How to Enhance Anti-Corrosion Properties Using GO?

GO Anti-Corrosion Background and Objectives

Graphene oxide (GO) has emerged as a promising material in the field of anti-corrosion coatings, attracting significant attention from researchers and industries alike. The development of GO-based anti-corrosion solutions represents a convergence of nanotechnology and materials science, aiming to address the persistent challenge of corrosion in various sectors, including aerospace, automotive, and marine industries.

The evolution of anti-corrosion technologies has seen a shift from traditional methods, such as galvanization and chromate conversion coatings, to more advanced and environmentally friendly alternatives. GO, with its unique two-dimensional structure and exceptional properties, has positioned itself at the forefront of this technological transition. The primary objective in this field is to harness the intrinsic characteristics of GO to create highly effective, durable, and sustainable anti-corrosion coatings.

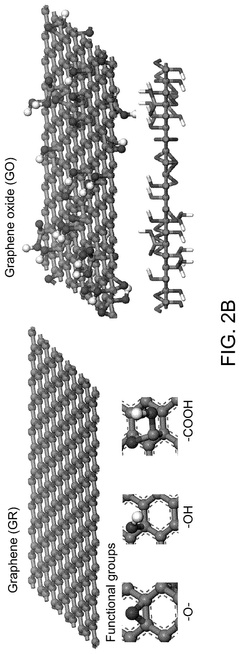

GO's potential in anti-corrosion applications stems from its remarkable barrier properties, high surface area, and ability to form strong interactions with polymer matrices. These attributes contribute to enhanced impermeability to corrosive agents and improved adhesion to substrate materials. The goal is to develop GO-based coatings that not only provide superior protection against corrosion but also offer additional functionalities such as self-healing capabilities and environmental sustainability.

The technological trajectory in this domain is focused on optimizing GO synthesis methods, improving dispersion techniques, and developing novel composite formulations. Researchers are exploring various approaches to functionalize GO, aiming to enhance its compatibility with different coating systems and substrates. The ultimate objective is to create a new generation of anti-corrosion coatings that outperform existing solutions in terms of protection efficiency, longevity, and cost-effectiveness.

As the field progresses, there is a growing emphasis on understanding the fundamental mechanisms of GO's anti-corrosion properties at the molecular level. This knowledge is crucial for tailoring GO-based solutions to specific environmental conditions and substrate materials. Additionally, efforts are being made to scale up production processes and overcome challenges related to the integration of GO into existing manufacturing workflows.

The development of GO-based anti-corrosion technologies aligns with broader industry trends towards sustainable and environmentally friendly solutions. As regulatory pressures mount to phase out toxic corrosion inhibitors, GO presents a promising alternative that could revolutionize corrosion protection strategies across multiple industries. The ongoing research and development in this area aim to bridge the gap between laboratory discoveries and practical, large-scale applications, paving the way for a new era in corrosion prevention and material protection.

Market Demand for Advanced Anti-Corrosion Solutions

The market demand for advanced anti-corrosion solutions has been steadily increasing across various industries, driven by the need to protect critical infrastructure, equipment, and materials from the detrimental effects of corrosion. This growing demand is particularly evident in sectors such as oil and gas, marine, aerospace, automotive, and construction, where corrosion-related issues can lead to significant economic losses and safety concerns.

In the oil and gas industry, the demand for effective anti-corrosion solutions is paramount due to the harsh operating environments and the high costs associated with equipment failure and maintenance. Offshore platforms, pipelines, and storage tanks are constantly exposed to corrosive elements, necessitating robust protective measures. The marine sector faces similar challenges, with ships, offshore structures, and port facilities requiring advanced anti-corrosion technologies to withstand the aggressive saltwater environment.

The aerospace industry has also been a key driver in the demand for innovative anti-corrosion solutions. Aircraft components are subjected to extreme temperature variations, moisture, and atmospheric pollutants, making corrosion protection a critical factor in ensuring safety and longevity. Similarly, the automotive sector has been increasingly focusing on corrosion resistance to extend vehicle lifespans and maintain structural integrity, particularly in regions with harsh weather conditions or high road salt usage.

In the construction industry, the demand for advanced anti-corrosion solutions has been fueled by the need to protect steel reinforcements in concrete structures, especially in coastal areas or regions with high humidity. The growing emphasis on sustainable and long-lasting infrastructure has further amplified this demand, as improved corrosion resistance directly translates to reduced maintenance costs and extended service life of buildings and bridges.

The market for anti-corrosion solutions has also been influenced by stringent environmental regulations and a shift towards more sustainable practices. This has led to increased interest in eco-friendly corrosion inhibitors and coating technologies that offer effective protection while minimizing environmental impact. As a result, there is a growing demand for innovative solutions that can provide superior corrosion resistance without relying on traditional, potentially harmful chemicals.

The integration of nanotechnology in anti-corrosion solutions has opened up new possibilities, with graphene oxide (GO) emerging as a promising material in this field. The unique properties of GO, including its high surface area, excellent barrier properties, and potential for functionalization, have attracted significant attention from researchers and industry professionals alike. This has created a niche market demand for GO-based anti-corrosion solutions that can offer enhanced protection compared to conventional methods.

Current Challenges in GO-based Anti-Corrosion Technology

Despite the promising potential of graphene oxide (GO) in anti-corrosion applications, several significant challenges persist in the development and implementation of GO-based anti-corrosion technologies. These challenges span across various aspects of material science, engineering, and practical application.

One of the primary challenges is achieving uniform and stable dispersion of GO in coating matrices. GO tends to agglomerate due to its high surface energy and strong van der Waals interactions between individual sheets. This agglomeration can lead to inconsistent coating performance and reduced effectiveness of the anti-corrosion properties. Researchers are exploring various dispersion techniques and surface modifications to overcome this issue, but a universally effective solution remains elusive.

Another critical challenge lies in the long-term stability of GO-based coatings. While initial anti-corrosion performance may be impressive, maintaining this effectiveness over extended periods, especially in harsh environmental conditions, is problematic. GO can degrade or detach from the substrate over time, compromising the protective barrier. Developing strategies to enhance the adhesion and durability of GO coatings is crucial for their practical implementation.

The scalability of GO production and coating processes presents a significant hurdle for industrial adoption. Current methods for producing high-quality GO are often limited to laboratory scales, and scaling up these processes while maintaining consistent quality and cost-effectiveness is challenging. Similarly, applying GO coatings uniformly and efficiently on large or complex surfaces requires further technological advancements.

Compatibility issues between GO and various substrate materials pose another challenge. Different metals and alloys may interact differently with GO, affecting adhesion and overall performance. Developing universal GO-based solutions that work effectively across a wide range of substrates is an ongoing area of research.

Environmental concerns and regulatory compliance also present challenges. While GO itself is considered relatively environmentally friendly, the production processes and potential long-term environmental impacts of GO-based coatings need thorough investigation. Ensuring that these coatings meet stringent environmental regulations without compromising performance is a delicate balance to achieve.

Lastly, the cost-effectiveness of GO-based anti-corrosion solutions compared to traditional methods remains a significant barrier to widespread adoption. While the potential benefits are clear, the current production costs and application processes of GO coatings often outweigh those of conventional anti-corrosion treatments. Bridging this economic gap is crucial for the commercial viability of GO-based anti-corrosion technologies.

Existing GO-based Anti-Corrosion Techniques

01 Graphene oxide coatings for corrosion protection

Graphene oxide (GO) can be used to create protective coatings on various materials to enhance their corrosion resistance. These coatings form a barrier that prevents corrosive agents from reaching the underlying substrate, thereby significantly improving the material's durability and lifespan in corrosive environments.- Graphene oxide coatings for corrosion protection: Graphene oxide (GO) can be used to create protective coatings on various materials to enhance their corrosion resistance. These coatings form a barrier that prevents corrosive agents from reaching the underlying substrate, thereby significantly improving the material's durability and lifespan in corrosive environments.

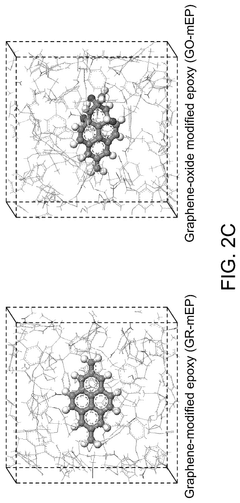

- GO-based composite materials for anti-corrosion applications: Composite materials incorporating graphene oxide exhibit enhanced anti-corrosion properties. These composites combine the barrier properties of GO with the mechanical strength of other materials, resulting in improved corrosion resistance and overall performance in harsh environments.

- Functionalized GO for improved corrosion inhibition: Functionalization of graphene oxide can further enhance its anti-corrosion properties. By modifying the surface of GO with specific functional groups or molecules, its ability to adhere to substrates and resist corrosion can be significantly improved, leading to more effective protective coatings.

- GO-based anticorrosion additives for coatings and paints: Graphene oxide can be used as an additive in various coatings and paints to impart anti-corrosion properties. When incorporated into these formulations, GO enhances the barrier properties and overall corrosion resistance of the coating, providing long-lasting protection to the underlying material.

- Electrochemical deposition of GO for corrosion protection: Electrochemical deposition techniques can be used to apply graphene oxide coatings on various substrates for corrosion protection. This method allows for precise control over the thickness and uniformity of the GO layer, resulting in highly effective anti-corrosion coatings for metals and other materials.

02 GO-based composite materials for anti-corrosion applications

Composite materials incorporating graphene oxide exhibit enhanced anti-corrosion properties. These composites often combine GO with polymers, metals, or other nanomaterials to create synergistic effects that improve corrosion resistance, mechanical strength, and overall performance in harsh environments.Expand Specific Solutions03 Functionalization of GO for improved anti-corrosion performance

Chemical functionalization of graphene oxide can further enhance its anti-corrosion properties. By modifying the surface of GO with specific functional groups or molecules, its compatibility with different substrates can be improved, leading to better adhesion and more effective corrosion protection.Expand Specific Solutions04 GO-based anti-corrosion coatings for metal substrates

Graphene oxide-based coatings are particularly effective in protecting metal substrates from corrosion. These coatings can be applied to various metals, including steel, aluminum, and copper, providing a durable and efficient barrier against oxidation and other corrosive processes.Expand Specific Solutions05 Self-healing GO coatings for long-term corrosion protection

Advanced GO-based coatings with self-healing properties have been developed to provide long-term corrosion protection. These coatings can autonomously repair minor damages or cracks, maintaining their protective function over extended periods and reducing the need for frequent maintenance or reapplication.Expand Specific Solutions

Key Players in GO Anti-Corrosion Research and Industry

The anti-corrosion properties enhancement using graphene oxide (GO) is an emerging field in materials science, currently in its growth phase. The market for GO-based anti-corrosion solutions is expanding rapidly, driven by increasing demand in industries such as aerospace, automotive, and marine. The technology's maturity is progressing, with academic institutions like Massachusetts Institute of Technology, Rensselaer Polytechnic Institute, and National University of Singapore leading fundamental research. Companies such as Chengdu Henggu New Material Technology Co., Ltd. and Daqing Baoyi Petroleum Technology Co., Ltd. are actively developing commercial applications, indicating a transition from laboratory to industrial scale. However, challenges in large-scale production and integration into existing coating systems suggest that the technology is still evolving, with significant potential for further advancements and market growth.

Chengdu Henggu New Material Technology Co., Ltd.

BBMG Corp.

Innovative GO Functionalization for Corrosion Resistance

- Cerium-modified zinc phosphate nanopigments are synthesized and grafted onto graphene oxide nanoplatforms, reducing hydrophilicity and providing a porous medium for encapsulating organic corrosion inhibitors, which can be released on demand to mitigate anodic and cathodic reactions.

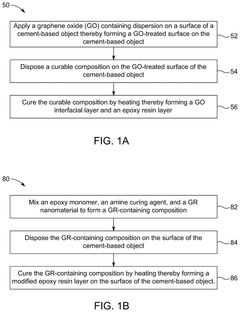

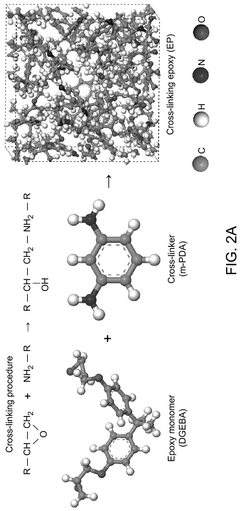

- A method involving the application of a graphene oxide (GO) containing dispersion on a cement-based object to form a GO-treated surface, followed by the application and curing of a curable composition that includes an epoxy monomer and amine curing agent, forming a GO interfacial layer that enhances adhesion by forming hydrogen bonds with hydrated calcium silicate particles, thereby improving the interfacial bonding and resistance to environmental conditions.

Environmental Impact of GO Anti-Corrosion Solutions

The use of graphene oxide (GO) in anti-corrosion solutions has gained significant attention due to its exceptional properties. However, it is crucial to consider the environmental impact of these solutions throughout their lifecycle. The production of GO involves chemical processes that may generate hazardous waste and consume substantial energy. The oxidation of graphite to create GO often requires strong oxidizing agents, which can lead to the release of toxic byproducts if not properly managed.

During the application of GO-based anti-corrosion coatings, there is potential for nanoparticle release into the environment. This raises concerns about the impact on aquatic ecosystems and soil microorganisms. Studies have shown that GO can interact with various organisms, potentially affecting their growth and reproduction. The long-term persistence of GO in the environment is another factor to consider, as its degradation pathways are not yet fully understood.

On the positive side, GO-enhanced anti-corrosion solutions can contribute to environmental protection by extending the lifespan of materials and reducing the need for frequent replacements. This, in turn, leads to decreased resource consumption and waste generation. Additionally, the improved corrosion resistance provided by GO can prevent the leaching of harmful metals from corroded surfaces into the environment.

The disposal of GO-containing products at the end of their life cycle presents both challenges and opportunities. While recycling these materials may be complex due to the presence of nanoparticles, proper recovery techniques could potentially allow for the reuse of GO in new applications, minimizing waste.

Research is ongoing to develop more environmentally friendly methods for GO production and application. Green synthesis approaches using plant extracts or microbial processes are being explored to reduce the environmental footprint of GO manufacturing. Furthermore, efforts are being made to optimize GO-based coatings to minimize nanoparticle release while maintaining their anti-corrosion efficacy.

As the use of GO in anti-corrosion solutions continues to grow, it is essential to conduct comprehensive life cycle assessments to fully understand and mitigate potential environmental impacts. This includes evaluating the entire process from raw material extraction to end-of-life disposal. By addressing these environmental considerations, researchers and industry professionals can work towards developing sustainable GO-based anti-corrosion solutions that balance performance with ecological responsibility.

Cost-Benefit Analysis of GO Anti-Corrosion Technologies

The cost-benefit analysis of graphene oxide (GO) anti-corrosion technologies reveals a complex interplay of economic factors and performance advantages. Initial implementation costs for GO-based coatings are generally higher than traditional anti-corrosion methods due to the specialized production processes and materials required. However, these upfront expenses are often offset by the long-term benefits of enhanced durability and reduced maintenance needs.

GO coatings demonstrate superior corrosion resistance compared to conventional alternatives, potentially extending the lifespan of protected surfaces by 2-3 times. This longevity translates to significant cost savings in terms of reduced frequency of reapplication and minimized downtime for maintenance. Industries such as marine, oil and gas, and infrastructure can particularly benefit from these extended protection periods, as corrosion-related failures in these sectors can lead to substantial financial losses and safety risks.

The thin nature of GO coatings allows for minimal material usage while maintaining effectiveness, potentially reducing overall material costs in large-scale applications. Additionally, GO's ability to form strong chemical bonds with various substrates enhances adhesion, further contributing to the coating's longevity and performance.

Environmental considerations also factor into the cost-benefit analysis. GO-based coatings often have lower volatile organic compound (VOC) emissions compared to traditional coatings, aligning with increasingly stringent environmental regulations. This can result in reduced compliance costs and improved corporate sustainability profiles, which may indirectly contribute to market competitiveness and brand value.

However, the scalability of GO production remains a challenge that impacts overall costs. Current manufacturing processes for high-quality GO are limited in scale, leading to higher material costs. As production technologies improve and economies of scale are achieved, the cost-effectiveness of GO anti-corrosion solutions is expected to increase significantly.

When considering labor costs, GO coatings may offer advantages due to their ease of application and potential for reduced maintenance frequency. This can lead to lower long-term labor expenses, particularly in industries where access to surfaces for recoating is challenging or costly.

In conclusion, while the initial investment in GO anti-corrosion technologies may be higher, the long-term benefits in terms of extended protection, reduced maintenance, and potential environmental advantages often justify the costs, especially in high-value or critical applications where corrosion prevention is paramount.