How to Leverage Graphene Oxide for Water Filtration?

Graphene Oxide Filtration Background and Objectives

Graphene oxide has emerged as a revolutionary material in the field of water filtration, offering unprecedented potential for addressing global water scarcity and contamination issues. The evolution of this technology can be traced back to the discovery of graphene in 2004, which sparked intense research into its derivatives and applications. Graphene oxide, a modified form of graphene, has since gained significant attention due to its unique properties that make it particularly suitable for water purification processes.

The primary objective of leveraging graphene oxide for water filtration is to develop highly efficient, cost-effective, and sustainable water treatment solutions. This technology aims to overcome the limitations of conventional filtration methods by offering superior contaminant removal capabilities, increased water flux, and enhanced durability. Researchers and industry professionals are focusing on harnessing graphene oxide's exceptional properties, such as its large surface area, high mechanical strength, and tunable surface chemistry, to create advanced filtration membranes and systems.

As water scarcity becomes an increasingly pressing global issue, the development of graphene oxide-based filtration technologies is driven by the need for more efficient water treatment processes. These innovations are expected to play a crucial role in addressing challenges related to water quality, accessibility, and conservation across various sectors, including municipal water treatment, industrial wastewater management, and point-of-use purification systems.

The technical goals for graphene oxide filtration encompass several key areas. Firstly, researchers aim to optimize the synthesis and functionalization of graphene oxide to enhance its filtration performance and selectivity for specific contaminants. Secondly, there is a focus on developing scalable and cost-effective manufacturing processes to enable widespread adoption of graphene oxide-based filtration technologies. Additionally, efforts are being made to improve the long-term stability and fouling resistance of graphene oxide membranes to ensure their viability in real-world applications.

Another important objective is to explore the integration of graphene oxide with other advanced materials and technologies, such as nanotechnology and smart sensors, to create multifunctional filtration systems. These hybrid solutions could offer enhanced performance, self-cleaning capabilities, and real-time monitoring of water quality. Furthermore, researchers are investigating the potential of graphene oxide in addressing emerging contaminants, such as pharmaceuticals and microplastics, which pose new challenges to conventional water treatment methods.

As the field progresses, there is also a growing emphasis on understanding and mitigating any potential environmental and health impacts associated with the use of graphene oxide in water treatment. This includes assessing the long-term stability of graphene oxide in aqueous environments and ensuring the safe disposal or recycling of used filtration materials.

Water Purification Market Analysis

The global water purification market has been experiencing significant growth in recent years, driven by increasing concerns over water quality and scarcity. As of 2021, the market was valued at approximately $29.5 billion, with projections indicating a compound annual growth rate (CAGR) of 7.2% from 2022 to 2030. This growth is primarily attributed to rising urbanization, industrialization, and population growth, which have led to increased water pollution and the need for advanced purification technologies.

The demand for clean water spans various sectors, including residential, commercial, and industrial applications. In the residential sector, there is a growing trend towards point-of-use (POU) and point-of-entry (POE) water treatment systems, as consumers become more aware of the potential contaminants in their tap water. The industrial sector, particularly in developing countries, is also a significant driver of market growth, as stringent regulations on wastewater discharge necessitate advanced treatment solutions.

Geographically, North America and Europe currently dominate the water purification market, owing to well-established infrastructure and stringent water quality regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, fueled by rapid industrialization, urbanization, and increasing government initiatives to improve water quality in countries like China and India.

The market is characterized by the presence of both large multinational corporations and smaller, specialized companies. Key players in the industry include Suez Water Technologies & Solutions, Veolia, Evoqua Water Technologies, and Pentair. These companies are continuously investing in research and development to introduce innovative purification technologies and maintain their competitive edge.

In terms of technology, membrane filtration, including reverse osmosis and ultrafiltration, continues to be a dominant segment in the water purification market. However, there is growing interest in advanced oxidation processes, UV disinfection, and nanotechnology-based solutions. The potential application of graphene oxide in water filtration represents an emerging trend in this landscape, offering promising opportunities for enhanced purification efficiency and cost-effectiveness.

The COVID-19 pandemic has further underscored the importance of clean water and sanitation, leading to increased investments in water infrastructure and treatment technologies. This has created new opportunities for market growth, particularly in the development of portable and decentralized water purification systems.

Looking ahead, the water purification market is expected to continue its upward trajectory, driven by factors such as climate change, water scarcity, and stricter environmental regulations. The integration of smart technologies, such as IoT and AI, in water treatment systems is also anticipated to shape the future of the market, enabling more efficient and sustainable water management solutions.

Current Graphene Oxide Filtration Challenges

Despite the promising potential of graphene oxide (GO) for water filtration, several significant challenges currently hinder its widespread adoption and practical implementation. One of the primary obstacles is the scalability of GO membrane production. While laboratory-scale experiments have demonstrated impressive results, translating these into large-scale, commercially viable manufacturing processes remains difficult. The production of high-quality, defect-free GO membranes with consistent properties at an industrial scale is a complex task that requires further technological advancements.

Another critical challenge is the long-term stability and durability of GO membranes in real-world water treatment scenarios. GO membranes are susceptible to degradation when exposed to various chemical compounds, biological contaminants, and physical stresses present in water sources. This degradation can lead to a decrease in filtration efficiency over time and potentially introduce GO particles into the treated water, raising concerns about environmental and health impacts.

The selectivity of GO membranes also presents a challenge. While GO demonstrates excellent rejection rates for certain contaminants, achieving high selectivity across a broad spectrum of pollutants simultaneously is still an area of ongoing research. Balancing high flux rates with effective contaminant removal remains a delicate trade-off that requires further optimization.

Fouling and clogging of GO membranes pose significant operational challenges. The accumulation of organic matter, minerals, and biological growth on the membrane surface can rapidly decrease filtration efficiency and necessitate frequent cleaning or replacement. Developing effective anti-fouling strategies that do not compromise the membrane's filtration properties is crucial for practical applications.

The environmental fate and potential toxicity of GO particles that may be released during the filtration process or membrane degradation are not yet fully understood. This uncertainty raises regulatory concerns and may impede the adoption of GO-based filtration technologies in sensitive applications such as drinking water treatment.

Cost-effectiveness remains a significant hurdle. While GO itself is derived from relatively inexpensive graphite, the processes required to produce high-quality GO membranes with precise pore sizes and surface functionalities are currently expensive and energy-intensive. Reducing production costs while maintaining membrane quality is essential for competing with established filtration technologies.

Lastly, the integration of GO membranes into existing water treatment infrastructure presents engineering challenges. Adapting current systems to accommodate GO-based filtration technologies may require significant modifications and investments, which could slow down adoption rates in the water treatment industry.

Existing Graphene Oxide Filtration Solutions

01 Graphene oxide membrane structure for enhanced filtration

Graphene oxide membranes with specific structural designs can significantly improve filtration efficiency. These structures may include layered configurations, pore size control, and surface modifications to enhance selectivity and permeability. The unique properties of graphene oxide allow for the creation of ultrathin membranes with high flux and excellent rejection rates for various contaminants.- Graphene oxide membrane structure for enhanced filtration: Graphene oxide membranes with specific structural designs can significantly improve filtration efficiency. These structures may include layered configurations, pore size control, and surface modifications to enhance selectivity and permeability. The unique properties of graphene oxide allow for the creation of ultrathin membranes with high flux and excellent rejection rates for various contaminants.

- Functionalization of graphene oxide for targeted filtration: Functionalization of graphene oxide surfaces can enhance its filtration efficiency for specific contaminants. This may involve attaching functional groups or nanoparticles to the graphene oxide sheets, creating selective binding sites or reactive surfaces. Such modifications can improve the removal of particular pollutants, heavy metals, or organic compounds from water or air.

- Composite materials incorporating graphene oxide for filtration: Combining graphene oxide with other materials can create composite filters with enhanced performance. These composites may include polymers, ceramics, or other nanomaterials, leveraging the synergistic effects of multiple components. Such combinations can improve mechanical strength, fouling resistance, and overall filtration efficiency across a broader range of contaminants.

- Graphene oxide-based filtration for specific applications: Tailoring graphene oxide filtration systems for specific applications can optimize performance in various fields. This includes designing filters for water purification, air filtration, gas separation, or even molecular sieving. The adaptability of graphene oxide allows for customized solutions in industries such as environmental remediation, healthcare, and industrial processing.

- Scale-up and manufacturing of graphene oxide filtration systems: Developing efficient methods for large-scale production and integration of graphene oxide into filtration systems is crucial for practical applications. This involves optimizing synthesis processes, improving membrane fabrication techniques, and designing scalable filtration modules. Addressing challenges in manufacturing and implementation is key to realizing the full potential of graphene oxide in filtration technologies.

02 Functionalization of graphene oxide for targeted filtration

Functionalization of graphene oxide surfaces can enhance its filtration efficiency for specific contaminants. This may involve the addition of functional groups or nanoparticles to the graphene oxide sheets, allowing for selective adsorption or rejection of particular molecules or ions. Such modifications can be tailored for applications in water purification, gas separation, or removal of specific pollutants.Expand Specific Solutions03 Composite materials incorporating graphene oxide for filtration

Combining graphene oxide with other materials can create composite filters with enhanced performance. These composites may include polymers, ceramics, or other nanomaterials, resulting in filters with improved mechanical strength, fouling resistance, and overall filtration efficiency. The synergistic effects of the combined materials can address limitations of graphene oxide alone and expand its application range.Expand Specific Solutions04 Graphene oxide-based filtration for specific applications

Graphene oxide filtration systems can be optimized for specific applications such as desalination, heavy metal removal, or gas purification. By tailoring the membrane properties and operating conditions, these systems can achieve high efficiency in removing targeted contaminants while maintaining high flux rates. This approach allows for the development of specialized filtration solutions for various industries and environmental challenges.Expand Specific Solutions05 Scale-up and manufacturing of graphene oxide filtration systems

Advancements in the production and scale-up of graphene oxide-based filtration systems are crucial for their widespread adoption. This includes developing cost-effective manufacturing processes, ensuring consistency in membrane quality, and addressing challenges related to large-scale implementation. Innovations in this area focus on improving the economic viability and practical applicability of graphene oxide filtration technologies.Expand Specific Solutions

Key Players in Graphene-Based Water Treatment

The graphene oxide water filtration market is in its growth phase, with increasing research and commercial interest. The global market for advanced water filtration technologies is expanding rapidly, driven by water scarcity and pollution concerns. Technologically, graphene oxide-based filtration is advancing, but still faces challenges in scalability and cost-effectiveness. Key players like The University of Manchester, Wuhan University of Technology, and King Abdullah University of Science & Technology are leading academic research, while companies such as Evove Ltd., BGT Materials Ltd., and Standardgraphene are working on commercialization. The involvement of government entities like the US Air Force and United States Army indicates strategic importance. Overall, the field is characterized by a mix of academic, industrial, and governmental efforts, suggesting a promising but still-developing technology landscape.

The University of Manchester

Evove Ltd.

Breakthrough Graphene Oxide Membrane Technologies

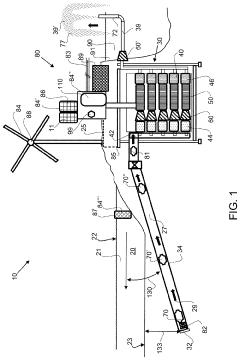

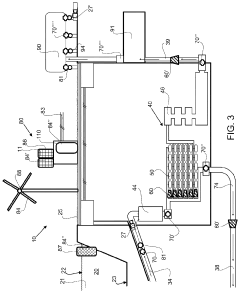

- A sophisticated water and air purification system is developed, utilizing a robust filtration system with a porous matrix immobilizing functionalized GO NPs, integrated with a flow control mechanism, pre-filter, and real-time monitoring, ensuring efficient contaminant and pathogen removal, and featuring periodic GO NP replenishment for sustained performance.

- An integrated power system that combines desalination with power production by using hydrostatic pressure from deep water intakes to drive turbines, producing excess power that can be stored or fed into the grid, and incorporates advanced filtration technologies like graphene filters and structured water systems to efficiently process water from various sources.

Environmental Impact of Graphene Oxide Filtration

The environmental impact of graphene oxide filtration is a critical consideration in the adoption of this technology for water treatment. Graphene oxide's unique properties make it highly effective for removing contaminants from water, but its potential effects on ecosystems and human health must be carefully evaluated.

One of the primary environmental concerns is the potential release of graphene oxide nanoparticles into water systems. While graphene oxide is designed to trap pollutants, there is a risk that some particles may detach from filtration membranes and enter the treated water. The long-term effects of these nanoparticles on aquatic life and ecosystems are not yet fully understood, necessitating further research and monitoring.

The production process of graphene oxide also raises environmental questions. The synthesis of graphene oxide often involves the use of strong oxidizing agents and acids, which can generate hazardous waste. Proper disposal and treatment of these byproducts are essential to prevent environmental contamination. Additionally, the energy-intensive nature of graphene oxide production may contribute to increased carbon emissions if not managed sustainably.

On the positive side, graphene oxide filtration has the potential to significantly reduce the use of chemical treatments in water purification processes. This could lead to a decrease in the release of harmful chemicals into the environment, benefiting aquatic ecosystems and reducing the overall environmental footprint of water treatment facilities.

The durability and reusability of graphene oxide filters may also contribute to waste reduction in the water treatment industry. Compared to traditional filtration materials that require frequent replacement, graphene oxide membranes have shown promising longevity, potentially reducing the amount of waste generated from spent filter materials.

However, the end-of-life management of graphene oxide filters presents another environmental challenge. The disposal or recycling of these materials must be carefully considered to prevent the release of nanoparticles into landfills or the environment. Developing effective recycling methods for graphene oxide filters could mitigate this concern and promote a more circular economy in water treatment technologies.

As research in this field progresses, it is crucial to conduct comprehensive life cycle assessments of graphene oxide filtration systems. These assessments should consider the environmental impacts from production to disposal, providing a holistic view of the technology's sustainability. Such studies will be instrumental in guiding the responsible development and implementation of graphene oxide filtration technologies in water treatment applications.

Scalability and Cost Analysis of Graphene Oxide Membranes

The scalability and cost analysis of graphene oxide membranes for water filtration is a critical aspect in determining their feasibility for large-scale applications. The production of graphene oxide membranes has shown promising results in laboratory settings, but scaling up to industrial levels presents several challenges.

One of the primary considerations is the production capacity of graphene oxide. Current methods, such as the modified Hummers method, can produce graphene oxide in quantities suitable for research purposes. However, to meet the demands of large-scale water filtration systems, significant improvements in production efficiency and yield are necessary. This includes optimizing the oxidation process, developing more efficient exfoliation techniques, and implementing continuous production methods.

The cost of raw materials is another crucial factor. While graphite, the primary precursor for graphene oxide, is relatively inexpensive, the chemicals used in the oxidation process can be costly. Scaling up production may lead to economies of scale, potentially reducing the overall cost per unit of graphene oxide produced. However, this needs to be balanced against the increased capital investment required for larger production facilities.

Membrane fabrication techniques also play a vital role in scalability. Current methods, such as vacuum filtration or layer-by-layer assembly, are effective for small-scale production but may not be suitable for industrial-scale manufacturing. Developing roll-to-roll processes or other continuous fabrication methods could significantly enhance production capacity and reduce costs.

The durability and lifespan of graphene oxide membranes in real-world applications are essential considerations for cost-effectiveness. While these membranes have shown excellent filtration properties, their long-term performance under various water conditions and contaminant loads needs to be thoroughly evaluated. Increased durability would reduce replacement frequency, thereby lowering operational costs.

Environmental and safety considerations in the production process also impact scalability and cost. Ensuring proper handling and disposal of chemicals used in graphene oxide synthesis, as well as implementing safety measures for workers, may add to the overall production costs. However, these are necessary investments for sustainable and responsible manufacturing practices.

In conclusion, while graphene oxide membranes show great promise for water filtration, significant challenges remain in scaling up production and reducing costs. Addressing these challenges through innovative production methods, improved membrane fabrication techniques, and careful consideration of long-term performance and environmental impacts will be crucial for the widespread adoption of this technology in water treatment applications.