How to Maximize HDPE Flexibility Through Advanced Techniques?

HDPE Flexibility Enhancement: Background and Objectives

High-density polyethylene (HDPE) has been a cornerstone material in various industries since its commercial introduction in the 1950s. Known for its high strength-to-density ratio and chemical resistance, HDPE has found widespread applications in packaging, construction, and automotive sectors. However, its inherent stiffness has often limited its use in applications requiring greater flexibility. The quest to enhance HDPE flexibility has been ongoing for decades, driven by the increasing demand for materials that combine strength with pliability.

The evolution of HDPE flexibility enhancement techniques has been marked by significant milestones. Early attempts focused on blending HDPE with more flexible polymers, which yielded mixed results due to compatibility issues. The advent of metallocene catalysts in the 1990s allowed for more precise control over polymer architecture, opening new avenues for improving HDPE's flexibility without compromising its desirable properties.

Recent technological advancements have shifted the focus towards molecular engineering and nano-scale modifications. These cutting-edge approaches aim to alter the polymer's structure at a fundamental level, potentially revolutionizing HDPE's performance characteristics. The integration of computational modeling and high-throughput experimentation has accelerated the development process, allowing researchers to explore a vast array of potential solutions more efficiently than ever before.

The primary objective of maximizing HDPE flexibility through advanced techniques is multifaceted. Firstly, it aims to expand the material's applicability in sectors where flexibility is crucial, such as flexible packaging and medical devices. Secondly, it seeks to improve the material's processability, potentially reducing energy consumption during manufacturing. Thirdly, enhanced flexibility could lead to improved impact resistance and durability, extending the lifespan of HDPE products and contributing to sustainability efforts.

Furthermore, the pursuit of increased HDPE flexibility aligns with broader industry trends towards lightweight, high-performance materials. As industries strive for energy efficiency and reduced carbon footprints, flexible HDPE could play a pivotal role in replacing heavier or less sustainable alternatives. This technological endeavor also intersects with the growing interest in circular economy principles, as more flexible HDPE could potentially enhance recyclability and reusability.

The path forward in HDPE flexibility enhancement is likely to involve a convergence of multiple disciplines, including polymer science, nanotechnology, and materials engineering. As researchers and industry players collaborate to push the boundaries of what's possible with HDPE, the potential for groundbreaking innovations remains high. The success in this field could not only transform the HDPE market but also set new standards for polymer engineering across the board.

Market Analysis for Flexible HDPE Applications

The market for flexible High-Density Polyethylene (HDPE) applications has been experiencing significant growth in recent years, driven by increasing demand across various industries. The versatility and adaptability of flexible HDPE have made it a preferred material in sectors such as packaging, construction, automotive, and consumer goods.

In the packaging industry, flexible HDPE has gained traction due to its excellent barrier properties, durability, and cost-effectiveness. The material's ability to withstand impact and resist moisture has led to its widespread use in food packaging, particularly for products requiring extended shelf life. The global food packaging market, which heavily utilizes flexible HDPE, is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026.

The construction sector has also embraced flexible HDPE for its lightweight nature and resistance to chemicals and weathering. Applications include geomembranes, pipes, and insulation materials. The global construction plastics market, where flexible HDPE plays a significant role, is expected to reach a value of $105.7 billion by 2027, growing at a CAGR of 6.5% from 2020 to 2027.

In the automotive industry, flexible HDPE is increasingly being used in fuel tanks, interior components, and under-the-hood applications. The material's ability to reduce vehicle weight while maintaining structural integrity aligns with the industry's focus on fuel efficiency and emissions reduction. The automotive plastics market, which includes flexible HDPE, is anticipated to grow at a CAGR of 11.2% from 2021 to 2028.

The consumer goods sector has also recognized the benefits of flexible HDPE in products such as toys, household items, and sporting goods. The material's durability, recyclability, and ability to be molded into various shapes have contributed to its popularity in this sector. The global plastic products market, encompassing flexible HDPE applications, is forecasted to reach $721.14 billion by 2025.

Regionally, Asia-Pacific dominates the flexible HDPE market, accounting for the largest share of global consumption. This is primarily due to rapid industrialization, urbanization, and increasing disposable incomes in countries like China and India. North America and Europe follow, with mature markets focusing on innovative applications and sustainable solutions.

The growing emphasis on sustainability and circular economy principles has further boosted the demand for flexible HDPE. Its recyclability and potential for use in recycled content products align with global efforts to reduce plastic waste and promote environmentally friendly materials. This trend is expected to drive further innovation in flexible HDPE applications and processing techniques.

Current Challenges in HDPE Flexibility Improvement

Despite the widespread use of High-Density Polyethylene (HDPE) in various industries, improving its flexibility remains a significant challenge. The inherent molecular structure of HDPE, characterized by its high crystallinity and strong intermolecular forces, contributes to its rigidity and limits its flexibility. This poses difficulties in applications where both strength and flexibility are required.

One of the primary challenges in enhancing HDPE flexibility is maintaining a balance between improved flexibility and other desirable properties. Attempts to increase flexibility often result in a trade-off with mechanical strength, chemical resistance, or thermal stability. This delicate balance is crucial for maintaining the overall performance of HDPE in diverse applications.

The conventional methods of improving HDPE flexibility, such as the incorporation of plasticizers or blending with more flexible polymers, face limitations. Plasticizers can migrate over time, leading to a loss of flexibility and potential contamination issues. Polymer blending, while effective, can lead to phase separation and inconsistent material properties, affecting the long-term performance and processability of the material.

Another significant challenge lies in the scalability and cost-effectiveness of advanced flexibility enhancement techniques. While laboratory-scale experiments may yield promising results, translating these into commercially viable, large-scale production processes presents considerable obstacles. The economic feasibility of implementing new technologies or incorporating novel additives must be carefully evaluated against the potential benefits in flexibility improvement.

Environmental concerns and regulatory compliance add another layer of complexity to HDPE flexibility enhancement. As sustainability becomes increasingly important, any new methods or additives used to improve flexibility must meet stringent environmental and safety standards. This includes considerations for recyclability, biodegradability, and the overall life cycle impact of the modified HDPE.

The development of tailored flexibility for specific applications presents a unique challenge. Different industries and products require varying degrees of flexibility, necessitating a customized approach to HDPE modification. Creating a versatile solution that can be easily adapted to meet diverse flexibility requirements across multiple applications remains a significant hurdle.

Lastly, the molecular-level understanding and control of HDPE structure-property relationships continue to be an area of active research. Developing advanced techniques to precisely manipulate the polymer chain architecture, crystallinity, and molecular weight distribution to enhance flexibility without compromising other critical properties requires sophisticated analytical tools and innovative approaches in polymer science.

Existing Methods for Increasing HDPE Flexibility

01 Blending HDPE with other polymers

Improving the flexibility of HDPE can be achieved by blending it with other polymers. This method involves mixing HDPE with more flexible polymers or elastomers to create a composite material that retains the strength of HDPE while increasing its flexibility. The resulting blend can have improved impact resistance and elongation properties.- Blending HDPE with other polymers: Improving the flexibility of HDPE by blending it with other polymers such as elastomers, polyolefins, or thermoplastic elastomers. This approach can enhance the overall flexibility of the material while maintaining its desirable properties.

- Incorporation of additives: Adding specific additives to HDPE to enhance its flexibility. These additives may include plasticizers, impact modifiers, or other chemical compounds that can alter the polymer structure and improve its flexibility without significantly compromising other properties.

- Modification of molecular structure: Altering the molecular structure of HDPE through various techniques such as copolymerization, branching, or crosslinking. These modifications can lead to improved flexibility by changing the arrangement and interaction of polymer chains.

- Processing techniques: Employing specific processing techniques during HDPE production or fabrication to enhance flexibility. This may include adjusting extrusion parameters, using specialized molding processes, or applying post-processing treatments to modify the material's properties.

- Nanocomposite formulations: Developing HDPE nanocomposites by incorporating nanoscale fillers or reinforcements. These nanocomposites can exhibit improved flexibility along with other enhanced properties such as strength and barrier performance.

02 Incorporation of plasticizers

Adding plasticizers to HDPE can enhance its flexibility. Plasticizers are substances that increase the plasticity or fluidity of a material. When incorporated into HDPE, they work by reducing the intermolecular forces between polymer chains, allowing for greater mobility and flexibility. This method can significantly improve the material's ability to bend and stretch without breaking.Expand Specific Solutions03 Modification of molecular structure

Altering the molecular structure of HDPE can lead to increased flexibility. This can be achieved through various methods such as controlling the polymerization process, adjusting the molecular weight distribution, or introducing branching in the polymer chains. These modifications can result in a more flexible HDPE while maintaining its high-density characteristics.Expand Specific Solutions04 Use of nanofillers

Incorporating nanofillers into HDPE can enhance its flexibility along with other properties. Nanofillers, such as nanoclay or carbon nanotubes, can be dispersed within the HDPE matrix. These nanoparticles can improve the material's flexibility by altering its internal structure and interfacial properties, leading to a more pliable yet strong material.Expand Specific Solutions05 Heat treatment and processing techniques

Applying specific heat treatment and processing techniques can improve the flexibility of HDPE. These methods may include controlled cooling rates, annealing processes, or specialized extrusion techniques. By manipulating the crystallinity and orientation of the polymer chains through these processes, the flexibility of HDPE can be enhanced without significantly compromising its other desirable properties.Expand Specific Solutions

Key Players in HDPE Modification Industry

The market for maximizing HDPE flexibility through advanced techniques is in a growth phase, driven by increasing demand for versatile and high-performance plastics. The global HDPE market size is projected to reach significant volumes, with key players like ExxonMobil Chemical Patents, Inc., Dow Global Technologies LLC, and SABIC Global Technologies BV leading innovation. These companies, along with others such as Borealis AG and Chevron Phillips Chemical Co. LP, are at the forefront of developing advanced techniques to enhance HDPE flexibility. The technology maturity varies, with established methods being refined and new approaches emerging. Research institutions like Shandong University and the Chinese Academy of Science Institute of Chemistry are contributing to technological advancements, indicating a dynamic and competitive landscape in this field.

Dow Global Technologies LLC

ExxonMobil Chemical Patents, Inc.

Innovative Approaches to HDPE Flexibility Maximization

- A foamable polymer composition comprising a polyolefin polymer, specifically linear low density polyethylene, combined with a blowing agent like citric acid or expandable polymeric microspheres, which allows for controlled foaming to enhance flexibility and tensile properties, thereby improving the cable's installation and durability.

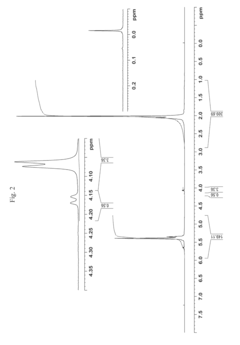

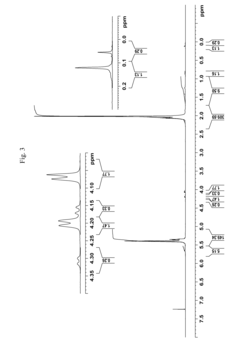

- The synthesis of dendritic polyethylenes through ring opening metathesis polymerization of cyclic olefins with bi-functional alkene chain terminating agents, followed by reaction with multifunctional coupling agents, to produce telechelic hydrocarbon polymers that are then reacted with trifunctional or tetrafunctional coupling agents to create dendritic structures, which can be used as additives in conventional polyethylenes.

Environmental Impact of Flexible HDPE Production

The production of flexible High-Density Polyethylene (HDPE) through advanced techniques has significant environmental implications that warrant careful consideration. While these innovative methods aim to enhance the material's flexibility and expand its applications, they also introduce new challenges and opportunities for environmental stewardship.

One of the primary environmental concerns associated with flexible HDPE production is the energy consumption during the manufacturing process. Advanced techniques often require additional processing steps or specialized equipment, potentially leading to increased energy usage. This heightened energy demand may result in a larger carbon footprint if not mitigated through the use of renewable energy sources or improved energy efficiency measures.

Chemical additives used to enhance HDPE flexibility can also pose environmental risks. These additives, while crucial for achieving desired material properties, may leach into the environment during the product's lifecycle. The potential for soil and water contamination necessitates rigorous testing and careful selection of environmentally friendly additives that maintain performance without compromising ecosystem health.

On the positive side, the enhanced flexibility of HDPE can contribute to reduced material usage in certain applications. Thinner, more flexible HDPE products may require less raw material, potentially decreasing the overall environmental impact of production. This reduction in material consumption can lead to lower transportation emissions and reduced waste generation throughout the supply chain.

The improved durability and versatility of flexible HDPE may also extend product lifespans, reducing the frequency of replacement and, consequently, the amount of plastic waste generated over time. However, this benefit must be balanced against the potential challenges in recycling these modified HDPE products, as the additives and altered molecular structure may complicate traditional recycling processes.

Water usage is another critical environmental factor to consider in flexible HDPE production. Advanced techniques may require additional cooling or processing steps that increase water consumption. Implementing closed-loop water systems and water-efficient technologies can help mitigate this impact, ensuring responsible water management in manufacturing facilities.

The end-of-life considerations for flexible HDPE products are particularly important from an environmental perspective. While the material's enhanced properties may open up new recycling opportunities, they may also create challenges for existing recycling infrastructure. Developing specialized recycling processes or designing products with end-of-life recyclability in mind becomes crucial for minimizing the environmental footprint of flexible HDPE throughout its lifecycle.

In conclusion, maximizing HDPE flexibility through advanced techniques presents a complex environmental landscape. While offering potential benefits in material efficiency and product longevity, it also introduces new challenges in energy consumption, chemical management, and recycling. Striking a balance between performance enhancement and environmental responsibility is essential for the sustainable development of flexible HDPE technologies.

Regulatory Considerations for Modified HDPE Materials

When considering the maximization of HDPE flexibility through advanced techniques, it is crucial to address the regulatory considerations for modified HDPE materials. These regulations play a significant role in ensuring the safety, quality, and compliance of the modified materials in various applications.

The regulatory landscape for modified HDPE materials is complex and varies across different regions and industries. In the United States, the Food and Drug Administration (FDA) oversees the use of HDPE in food contact applications. The FDA requires that any modifications to HDPE intended for food contact must comply with the regulations outlined in 21 CFR 177.1520, which specifies the permissible additives and processing aids.

The European Union has its own set of regulations governing the use of modified HDPE materials. The European Food Safety Authority (EFSA) evaluates the safety of substances used in food contact materials, including modified HDPE. Manufacturers must ensure that their products comply with Regulation (EC) No 1935/2004 on materials and articles intended to come into contact with food.

In addition to food contact regulations, modified HDPE materials used in other applications, such as automotive or construction, must adhere to specific industry standards. For instance, the automotive industry often requires compliance with standards set by organizations like the Society of Automotive Engineers (SAE) or the International Organization for Standardization (ISO).

Environmental regulations also play a crucial role in the development and use of modified HDPE materials. Many countries have implemented regulations to promote the recyclability and sustainability of plastic materials. For example, the European Union's Circular Economy Action Plan aims to ensure that all plastic packaging is recyclable or reusable by 2030. This has implications for the development of modified HDPE materials, as they must be designed with recyclability in mind.

When developing advanced techniques to maximize HDPE flexibility, manufacturers must consider the potential impact on the material's regulatory status. Any modifications that significantly alter the chemical composition or physical properties of HDPE may require additional regulatory approvals or certifications. This includes the use of novel additives, processing techniques, or the incorporation of nanomaterials.

It is essential for manufacturers to maintain thorough documentation of their modification processes and conduct rigorous testing to demonstrate compliance with relevant regulations. This may include migration studies, toxicological assessments, and performance testing to ensure that the modified HDPE materials meet the required safety and quality standards.

As regulations continue to evolve, particularly in response to environmental concerns and emerging technologies, manufacturers must stay informed about changes in regulatory requirements. This may involve engaging with regulatory bodies, participating in industry associations, and conducting ongoing compliance assessments to ensure that modified HDPE materials remain in line with current and future regulations.