How to Ensure Biodegradability in Cellophane Production?

JUL 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cellophane Biodegradability: Background and Objectives

Cellophane, a transparent film made from regenerated cellulose, has been a staple in packaging and various industrial applications since its invention in the early 20th century. As environmental concerns have grown, the focus on biodegradable materials has intensified, bringing cellophane back into the spotlight due to its potential for eco-friendly disposal. This renewed interest stems from the global push towards sustainable packaging solutions and the reduction of plastic waste.

The evolution of cellophane technology has been marked by significant milestones, from its initial discovery by Jacques E. Brandenberger in 1900 to modern innovations in production techniques. Originally developed as a protective coating for tablecloths, cellophane quickly found its way into various industries due to its unique properties. Over the decades, improvements in manufacturing processes have enhanced its performance characteristics while maintaining its core biodegradable nature.

Current technological trends in cellophane production are primarily focused on improving its biodegradability while maintaining or enhancing its functional properties. This includes research into optimizing the cellulose regeneration process, exploring new sources of cellulose, and developing additives that can accelerate decomposition without compromising the material's integrity during use. The goal is to create a cellophane product that can reliably break down in natural environments within a reasonable timeframe.

The primary objective of ensuring biodegradability in cellophane production is to address the growing environmental concerns associated with packaging waste. This involves developing cellophane that can decompose completely in various environmental conditions, leaving no harmful residues. Additionally, there is a focus on reducing the energy and chemical inputs required in the production process, further enhancing the material's overall environmental profile.

Another key objective is to improve the compatibility of cellophane with industrial composting systems. This requires fine-tuning the material's composition to ensure it meets international standards for compostability, such as those set by ASTM International or the European Committee for Standardization. Achieving these certifications is crucial for widespread adoption in environmentally conscious markets.

Furthermore, researchers and manufacturers are aiming to extend the applications of biodegradable cellophane beyond traditional packaging. This includes exploring its potential in agriculture, medical supplies, and other sectors where biodegradability is a valuable attribute. The challenge lies in developing formulations that can meet the diverse performance requirements of these applications while maintaining rapid and complete biodegradation.

The evolution of cellophane technology has been marked by significant milestones, from its initial discovery by Jacques E. Brandenberger in 1900 to modern innovations in production techniques. Originally developed as a protective coating for tablecloths, cellophane quickly found its way into various industries due to its unique properties. Over the decades, improvements in manufacturing processes have enhanced its performance characteristics while maintaining its core biodegradable nature.

Current technological trends in cellophane production are primarily focused on improving its biodegradability while maintaining or enhancing its functional properties. This includes research into optimizing the cellulose regeneration process, exploring new sources of cellulose, and developing additives that can accelerate decomposition without compromising the material's integrity during use. The goal is to create a cellophane product that can reliably break down in natural environments within a reasonable timeframe.

The primary objective of ensuring biodegradability in cellophane production is to address the growing environmental concerns associated with packaging waste. This involves developing cellophane that can decompose completely in various environmental conditions, leaving no harmful residues. Additionally, there is a focus on reducing the energy and chemical inputs required in the production process, further enhancing the material's overall environmental profile.

Another key objective is to improve the compatibility of cellophane with industrial composting systems. This requires fine-tuning the material's composition to ensure it meets international standards for compostability, such as those set by ASTM International or the European Committee for Standardization. Achieving these certifications is crucial for widespread adoption in environmentally conscious markets.

Furthermore, researchers and manufacturers are aiming to extend the applications of biodegradable cellophane beyond traditional packaging. This includes exploring its potential in agriculture, medical supplies, and other sectors where biodegradability is a valuable attribute. The challenge lies in developing formulations that can meet the diverse performance requirements of these applications while maintaining rapid and complete biodegradation.

Market Demand for Eco-Friendly Packaging Solutions

The global market for eco-friendly packaging solutions has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. Cellophane, as a biodegradable alternative to traditional plastic packaging, has garnered substantial attention from both consumers and businesses seeking sustainable options.

Consumer demand for environmentally responsible products has surged, with a notable shift towards packaging materials that minimize ecological impact. This trend is particularly evident in the food and beverage industry, where cellophane's transparency and barrier properties make it an attractive option for product visibility and freshness preservation. The personal care and cosmetics sectors have also shown increased interest in biodegradable cellophane packaging, aligning with the growing consumer preference for natural and eco-friendly products.

Retailers and e-commerce platforms have responded to this demand by prioritizing suppliers who offer sustainable packaging solutions. Many have set ambitious targets to reduce plastic waste, creating a favorable market environment for biodegradable cellophane products. This shift has been further accelerated by government initiatives and regulations aimed at reducing single-use plastics, providing additional impetus for the adoption of biodegradable alternatives like cellophane.

The food service industry, facing pressure to eliminate plastic straws and utensils, has turned to cellophane-based products as a viable solution. Quick-service restaurants and cafes have begun incorporating biodegradable cellophane in their packaging strategies, responding to both consumer expectations and regulatory requirements.

Market research indicates that the global biodegradable packaging market, including cellophane, is projected to grow at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is attributed to factors such as increasing environmental concerns, rising disposal costs for non-biodegradable waste, and the development of new, cost-effective production technologies for biodegradable materials.

However, challenges remain in meeting the full spectrum of market demands. While biodegradability is a key selling point, consumers and businesses also expect these eco-friendly solutions to match or exceed the performance characteristics of traditional plastics. This includes factors such as durability, shelf life, and cost-effectiveness. As a result, there is a growing need for innovation in cellophane production to enhance its properties while maintaining its biodegradable nature.

The market demand for biodegradable cellophane extends beyond packaging to include applications in agriculture, textiles, and medical products. This diversification of end-use sectors presents significant opportunities for growth and innovation in cellophane production. As research and development efforts continue to improve the material's properties and production efficiency, the market for biodegradable cellophane is expected to expand further, meeting the evolving needs of environmentally conscious consumers and businesses across various industries.

Consumer demand for environmentally responsible products has surged, with a notable shift towards packaging materials that minimize ecological impact. This trend is particularly evident in the food and beverage industry, where cellophane's transparency and barrier properties make it an attractive option for product visibility and freshness preservation. The personal care and cosmetics sectors have also shown increased interest in biodegradable cellophane packaging, aligning with the growing consumer preference for natural and eco-friendly products.

Retailers and e-commerce platforms have responded to this demand by prioritizing suppliers who offer sustainable packaging solutions. Many have set ambitious targets to reduce plastic waste, creating a favorable market environment for biodegradable cellophane products. This shift has been further accelerated by government initiatives and regulations aimed at reducing single-use plastics, providing additional impetus for the adoption of biodegradable alternatives like cellophane.

The food service industry, facing pressure to eliminate plastic straws and utensils, has turned to cellophane-based products as a viable solution. Quick-service restaurants and cafes have begun incorporating biodegradable cellophane in their packaging strategies, responding to both consumer expectations and regulatory requirements.

Market research indicates that the global biodegradable packaging market, including cellophane, is projected to grow at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is attributed to factors such as increasing environmental concerns, rising disposal costs for non-biodegradable waste, and the development of new, cost-effective production technologies for biodegradable materials.

However, challenges remain in meeting the full spectrum of market demands. While biodegradability is a key selling point, consumers and businesses also expect these eco-friendly solutions to match or exceed the performance characteristics of traditional plastics. This includes factors such as durability, shelf life, and cost-effectiveness. As a result, there is a growing need for innovation in cellophane production to enhance its properties while maintaining its biodegradable nature.

The market demand for biodegradable cellophane extends beyond packaging to include applications in agriculture, textiles, and medical products. This diversification of end-use sectors presents significant opportunities for growth and innovation in cellophane production. As research and development efforts continue to improve the material's properties and production efficiency, the market for biodegradable cellophane is expected to expand further, meeting the evolving needs of environmentally conscious consumers and businesses across various industries.

Current Challenges in Biodegradable Cellophane Production

The production of biodegradable cellophane faces several significant challenges that hinder its widespread adoption and commercial viability. One of the primary obstacles is the difficulty in achieving consistent and reliable biodegradability while maintaining the desired physical properties of traditional cellophane. The delicate balance between biodegradability and functionality often results in compromised performance, particularly in terms of moisture barrier properties and mechanical strength.

Another major challenge lies in the sourcing and processing of suitable raw materials. While traditional cellophane is derived from regenerated cellulose, biodegradable alternatives often require specialized bio-based polymers or modified cellulose derivatives. These materials can be more expensive and less readily available, leading to increased production costs and potential supply chain disruptions.

The manufacturing process itself presents technical hurdles. Existing cellophane production equipment and techniques may not be directly compatible with biodegradable formulations, necessitating significant investments in new machinery or process modifications. This can be a substantial barrier for manufacturers looking to transition to more environmentally friendly production methods.

Quality control and consistency in biodegradable cellophane production also pose challenges. Variations in raw material composition and processing conditions can lead to inconsistencies in the final product's biodegradability and performance characteristics. Developing robust quality assurance protocols and standardized testing methods for biodegradability is crucial but remains an ongoing challenge in the industry.

Environmental conditions play a critical role in the biodegradation process, and ensuring that biodegradable cellophane performs as intended across various disposal scenarios is complex. Factors such as temperature, humidity, and microbial activity can significantly impact the rate and extent of biodegradation, making it difficult to guarantee consistent end-of-life behavior.

Regulatory compliance and certification present additional hurdles. The lack of universally accepted standards for biodegradability and conflicting regulations across different regions create uncertainty for manufacturers and can impede market acceptance. Obtaining certifications and meeting diverse regulatory requirements adds complexity and cost to the production process.

Lastly, the economic viability of biodegradable cellophane production remains a significant challenge. Higher production costs, coupled with the need for extensive research and development, make it difficult for biodegradable alternatives to compete with traditional cellophane on price. This economic barrier often slows down the adoption of more sustainable packaging solutions in price-sensitive markets.

Another major challenge lies in the sourcing and processing of suitable raw materials. While traditional cellophane is derived from regenerated cellulose, biodegradable alternatives often require specialized bio-based polymers or modified cellulose derivatives. These materials can be more expensive and less readily available, leading to increased production costs and potential supply chain disruptions.

The manufacturing process itself presents technical hurdles. Existing cellophane production equipment and techniques may not be directly compatible with biodegradable formulations, necessitating significant investments in new machinery or process modifications. This can be a substantial barrier for manufacturers looking to transition to more environmentally friendly production methods.

Quality control and consistency in biodegradable cellophane production also pose challenges. Variations in raw material composition and processing conditions can lead to inconsistencies in the final product's biodegradability and performance characteristics. Developing robust quality assurance protocols and standardized testing methods for biodegradability is crucial but remains an ongoing challenge in the industry.

Environmental conditions play a critical role in the biodegradation process, and ensuring that biodegradable cellophane performs as intended across various disposal scenarios is complex. Factors such as temperature, humidity, and microbial activity can significantly impact the rate and extent of biodegradation, making it difficult to guarantee consistent end-of-life behavior.

Regulatory compliance and certification present additional hurdles. The lack of universally accepted standards for biodegradability and conflicting regulations across different regions create uncertainty for manufacturers and can impede market acceptance. Obtaining certifications and meeting diverse regulatory requirements adds complexity and cost to the production process.

Lastly, the economic viability of biodegradable cellophane production remains a significant challenge. Higher production costs, coupled with the need for extensive research and development, make it difficult for biodegradable alternatives to compete with traditional cellophane on price. This economic barrier often slows down the adoption of more sustainable packaging solutions in price-sensitive markets.

Existing Biodegradable Cellophane Production Methods

01 Enzymatic degradation of cellophane

Cellophane biodegradability can be enhanced through enzymatic degradation. Specific enzymes are used to break down the cellulose structure of cellophane, making it more susceptible to natural decomposition. This method accelerates the biodegradation process and can be applied in various environmental conditions.- Enzymatic degradation of cellophane: Cellophane biodegradability can be enhanced through enzymatic degradation. This process involves using specific enzymes that can break down the cellulose structure of cellophane, making it more susceptible to natural decomposition. The enzymatic treatment can be optimized for different types of cellophane materials, improving their overall biodegradability.

- Biodegradable cellophane composites: Developing biodegradable cellophane composites by blending cellophane with other biodegradable materials can improve its overall biodegradability. These composites may incorporate natural fibers, biopolymers, or other eco-friendly additives that enhance the material's ability to break down in natural environments while maintaining desired physical properties.

- Modified cellophane production processes: Altering the production process of cellophane can lead to improved biodegradability. This may involve modifying the chemical structure during manufacturing, incorporating biodegradable additives, or using alternative raw materials that result in a more environmentally friendly end product while maintaining the desired properties of traditional cellophane.

- Biodegradation testing methods for cellophane: Developing and standardizing biodegradation testing methods specific to cellophane is crucial for assessing and improving its biodegradability. These methods may include simulated environmental conditions, microbial degradation tests, and long-term studies to accurately measure the rate and extent of cellophane decomposition in various settings.

- Cellophane disposal and recycling techniques: Implementing effective disposal and recycling techniques can enhance the overall environmental impact of cellophane. This may include developing specialized composting facilities, creating closed-loop recycling systems, or establishing collection and processing methods that facilitate the biodegradation or repurposing of cellophane products after use.

02 Modification of cellophane structure

The biodegradability of cellophane can be improved by modifying its molecular structure. This involves incorporating biodegradable additives or altering the cellulose chains to make them more susceptible to environmental breakdown. Such modifications can significantly reduce the time required for complete decomposition.Expand Specific Solutions03 Composting methods for cellophane

Specific composting techniques can be employed to enhance the biodegradability of cellophane. These methods involve controlled environmental conditions, such as temperature, humidity, and microbial activity, to accelerate the decomposition process. Industrial composting facilities can effectively break down cellophane using these specialized techniques.Expand Specific Solutions04 Biodegradable cellophane alternatives

Development of alternative materials that mimic cellophane's properties while offering improved biodegradability. These alternatives are often based on renewable resources and are designed to decompose more readily in natural environments. They can serve as eco-friendly substitutes in various applications where traditional cellophane is used.Expand Specific Solutions05 Environmental impact assessment of cellophane biodegradation

Studies and methodologies for assessing the environmental impact of cellophane biodegradation. This includes analyzing the byproducts of decomposition, the time required for complete breakdown in different ecosystems, and the overall effect on soil and water quality. Such assessments help in understanding the long-term environmental consequences of cellophane use and disposal.Expand Specific Solutions

Key Players in Biodegradable Packaging Industry

The biodegradable cellophane production market is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is advancing rapidly, with companies like Kemira Oyj, Novozymes A/S, and Kaneka Corp. leading innovation in biodegradable materials. These firms are developing novel enzymes and biopolymers to enhance cellophane's biodegradability while maintaining its functional properties. Smaller players like Hainan Shiner Industrial Co., Ltd. and Jiangxi Guande New Material Technology Co., Ltd. are also contributing to the competitive landscape, focusing on niche applications and regional markets. The industry is characterized by a mix of established chemical companies and emerging biotech firms, indicating a dynamic and evolving competitive environment.

Daicel Corp.

Technical Solution: Daicel Corp. has developed a cutting-edge approach to ensure biodegradability in cellophane production. Their method involves the use of specially engineered cellulose derivatives that maintain the desirable properties of traditional cellophane while significantly enhancing its biodegradability. Daicel's process incorporates bio-based additives that act as catalysts for microbial decomposition, accelerating the breakdown of the cellophane structure in various environmental conditions[8]. The company has also implemented a unique cross-linking technique that allows for controlled degradation, ensuring the cellophane remains stable during use but biodegrades efficiently after disposal[9]. Additionally, Daicel has invested in developing eco-friendly plasticizers that not only improve the film's flexibility but also contribute to its overall biodegradability profile[10].

Strengths: Engineered cellulose derivatives for enhanced biodegradability; Controlled degradation through cross-linking; Use of eco-friendly plasticizers. Weaknesses: Potentially higher production costs; May have limitations in certain high-barrier applications.

Novozymes A/S

Technical Solution: Novozymes A/S has developed an enzymatic approach to ensure biodegradability in cellophane production. Their innovative method involves the integration of specific enzymes into the cellophane manufacturing process, which are designed to break down the cellulose structure under certain environmental conditions. This approach allows for the production of cellophane that maintains its integrity during use but can be rapidly biodegraded when disposed of in appropriate environments. Novozymes has also developed a range of bio-based additives that enhance the material's susceptibility to microbial breakdown without compromising its functional properties[11]. The company's research has focused on optimizing enzyme formulations to achieve controlled biodegradation rates that meet various industry standards and environmental regulations[12].

Strengths: Enzymatic approach for enhanced biodegradability; Bio-based additives for improved breakdown; Controlled biodegradation rates. Weaknesses: May require specific disposal conditions for optimal enzyme activity; Potential for higher production costs due to enzyme integration.

Innovative Approaches to Enhance Cellophane Biodegradability

Biodegradable cellulose-based fabric and method for manufacturing same

PatentWO2022107986A1

Innovation

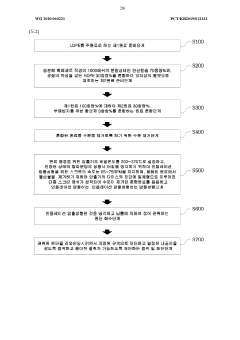

- A biodegradable cellulose-based fabric is manufactured using natural cellulose nonwoven fibers, a photopolymerization initiator, and a coating solution containing urethane or silicone, which is then photopolymerized and compressed to maintain filtering and separation functions while ensuring excellent biodegradability, suitable for use in filters, hygiene products, and secondary battery separators.

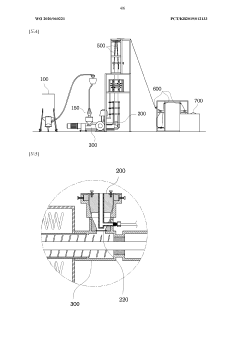

Method for manufacturing biodegradable packaging vinyl sheet

PatentWO2020060221A1

Innovation

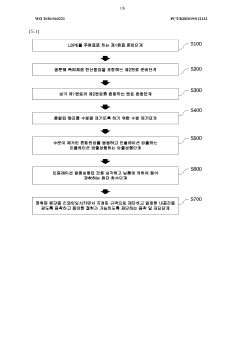

- A method involving the use of low-density polyethylene (LDPE) as the main raw material, calcium carbonate as a biodegradation catalyst, and high-density polyethylene (HDPE) to maintain strength, combined with an antibacterial agent, and a multi-layer screen mesh to filter impurities, ensuring consistent extrusion speed and density during inflation extrusion molding.

Environmental Impact Assessment of Biodegradable Cellophane

The environmental impact assessment of biodegradable cellophane is a critical component in evaluating the sustainability of this innovative packaging material. Biodegradable cellophane offers a promising alternative to traditional plastic packaging, potentially reducing the long-term environmental burden associated with non-biodegradable materials.

One of the primary environmental benefits of biodegradable cellophane is its ability to decompose naturally, significantly reducing the accumulation of plastic waste in landfills and ecosystems. This decomposition process, when properly managed, can result in a lower carbon footprint compared to conventional plastics that persist in the environment for hundreds of years.

However, the environmental impact of biodegradable cellophane extends beyond its end-of-life characteristics. The production process itself must be scrutinized to ensure that the environmental benefits are not outweighed by the resources and energy required for manufacturing. This includes assessing the sourcing of raw materials, typically derived from renewable resources such as wood pulp or cotton linters.

Water usage and quality are important factors to consider in the environmental impact assessment. The production of cellophane involves water-intensive processes, and it is crucial to implement efficient water management systems and treatment technologies to minimize water consumption and prevent pollution of local water bodies.

Energy consumption during production is another key aspect of the assessment. The energy required for the various stages of cellophane manufacturing, including dissolution, regeneration, and drying, must be evaluated. Implementing energy-efficient technologies and exploring renewable energy sources can significantly reduce the carbon footprint associated with production.

The use of chemicals in the manufacturing process, particularly in the regeneration of cellulose, requires careful consideration. Assessing the toxicity and environmental persistence of these chemicals is essential to ensure that the production of biodegradable cellophane does not introduce harmful substances into the environment.

Land use and biodiversity impacts should also be addressed in the assessment. If the raw materials for cellophane production are sourced from forests or agricultural lands, sustainable management practices must be in place to prevent deforestation and maintain ecosystem balance.

Transportation and distribution of both raw materials and finished products contribute to the overall environmental impact. Optimizing logistics and exploring local sourcing options can help reduce the carbon emissions associated with long-distance transportation.

Finally, the end-of-life management of biodegradable cellophane must be carefully evaluated. While biodegradability is a significant advantage, proper disposal and composting infrastructure are necessary to realize these benefits fully. The assessment should consider the availability of appropriate waste management facilities and the potential for contamination of recycling streams if biodegradable cellophane is not properly sorted.

One of the primary environmental benefits of biodegradable cellophane is its ability to decompose naturally, significantly reducing the accumulation of plastic waste in landfills and ecosystems. This decomposition process, when properly managed, can result in a lower carbon footprint compared to conventional plastics that persist in the environment for hundreds of years.

However, the environmental impact of biodegradable cellophane extends beyond its end-of-life characteristics. The production process itself must be scrutinized to ensure that the environmental benefits are not outweighed by the resources and energy required for manufacturing. This includes assessing the sourcing of raw materials, typically derived from renewable resources such as wood pulp or cotton linters.

Water usage and quality are important factors to consider in the environmental impact assessment. The production of cellophane involves water-intensive processes, and it is crucial to implement efficient water management systems and treatment technologies to minimize water consumption and prevent pollution of local water bodies.

Energy consumption during production is another key aspect of the assessment. The energy required for the various stages of cellophane manufacturing, including dissolution, regeneration, and drying, must be evaluated. Implementing energy-efficient technologies and exploring renewable energy sources can significantly reduce the carbon footprint associated with production.

The use of chemicals in the manufacturing process, particularly in the regeneration of cellulose, requires careful consideration. Assessing the toxicity and environmental persistence of these chemicals is essential to ensure that the production of biodegradable cellophane does not introduce harmful substances into the environment.

Land use and biodiversity impacts should also be addressed in the assessment. If the raw materials for cellophane production are sourced from forests or agricultural lands, sustainable management practices must be in place to prevent deforestation and maintain ecosystem balance.

Transportation and distribution of both raw materials and finished products contribute to the overall environmental impact. Optimizing logistics and exploring local sourcing options can help reduce the carbon emissions associated with long-distance transportation.

Finally, the end-of-life management of biodegradable cellophane must be carefully evaluated. While biodegradability is a significant advantage, proper disposal and composting infrastructure are necessary to realize these benefits fully. The assessment should consider the availability of appropriate waste management facilities and the potential for contamination of recycling streams if biodegradable cellophane is not properly sorted.

Regulatory Framework for Biodegradable Packaging Materials

The regulatory framework for biodegradable packaging materials plays a crucial role in ensuring the environmental sustainability of cellophane production. As governments and international organizations increasingly focus on reducing plastic waste, manufacturers must navigate a complex landscape of regulations and standards.

At the forefront of this regulatory environment is the European Union's Packaging and Packaging Waste Directive (PPWD). This directive sets specific targets for the recovery and recycling of packaging materials, including biodegradable options. It also establishes essential requirements for the composition and reusability of packaging, which directly impact cellophane production processes.

In the United States, the Federal Trade Commission (FTC) has issued Green Guides that provide guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to substantiate their biodegradability claims with scientific evidence, ensuring that consumers are not misled by false or exaggerated environmental benefits.

The International Organization for Standardization (ISO) has developed several standards relevant to biodegradable packaging materials. ISO 14851 and ISO 14852 provide methods for determining the aerobic biodegradability of plastic materials in an aqueous medium, while ISO 17088 specifies requirements for compostable plastics.

Many countries have implemented their own certification systems for biodegradable materials. For instance, the European Bioplastics Association's "Seedling" logo and the US-based Biodegradable Products Institute's (BPI) certification are widely recognized marks of compliance with biodegradability standards.

Regulatory bodies are increasingly focusing on the entire lifecycle of packaging materials. This approach requires cellophane producers to consider not only the biodegradability of their products but also the environmental impact of raw material sourcing, manufacturing processes, and end-of-life disposal.

Emerging regulations are also addressing the issue of microplastics, which can be released during the degradation of some biodegradable materials. Manufacturers must now demonstrate that their biodegradable cellophane does not contribute to microplastic pollution in soil or water ecosystems.

As the regulatory landscape continues to evolve, cellophane producers must stay informed about new and upcoming legislation. This includes participating in industry consultations, engaging with policymakers, and contributing to the development of new standards that balance environmental protection with practical manufacturing considerations.

Compliance with these regulations often requires significant investment in research and development, as well as changes to production processes. However, adherence to these standards not only ensures legal compliance but also enhances brand reputation and meets growing consumer demand for environmentally responsible packaging solutions.

At the forefront of this regulatory environment is the European Union's Packaging and Packaging Waste Directive (PPWD). This directive sets specific targets for the recovery and recycling of packaging materials, including biodegradable options. It also establishes essential requirements for the composition and reusability of packaging, which directly impact cellophane production processes.

In the United States, the Federal Trade Commission (FTC) has issued Green Guides that provide guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to substantiate their biodegradability claims with scientific evidence, ensuring that consumers are not misled by false or exaggerated environmental benefits.

The International Organization for Standardization (ISO) has developed several standards relevant to biodegradable packaging materials. ISO 14851 and ISO 14852 provide methods for determining the aerobic biodegradability of plastic materials in an aqueous medium, while ISO 17088 specifies requirements for compostable plastics.

Many countries have implemented their own certification systems for biodegradable materials. For instance, the European Bioplastics Association's "Seedling" logo and the US-based Biodegradable Products Institute's (BPI) certification are widely recognized marks of compliance with biodegradability standards.

Regulatory bodies are increasingly focusing on the entire lifecycle of packaging materials. This approach requires cellophane producers to consider not only the biodegradability of their products but also the environmental impact of raw material sourcing, manufacturing processes, and end-of-life disposal.

Emerging regulations are also addressing the issue of microplastics, which can be released during the degradation of some biodegradable materials. Manufacturers must now demonstrate that their biodegradable cellophane does not contribute to microplastic pollution in soil or water ecosystems.

As the regulatory landscape continues to evolve, cellophane producers must stay informed about new and upcoming legislation. This includes participating in industry consultations, engaging with policymakers, and contributing to the development of new standards that balance environmental protection with practical manufacturing considerations.

Compliance with these regulations often requires significant investment in research and development, as well as changes to production processes. However, adherence to these standards not only ensures legal compliance but also enhances brand reputation and meets growing consumer demand for environmentally responsible packaging solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!