adoption across various industries.

HDPE Challenges and Limitations

While HDPE (High-Density Polyethylene) offers numerous advantages in the quest to eliminate single-use plastics, it also faces several challenges and limitations that must be addressed for its widespread adoption and effectiveness.

One of the primary challenges is the energy-intensive production process of HDPE. The manufacturing of HDPE requires significant amounts of fossil fuels, contributing to greenhouse gas emissions and environmental concerns. This contradicts the sustainability goals that drive the elimination of single-use plastics, creating a paradox that needs resolution through more efficient production methods or alternative energy sources.

Recycling HDPE presents another major hurdle. Although HDPE is recyclable, the recycling process is not without its complications. Contamination from food residues, labels, and other materials can compromise the quality of recycled HDPE, limiting its applications. Additionally, the collection and sorting of HDPE products pose logistical challenges, especially in areas with underdeveloped waste management infrastructure.

The durability of HDPE, while generally an advantage, can become a limitation in certain contexts. HDPE products, if not properly disposed of or recycled, can persist in the environment for hundreds of years, potentially contributing to long-term pollution. This persistence necessitates the development of more effective end-of-life management strategies for HDPE products.

Consumer perception and behavior also present challenges to HDPE's role in eliminating single-use plastics. Many consumers associate plastic products, including those made from HDPE, with environmental harm. Overcoming this perception requires extensive education and awareness campaigns to highlight the benefits and recyclability of HDPE compared to other single-use materials.

From a technical standpoint, HDPE has limitations in certain applications where barrier properties or heat resistance are crucial. For instance, HDPE is not suitable for hot-fill applications or for packaging products that require a high oxygen barrier. This restricts its use in some food and beverage packaging, where alternative materials may still be preferred.

The economic aspect also poses challenges. The fluctuating costs of raw materials for HDPE production, primarily derived from natural gas and petroleum, can impact its economic viability compared to other materials. Moreover, the investment required to transition existing manufacturing processes to HDPE-based solutions can be substantial, deterring some businesses from making the switch.

Regulatory hurdles and inconsistent policies across different regions complicate the widespread adoption of HDPE as a solution to single-use plastics. Varying recycling standards, labeling requirements, and restrictions on plastic use create a complex landscape for manufacturers and consumers alike, potentially slowing the transition to HDPE-based alternatives.

Current HDPE Solutions

01 Chemical degradation of HDPE

Chemical methods can be employed to break down HDPE into smaller molecules or convert it into other useful products. This process often involves the use of catalysts or specific chemical reactions to depolymerize the HDPE structure, making it easier to eliminate or recycle.- Chemical degradation of HDPE: Chemical methods can be employed to break down HDPE into smaller molecules or convert it into other useful products. This process often involves the use of catalysts or specific chemical reactions to depolymerize the HDPE structure, making it easier to eliminate or recycle.

- Thermal treatment for HDPE elimination: Thermal processes can be used to break down HDPE at high temperatures. This method can include pyrolysis, gasification, or other heat-based treatments that convert HDPE into smaller hydrocarbon molecules or energy sources, effectively eliminating the original polymer structure.

- Mechanical recycling and processing of HDPE: Mechanical methods involve grinding, shredding, or otherwise physically processing HDPE to reduce it to smaller pieces. These can then be reprocessed into new products or further treated for elimination. This approach focuses on size reduction and potential reuse rather than complete chemical breakdown.

- Biological degradation of HDPE: Biological methods utilize microorganisms or enzymes to break down HDPE. This eco-friendly approach involves the use of specific bacteria or fungi that can metabolize the polymer, potentially converting it into harmless byproducts or biomass over time.

- HDPE upcycling and conversion to value-added products: Instead of complete elimination, HDPE can be converted into higher-value products through various chemical or physical processes. This approach focuses on transforming HDPE waste into useful materials or chemicals, effectively eliminating it from the waste stream while creating economic value.

02 Thermal treatment for HDPE elimination

Thermal processes can be used to break down HDPE at high temperatures. This may include pyrolysis or gasification techniques, which convert the polymer into smaller hydrocarbon molecules or gases that can be used as fuel or chemical feedstock.Expand Specific Solutions03 Mechanical recycling of HDPE

Mechanical methods involve grinding, shredding, or melting HDPE products to create recycled HDPE pellets or flakes. These can then be used to manufacture new products, effectively eliminating the original HDPE waste while conserving resources.Expand Specific Solutions04 Biological degradation of HDPE

Research into biological methods for HDPE elimination focuses on identifying and utilizing microorganisms or enzymes capable of breaking down the polymer. This approach aims to develop more environmentally friendly ways to degrade HDPE in natural settings.Expand Specific Solutions05 HDPE upcycling and repurposing

Instead of complete elimination, HDPE can be upcycled or repurposed into new products with higher value or different applications. This approach extends the life cycle of the material and reduces the need for new HDPE production, indirectly contributing to its elimination from waste streams.Expand Specific Solutions

Key HDPE Industry Players

The HDPE market for eliminating single-use plastics is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size for HDPE in this application is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, HDPE solutions are relatively mature, with major players like Dow Global Technologies, ExxonMobil Chemical Patents, and NOVA Chemicals leading innovation. Companies such as Procter & Gamble and LG Chem are also contributing to advancements in HDPE applications for sustainable packaging. Research institutions like South China University of Technology and Rutgers State University are further pushing the boundaries of HDPE technology, focusing on improving recyclability and biodegradability to enhance its role in reducing single-use plastic waste.

Dow Global Technologies LLC

DuPont de Nemours, Inc.

HDPE Innovations and Patents

- A thermofusion process involving crushing, washing, drying, and boiling HDPE waste in a preheated furnace, followed by pressing and extraction, to produce laminated or block-shaped products with specific characteristics such as durability, texturability, and chemical resistance.

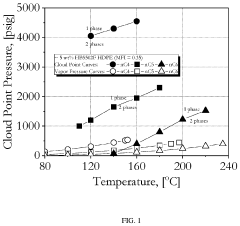

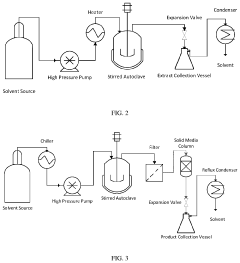

- A method involving the use of a pressurized solvent to form a one-phase solution with HDPE at specific temperature and pressure conditions, followed by extraction, dissolution, and purification steps using solid media to achieve HDPE with natural-like optical properties, characterized by L* greater than 75, a* greater than -6, b* less than 11, and Y less than 80.

Environmental Impact Assessment

The environmental impact assessment of High-Density Polyethylene (HDPE) in the context of eliminating single-use plastics reveals a complex interplay of benefits and challenges. HDPE, known for its durability and recyclability, offers potential advantages over traditional single-use plastics in terms of environmental sustainability.

One of the primary environmental benefits of HDPE is its recyclability. Unlike many single-use plastics, HDPE can be recycled multiple times without significant degradation in quality. This characteristic reduces the amount of plastic waste entering landfills and oceans, thereby mitigating the long-term environmental impact associated with plastic pollution. The recycling process of HDPE also consumes less energy compared to the production of virgin plastic, contributing to a reduction in overall carbon emissions.

However, the production of HDPE still relies on fossil fuels, which raises concerns about its carbon footprint. The extraction and processing of these raw materials contribute to greenhouse gas emissions and other environmental pollutants. While the long-term use of HDPE products can offset some of these impacts, the initial production phase remains a significant environmental consideration.

In terms of biodegradability, HDPE performs poorly compared to some alternative materials. It can take hundreds of years to decompose naturally, potentially leading to long-lasting environmental contamination if not properly managed. This persistence in the environment is a major concern, especially if HDPE products are not correctly disposed of or recycled.

The use of HDPE in replacing single-use plastics also presents challenges in waste management systems. While recyclable, HDPE requires proper sorting and processing facilities, which are not universally available. In regions lacking adequate recycling infrastructure, HDPE products may end up in landfills or incineration facilities, negating their potential environmental benefits.

On the positive side, the durability of HDPE allows for the creation of reusable products that can replace multiple single-use items. This shift towards reusability can significantly reduce the overall plastic waste generated. For instance, HDPE shopping bags can be used hundreds of times, potentially replacing thousands of single-use plastic bags over their lifetime.

The environmental impact of HDPE also extends to marine ecosystems. While it is less likely to break down into microplastics compared to some other plastics, HDPE products that do enter marine environments can still pose risks to wildlife through entanglement or ingestion. However, the higher recyclability of HDPE could lead to improved collection and recycling rates, potentially reducing the amount of plastic reaching marine environments.

In conclusion, while HDPE offers several environmental advantages over traditional single-use plastics, its impact is not uniformly positive. The key to maximizing its environmental benefits lies in effective recycling programs, consumer education, and the development of more sustainable production methods. As research continues, innovations in bio-based HDPE and improved recycling technologies may further enhance its role in creating a more sustainable plastic ecosystem.

Regulatory Framework for HDPE

The regulatory framework for HDPE in the context of eliminating single-use plastics is complex and evolving, reflecting the growing global concern over plastic pollution. Many countries and regions have implemented or are considering regulations that directly impact the production, use, and disposal of HDPE products.

In the European Union, the Single-Use Plastics Directive, implemented in 2019, aims to reduce the impact of certain plastic products on the environment. While this directive primarily targets items like plastic bags and food containers, it has indirect implications for HDPE manufacturers. The directive encourages the use of more sustainable alternatives, which has led to increased interest in recyclable HDPE products.

The United States lacks comprehensive federal legislation specifically addressing single-use plastics. However, several states have enacted their own regulations. California, for instance, has implemented a ban on single-use plastic bags, which has spurred innovation in reusable HDPE bag designs. Other states, such as New York and Oregon, have followed suit with similar bans, creating a patchwork of regulations that HDPE manufacturers must navigate.

In Asia, countries like China and India have also taken steps to regulate single-use plastics. China's ban on importing plastic waste has had a significant impact on the global recycling industry, including HDPE recycling. This has led to increased pressure on domestic recycling capabilities and a push for more sustainable HDPE product designs.

International agreements, such as the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal, have been amended to include plastic waste. This has implications for the global trade of HDPE waste and recycled materials, potentially affecting the supply chain for HDPE manufacturers.

The regulatory landscape also includes standards and certifications for recycled content and biodegradability. For instance, the ASTM International has developed standards for testing the biodegradability of plastics, which can apply to certain HDPE products. These standards are often referenced in regulations and can influence product development and marketing strategies.

As regulations continue to evolve, HDPE manufacturers are increasingly focusing on circular economy principles. This includes designing products for easier recycling, increasing the use of recycled HDPE in new products, and exploring bio-based alternatives. The regulatory framework is thus not only a set of restrictions but also a driver of innovation in the HDPE industry.