How to Boost Heat-Sealability of Cellophane?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Heat-Sealing Evolution and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging since its invention in the early 20th century. The evolution of cellophane's heat-sealing capabilities has been driven by the increasing demand for efficient, reliable, and sustainable packaging solutions. Initially, cellophane's inherent properties made it challenging to heat-seal effectively, limiting its applications in the packaging industry.

The primary objective in boosting the heat-sealability of cellophane is to enhance its performance as a packaging material while maintaining its eco-friendly characteristics. This goal aligns with the growing global emphasis on sustainable packaging solutions and the reduction of plastic waste. Improving cellophane's heat-sealing properties would expand its utility across various industries, including food packaging, pharmaceuticals, and consumer goods.

Over the years, researchers and manufacturers have explored various approaches to enhance cellophane's heat-sealability. These efforts have focused on modifying the surface properties of cellophane, developing compatible coatings, and optimizing the heat-sealing process parameters. The evolution of these techniques has been marked by a shift from simple mechanical modifications to more sophisticated chemical treatments and nanotechnology applications.

One significant milestone in this journey was the development of moisture-proof cellophane in the 1930s, which improved its barrier properties and made it more suitable for food packaging. This innovation paved the way for further advancements in cellophane's heat-sealing capabilities. Subsequent developments included the introduction of heat-sealable coatings and the exploration of biodegradable additives to enhance sealing performance while maintaining environmental sustainability.

The current technological landscape presents both challenges and opportunities for cellophane heat-sealing. Advancements in material science and nanotechnology offer promising avenues for improving cellophane's heat-sealability without compromising its biodegradability. Researchers are investigating novel surface modification techniques, such as plasma treatment and the application of nanoparticles, to enhance the film's heat-sealing properties.

Looking ahead, the objectives for boosting cellophane's heat-sealability include developing more efficient and cost-effective methods for surface modification, creating stronger and more reliable seals, and reducing the energy requirements for the heat-sealing process. Additionally, there is a focus on ensuring that any improvements in heat-sealability do not compromise cellophane's recyclability or biodegradability, aligning with the growing demand for sustainable packaging solutions.

The primary objective in boosting the heat-sealability of cellophane is to enhance its performance as a packaging material while maintaining its eco-friendly characteristics. This goal aligns with the growing global emphasis on sustainable packaging solutions and the reduction of plastic waste. Improving cellophane's heat-sealing properties would expand its utility across various industries, including food packaging, pharmaceuticals, and consumer goods.

Over the years, researchers and manufacturers have explored various approaches to enhance cellophane's heat-sealability. These efforts have focused on modifying the surface properties of cellophane, developing compatible coatings, and optimizing the heat-sealing process parameters. The evolution of these techniques has been marked by a shift from simple mechanical modifications to more sophisticated chemical treatments and nanotechnology applications.

One significant milestone in this journey was the development of moisture-proof cellophane in the 1930s, which improved its barrier properties and made it more suitable for food packaging. This innovation paved the way for further advancements in cellophane's heat-sealing capabilities. Subsequent developments included the introduction of heat-sealable coatings and the exploration of biodegradable additives to enhance sealing performance while maintaining environmental sustainability.

The current technological landscape presents both challenges and opportunities for cellophane heat-sealing. Advancements in material science and nanotechnology offer promising avenues for improving cellophane's heat-sealability without compromising its biodegradability. Researchers are investigating novel surface modification techniques, such as plasma treatment and the application of nanoparticles, to enhance the film's heat-sealing properties.

Looking ahead, the objectives for boosting cellophane's heat-sealability include developing more efficient and cost-effective methods for surface modification, creating stronger and more reliable seals, and reducing the energy requirements for the heat-sealing process. Additionally, there is a focus on ensuring that any improvements in heat-sealability do not compromise cellophane's recyclability or biodegradability, aligning with the growing demand for sustainable packaging solutions.

Market Analysis for Enhanced Cellophane Packaging

The global cellophane packaging market has been experiencing steady growth, driven by increasing demand for sustainable and biodegradable packaging solutions. As consumers become more environmentally conscious, the appeal of cellophane as a renewable and compostable material has risen significantly. The market size for cellophane packaging was valued at approximately $600 million in 2020 and is projected to reach $900 million by 2026, growing at a CAGR of around 6.5% during the forecast period.

The food and beverage industry remains the largest end-user segment for cellophane packaging, accounting for over 40% of the market share. This is primarily due to cellophane's excellent barrier properties against moisture and gases, making it ideal for preserving food freshness. The pharmaceutical and personal care sectors are also significant contributors to market growth, with increasing adoption of cellophane for blister packs and cosmetic packaging.

Geographically, Asia-Pacific leads the cellophane packaging market, followed by North America and Europe. The rapid growth in the Asia-Pacific region is attributed to the expanding food processing industry and rising disposable incomes in countries like China and India. North America and Europe, while mature markets, continue to see steady demand driven by the shift towards eco-friendly packaging alternatives.

The enhanced heat-sealability of cellophane presents a significant market opportunity. Improved heat-sealing properties can address one of the main limitations of traditional cellophane, potentially expanding its applications in various industries. This enhancement could lead to increased market penetration in sectors where airtight sealing is crucial, such as in modified atmosphere packaging for fresh produce or medical device packaging.

Key market drivers for enhanced cellophane packaging include stringent regulations on plastic usage, growing consumer preference for sustainable packaging, and technological advancements in bioplastics. However, challenges such as competition from other biodegradable materials and the higher cost compared to conventional plastics need to be addressed to fully capitalize on market potential.

The market landscape is characterized by a mix of established players and innovative startups. Major companies are investing in research and development to improve cellophane properties, including heat-sealability. Collaborations between material scientists, packaging manufacturers, and end-users are becoming more common, fostering innovation in this space.

The food and beverage industry remains the largest end-user segment for cellophane packaging, accounting for over 40% of the market share. This is primarily due to cellophane's excellent barrier properties against moisture and gases, making it ideal for preserving food freshness. The pharmaceutical and personal care sectors are also significant contributors to market growth, with increasing adoption of cellophane for blister packs and cosmetic packaging.

Geographically, Asia-Pacific leads the cellophane packaging market, followed by North America and Europe. The rapid growth in the Asia-Pacific region is attributed to the expanding food processing industry and rising disposable incomes in countries like China and India. North America and Europe, while mature markets, continue to see steady demand driven by the shift towards eco-friendly packaging alternatives.

The enhanced heat-sealability of cellophane presents a significant market opportunity. Improved heat-sealing properties can address one of the main limitations of traditional cellophane, potentially expanding its applications in various industries. This enhancement could lead to increased market penetration in sectors where airtight sealing is crucial, such as in modified atmosphere packaging for fresh produce or medical device packaging.

Key market drivers for enhanced cellophane packaging include stringent regulations on plastic usage, growing consumer preference for sustainable packaging, and technological advancements in bioplastics. However, challenges such as competition from other biodegradable materials and the higher cost compared to conventional plastics need to be addressed to fully capitalize on market potential.

The market landscape is characterized by a mix of established players and innovative startups. Major companies are investing in research and development to improve cellophane properties, including heat-sealability. Collaborations between material scientists, packaging manufacturers, and end-users are becoming more common, fostering innovation in this space.

Current Challenges in Cellophane Heat-Sealability

Despite the numerous advantages of cellophane as a packaging material, its heat-sealability remains a significant challenge in the industry. The primary issue lies in cellophane's inherent chemical structure, which lacks the thermoplastic properties necessary for effective heat sealing. Unlike materials such as polyethylene or polypropylene, cellophane does not melt or flow when heated, making it difficult to create strong, reliable seals using conventional heat-sealing methods.

One of the major challenges is achieving consistent seal strength across different cellophane grades and thicknesses. The variability in cellophane composition, particularly in terms of moisture content and surface treatments, can lead to inconsistent sealing results. This inconsistency poses problems in large-scale manufacturing processes where uniformity and reliability are crucial.

Another significant hurdle is the narrow temperature window for effective sealing. Cellophane requires precise temperature control during the sealing process. If the temperature is too low, the seal may not form properly, leading to weak bonds and potential package failures. Conversely, if the temperature is too high, it can cause degradation of the cellophane structure, compromising the integrity of the packaging material.

The speed of the sealing process also presents challenges. In high-speed packaging lines, the time available for heat sealing is limited. Achieving a strong, reliable seal within these time constraints is difficult with cellophane, especially when compared to more readily heat-sealable materials.

Moisture sensitivity is another critical issue affecting cellophane's heat-sealability. Cellophane's hygroscopic nature means that its moisture content can fluctuate based on environmental conditions. This variability can significantly impact the material's behavior during the heat-sealing process, leading to inconsistent results and potential seal failures.

The environmental impact of improving cellophane's heat-sealability is also a growing concern. Many current solutions involve adding synthetic coatings or layers to enhance sealability, which can compromise the material's biodegradability and recyclability. Balancing improved heat-sealability with maintaining cellophane's eco-friendly properties remains a significant challenge for researchers and manufacturers.

Lastly, the cost-effectiveness of enhancing cellophane's heat-sealability is a major consideration. Developing new technologies or applying additional treatments to improve sealability often increases production costs, which can be prohibitive in an industry where cost competitiveness is crucial. Finding economically viable solutions that do not significantly increase the overall cost of cellophane packaging is an ongoing challenge in the industry.

One of the major challenges is achieving consistent seal strength across different cellophane grades and thicknesses. The variability in cellophane composition, particularly in terms of moisture content and surface treatments, can lead to inconsistent sealing results. This inconsistency poses problems in large-scale manufacturing processes where uniformity and reliability are crucial.

Another significant hurdle is the narrow temperature window for effective sealing. Cellophane requires precise temperature control during the sealing process. If the temperature is too low, the seal may not form properly, leading to weak bonds and potential package failures. Conversely, if the temperature is too high, it can cause degradation of the cellophane structure, compromising the integrity of the packaging material.

The speed of the sealing process also presents challenges. In high-speed packaging lines, the time available for heat sealing is limited. Achieving a strong, reliable seal within these time constraints is difficult with cellophane, especially when compared to more readily heat-sealable materials.

Moisture sensitivity is another critical issue affecting cellophane's heat-sealability. Cellophane's hygroscopic nature means that its moisture content can fluctuate based on environmental conditions. This variability can significantly impact the material's behavior during the heat-sealing process, leading to inconsistent results and potential seal failures.

The environmental impact of improving cellophane's heat-sealability is also a growing concern. Many current solutions involve adding synthetic coatings or layers to enhance sealability, which can compromise the material's biodegradability and recyclability. Balancing improved heat-sealability with maintaining cellophane's eco-friendly properties remains a significant challenge for researchers and manufacturers.

Lastly, the cost-effectiveness of enhancing cellophane's heat-sealability is a major consideration. Developing new technologies or applying additional treatments to improve sealability often increases production costs, which can be prohibitive in an industry where cost competitiveness is crucial. Finding economically viable solutions that do not significantly increase the overall cost of cellophane packaging is an ongoing challenge in the industry.

Existing Heat-Sealing Solutions for Cellophane

01 Composition for improving heat-sealability

Various compositions can be used to enhance the heat-sealability of cellophane. These may include specific polymers, additives, or coatings that improve the material's ability to form strong seals when heat is applied. The compositions are designed to lower the sealing temperature, increase seal strength, or improve overall sealability performance.- Composition for improving heat-sealability: Various compositions can be added to cellophane to enhance its heat-sealability. These may include specific polymers, resins, or additives that lower the sealing temperature or improve the bond strength. Such compositions can be applied as coatings or incorporated into the cellophane structure during manufacturing.

- Surface treatment techniques: Different surface treatment methods can be employed to modify the cellophane surface and improve its heat-sealing properties. These may include corona discharge treatment, plasma treatment, or chemical modifications that increase the surface energy and promote better adhesion during heat-sealing.

- Multi-layer structures for enhanced sealability: Developing multi-layer structures that combine cellophane with other materials can improve heat-sealability. This may involve laminating cellophane with heat-sealable polymers or creating composite structures that maintain cellophane's properties while enhancing its sealing capabilities.

- Heat-sealing equipment and process optimization: Specialized heat-sealing equipment and optimized sealing processes can improve the heat-sealability of cellophane. This may include precise temperature control, pressure application techniques, and sealing time adjustments to achieve optimal bonding without damaging the cellophane.

- Nanotechnology applications: Incorporating nanoparticles or nanostructures into cellophane or its coatings can enhance heat-sealability. These nanomaterials may improve thermal conductivity, lower sealing temperatures, or create stronger interfacial bonds during the heat-sealing process.

02 Surface treatment methods

Different surface treatment methods can be applied to cellophane to improve its heat-sealability. These may include corona discharge treatment, plasma treatment, or chemical modifications of the surface. Such treatments can alter the surface properties of cellophane, making it more receptive to heat-sealing.Expand Specific Solutions03 Multilayer structures

Developing multilayer structures that incorporate cellophane can enhance heat-sealability. This may involve laminating cellophane with other materials that have better heat-sealing properties or creating composite structures that combine the benefits of cellophane with improved sealability.Expand Specific Solutions04 Heat-sealing equipment and processes

Specialized equipment and optimized processes can be used to improve the heat-sealability of cellophane. This may include precise temperature control, pressure application techniques, or innovative sealing mechanisms designed specifically for cellophane materials.Expand Specific Solutions05 Additives for enhanced heat-sealability

Specific additives can be incorporated into cellophane or applied as coatings to improve its heat-sealability. These may include plasticizers, heat-activated adhesives, or other chemical compounds that enhance the material's ability to form strong seals when heat is applied.Expand Specific Solutions

Key Players in Cellophane Manufacturing Industry

The heat-sealability enhancement of cellophane is in a mature stage of development, with a substantial market size driven by packaging industry demands. The technology's maturity is evident from the involvement of established players like Corning, Inc., DIC Corp., and Nippon Paper Industries Co., Ltd. These companies leverage their expertise in materials science and chemical engineering to develop advanced solutions. The competitive landscape is diverse, including both specialized chemical manufacturers and large conglomerates with broad portfolios. While the core technology is well-established, ongoing research focuses on improving performance, sustainability, and cost-effectiveness, indicating potential for further innovation and market growth in this sector.

Corning, Inc.

Technical Solution: Corning has developed advanced glass and ceramic technologies that can be applied to improve the heat-sealability of cellophane. Their approach involves creating a thin, heat-resistant coating that can be applied to cellophane surfaces. This coating is composed of specialized glass ceramics that maintain structural integrity at high temperatures while allowing for effective heat sealing[1]. The coating is applied using a vapor deposition process, ensuring uniform coverage and strong adhesion to the cellophane substrate[3]. Additionally, Corning has incorporated nanoparticles into the coating to enhance its thermal conductivity, allowing for more efficient heat transfer during the sealing process[5].

Strengths: Superior heat resistance, improved seal strength, and compatibility with existing cellophane manufacturing processes. Weaknesses: Potentially higher production costs and the need for specialized equipment for coating application.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents has developed a polymer-based solution to improve the heat-sealability of cellophane. Their approach involves co-extruding a thin layer of specially engineered polyolefin onto the cellophane substrate[15]. This polyolefin layer is designed to have excellent adhesion to cellophane while providing superior heat-sealing properties. The company has developed a proprietary blend of metallocene catalyzed polyethylene and polypropylene copolymers that offer a wide sealing temperature range and high seal strength[17]. Additionally, ExxonMobil has incorporated nano-scale clay particles into the polyolefin layer, which act as barriers to moisture and oxygen, further enhancing the protective properties of the sealed cellophane[19]. The company has also developed a corona treatment process that improves the bonding between the cellophane and the polyolefin layer, ensuring long-term stability of the heat-sealable properties[21].

Strengths: Wide sealing temperature range, high seal strength, and improved barrier properties. Weaknesses: Potential reduction in the overall biodegradability of the cellophane product.

Innovative Approaches to Improve Heat-Sealability

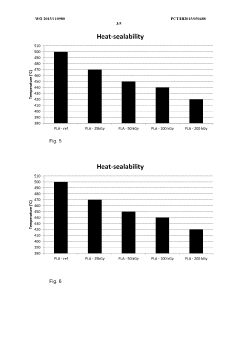

Methods for lowering melt viscosity and improving heat-sealability of polyester and for manufacturing a heat-sealed container or package

PatentWO2015110980A1

Innovation

- Subjecting polyester coatings to electron beam (EB) radiation to lower melt viscosity and improve heat-sealability, avoiding catalysts that promote cross-linking, and combining with other treatments like UV radiation and flame treatment to enhance adhesion and reduce heat-sealing temperatures.

Heat sealing agent, laminate body using same, and solar cell module

PatentWO2013136861A1

Innovation

- A heat-sealing agent comprising a urethane resin, polyolefin resin, and a cross-linking agent, specifically using a combination of alkylated methylol melamine resin and epoxy compounds, which forms a cross-linked structure to enhance adhesion and moisture resistance, applied in advance to one substrate and cured before bonding, ensuring strong and durable bonds.

Environmental Impact of Cellophane Heat-Sealing

The environmental impact of cellophane heat-sealing is a critical consideration in the packaging industry, particularly as sustainability becomes increasingly important. Cellophane, a biodegradable material derived from cellulose, offers certain environmental advantages over traditional plastic films. However, the heat-sealing process and its associated materials can introduce additional environmental concerns.

The heat-sealing of cellophane typically requires the application of a heat-sealable coating, which may contain synthetic polymers or other additives. These coatings can potentially reduce the biodegradability of the cellophane, impacting its end-of-life environmental profile. The composition of these coatings and their compatibility with recycling or composting systems is a key factor in assessing the overall environmental impact.

Energy consumption during the heat-sealing process is another significant environmental consideration. The process requires precise temperature control and consistent heat application, which can be energy-intensive. Improving the energy efficiency of heat-sealing equipment and processes can help mitigate this impact. Additionally, the development of low-temperature sealing technologies could further reduce energy requirements.

The disposal of heat-sealed cellophane packaging presents both challenges and opportunities. While uncoated cellophane is biodegradable, heat-sealed versions may not break down as readily in natural environments. Proper waste management and consumer education are crucial to ensure that these materials are disposed of correctly, either through specialized recycling programs or industrial composting facilities.

The production of cellophane itself, while based on renewable resources, involves chemical processes that can have environmental implications. Efforts to improve the sustainability of cellophane production, such as using more environmentally friendly solvents or optimizing manufacturing processes, can contribute to reducing the overall environmental footprint of heat-sealed cellophane products.

Water usage and potential water pollution are additional factors to consider in the environmental assessment of cellophane heat-sealing. The production of cellophane and the application of heat-sealable coatings may involve water-intensive processes. Implementing water recycling systems and treating wastewater effectively can help mitigate these impacts.

As the packaging industry moves towards more sustainable solutions, research into bio-based and fully compostable heat-sealable coatings for cellophane is gaining momentum. These innovations aim to maintain the functional benefits of heat-sealing while minimizing environmental impact throughout the product lifecycle.

The heat-sealing of cellophane typically requires the application of a heat-sealable coating, which may contain synthetic polymers or other additives. These coatings can potentially reduce the biodegradability of the cellophane, impacting its end-of-life environmental profile. The composition of these coatings and their compatibility with recycling or composting systems is a key factor in assessing the overall environmental impact.

Energy consumption during the heat-sealing process is another significant environmental consideration. The process requires precise temperature control and consistent heat application, which can be energy-intensive. Improving the energy efficiency of heat-sealing equipment and processes can help mitigate this impact. Additionally, the development of low-temperature sealing technologies could further reduce energy requirements.

The disposal of heat-sealed cellophane packaging presents both challenges and opportunities. While uncoated cellophane is biodegradable, heat-sealed versions may not break down as readily in natural environments. Proper waste management and consumer education are crucial to ensure that these materials are disposed of correctly, either through specialized recycling programs or industrial composting facilities.

The production of cellophane itself, while based on renewable resources, involves chemical processes that can have environmental implications. Efforts to improve the sustainability of cellophane production, such as using more environmentally friendly solvents or optimizing manufacturing processes, can contribute to reducing the overall environmental footprint of heat-sealed cellophane products.

Water usage and potential water pollution are additional factors to consider in the environmental assessment of cellophane heat-sealing. The production of cellophane and the application of heat-sealable coatings may involve water-intensive processes. Implementing water recycling systems and treating wastewater effectively can help mitigate these impacts.

As the packaging industry moves towards more sustainable solutions, research into bio-based and fully compostable heat-sealable coatings for cellophane is gaining momentum. These innovations aim to maintain the functional benefits of heat-sealing while minimizing environmental impact throughout the product lifecycle.

Regulatory Compliance for Cellophane Packaging

Regulatory compliance is a critical aspect of cellophane packaging, particularly when considering heat-sealability enhancements. The Food and Drug Administration (FDA) in the United States and the European Food Safety Authority (EFSA) in the European Union are the primary regulatory bodies overseeing the safety of food packaging materials, including cellophane.

For cellophane to be used in food packaging applications, it must comply with FDA regulations, specifically 21 CFR 177.1200, which outlines the requirements for cellophane intended for food contact. This regulation stipulates the permissible raw materials, additives, and manufacturing processes for cellophane. Any modifications to improve heat-sealability must adhere to these guidelines to ensure food safety.

In the EU, cellophane must comply with Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, Commission Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food may apply if the cellophane is coated with certain substances to enhance heat-sealability.

When developing heat-sealable cellophane, manufacturers must consider migration limits for any substances used in the coating or modification process. These limits ensure that potentially harmful substances do not transfer from the packaging to the food in quantities that could pose a risk to human health or alter the food's composition or organoleptic properties.

Compliance testing is a crucial step in the regulatory process. This typically involves migration testing, where the packaging material is exposed to food simulants under specific time and temperature conditions to assess the potential transfer of substances. The results of these tests must fall within the established limits for the packaging to be deemed safe for food contact.

Environmental regulations also play a role in cellophane packaging compliance. As sustainability becomes increasingly important, regulations around biodegradability and compostability may impact the development of heat-sealable cellophane. In the EU, for instance, packaging claiming to be compostable must meet the requirements of EN 13432.

Manufacturers seeking to boost the heat-sealability of cellophane must navigate these regulatory frameworks carefully. Any new additives or processes introduced to enhance heat-sealability must be thoroughly evaluated for their safety and compliance with existing regulations. This may involve submitting new food contact notifications to regulatory authorities or obtaining specific clearances for novel substances or technologies.

For cellophane to be used in food packaging applications, it must comply with FDA regulations, specifically 21 CFR 177.1200, which outlines the requirements for cellophane intended for food contact. This regulation stipulates the permissible raw materials, additives, and manufacturing processes for cellophane. Any modifications to improve heat-sealability must adhere to these guidelines to ensure food safety.

In the EU, cellophane must comply with Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food. This regulation sets out general principles of safety and inertness for all food contact materials. Additionally, Commission Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food may apply if the cellophane is coated with certain substances to enhance heat-sealability.

When developing heat-sealable cellophane, manufacturers must consider migration limits for any substances used in the coating or modification process. These limits ensure that potentially harmful substances do not transfer from the packaging to the food in quantities that could pose a risk to human health or alter the food's composition or organoleptic properties.

Compliance testing is a crucial step in the regulatory process. This typically involves migration testing, where the packaging material is exposed to food simulants under specific time and temperature conditions to assess the potential transfer of substances. The results of these tests must fall within the established limits for the packaging to be deemed safe for food contact.

Environmental regulations also play a role in cellophane packaging compliance. As sustainability becomes increasingly important, regulations around biodegradability and compostability may impact the development of heat-sealable cellophane. In the EU, for instance, packaging claiming to be compostable must meet the requirements of EN 13432.

Manufacturers seeking to boost the heat-sealability of cellophane must navigate these regulatory frameworks carefully. Any new additives or processes introduced to enhance heat-sealability must be thoroughly evaluated for their safety and compliance with existing regulations. This may involve submitting new food contact notifications to regulatory authorities or obtaining specific clearances for novel substances or technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!