How to Increase Composite Efficiency Using Graphene Oxide?

Graphene Oxide Composites: Background and Objectives

Graphene oxide (GO) has emerged as a revolutionary material in the field of composite technology, offering unprecedented opportunities for enhancing material properties and performance. The development of graphene oxide composites represents a significant leap forward in materials science, combining the exceptional characteristics of graphene with the versatility of composite structures.

The evolution of graphene oxide composites can be traced back to the discovery of graphene in 2004, which sparked intense research into two-dimensional materials. As scientists explored the potential of graphene, they recognized the need for a more processable form, leading to the development of graphene oxide. This oxidized version of graphene offered improved dispersibility and compatibility with various matrices, making it an ideal candidate for composite applications.

Over the past decade, research into graphene oxide composites has accelerated rapidly, driven by the material's extraordinary mechanical, thermal, and electrical properties. The primary objective in this field is to harness these properties to create composites with enhanced performance characteristics, such as increased strength, improved conductivity, and superior barrier properties.

The potential applications for graphene oxide composites span a wide range of industries, including aerospace, automotive, electronics, and energy storage. In the aerospace sector, for instance, researchers aim to develop lightweight yet strong composites that can reduce fuel consumption and improve aircraft efficiency. In the automotive industry, the focus is on creating materials that enhance vehicle safety and performance while reducing weight.

One of the key challenges in graphene oxide composite research is achieving uniform dispersion of GO within the matrix material. This is crucial for maximizing the benefits of GO and ensuring consistent properties throughout the composite. Researchers are exploring various techniques, including chemical functionalization and advanced mixing methods, to overcome this challenge.

Another important objective is to optimize the interface between graphene oxide and the matrix material. Strong interfacial bonding is essential for effective load transfer and overall composite performance. Scientists are investigating different surface modification techniques and coupling agents to enhance this interaction.

The development of scalable and cost-effective production methods for graphene oxide composites is also a primary goal. While laboratory-scale production has shown promising results, transitioning to industrial-scale manufacturing presents significant challenges. Researchers are working on innovative processing techniques and exploring new synthesis routes to make large-scale production more feasible.

As we look to the future, the objectives for graphene oxide composite research continue to evolve. There is a growing emphasis on developing multifunctional composites that can simultaneously address multiple performance requirements. Additionally, researchers are exploring the potential of graphene oxide composites in emerging fields such as flexible electronics, biomedical applications, and environmental remediation.

Market Analysis for High-Efficiency Composites

The market for high-efficiency composites is experiencing significant growth, driven by the increasing demand for lightweight and durable materials across various industries. Graphene oxide, a derivative of graphene, has emerged as a promising additive to enhance the efficiency of composite materials. The global composite materials market is projected to reach $130 billion by 2024, with a compound annual growth rate (CAGR) of 7.8% from 2019 to 2024.

The aerospace and automotive sectors are the primary drivers of this market growth, as they seek to reduce fuel consumption and improve overall performance through the use of lightweight, high-strength materials. In the aerospace industry, composites account for over 50% of the structural weight in modern aircraft, such as the Boeing 787 Dreamliner and Airbus A350 XWB. The automotive industry is also rapidly adopting composite materials, with an estimated market value of $5.8 billion in 2020 and expected to reach $8.9 billion by 2025.

The incorporation of graphene oxide into composite materials has shown promising results in enhancing mechanical, thermal, and electrical properties. This has led to increased interest from industries such as electronics, energy storage, and construction. The global graphene market, including graphene oxide, is expected to grow at a CAGR of 38.7% from 2020 to 2027, reaching $1.08 billion by 2027.

Key market players in the high-efficiency composites sector include Hexcel Corporation, Toray Industries, Teijin Limited, and Solvay S.A. These companies are investing heavily in research and development to incorporate advanced materials like graphene oxide into their product offerings. Start-ups and research institutions are also contributing to market growth through innovative applications and manufacturing processes.

The Asia-Pacific region is expected to witness the highest growth rate in the high-efficiency composites market, driven by rapid industrialization and increasing demand from emerging economies such as China and India. North America and Europe continue to be significant markets, with a focus on advanced applications in aerospace and automotive industries.

Challenges in the market include high production costs, complex manufacturing processes, and the need for standardization in quality control. However, ongoing research and development efforts are addressing these issues, with a focus on scalable production methods and improved integration of graphene oxide into existing composite manufacturing processes.

As environmental regulations become more stringent, the demand for sustainable and recyclable composite materials is increasing. This trend is driving innovation in bio-based composites and recycling technologies, creating new opportunities for market growth and differentiation among manufacturers.

Current Challenges in Graphene Oxide Composite Efficiency

Despite the promising potential of graphene oxide (GO) in enhancing composite efficiency, several significant challenges persist in its practical application. One of the primary obstacles is the difficulty in achieving uniform dispersion of GO within the composite matrix. The tendency of GO sheets to agglomerate due to strong van der Waals forces hinders the formation of a homogeneous composite structure, potentially leading to reduced mechanical and functional properties.

Another critical challenge lies in the interfacial interactions between GO and the matrix material. Inadequate bonding at this interface can result in poor stress transfer and diminished overall composite performance. Researchers are grappling with the task of optimizing surface functionalization techniques to enhance compatibility and adhesion between GO and various matrix materials, including polymers, metals, and ceramics.

The scalability of GO production and composite manufacturing processes presents a significant hurdle in industrial applications. Current methods for producing high-quality GO in large quantities are often time-consuming and costly, limiting the widespread adoption of GO-based composites in commercial products. Additionally, integrating GO into existing manufacturing processes without compromising its unique properties remains a complex challenge.

Stability and long-term performance of GO composites under various environmental conditions pose another set of challenges. Factors such as temperature fluctuations, humidity, and exposure to chemicals can potentially degrade the GO structure or alter its interactions with the matrix, affecting the composite's durability and efficiency over time.

The variability in GO quality and characteristics across different production batches introduces inconsistencies in composite performance. Standardization of GO production and characterization methods is crucial for ensuring reproducible results and reliable composite properties. This lack of standardization hampers the development of consistent, high-performance GO composites.

Lastly, the potential environmental and health impacts of GO nanoparticles remain a concern. The long-term effects of GO exposure on human health and ecosystems are not fully understood, necessitating careful consideration of safety measures in the production, handling, and disposal of GO-based composites. Addressing these challenges requires interdisciplinary collaboration and innovative approaches to unlock the full potential of GO in enhancing composite efficiency.

Existing Methods to Enhance Composite Efficiency

01 Graphene oxide composite for energy storage

Graphene oxide composites are utilized in energy storage applications, particularly in batteries and supercapacitors. These composites enhance the efficiency of energy storage devices by improving conductivity, increasing surface area, and enhancing charge storage capacity. The incorporation of graphene oxide in electrode materials leads to improved performance and longer cycle life of energy storage systems.- Graphene oxide composite for energy storage: Graphene oxide composites are utilized in energy storage applications, particularly in batteries and supercapacitors. These composites enhance the efficiency of energy storage devices by improving conductivity, increasing surface area, and enhancing charge storage capacity. The incorporation of graphene oxide in electrode materials leads to improved performance and longer cycle life of energy storage systems.

- Graphene oxide composite in water treatment: Graphene oxide composites demonstrate high efficiency in water treatment applications. These materials exhibit excellent adsorption capabilities for various pollutants, including heavy metals and organic contaminants. The large surface area and functional groups of graphene oxide contribute to its effectiveness in water purification processes, making it a promising material for environmental remediation.

- Graphene oxide composite for enhanced mechanical properties: Incorporating graphene oxide into composite materials significantly improves their mechanical properties. These composites exhibit increased strength, stiffness, and toughness compared to conventional materials. The unique structure of graphene oxide allows for effective load transfer and reinforcement in various matrices, leading to enhanced durability and performance in structural applications.

- Graphene oxide composite in photocatalysis: Graphene oxide composites show high efficiency in photocatalytic applications. These materials enhance the photocatalytic activity of semiconductors by improving charge separation and extending the light absorption range. The composites are effective in degrading organic pollutants and producing hydrogen through water splitting, demonstrating potential in environmental remediation and clean energy production.

- Graphene oxide composite for thermal management: Graphene oxide composites exhibit excellent thermal management properties. These materials demonstrate high thermal conductivity and can efficiently dissipate heat in various applications. The incorporation of graphene oxide in polymers or other matrices leads to improved thermal stability and heat dissipation, making these composites suitable for use in electronic devices and thermal interface materials.

02 Graphene oxide composite for water treatment

Graphene oxide composites are employed in water treatment applications due to their high adsorption capacity and selectivity. These composites effectively remove various contaminants, including heavy metals, organic pollutants, and microorganisms from water. The large surface area and functional groups of graphene oxide enable efficient water purification, making it a promising material for advanced water treatment technologies.Expand Specific Solutions03 Graphene oxide composite for enhanced mechanical properties

Graphene oxide composites are used to improve the mechanical properties of various materials. When incorporated into polymers, ceramics, or metals, these composites significantly enhance strength, stiffness, and toughness. The unique structure of graphene oxide allows for better load transfer and stress distribution, resulting in materials with superior mechanical performance for applications in aerospace, automotive, and construction industries.Expand Specific Solutions04 Graphene oxide composite for thermal management

Graphene oxide composites are utilized in thermal management applications due to their excellent thermal conductivity. These composites are incorporated into materials to enhance heat dissipation and improve overall thermal performance. The high thermal conductivity of graphene oxide allows for efficient heat transfer, making it suitable for use in electronic devices, heat exchangers, and thermal interface materials.Expand Specific Solutions05 Graphene oxide composite for sensing applications

Graphene oxide composites are employed in various sensing applications due to their unique electrical and chemical properties. These composites are used to develop highly sensitive and selective sensors for detecting gases, biomolecules, and environmental pollutants. The large surface area and functional groups of graphene oxide enable efficient interaction with target analytes, resulting in improved sensor performance and detection limits.Expand Specific Solutions

Key Players in Graphene Oxide Composite Industry

The graphene oxide composite efficiency market is in a growth phase, with increasing research and commercial applications. The global market size for graphene-based products is projected to expand significantly in the coming years. Technologically, the field is rapidly evolving, with varying levels of maturity across different applications. Leading academic institutions like MIT, Harvard, and Sichuan University are driving fundamental research, while companies such as XG Sciences and Boeing are focusing on practical implementations. The involvement of diverse players, from universities to large corporations, indicates a competitive landscape with opportunities for both breakthrough innovations and incremental improvements in composite efficiency using graphene oxide.

Massachusetts Institute of Technology

XG Sciences, Inc.

Innovative Approaches in Graphene Oxide Integration

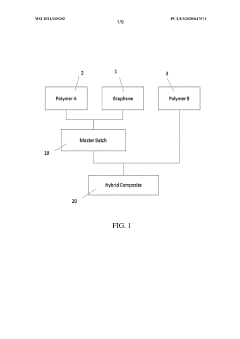

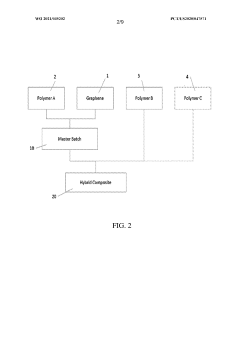

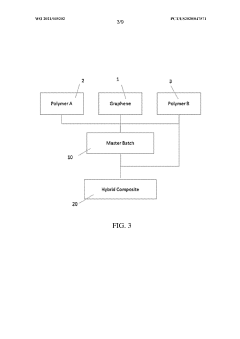

- A process involving direct dispersion or master batch formation of graphene nanoplatelets into multiple polymer resins, followed by let-down ratios, to achieve high homogeneity and improved mechanical, thermal, and electric properties in hybrid composites.

- Functionalization of graphene oxide through chemical modification with additives like Tetra Ethyl Ortho Silicate, Hydroxysuccinimide, and Naphthalene, followed by sonication, to enhance its dispersibility and form covalent bonds with cement hydration products, maintaining high slump factors and improving mechanical properties.

Environmental Impact of Graphene Oxide Composites

The environmental impact of graphene oxide composites is a critical consideration in their development and application. These composites offer significant potential for enhancing material properties, but their environmental implications must be carefully evaluated.

Graphene oxide composites can contribute to reduced material consumption due to their superior strength-to-weight ratio. This efficiency can lead to decreased resource extraction and energy use in manufacturing processes. Additionally, the improved durability of graphene oxide-enhanced materials may result in longer product lifespans, potentially reducing waste generation and the need for frequent replacements.

However, the production of graphene oxide itself raises environmental concerns. The synthesis process often involves the use of strong oxidizing agents and acids, which can generate hazardous waste streams if not properly managed. The energy-intensive nature of graphene oxide production also contributes to its carbon footprint, necessitating a comprehensive life cycle assessment to determine the net environmental impact.

The potential release of graphene oxide nanoparticles into the environment during the use or disposal of composite materials is another area of concern. These nanoparticles may interact with ecosystems in ways that are not yet fully understood, potentially affecting soil and aquatic organisms. Research into the ecotoxicological effects of graphene oxide is ongoing, with some studies suggesting possible adverse impacts on certain species.

On the positive side, graphene oxide composites have shown promise in environmental remediation applications. Their high surface area and adsorption capabilities make them effective in removing pollutants from water and air. This potential for environmental clean-up could offset some of the negative impacts associated with their production and use.

The recyclability and end-of-life management of graphene oxide composites are crucial factors in assessing their overall environmental impact. While the enhanced properties of these materials may improve their recyclability, the presence of graphene oxide may complicate traditional recycling processes. Developing specific recycling methods for these composites is essential to minimize their environmental footprint and promote a circular economy approach.

As research progresses, efforts are being made to develop more environmentally friendly production methods for graphene oxide and its composites. Green synthesis approaches, using less harmful reagents and renewable resources, are being explored to mitigate the environmental impact of production processes. Additionally, the optimization of composite formulations to maximize performance while minimizing graphene oxide content can help reduce potential environmental risks.

Scalability and Cost-Effectiveness Analysis

The scalability and cost-effectiveness of incorporating graphene oxide (GO) into composites are critical factors in determining the viability of this technology for widespread industrial adoption. Current production methods for GO face significant challenges in scaling up to meet potential demand while maintaining consistent quality and reasonable costs.

Large-scale production of GO typically involves chemical exfoliation of graphite, which can be energy-intensive and environmentally problematic due to the use of strong oxidizing agents. Efforts to develop more sustainable and scalable production methods are ongoing, with promising approaches including electrochemical exfoliation and mechanochemical processes. These methods aim to reduce chemical waste and energy consumption while increasing production rates.

The cost of GO production remains a significant barrier to its widespread use in composites. Current prices for high-quality GO can range from $50 to $200 per gram, depending on purity and production method. This high cost is primarily due to the complexity of the production process and the need for specialized equipment. However, as production techniques improve and economies of scale are realized, the price is expected to decrease substantially.

Scalability also depends on the availability of raw materials. Graphite, the primary precursor for GO, is abundant and relatively inexpensive. However, the demand for high-purity graphite suitable for GO production may increase significantly if large-scale adoption occurs, potentially affecting supply chains and prices.

The integration of GO into composite manufacturing processes presents another scalability challenge. Ensuring uniform dispersion of GO within the matrix material is crucial for achieving the desired property enhancements. Current methods often involve solution-based processes, which can be difficult to scale up efficiently. Developing dry mixing techniques or in-situ GO formation within the composite could improve scalability but requires further research and development.

Cost-effectiveness analysis must consider not only the production costs of GO but also the potential benefits in terms of improved composite performance. The enhanced mechanical, thermal, and electrical properties of GO-reinforced composites may justify higher material costs in certain high-value applications. However, for widespread adoption in more cost-sensitive markets, further reductions in GO production costs and improvements in composite manufacturing efficiency are necessary.

In conclusion, while the potential benefits of GO in composites are significant, addressing scalability and cost-effectiveness remains a key challenge. Continued research into more efficient and sustainable production methods, along with innovations in composite manufacturing processes, will be crucial in realizing the full potential of GO-enhanced composites across a broader range of industries and applications.