High Density Polyethylene in Electronics: Trends and Developments

HDPE in Electronics: Background and Objectives

High Density Polyethylene (HDPE) has emerged as a significant material in the electronics industry, marking a notable shift from its traditional applications in packaging and construction. This evolution is driven by the increasing demand for lightweight, durable, and cost-effective materials in electronic devices and components. The journey of HDPE in electronics began in the late 20th century, with its initial use in simple insulation and protective casings.

As electronic devices became more compact and multifunctional, the need for materials with superior properties grew. HDPE's excellent electrical insulation properties, coupled with its resistance to chemicals and moisture, positioned it as a promising candidate for various electronic applications. The material's versatility allowed it to be molded into complex shapes, making it suitable for intricate electronic housings and components.

The technological evolution in the electronics sector has been pushing the boundaries of material science, and HDPE has been adapting to meet these new challenges. Recent years have seen significant advancements in HDPE formulations, enhancing its thermal stability, flame retardancy, and mechanical strength. These improvements have expanded its potential applications in electronics, from simple casings to more critical components in circuit boards and connectors.

The primary objective in the development of HDPE for electronics is to create a material that can withstand the harsh conditions often encountered in electronic devices, such as high temperatures, electromagnetic interference, and mechanical stress. Researchers and manufacturers are focusing on developing HDPE composites that incorporate nanomaterials or other additives to enhance its properties further.

Another key goal is to improve the recyclability and sustainability of HDPE in electronics. As environmental concerns grow, there is a push towards creating HDPE formulations that are easier to recycle and reuse, aligning with the global trend towards more sustainable electronic products. This includes developing HDPE blends that maintain their high-performance characteristics while being more environmentally friendly.

The future trajectory of HDPE in electronics is likely to involve further miniaturization of components, increased durability, and enhanced functionality. As the Internet of Things (IoT) and wearable technologies continue to evolve, HDPE is expected to play a crucial role in creating flexible, lightweight, and robust electronic devices. The ongoing research in this field aims to unlock new potentials of HDPE, potentially revolutionizing its role in the electronics industry.

Market Analysis for HDPE in Electronic Applications

The market for High Density Polyethylene (HDPE) in electronic applications is experiencing significant growth and transformation. This trend is driven by the increasing demand for lightweight, durable, and cost-effective materials in the electronics industry. HDPE's unique properties, including excellent chemical resistance, low moisture absorption, and high impact strength, make it an attractive option for various electronic components and packaging solutions.

In the consumer electronics sector, HDPE is gaining traction in the production of housings for smartphones, tablets, and laptops. The material's ability to withstand daily wear and tear while maintaining its aesthetic appeal has led to its increased adoption by manufacturers seeking to enhance product durability and reduce production costs. Additionally, HDPE's recyclability aligns with the growing consumer preference for environmentally friendly products, further boosting its market potential in this segment.

The automotive electronics market presents another significant opportunity for HDPE applications. As vehicles become increasingly electrified and connected, the demand for lightweight, heat-resistant materials for electronic components and wiring systems is rising. HDPE's low density and excellent electrical insulation properties make it an ideal candidate for these applications, contributing to improved fuel efficiency and overall vehicle performance.

In the field of industrial electronics, HDPE is finding new applications in the production of protective casings for sensors, control units, and other electronic devices exposed to harsh environments. The material's resistance to chemicals, moisture, and extreme temperatures ensures the longevity and reliability of critical electronic components in industrial settings, driving its adoption across various manufacturing sectors.

The telecommunications industry is another key market for HDPE in electronic applications. The ongoing expansion of 5G networks and fiber-optic infrastructure has created a substantial demand for durable, weather-resistant materials for outdoor equipment housings and cable protection. HDPE's ability to withstand UV radiation and its excellent impact resistance make it a preferred choice for these applications, supporting the growth of telecommunications infrastructure worldwide.

Emerging technologies such as Internet of Things (IoT) devices and wearable electronics are also contributing to the expanding market for HDPE in electronics. These applications require materials that are lightweight, flexible, and capable of protecting sensitive electronic components from environmental factors. HDPE's versatility and cost-effectiveness position it as a competitive option in this rapidly evolving market segment.

As the electronics industry continues to innovate and diversify, the market for HDPE is expected to grow steadily. Manufacturers are increasingly recognizing the material's potential to address key challenges in electronic design and production, including weight reduction, durability enhancement, and cost optimization. This trend is likely to drive further research and development efforts aimed at expanding HDPE's applications in the electronics sector, potentially leading to new formulations and processing techniques tailored to specific electronic applications.

Current State and Challenges of HDPE in Electronics

High Density Polyethylene (HDPE) has gained significant traction in the electronics industry due to its unique properties and versatility. Currently, HDPE is widely used in various electronic applications, including cable insulation, connectors, and protective casings. Its excellent electrical insulation properties, coupled with high chemical resistance and durability, make it an attractive material for manufacturers.

In recent years, the integration of HDPE in electronics has expanded to more advanced applications, such as flexible electronics and wearable devices. The material's flexibility and lightweight nature have opened up new possibilities for innovative product designs. However, despite these advancements, several challenges persist in the widespread adoption of HDPE in high-performance electronic applications.

One of the primary challenges is the limited thermal conductivity of HDPE. As electronic devices become more powerful and compact, heat dissipation becomes crucial. The inherent insulating properties of HDPE, while beneficial for electrical insulation, pose a significant hurdle in managing thermal loads. This limitation restricts its use in applications where efficient heat dissipation is critical.

Another challenge lies in the material's relatively low surface energy, which can lead to poor adhesion with other materials. This characteristic complicates the process of bonding HDPE components with other electronic parts or applying coatings, potentially affecting the overall integrity and performance of electronic devices.

The recyclability of HDPE in electronic applications also presents a complex challenge. While HDPE is generally recyclable, the presence of additives and other materials in electronic components can complicate the recycling process. This issue is particularly relevant in the context of growing environmental concerns and regulations surrounding electronic waste management.

From a global perspective, the development and application of HDPE in electronics show geographical variations. Advanced economies like the United States, Japan, and several European countries lead in research and high-end applications. Meanwhile, emerging economies, particularly in Asia, are rapidly advancing in manufacturing capabilities and are becoming significant players in the HDPE electronics market.

Looking ahead, overcoming these challenges requires concerted efforts in research and development. Innovations in composite materials, such as HDPE blends with enhanced thermal properties, are being explored. Additionally, surface modification techniques to improve adhesion and compatibility with other materials are areas of active research. The industry is also focusing on developing more environmentally friendly formulations of HDPE for electronics, addressing the growing demand for sustainable materials in consumer electronics.

Existing HDPE Solutions for Electronic Components

01 Composition and properties of HDPE

High Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength and improved chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and containers.- Composition and properties of HDPE: High Density Polyethylene (HDPE) is a thermoplastic polymer with a high strength-to-density ratio. It is characterized by its long linear chains with minimal branching, resulting in higher tensile strength and improved chemical resistance compared to other polyethylene types. HDPE's properties make it suitable for various applications, including packaging, pipes, and containers.

- HDPE blends and composites: HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites often aim to improve mechanical strength, thermal stability, or specific functional characteristics. Common additives include other polymers, fibers, nanoparticles, or mineral fillers, resulting in materials with tailored properties for specific applications.

- HDPE processing techniques: Various processing techniques are employed to manufacture HDPE products. These include injection molding, extrusion, blow molding, and rotational molding. Each technique offers specific advantages and is suited for different product types. Innovations in processing methods focus on improving efficiency, reducing cycle times, and enhancing the quality of the final products.

- Recycling and sustainability of HDPE: HDPE is recyclable and efforts are being made to improve its recycling processes and increase the use of recycled HDPE in various applications. Research focuses on enhancing the properties of recycled HDPE, developing more efficient recycling methods, and finding new applications for recycled materials. This aligns with global sustainability goals and circular economy principles.

- HDPE applications in specific industries: HDPE finds applications in diverse industries due to its versatile properties. It is widely used in packaging, construction, automotive, and medical industries. Specific applications include food packaging, water pipes, fuel tanks, medical devices, and consumer goods. Ongoing research aims to expand HDPE's use in new areas and improve its performance in existing applications.

02 HDPE blends and composites

HDPE can be blended with other materials or reinforced with additives to enhance its properties. These blends and composites can improve characteristics such as impact resistance, thermal stability, and mechanical strength. Common additives include other polymers, fibers, and nanoparticles, which can be tailored to specific application requirements.Expand Specific Solutions03 HDPE processing techniques

Various processing techniques are used to manufacture HDPE products, including injection molding, extrusion, and blow molding. These methods allow for the production of a wide range of HDPE items, from thin films to large containers. Advanced processing techniques can improve the material's performance and expand its applications in different industries.Expand Specific Solutions04 Recycling and sustainability of HDPE

HDPE is highly recyclable, making it an environmentally friendly option for many applications. Recycling processes for HDPE involve collection, sorting, cleaning, and reprocessing into new products. Innovations in recycling technologies aim to improve the quality of recycled HDPE and increase its use in various industries, contributing to circular economy initiatives.Expand Specific Solutions05 Novel applications of HDPE

Ongoing research and development are expanding the applications of HDPE in various fields. These include advanced packaging solutions, medical devices, automotive components, and construction materials. Novel applications often involve modifying HDPE or combining it with other materials to meet specific performance requirements in challenging environments.Expand Specific Solutions

Key Players in HDPE and Electronics Industries

The high-density polyethylene (HDPE) market in electronics is experiencing significant growth, driven by increasing demand for lightweight, durable, and cost-effective materials. The industry is in a mature stage but continues to evolve with technological advancements. Market size is expanding, particularly in emerging economies, as HDPE finds new applications in electronic components and packaging. Technologically, companies like Dow Global Technologies LLC, LG Chem Ltd., and SABIC Global Technologies BV are at the forefront, developing innovative HDPE formulations with enhanced properties for electronic applications. Research institutions such as Penn State Research Foundation and the University of Connecticut are contributing to advancements in HDPE technology, focusing on improving electrical and thermal properties for specialized electronic uses.

Dow Global Technologies LLC

Panasonic Intellectual Property Management Co. Ltd.

Innovations in HDPE for Electronic Applications

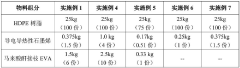

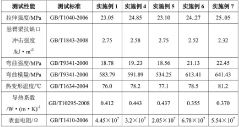

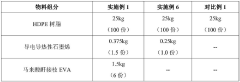

- Graphene is used as an antistatic modifier, and maleic anhydride is grafted onto EVA as a compatibilizer to promote the combination of graphene and high-density polyethylene to form a stable blend and improve its dispersion and mechanical properties.

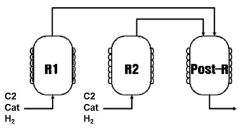

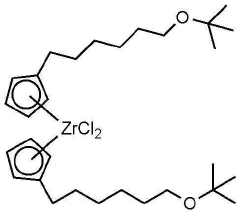

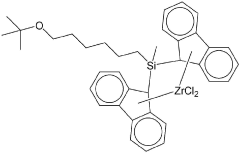

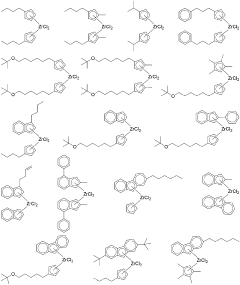

- The production of high-density polyethylene with a molecular weight distribution (Mw/Mn) of 4.5 or less and a ratio of Z-average molecular weight to weight average molecular weight (Mz/Mw) of 2.8 or less, achieved through a bimodal homopolymerization process using a metallocene catalyst, which fine-tunes the molecular weights to optimize film properties.

Environmental Impact and Sustainability of HDPE in Electronics

The environmental impact and sustainability of High Density Polyethylene (HDPE) in electronics have become increasingly important considerations in recent years. As the electronics industry continues to grow, the use of HDPE in various components and packaging has raised concerns about its long-term effects on the environment.

HDPE, being a petroleum-based plastic, contributes to the depletion of non-renewable resources. The extraction and processing of fossil fuels for HDPE production result in significant greenhouse gas emissions, contributing to climate change. Additionally, the manufacturing process of HDPE involves energy-intensive procedures, further increasing its carbon footprint.

One of the primary environmental challenges associated with HDPE in electronics is its persistence in the environment. HDPE is not biodegradable and can take hundreds of years to decompose naturally. This longevity leads to the accumulation of plastic waste in landfills and oceans, posing threats to wildlife and ecosystems. Microplastics derived from HDPE have been found in various marine organisms, potentially entering the food chain and affecting human health.

However, the recyclability of HDPE offers a potential solution to mitigate its environmental impact. HDPE is one of the most widely recycled plastics, with established recycling infrastructure in many countries. When properly collected and processed, HDPE can be recycled multiple times without significant loss of quality. This characteristic makes it a more sustainable option compared to some other plastics used in electronics.

The electronics industry has been exploring various strategies to enhance the sustainability of HDPE usage. One approach is the development of bio-based HDPE, derived from renewable resources such as sugarcane or other plant-based materials. While still in the early stages, bio-based HDPE has the potential to reduce the reliance on fossil fuels and decrease the overall carbon footprint of the material.

Another trend in improving the sustainability of HDPE in electronics is the implementation of closed-loop recycling systems. Some electronics manufacturers are partnering with recycling facilities to ensure that HDPE components from their products are collected, processed, and reused in new products. This approach not only reduces waste but also decreases the demand for virgin HDPE production.

Advancements in HDPE formulations are also contributing to improved sustainability. Researchers are developing HDPE variants with enhanced durability and resistance to degradation, potentially extending the lifespan of electronic components and reducing the frequency of replacements. Additionally, efforts are being made to create HDPE blends that are more easily recyclable or have improved biodegradability without compromising performance.

As regulations and consumer awareness regarding environmental issues continue to grow, the electronics industry is likely to face increased pressure to address the sustainability challenges associated with HDPE usage. This may lead to further innovations in material science, recycling technologies, and product design to minimize the environmental impact of HDPE in electronics while maintaining its beneficial properties.

Regulatory Landscape for HDPE Use in Electronics

The regulatory landscape for High Density Polyethylene (HDPE) use in electronics is complex and evolving, reflecting the growing importance of this material in the industry. Regulatory bodies worldwide are increasingly focusing on the safety, environmental impact, and performance of materials used in electronic devices, including HDPE.

In the United States, the Environmental Protection Agency (EPA) and the Consumer Product Safety Commission (CPSC) play crucial roles in regulating HDPE use in electronics. The EPA's Toxic Substances Control Act (TSCA) governs the production, importation, use, and disposal of chemical substances, including those used in HDPE manufacturing. The CPSC, on the other hand, enforces safety standards for consumer products, including electronic devices that may incorporate HDPE components.

The European Union has implemented stringent regulations through directives such as the Restriction of Hazardous Substances (RoHS) and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH). These directives aim to restrict the use of certain hazardous substances in electrical and electronic equipment and ensure the safe use of chemicals, respectively. While HDPE itself is generally considered safe, manufacturers must ensure that any additives or processing aids used in HDPE production for electronics comply with these regulations.

In Asia, countries like China and Japan have also established their own regulatory frameworks. China's Restriction of Hazardous Substances (China RoHS) and Japan's J-MOSS (Japanese version of RoHS) set similar standards to their European counterpart, affecting the use of HDPE in electronics exported to or manufactured in these countries.

The regulatory landscape also extends to recycling and waste management. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive mandates the proper disposal and recycling of electronic waste, including components made from HDPE. This has led to increased focus on the recyclability and end-of-life management of HDPE used in electronic applications.

As sustainability becomes a global priority, regulations are increasingly emphasizing the use of recycled materials in electronics. This trend is likely to impact HDPE use, potentially driving demand for recycled HDPE in electronic applications. Manufacturers are now required to consider the entire lifecycle of their products, from raw material sourcing to end-of-life disposal.

The regulatory landscape for HDPE in electronics is not static. Ongoing research into the long-term effects of plastics on human health and the environment may lead to new regulations. Additionally, the growing concern over microplastics could result in stricter controls on plastic use in consumer products, including electronics.