How to Improve the Thermal Properties of HDPE?

HDPE Thermal Enhancement Background and Objectives

High-density polyethylene (HDPE) has been a cornerstone material in various industries due to its excellent mechanical properties, chemical resistance, and low cost. However, its thermal properties have long been a limiting factor in many applications. The quest to improve the thermal properties of HDPE has gained significant momentum in recent years, driven by the increasing demand for high-performance polymers in sectors such as automotive, aerospace, and electronics.

The thermal enhancement of HDPE is primarily focused on two key aspects: improving its thermal conductivity and enhancing its heat resistance. Historically, HDPE has been known for its low thermal conductivity, typically ranging from 0.3 to 0.5 W/mK, which restricts its use in heat management applications. Additionally, its relatively low melting point and poor dimensional stability at elevated temperatures have limited its adoption in high-temperature environments.

The evolution of HDPE thermal enhancement techniques can be traced back to the 1980s when researchers began exploring the incorporation of thermally conductive fillers. Early attempts involved the use of metal particles and carbon-based additives, which showed promise but often came at the cost of compromised mechanical properties or processability.

As material science and nanotechnology have advanced, new avenues for enhancing HDPE's thermal properties have emerged. The introduction of nanofillers, such as carbon nanotubes, graphene, and boron nitride, has opened up possibilities for significant improvements in thermal conductivity without substantial degradation of other desirable properties.

The objectives of current research and development efforts in HDPE thermal enhancement are multifaceted. Primarily, there is a push to achieve thermal conductivity values exceeding 2 W/mK while maintaining or improving the polymer's mechanical strength, processability, and cost-effectiveness. Another critical goal is to increase the heat deflection temperature and overall thermal stability of HDPE, enabling its use in more demanding thermal environments.

Furthermore, researchers are aiming to develop scalable and environmentally sustainable methods for enhancing HDPE's thermal properties. This includes exploring bio-based fillers and developing recycling-friendly composites that align with the growing emphasis on circular economy principles in the plastics industry.

The pursuit of improved thermal properties in HDPE is not merely an academic exercise but a response to real-world industrial needs. Enhanced thermal management in plastic components can lead to more efficient heat dissipation in electronic devices, lighter and more durable automotive parts, and improved performance in various consumer products. As such, the successful development of thermally enhanced HDPE has the potential to unlock new applications and markets for this versatile polymer.

Market Analysis for Thermally Enhanced HDPE

The market for thermally enhanced High-Density Polyethylene (HDPE) is experiencing significant growth driven by increasing demand across various industries. The global HDPE market size was valued at USD 84.79 billion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 4.5% from 2022 to 2030. Within this broader market, the demand for thermally enhanced HDPE is growing at an even faster rate due to its superior properties and expanding applications.

The construction industry is a major driver for thermally enhanced HDPE, particularly in the production of pipes and fittings. The improved thermal properties allow for better performance in extreme temperature conditions, making it ideal for both hot and cold water systems. Additionally, the automotive sector is increasingly adopting thermally enhanced HDPE for various components, as it offers weight reduction while maintaining structural integrity under high-temperature conditions.

In the packaging industry, thermally enhanced HDPE is gaining traction for its ability to withstand higher temperatures during filling processes and transportation. This is particularly valuable in the food and beverage sector, where hot-fill applications require materials that can maintain their properties under thermal stress.

The electronics industry is another key market for thermally enhanced HDPE. With the increasing miniaturization of electronic devices and the need for better heat management, thermally conductive plastics like enhanced HDPE are becoming more prevalent in casings and components.

Geographically, Asia-Pacific dominates the market for thermally enhanced HDPE, driven by rapid industrialization and infrastructure development in countries like China and India. North America and Europe follow, with strong demand from the automotive and packaging sectors.

The market is also influenced by growing environmental concerns and regulations. Thermally enhanced HDPE offers potential for improved recyclability and energy efficiency in various applications, aligning with sustainability goals of many industries and governments.

Looking ahead, the market for thermally enhanced HDPE is expected to continue its growth trajectory. Emerging applications in renewable energy, such as solar panel components and geothermal piping systems, present new opportunities. Moreover, ongoing research and development efforts to further improve the thermal properties of HDPE are likely to expand its potential applications and market reach in the coming years.

Current Limitations in HDPE Thermal Properties

High-density polyethylene (HDPE) is widely used in various industries due to its excellent mechanical properties, chemical resistance, and low cost. However, its thermal properties present significant limitations that hinder its application in certain high-temperature environments. The primary thermal limitation of HDPE is its relatively low melting point, typically ranging from 120°C to 135°C, which restricts its use in applications requiring higher temperature resistance.

Another critical limitation is HDPE's poor thermal conductivity, approximately 0.45-0.52 W/(m·K) at room temperature. This low thermal conductivity limits heat transfer efficiency in applications where rapid heat dissipation is crucial, such as in heat exchangers or thermal management systems. The material's high coefficient of thermal expansion, around 100-200 × 10^-6 /K, further complicates its use in applications with significant temperature fluctuations, as it can lead to dimensional instability and potential structural issues.

HDPE's thermal degradation is another concern, particularly when exposed to elevated temperatures for extended periods. The polymer chains begin to break down at temperatures above 250°C, leading to a loss of mechanical properties and potential release of harmful volatile organic compounds. This thermal instability limits HDPE's long-term performance in high-temperature environments and poses challenges for recycling and processing at elevated temperatures.

The material's low heat deflection temperature (HDT), typically between 40°C and 60°C under a load of 0.45 MPa, further restricts its use in load-bearing applications at moderately elevated temperatures. This limitation is particularly problematic in automotive and industrial components that may experience both mechanical stress and thermal loads simultaneously.

HDPE's poor flame resistance is another significant thermal limitation. The material is highly flammable and tends to melt and drip when exposed to fire, potentially spreading flames rapidly. This characteristic severely restricts its use in applications where fire safety is a critical concern, such as in building materials or electrical enclosures.

The material's low surface energy also presents challenges in terms of thermal bonding and adhesion. This property makes it difficult to apply coatings or join HDPE components using thermal methods, limiting design flexibility and potential applications where multi-material systems are required.

Addressing these thermal limitations is crucial for expanding HDPE's application range and improving its performance in existing uses. Researchers and industry professionals are actively exploring various strategies to enhance HDPE's thermal properties, including the development of nanocomposites, blending with other polymers, and the incorporation of flame retardants and heat stabilizers. However, significant challenges remain in balancing improved thermal properties with other desirable characteristics of HDPE, such as its low cost, ease of processing, and excellent chemical resistance.

Existing HDPE Thermal Enhancement Techniques

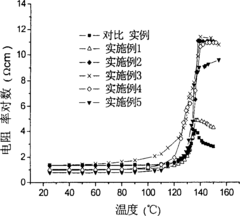

01 Thermal conductivity measurement of HDPE

Various methods and devices are used to measure the thermal conductivity of HDPE. These include specialized testing equipment and techniques to accurately determine the material's heat transfer properties under different conditions. Understanding thermal conductivity is crucial for applications requiring specific heat management characteristics.- Thermal conductivity and insulation properties: HDPE exhibits low thermal conductivity, making it an excellent insulator. This property is utilized in various applications where thermal insulation is required, such as in building materials and packaging. The thermal conductivity of HDPE can be modified by incorporating additives or through processing techniques to suit specific requirements.

- Melting point and crystallinity: The melting point of HDPE typically ranges from 120°C to 135°C, depending on its molecular weight and degree of crystallinity. HDPE's high crystallinity contributes to its excellent mechanical properties and chemical resistance. The melting behavior and crystallization kinetics of HDPE are important factors in processing and end-use applications.

- Thermal expansion and dimensional stability: HDPE has a relatively high coefficient of thermal expansion compared to metals and some other plastics. This property needs to be considered in applications where dimensional stability is critical, especially in environments with temperature fluctuations. Various techniques, such as the addition of fillers or cross-linking, can be employed to improve the dimensional stability of HDPE products.

- Heat deflection temperature and thermal resistance: The heat deflection temperature of HDPE is an important parameter for determining its suitability in high-temperature applications. HDPE generally has good thermal resistance, but its properties can degrade at elevated temperatures. Additives and processing techniques can be used to enhance the thermal resistance and heat deflection temperature of HDPE for specific applications.

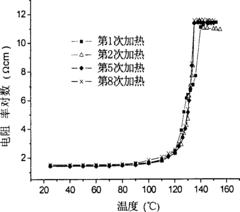

- Thermal aging and weathering resistance: HDPE exhibits good resistance to thermal aging and weathering, making it suitable for outdoor applications. However, prolonged exposure to high temperatures and UV radiation can lead to degradation of its properties. Various stabilizers and additives can be incorporated into HDPE to improve its long-term thermal stability and weathering resistance, extending the service life of HDPE products in demanding environments.

02 HDPE composites with enhanced thermal properties

Researchers have developed HDPE composites with improved thermal properties by incorporating various additives or fillers. These composites may exhibit better heat resistance, thermal stability, or insulation properties compared to pure HDPE. The modifications aim to expand the material's applications in areas requiring specific thermal performance.Expand Specific Solutions03 Thermal behavior of HDPE in extreme conditions

Studies have been conducted on the thermal behavior of HDPE under extreme conditions, such as high temperatures or pressure. These investigations help understand the material's limitations, phase transitions, and potential structural changes when subjected to thermal stress. The findings are valuable for determining suitable applications and safety considerations.Expand Specific Solutions04 HDPE thermal properties in packaging applications

The thermal properties of HDPE play a crucial role in packaging applications. Research focuses on optimizing these properties for food packaging, storage containers, and other packaging solutions. This includes studying heat sealing characteristics, temperature resistance, and thermal insulation capabilities to ensure product integrity and safety.Expand Specific Solutions05 Influence of processing conditions on HDPE thermal properties

The thermal properties of HDPE can be significantly influenced by processing conditions during manufacturing. Studies have examined how factors such as cooling rates, extrusion parameters, and molding techniques affect the final thermal characteristics of HDPE products. Understanding these relationships helps optimize production processes for desired thermal performance.Expand Specific Solutions

Key Players in HDPE Thermal Enhancement

The thermal properties improvement of HDPE is a competitive field in the mature plastics industry, with a substantial market size driven by diverse applications. The technology is in an advanced development stage, with ongoing research to enhance performance. Key players like Dow Global Technologies LLC, ExxonMobil Chemical Patents, Inc., and Borealis AG are at the forefront, leveraging their extensive R&D capabilities. Emerging companies such as Sichuan University and Central South University are contributing innovative approaches. The competition is intensifying as both established corporations and research institutions strive to develop novel solutions, focusing on nanocomposites, blending techniques, and chemical modifications to optimize HDPE's thermal characteristics for various industrial and consumer applications.

Dow Global Technologies LLC

China Petroleum & Chemical Corp.

Innovative Approaches to HDPE Thermal Modification

- By irradiating high-density polyethylene (HDPE) and oxidizing carbon black in ozone gas, the interface between HDPE and carbon black is enhanced, the dispersion of carbon black is improved, and a simple process is used for melting, mixing and Molding preparation to produce high-density polyethylene/carbon black composite materials.

- A thermoplastic polyolefin composition comprising 10-75% HDPE, 8-30% elastomer, and 5-45% filler, with a Melt Flow Rate of 1.0-20 g/10 min, which improves sub-ambient impact strength and retains mechanical properties, suitable for automotive and other applications.

Environmental Impact of HDPE Thermal Enhancements

The environmental impact of thermal enhancements for High-Density Polyethylene (HDPE) is a critical consideration in the pursuit of improved thermal properties. As industries seek to enhance HDPE's thermal performance, it is essential to evaluate the ecological consequences of these modifications. The addition of thermal enhancers or the alteration of HDPE's structure can lead to both positive and negative environmental outcomes.

One of the primary environmental benefits of improving HDPE's thermal properties is the potential for increased energy efficiency in various applications. Enhanced thermal insulation capabilities can result in reduced energy consumption for heating and cooling systems, particularly in building materials and packaging. This reduction in energy usage translates to lower greenhouse gas emissions and a decreased carbon footprint over the lifecycle of HDPE products.

However, the incorporation of thermal enhancers may introduce new environmental challenges. Some additives used to improve thermal properties could be non-biodegradable or potentially toxic, leading to long-term environmental persistence and potential harm to ecosystems if not properly managed at the end of the product's life. The production of these additives may also require additional energy and resources, potentially offsetting some of the environmental gains achieved through improved thermal performance.

Recycling considerations are paramount when assessing the environmental impact of thermally enhanced HDPE. The presence of additives or modified structures can complicate recycling processes, potentially reducing the recyclability of HDPE products. This could lead to increased waste and the need for more virgin material production, countering the sustainability benefits of improved thermal properties.

The manufacturing processes for thermally enhanced HDPE may also have environmental implications. Advanced production techniques or additional processing steps could increase energy consumption and emissions during manufacturing. It is crucial to balance these potential negative impacts against the long-term environmental benefits of improved thermal performance in HDPE products.

Water usage and pollution are additional factors to consider. Some thermal enhancement methods may require increased water consumption or result in wastewater that contains chemical additives, necessitating careful treatment and disposal to prevent environmental contamination.

Life cycle assessment (LCA) studies are essential for comprehensively evaluating the environmental impact of thermally enhanced HDPE. These assessments can provide valuable insights into the overall environmental footprint, considering factors such as raw material extraction, production, use phase, and end-of-life management. LCA results can guide decision-making processes to ensure that thermal enhancements truly contribute to environmental sustainability.

In conclusion, while improving the thermal properties of HDPE offers potential environmental benefits through increased energy efficiency, it is crucial to carefully consider and mitigate any negative environmental impacts associated with the enhancement processes and additives used. Balancing performance improvements with environmental stewardship remains a key challenge in the development of thermally enhanced HDPE materials.

Cost-Benefit Analysis of Improved HDPE

Improving the thermal properties of High-Density Polyethylene (HDPE) can lead to significant benefits in various applications, but it also comes with associated costs. This cost-benefit analysis aims to evaluate the economic implications of enhancing HDPE's thermal characteristics.

The primary benefit of improving HDPE's thermal properties is the expansion of its application range. Enhanced thermal stability allows HDPE to be used in high-temperature environments, potentially opening up new markets in automotive, aerospace, and industrial sectors. This market expansion could lead to increased sales and revenue for manufacturers.

Improved thermal properties also contribute to better product performance and longevity. HDPE products with enhanced thermal resistance are less likely to deform or degrade under heat stress, resulting in longer product lifespans and reduced replacement costs for end-users. This improved durability can justify premium pricing, potentially increasing profit margins for manufacturers.

From an environmental perspective, thermally enhanced HDPE may reduce the need for more energy-intensive materials in certain applications. This could lead to energy savings in production processes and contribute to a company's sustainability goals, potentially improving brand image and attracting environmentally conscious consumers.

However, these benefits come with associated costs. The most significant expense is likely to be research and development. Improving HDPE's thermal properties often requires advanced polymer science, potentially involving the development of new additives or processing techniques. This R&D process can be time-consuming and expensive, requiring specialized equipment and highly skilled personnel.

Implementation of new manufacturing processes or the integration of new additives into existing production lines may necessitate significant capital investment. This could include the purchase of new machinery, retooling of existing equipment, or even the construction of new production facilities.

Additionally, the use of advanced additives or more complex processing methods may increase the per-unit production cost of the improved HDPE. This could potentially squeeze profit margins unless the additional costs can be passed on to consumers through higher pricing.

Regulatory compliance and testing costs should also be considered. New or modified materials may require extensive testing to ensure they meet safety and performance standards, particularly for applications in sensitive industries like food packaging or medical devices.

In conclusion, while improving the thermal properties of HDPE offers substantial benefits in terms of market expansion, product performance, and potential environmental advantages, it also entails significant costs related to R&D, capital investment, and potentially higher production expenses. The balance between these factors will largely depend on the specific application targets and the scale of production. Companies must carefully weigh these considerations against their strategic objectives and market positioning to determine if the investment in improved HDPE is economically viable.